Professional Documents

Culture Documents

rohini_32001918232

rohini_32001918232

Uploaded by

wannaphyoCopyright:

Available Formats

You might also like

- MS Installation Ductile Iron Water Supply (Scribd)Document17 pagesMS Installation Ductile Iron Water Supply (Scribd)Mohd Asyhar91% (33)

- Allstate/McKinsey Bates H000001010Document495 pagesAllstate/McKinsey Bates H0000010104207west59th100% (3)

- Chat GPTDocument13 pagesChat GPTsuly maniyahNo ratings yet

- Immersed TunnelsDocument44 pagesImmersed TunnelsapmegremisNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Sequence of Operation of FahuDocument1 pageSequence of Operation of FahuahmedNo ratings yet

- 66 Job Interview Questions For Data ScientistsDocument10 pages66 Job Interview Questions For Data ScientistsRavi RanjanNo ratings yet

- Measurement of Line Impedances and Mutual Coupling of Parallel LinesDocument8 pagesMeasurement of Line Impedances and Mutual Coupling of Parallel LinesKhandai SeenananNo ratings yet

- Ce3013 u1Document41 pagesCe3013 u1NagarjunNo ratings yet

- Box Jacking Explanation: Unit Iii Sub Structure ConstructionDocument28 pagesBox Jacking Explanation: Unit Iii Sub Structure ConstructionVallabi CNo ratings yet

- Unit 1Document41 pagesUnit 1Bravin EbaneshNo ratings yet

- Unit Iii-Sub Structure ConstructionDocument30 pagesUnit Iii-Sub Structure Constructionumamaheswari skNo ratings yet

- CP Unit 2Document184 pagesCP Unit 2Dhanashri Patil100% (1)

- Box Pushing and Trenchless TechnologyDocument18 pagesBox Pushing and Trenchless TechnologySanjay HNNo ratings yet

- Construction Techniques, Equipments & Practice: WelcomeDocument88 pagesConstruction Techniques, Equipments & Practice: WelcomeRON SAMUEL 401935No ratings yet

- Pipe JackingDocument17 pagesPipe JackingnurulzulkipliNo ratings yet

- 1.box JackingDocument12 pages1.box JackingManeesha RajendranNo ratings yet

- 1.2 Pipe JackingDocument11 pages1.2 Pipe JackingKandasamy AsohanNo ratings yet

- 1.2 Pipe JackingDocument11 pages1.2 Pipe Jackinganku4frenz100% (1)

- Sub-Structure and Super-StructureDocument27 pagesSub-Structure and Super-StructureRyuuNo ratings yet

- Box Pushing Technology PresentationDocument20 pagesBox Pushing Technology PresentationRavindra RajuNo ratings yet

- Box Pushing Technology PresentationDocument20 pagesBox Pushing Technology PresentationH S Vishwa NathNo ratings yet

- Specialized Construction Techniques - FinalDocument102 pagesSpecialized Construction Techniques - FinalSabella JimenezNo ratings yet

- Underground Water Tank Installation GuidelinesDocument3 pagesUnderground Water Tank Installation Guidelinesenochkalembe1No ratings yet

- TunnelingDocument21 pagesTunnelingDanielsNo ratings yet

- 1.1 Box JackingDocument14 pages1.1 Box JackinggeethaNo ratings yet

- 1 150228085423 Conversion Gate01 PDFDocument14 pages1 150228085423 Conversion Gate01 PDFSanjay EvaneNo ratings yet

- Tunnel 05 - Construction of Tunnels - Part 2Document65 pagesTunnel 05 - Construction of Tunnels - Part 2Andika Febrian0% (1)

- Outline Construction Method StatementDocument15 pagesOutline Construction Method Statementtsuak100% (2)

- Trenchless TechnologiesDocument24 pagesTrenchless TechnologiesAnupam KumarNo ratings yet

- Technical Note-Water Seepage Through PilesDocument5 pagesTechnical Note-Water Seepage Through PilesLijo Joseph100% (2)

- Lec11-Soft Ground TunnelingDocument28 pagesLec11-Soft Ground TunnelingAmraha NoorNo ratings yet

- Underground ConstDocument19 pagesUnderground ConstGagana D J 1DC19AT025No ratings yet

- Underground-Construction RDDocument19 pagesUnderground-Construction RDKarthik U WCFANo ratings yet

- Pipeline Execution PlanDocument23 pagesPipeline Execution PlanRawnakul Islam Opu100% (1)

- Pre Fab..Document29 pagesPre Fab..mohibNo ratings yet

- Construction Practice For Site EngineerDocument48 pagesConstruction Practice For Site EngineerGautam UmariaNo ratings yet

- Pipeline Laying in WaterDocument33 pagesPipeline Laying in WaterJai Krishna Sahith100% (2)

- Method Statement For Construction of Precast Concrete Pipe CulvertDocument4 pagesMethod Statement For Construction of Precast Concrete Pipe CulvertDanny NguNo ratings yet

- Trenchless TechnologyDocument41 pagesTrenchless TechnologyESAM ALHASHEDINo ratings yet

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDocument6 pagesMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953No ratings yet

- Dewatering TechniquesDocument34 pagesDewatering TechniquesAhmed Khalifa100% (1)

- Underwater ConstructionDocument23 pagesUnderwater ConstructionSujay Raghavendra N88% (16)

- Method Statement-Manshield MethodDocument7 pagesMethod Statement-Manshield Methodasr.engineering2023No ratings yet

- Inspection of Reinforcing WorksDocument3 pagesInspection of Reinforcing Worksnavodi.sathsara99No ratings yet

- Fore PolingDocument5 pagesFore PolingSurinderPalSinghGillNo ratings yet

- Precast Technology With The Case Study of BWSLDocument93 pagesPrecast Technology With The Case Study of BWSLer_hvpatelNo ratings yet

- Tunnel Boring MachinesDocument58 pagesTunnel Boring MachinesAliArababadiNo ratings yet

- Sewage PPT ManeeshDocument14 pagesSewage PPT ManeeshSUBHAJEET TEWARINo ratings yet

- Pipe Jacking: Technique - Factors - Applications - AdvantagesDocument18 pagesPipe Jacking: Technique - Factors - Applications - AdvantagesGakwaya Jules CesarNo ratings yet

- 12.excavation and Basement ConstructionDocument22 pages12.excavation and Basement ConstructionNiluka Ekanayaka100% (1)

- Box Pushing Technology: Seminar Report Submitted by Uvais.A REG NO:20010536 Civil EngineeringDocument18 pagesBox Pushing Technology: Seminar Report Submitted by Uvais.A REG NO:20010536 Civil EngineeringUvais Majeed100% (2)

- Auger BoringDocument7 pagesAuger BoringMuhammad AmjadNo ratings yet

- Inst Instructions 10 000 v1.0Document9 pagesInst Instructions 10 000 v1.0gangrukaNo ratings yet

- Unit 2Document97 pagesUnit 2Sid SNo ratings yet

- Methodology For TrenchingDocument6 pagesMethodology For Trenchinginsk0% (1)

- Submerged Floating TunnelDocument31 pagesSubmerged Floating TunnelRAKESH KUMAR 061No ratings yet

- Construction Techniques, Equipments & Practice: WelcomeDocument40 pagesConstruction Techniques, Equipments & Practice: WelcomedhanabalNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Good Construction PracticesDocument48 pagesGood Construction Practicespetrus jacobNo ratings yet

- Tunnel EngineeringDocument53 pagesTunnel EngineeringshankaregowdaNo ratings yet

- PipelineConstructionPprocess 14july2011Document6 pagesPipelineConstructionPprocess 14july2011mark_fish22No ratings yet

- Cut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFDocument5 pagesCut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFfethi42No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- TV Ole 2020Document1 pageTV Ole 2020david floresNo ratings yet

- Samsung RF27T5501Document164 pagesSamsung RF27T5501Brian MasseyNo ratings yet

- Südmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesDocument2 pagesSüdmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesBob DylanNo ratings yet

- COCOMO II ExampleDocument26 pagesCOCOMO II ExampleQuốc ĐạiNo ratings yet

- Swot Analysis - Transnational CrimeDocument14 pagesSwot Analysis - Transnational CrimeCharmis Tubil100% (1)

- M01e1-Introduction of Optometrists & Opticians Act 2007 PresentationDocument45 pagesM01e1-Introduction of Optometrists & Opticians Act 2007 Presentationsytwins100% (1)

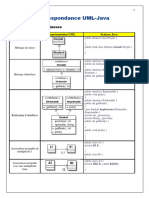

- 8 - Correspondance UML-JAVADocument3 pages8 - Correspondance UML-JAVAoussama sfiriNo ratings yet

- Criminal Law II - Quasi OffensesDocument2 pagesCriminal Law II - Quasi OffensesJanine Prelle DacanayNo ratings yet

- Accounting Q&ADocument6 pagesAccounting Q&AIftikharNo ratings yet

- Interrupts On Firebird-V Robot: E-Yantra Team Embedded Real-Time Systems Lab Indian Institute of Technology-BombayDocument67 pagesInterrupts On Firebird-V Robot: E-Yantra Team Embedded Real-Time Systems Lab Indian Institute of Technology-BombaySridhar JayaramanNo ratings yet

- SPP ADC Flightplan UnderstandingDocument25 pagesSPP ADC Flightplan UnderstandingYesid BarraganNo ratings yet

- SAP S/4HANA Supply Chain For Transportation Management 1809Document73 pagesSAP S/4HANA Supply Chain For Transportation Management 1809trishqNo ratings yet

- Chapter 13 - Basic DerivativesDocument59 pagesChapter 13 - Basic Derivativesjelyn bermudezNo ratings yet

- Performance Task 1. Piecewise FunctionDocument3 pagesPerformance Task 1. Piecewise FunctionKatherine Jane GeronaNo ratings yet

- Wagner Power Steamer ManualDocument8 pagesWagner Power Steamer ManualagsmarioNo ratings yet

- UHN - Careers at UHN - Job Application PDFDocument4 pagesUHN - Careers at UHN - Job Application PDFKARTHIKEYAN ARTISTNo ratings yet

- Definition, Nature & Development of Tort Law-1Document40 pagesDefinition, Nature & Development of Tort Law-1Dhinesh Vijayaraj100% (1)

- Shipham Special Alloy ValvesDocument62 pagesShipham Special Alloy ValvesYogi173No ratings yet

- AdvertisingDocument16 pagesAdvertisingSun KambojNo ratings yet

- The 2020 Lithium-Ion Battery Guide - The Easy DIY Guide To Building Your Own Battery Packs (Lithium Ion Battery Book Book 1)Document101 pagesThe 2020 Lithium-Ion Battery Guide - The Easy DIY Guide To Building Your Own Battery Packs (Lithium Ion Battery Book Book 1)Hangar Graus75% (4)

- Group 8 Design Main Report + Appendix (1) 1 400Document400 pagesGroup 8 Design Main Report + Appendix (1) 1 400Manishaa Varatha RajuNo ratings yet

- Competency Based LearningDocument9 pagesCompetency Based Learningkarapetyanines08No ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- PayfixationoptionsDocument5 pagesPayfixationoptionsGK TiwariNo ratings yet

- Ruwanpura Expressway Design ProjectDocument5 pagesRuwanpura Expressway Design ProjectMuhammadh MANo ratings yet

rohini_32001918232

rohini_32001918232

Uploaded by

wannaphyoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

rohini_32001918232

rohini_32001918232

Uploaded by

wannaphyoCopyright:

Available Formats

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

BOX JACKING EXPLANATION

� •It is the process in which a pre-cast R.C.C box or a rigid box is pushed

into the soil with the help of hydraulic jacks

� •It is non-intrusive method beneath the existing surface.

� •It is more often used when a subway or a aqueduct or a underground

structure is to be

constructed.

� •It enables the traffic flow without disruption.

METHODS OF BOX JACKING

Box Jacking

� Non –intrusive method beneath existing surface infrastructure

� Frequently used where an existing road or rail tracks is an

embankment and space exists for the structure to be cast at the side

� Enables traffic flows to be maintained disruption

Procedure

� It involves the advancement of a site-cast rectangular or other

shaped box using high capacity hydraulic jacks.

� An open ended reinforced concrete box is cast on a jacking base.

� A purpose designed tunneling shield is provided at its leading end

and thrust jacks are provided at its rear end reacting against a

CE

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

jacking slab

� The box is then jacked carefully through the ground

� Excavation and jacking take place in small increments of advance.

� Measure are taken to ensure stability of the tunnel face and to

prevent the ground from being dragged forward by the advancing

box

� When the box has reached its final position the shield and

jacking equipment are removed.

R.C.C box jacking

� Is adopted where it is not possible to constructed in situ R.C.C

boxes

� These boxes are used for canal siphon, road under bridge and

culvert for conveying water/service pipes

� The box is provided with a shield in front in front called “Front

shield”

Which pierces through the soil by cutting

CE

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

R.C.C BOX JACKING

� •First the box section is designed and cast at the site or can be

transported to the site according to the requirement.

� •The foundation boxes are jacked into the ground designed to carry the

dead and the live loads.

� •Then the high capacity jacks are placed at the back and it pushes the

box into the ground.

� •A purpose designed tunneling shield is provided in the front end.

� •Then the box is jacked carefully through the earth.

� •Excavation and jacking are done in small increments in advance.

� •Measures should be taken to prevent the soil being dragged towards

the box.

R.C.C BOX JACKING

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Throustboring method

� Is a process of simultaneously jacking pipe through the earth

while removing the soil inside the encasement by means of a

rotating auger.

� In unstable soil conditions, the end of the auger is kept retracted

back inside the encasement so as not to cause voids.

� In stable conditions, the auger can be successfully extended

beyond the end of the encasement.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

ARCHED JACKING

THRUST BORING METHOD

� •It is a process of simultaneously jacking the pipe through the earth

while removing the

earth inside the box by means of a rotating auger.

� •Unstable conditions- the end of auger is kept retracted inside the

encasement so as not to cause voids.

� •Stable conditions- the auger can be successfully extended beyond the

encasement.

� •This can be successfully used in any kind of soil conditions.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

PROBLEMS ENCOUNTERED IN JACKING

� •Settlement of the above ground.

� •Seepage of ground water.

� •Caving in of soil etc.

FREEZING OF GROUN

� •This method is used when we encounter the problem of ground water

seepage and settlement of ground.

� •In this method a brine solution is continuously passed through the

pipes fixed in the soil.

� •The temperature of the brine would be -30°c.

� •So when this brine solution is circulated through these pipes it freezes

the ground and the ground behaves like an ice block.

� •The spacing of the freezing pipes will vary according to the type of

soil, its permeability and other factors.

� •Generally it is kept at a spacing of 1.2 m

PROBLEMS IN FREEZING

� •The main problem in the freezing method is the UPHEAVING of the

above ground.

� •To avoid the upheavement problem we should be careful in the ground

freezing process and the temperature of the brine solution.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

CASE STUDY - SOUTHERN BOSTON PIERS TRANSIT WAY

� •The carriageway has to go beneath – a Russian building,100 year old

� •2m thick soil was frozen.

� •Under pinning was also done using mini piles.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

PLAN OF THE RUSSIAN BUILDING

ADVANTAGES

� •Timely completion of project.

� •No disruption of traffic.

� •No need to divert the traffic.

DISADVANTAGES

� •Cost of project increases.

� •Skilled personnel required.

� •Safety precautions to be done properly.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

PIPE JACKING

ABOUT THE TECHNIQUE

� •It is generally referred as “Micro tunneling”

� •Pipes are pushed through the ground behind the shield using powerful

jacks.

� •Simultaneously excavation takes place within the shield.

� •This process is continued until the pipeline is completed.

� •The method provides a flexible, structural, watertight, finished

pipeline as the tunnel is excavated.

� •No theoretical limit to the length of individual pipelines.

� •Pipes range from 150mm to 3000mm diameter can be installed in

straight line or in curvature.

� •Thrust wall is provided for the reaction of the jacks.

� •In case of poor soil, the thrust wall may punch inside the soil.

� •Then piles or ground anchoring methods can be used.

PROCEDURE

� •The thrust pit and the reception pit are excavated at the required

places.

� •Then the thrust wall is set up in the thrust pit according to the

requirement.

� •In case of mechanized excavations, a very large pit is required.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

� •But in case of manual excavation, a small pit is enough.

� •Thrust ring is provided to ensure the even distribution of stress along

the circumference of the pipe.

� •The number of jacks vary upon the frictional resistance of the soil,

strength of pipes etc.,

� •The size of the reception pit is to be big enough to receive the jacking

shield.

� •To maintain the accuracy of alignment a steer able shield is used

during the pipe jacking.

� •In case of small and short distance excavations, ordinary survey

method is sufficient.

� •But in case of long excavations, remote sensing and other techniques

can be used.

GENERAL ARRANGEMENTS

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

PIPE JACKING SETUP

THRUST SETUP

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

COMPUTER GUIDANCE SYSTEM

� •The computer system enables us to control the work remotely.

ADVANTAGES

� •It avoids the excavation of trenches. So it is also called as “Trench

less Technique”.

� •There won’t be any leak problems in the future.

� •Timely finish of projects.

DISADVANTAGES

� •Very costly method.

� •Skilled personnel is required.

CE8401 CONSTRUCTION TECHNIQUES AND PRACTICES

You might also like

- MS Installation Ductile Iron Water Supply (Scribd)Document17 pagesMS Installation Ductile Iron Water Supply (Scribd)Mohd Asyhar91% (33)

- Allstate/McKinsey Bates H000001010Document495 pagesAllstate/McKinsey Bates H0000010104207west59th100% (3)

- Chat GPTDocument13 pagesChat GPTsuly maniyahNo ratings yet

- Immersed TunnelsDocument44 pagesImmersed TunnelsapmegremisNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Sequence of Operation of FahuDocument1 pageSequence of Operation of FahuahmedNo ratings yet

- 66 Job Interview Questions For Data ScientistsDocument10 pages66 Job Interview Questions For Data ScientistsRavi RanjanNo ratings yet

- Measurement of Line Impedances and Mutual Coupling of Parallel LinesDocument8 pagesMeasurement of Line Impedances and Mutual Coupling of Parallel LinesKhandai SeenananNo ratings yet

- Ce3013 u1Document41 pagesCe3013 u1NagarjunNo ratings yet

- Box Jacking Explanation: Unit Iii Sub Structure ConstructionDocument28 pagesBox Jacking Explanation: Unit Iii Sub Structure ConstructionVallabi CNo ratings yet

- Unit 1Document41 pagesUnit 1Bravin EbaneshNo ratings yet

- Unit Iii-Sub Structure ConstructionDocument30 pagesUnit Iii-Sub Structure Constructionumamaheswari skNo ratings yet

- CP Unit 2Document184 pagesCP Unit 2Dhanashri Patil100% (1)

- Box Pushing and Trenchless TechnologyDocument18 pagesBox Pushing and Trenchless TechnologySanjay HNNo ratings yet

- Construction Techniques, Equipments & Practice: WelcomeDocument88 pagesConstruction Techniques, Equipments & Practice: WelcomeRON SAMUEL 401935No ratings yet

- Pipe JackingDocument17 pagesPipe JackingnurulzulkipliNo ratings yet

- 1.box JackingDocument12 pages1.box JackingManeesha RajendranNo ratings yet

- 1.2 Pipe JackingDocument11 pages1.2 Pipe JackingKandasamy AsohanNo ratings yet

- 1.2 Pipe JackingDocument11 pages1.2 Pipe Jackinganku4frenz100% (1)

- Sub-Structure and Super-StructureDocument27 pagesSub-Structure and Super-StructureRyuuNo ratings yet

- Box Pushing Technology PresentationDocument20 pagesBox Pushing Technology PresentationRavindra RajuNo ratings yet

- Box Pushing Technology PresentationDocument20 pagesBox Pushing Technology PresentationH S Vishwa NathNo ratings yet

- Specialized Construction Techniques - FinalDocument102 pagesSpecialized Construction Techniques - FinalSabella JimenezNo ratings yet

- Underground Water Tank Installation GuidelinesDocument3 pagesUnderground Water Tank Installation Guidelinesenochkalembe1No ratings yet

- TunnelingDocument21 pagesTunnelingDanielsNo ratings yet

- 1.1 Box JackingDocument14 pages1.1 Box JackinggeethaNo ratings yet

- 1 150228085423 Conversion Gate01 PDFDocument14 pages1 150228085423 Conversion Gate01 PDFSanjay EvaneNo ratings yet

- Tunnel 05 - Construction of Tunnels - Part 2Document65 pagesTunnel 05 - Construction of Tunnels - Part 2Andika Febrian0% (1)

- Outline Construction Method StatementDocument15 pagesOutline Construction Method Statementtsuak100% (2)

- Trenchless TechnologiesDocument24 pagesTrenchless TechnologiesAnupam KumarNo ratings yet

- Technical Note-Water Seepage Through PilesDocument5 pagesTechnical Note-Water Seepage Through PilesLijo Joseph100% (2)

- Lec11-Soft Ground TunnelingDocument28 pagesLec11-Soft Ground TunnelingAmraha NoorNo ratings yet

- Underground ConstDocument19 pagesUnderground ConstGagana D J 1DC19AT025No ratings yet

- Underground-Construction RDDocument19 pagesUnderground-Construction RDKarthik U WCFANo ratings yet

- Pipeline Execution PlanDocument23 pagesPipeline Execution PlanRawnakul Islam Opu100% (1)

- Pre Fab..Document29 pagesPre Fab..mohibNo ratings yet

- Construction Practice For Site EngineerDocument48 pagesConstruction Practice For Site EngineerGautam UmariaNo ratings yet

- Pipeline Laying in WaterDocument33 pagesPipeline Laying in WaterJai Krishna Sahith100% (2)

- Method Statement For Construction of Precast Concrete Pipe CulvertDocument4 pagesMethod Statement For Construction of Precast Concrete Pipe CulvertDanny NguNo ratings yet

- Trenchless TechnologyDocument41 pagesTrenchless TechnologyESAM ALHASHEDINo ratings yet

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDocument6 pagesMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953No ratings yet

- Dewatering TechniquesDocument34 pagesDewatering TechniquesAhmed Khalifa100% (1)

- Underwater ConstructionDocument23 pagesUnderwater ConstructionSujay Raghavendra N88% (16)

- Method Statement-Manshield MethodDocument7 pagesMethod Statement-Manshield Methodasr.engineering2023No ratings yet

- Inspection of Reinforcing WorksDocument3 pagesInspection of Reinforcing Worksnavodi.sathsara99No ratings yet

- Fore PolingDocument5 pagesFore PolingSurinderPalSinghGillNo ratings yet

- Precast Technology With The Case Study of BWSLDocument93 pagesPrecast Technology With The Case Study of BWSLer_hvpatelNo ratings yet

- Tunnel Boring MachinesDocument58 pagesTunnel Boring MachinesAliArababadiNo ratings yet

- Sewage PPT ManeeshDocument14 pagesSewage PPT ManeeshSUBHAJEET TEWARINo ratings yet

- Pipe Jacking: Technique - Factors - Applications - AdvantagesDocument18 pagesPipe Jacking: Technique - Factors - Applications - AdvantagesGakwaya Jules CesarNo ratings yet

- 12.excavation and Basement ConstructionDocument22 pages12.excavation and Basement ConstructionNiluka Ekanayaka100% (1)

- Box Pushing Technology: Seminar Report Submitted by Uvais.A REG NO:20010536 Civil EngineeringDocument18 pagesBox Pushing Technology: Seminar Report Submitted by Uvais.A REG NO:20010536 Civil EngineeringUvais Majeed100% (2)

- Auger BoringDocument7 pagesAuger BoringMuhammad AmjadNo ratings yet

- Inst Instructions 10 000 v1.0Document9 pagesInst Instructions 10 000 v1.0gangrukaNo ratings yet

- Unit 2Document97 pagesUnit 2Sid SNo ratings yet

- Methodology For TrenchingDocument6 pagesMethodology For Trenchinginsk0% (1)

- Submerged Floating TunnelDocument31 pagesSubmerged Floating TunnelRAKESH KUMAR 061No ratings yet

- Construction Techniques, Equipments & Practice: WelcomeDocument40 pagesConstruction Techniques, Equipments & Practice: WelcomedhanabalNo ratings yet

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Good Construction PracticesDocument48 pagesGood Construction Practicespetrus jacobNo ratings yet

- Tunnel EngineeringDocument53 pagesTunnel EngineeringshankaregowdaNo ratings yet

- PipelineConstructionPprocess 14july2011Document6 pagesPipelineConstructionPprocess 14july2011mark_fish22No ratings yet

- Cut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFDocument5 pagesCut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFfethi42No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- TV Ole 2020Document1 pageTV Ole 2020david floresNo ratings yet

- Samsung RF27T5501Document164 pagesSamsung RF27T5501Brian MasseyNo ratings yet

- Südmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesDocument2 pagesSüdmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesBob DylanNo ratings yet

- COCOMO II ExampleDocument26 pagesCOCOMO II ExampleQuốc ĐạiNo ratings yet

- Swot Analysis - Transnational CrimeDocument14 pagesSwot Analysis - Transnational CrimeCharmis Tubil100% (1)

- M01e1-Introduction of Optometrists & Opticians Act 2007 PresentationDocument45 pagesM01e1-Introduction of Optometrists & Opticians Act 2007 Presentationsytwins100% (1)

- 8 - Correspondance UML-JAVADocument3 pages8 - Correspondance UML-JAVAoussama sfiriNo ratings yet

- Criminal Law II - Quasi OffensesDocument2 pagesCriminal Law II - Quasi OffensesJanine Prelle DacanayNo ratings yet

- Accounting Q&ADocument6 pagesAccounting Q&AIftikharNo ratings yet

- Interrupts On Firebird-V Robot: E-Yantra Team Embedded Real-Time Systems Lab Indian Institute of Technology-BombayDocument67 pagesInterrupts On Firebird-V Robot: E-Yantra Team Embedded Real-Time Systems Lab Indian Institute of Technology-BombaySridhar JayaramanNo ratings yet

- SPP ADC Flightplan UnderstandingDocument25 pagesSPP ADC Flightplan UnderstandingYesid BarraganNo ratings yet

- SAP S/4HANA Supply Chain For Transportation Management 1809Document73 pagesSAP S/4HANA Supply Chain For Transportation Management 1809trishqNo ratings yet

- Chapter 13 - Basic DerivativesDocument59 pagesChapter 13 - Basic Derivativesjelyn bermudezNo ratings yet

- Performance Task 1. Piecewise FunctionDocument3 pagesPerformance Task 1. Piecewise FunctionKatherine Jane GeronaNo ratings yet

- Wagner Power Steamer ManualDocument8 pagesWagner Power Steamer ManualagsmarioNo ratings yet

- UHN - Careers at UHN - Job Application PDFDocument4 pagesUHN - Careers at UHN - Job Application PDFKARTHIKEYAN ARTISTNo ratings yet

- Definition, Nature & Development of Tort Law-1Document40 pagesDefinition, Nature & Development of Tort Law-1Dhinesh Vijayaraj100% (1)

- Shipham Special Alloy ValvesDocument62 pagesShipham Special Alloy ValvesYogi173No ratings yet

- AdvertisingDocument16 pagesAdvertisingSun KambojNo ratings yet

- The 2020 Lithium-Ion Battery Guide - The Easy DIY Guide To Building Your Own Battery Packs (Lithium Ion Battery Book Book 1)Document101 pagesThe 2020 Lithium-Ion Battery Guide - The Easy DIY Guide To Building Your Own Battery Packs (Lithium Ion Battery Book Book 1)Hangar Graus75% (4)

- Group 8 Design Main Report + Appendix (1) 1 400Document400 pagesGroup 8 Design Main Report + Appendix (1) 1 400Manishaa Varatha RajuNo ratings yet

- Competency Based LearningDocument9 pagesCompetency Based Learningkarapetyanines08No ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- PayfixationoptionsDocument5 pagesPayfixationoptionsGK TiwariNo ratings yet

- Ruwanpura Expressway Design ProjectDocument5 pagesRuwanpura Expressway Design ProjectMuhammadh MANo ratings yet