Professional Documents

Culture Documents

MST Water Pipe Relocation

MST Water Pipe Relocation

Uploaded by

slayerzzz22Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MST Water Pipe Relocation

MST Water Pipe Relocation

Uploaded by

slayerzzz22Copyright:

Available Formats

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

METHOD STATEMENT FOR

WATER PIPE RELOCATION

Reference No: RWTP-GB-C&S-MST- 000002-01

Revision : 00

Date : 23rd November 2022

Action Name Designation Signature

Approved by Khor Thiam Chay Project Director

Reviewed by Tan Jin Soon Lead Consultant

Construction

Reviewed by Chin Sau Lun

Manager

Reviewed by Syerifaizal QAQC Manager

Prepared by Ooi Jeh Tsong Project Engineer

Contents

Contents....................................................................................................................................................................2

REF. NO : RWTP-GB-C&S-MST- 000002 Page 1

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

1.0 SCOPE OF WORKS................................................................................................................................4

1.1 General Description..........................................................................................................................4

1.2 Reference.............................................................................................................................................4

1.3 Materials...............................................................................................................................................4

1.4 Plant and Equipment........................................................................................................................5

1.5 Manpower............................................................................................................................................5

1.6 Work Procedures...............................................................................................................................7

1.6.1 Preparation of Works........................................................................................................................7

1.6.2 Method of Construction...................................................................................................................7

1.6.3 Traffic Control System.....................................................................................................................8

1.6.4 Site Material Transportation...........................................................................................................8

1.6.5 Pipe Trench Excavation...................................................................................................................8

1.6.6 Hauling and Handling of Pipe.........................................................................................................9

1.6.7 Laying Pipes and Fittings..............................................................................................................10

1.6.8 Pipe Jointing and Assembly.........................................................................................................10

1.6.9 Construction of Thrust Block.......................................................................................................12

1.6.10 Installation of Pipe S - Bend (Above Ground).....................................................................13

1.6.11 Installation of Tees and Valves................................................................................................13

1.6.12 Backfilling of Pipe Trenches....................................................................................................14

1.6.13 Construction of Valves Chamber............................................................................................14

1.6.14 Pressure and Leakage Test......................................................................................................15

1.6.15 Sterilising and Flushing of Pipelines.....................................................................................16

2.0 SAFETY AND HEALTH REQUIREMENTS......................................................................................17

2.1 Job Safety & Health Analysis.......................................................................................................17

2.2 Information to Personnel...............................................................................................................17

2.3 Emergency Arrangements............................................................................................................17

2.4 Permit Requirements......................................................................................................................18

2.5 Housekeeping...................................................................................................................................18

4.0 QUALITY ASSURANCE & QUALITY CONTROL...........................................................................20

4.1 Contractual Requirements............................................................................................................20

4.2 Inspection and Testing...................................................................................................................20

5.0 APPENDICES...............................................................................................................................................21

5.1 Job Safety Analysis...............................................................................................................................21

5.2 Emergency Response Flow Chart......................................................................................................22

5.3 Environmental Aspect & Impact Register........................................................................................25

5.4 Inspection & Test Plan..........................................................................................................................26

REF. NO : RWTP-GB-C&S-MST- 000002 Page 2

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

REF. NO : RWTP-GB-C&S-MST- 000002 Page 3

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

1.0 SCOPE OF WORKS

1.1 General Description

This Method Statement (MS) is developed and describes the methodology of Water

Pipe Relocation for Package 1 – Design and Build of Proposed Rasau Intake, Raw

Water Pumping Mains, Water Treatment Plant and Associated Works.

1.2 Reference

1) Item 3 – Steel Pipe Work, Tender Document Vol 2: Need Statement &

Specifications

1.3 Materials

1.3.1 Materials for pipe laying works include the following:

Item Materials Size (mm)

1. MS/DI pipes, specials and fittings 300mm diameter

2. MS/DI pipes, specials and fittings 450mm diameter

3. MS/DI pipes, specials and fittings 500mm diameter

4. MS/DI pipes, specials and fittings 1400mm diameter

5. Sand for backfilling As per required

6. Crusher run As per required

7. Asphalt concrete mix As per required

8. Lath As per required

9. Cable Marker Route As per required

1.3.2 The material shall have approval certificates from SYABAS. Source and make of

all major materials such as all pipes and fittings, joints, valves, saddles, chamber

covers etc. will be submitted to consultant. Material deliver to the site will be

jointly inspected with consultant and SYABAS Representative. Only materials

that have been inspected and approved by the Consultant/SYABAS will be used

for the works. Type of materials shall be accordance to BS and/or JKR

specification & standards (based on existing materials used at site).

REF. NO : RWTP-GB-C&S-MST- 000002 Page 4

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

1.3.3 All piping and fitting materials including fill materials and road reinstatement work

materials must be submitted to PDP for approval prior to usage at site.

1.4 Plant and Equipment

Item Machinery / Equipment

1. Backhoe

2. Excavator

3. Lorries (10 tonnes)

4. Generator Set (6 kW@7.5 amps, 1800va)

5. Welding Set

6. Water Pump

7. Roller Compactor

8. Plate Compactor

9. Mobile Crane

10. Electromagnetic Location (EML)

11. Ground-penetrating Radar (GPR)

12. Spotlight

1.5 Manpower

Item Designation Responsibilities

1. Construction Manager Responsible for overall commercial, contractual

and technical performances associated with

specific

projects. Responsible to the Project Manager.

2. Assistant Manager Assisting Construction Manager to ensure overall

works implementation is in order and coordinates

all site activities of pipe relocation works.

3. Project Engineer Planning, coordinating and supervising site

activities

4. Site Supervisor Supervising site construction activities

5. Foreman In charged of planning, coordinating and monitoring

of site works

REF. NO : RWTP-GB-C&S-MST- 000002 Page 5

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

6. Surveyor/chainman Prepare setting out and survey works at site

7. Machinery Operators Operating machinery

8. Safety & Health Personnel To control and ensure the Safety & Health

requirements are adhered at site.

9. QA/QC Personnel To control and ensure the quality of works is

adhered at site.

10. Environment Coordinating the environmental control measures

Manager as detailed in the EMP. Report directly to Project

Manager.

11. Environment Officer Carrying out measures for protecting public health,

including administering and enforcing legislation

related to environmental health and providing

support to minimize health and safety hazards.

12. General Workers Conduct general works at site

13. Certified Welder Welder with certificate will be use for the pipe

jointing

work

14. Flagman & Traffic Control To control traffic and avoid public enter to the

workplace

15. Traffic management officer Make sure activity at site adhere to Traffic

Management Plan

REF. NO : RWTP-GB-C&S-MST- 000002 Page 6

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

1.6 Work Procedures

1.6.1 Preparation of Works

1.6.1.1 Prior to commencement the excavation and pipe laying works shall be carrying

out:

i. Ensure that the pipe route for the trench shall be pegged out accurately to

obtain consultant approval.

ii. Application of Permit to Work (PTW) from local authorities JKR, Majlis

Perbandaran Kuala Langat (MPKL), Majlis Perbandaran Sepang (MPS),

LLM, and SYABAS before starting of work.

iii. Detection and piloting excavation shall be conducted, to locate existing

services where necessary.

iv. Details of proposed materials to be submitted for approval prior to usage.

v. Preparation of shop drawing for approval from consultant and SYABAS prior

to start work.

vi. Potentially affected stakeholders who are using the said/affected utilities are

to be notified via Notice Mail Drops at least 5 days in advance done by

contractor. Content of the notice must contain information on the works

duration, hours, affected area and contact details (person, company and

contact number) for public to contact for information or to complaint.

vii. Should water disruption happen apart/away from the agreed notification

details, contractor is responsible to provide a temporary solution to assist the

affected stakeholder such as provision of a water truck.

1.6.2 Method of Construction

i. Establishing store yard

ii. Provide the traffic control system

iii. To apply work permit from local authorities

(DBKL/SYABAS/LLM/ANIH/BESRAYA)

iv. To obtain Permit to Excavate for excavation work

v. Pilot excavation (follow piloting method statement)

vi. Pipe trench excavation and pipe laying works

REF. NO : RWTP-GB-C&S-MST- 000002 Page 7

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

vii. Backfilling with suitable material, sand and crusher run as satisfactory.

Reinstatement works and cleans up of work area.

1.6.3 Traffic Control System

i. This traffic control shall be conducted before the pilot excavation and trench

excavation for pipe laying works is carried out.

ii. All the signboard and safety equipment shall be ready and compliance the

requirement of the authorities and approved by PDP.

iii. Flagman will be provided to control the traffic flow during pipe laying works

to ensure that the traffic flow during pipe laying works is smoothly.

iv. Should a lane or road closure is required as part of the TMP, a Traffic

Announcement is needed. SOP of Traffic Announcement is listed in the PR

and Stakeholder Manual.

1.6.4 Site Material Transportation

1.6.4.1 Data from the site measurement will be referred for material delivery in

accordance with the need and availability. A number of pipes will be unloaded at

a WPC’s(Work Package Contractor????) store yard for reasonable intervals

along the proposed pipe alignment by obtain the approval from local authority.

The location where pipes will be unloaded must be carefully selected to avoid

users around that area.

1.6.4.2 All the materials shall be approved by SYABAS, SC and PDP prior delivery to

WPC’s store yard.

1.6.4.3 All materials should be carefully inspected at the time delivery and any defective

material set-aside before accepting the delivery into stores. The defective

materials should be returned to the suppliers immediately.

1.6.4.4 All pipe stacks should be made on sufficiently firm, flat ground to support the

weight of the pipes and necessary lifting equipment. Pipe can only be stack

maximum of 2 layers.

1.6.5 Pipe Trench Excavation

1.6.5.1 Pipe laying works shall only be commenced upon approval of alignment by

REF. NO : RWTP-GB-C&S-MST- 000002 Page 8

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

SYABAS. Before commencement the excavation works, tar macadam and

similar road surfaces shall be broken out neatly to a minimum of 1.0m width or to

the requirement of local authority along the trench line using diamond disc road

cutter to keep the edges straight and vertical.

1.6.5.2 Trench excavation for laying the new pipes shall be carried out with the use of

backhoe.

1.6.5.3 The run of pipe trenches opened up ahead of pipe laying operation at any one

time shall not be more than 100m.

1.6.5.4 The trenches shall be excavated to the widths as follows:

External Pipe Diameter D (mm) Width of Trench (mm)

Not Exceeding 460 D +450

500 to 750 D + 600

Exceeding 750 D + 900

1.6.5.5 The depth of trench to be excavated shall be the depth indicated in the

construction drawing with an additional of 150mm thick sand bedding.

1.6.5.6 At joint's area, the trench shall be excavated to give a working space of not less

than 300mm around the joint. Where bends are made by deflecting pipes at

joints, the trench shall be widen to permit this operation and for the construction

of thrust/ anchor blocks.

1.6.5.7 The side of the trench shall be cut vertically and where necessary, shall be

protected against caving in as recommended in the Job Safety Analysis (JSA).

1.6.5.8 The good excavated materials shall be stockpiled at both sides along the trench.

1.6.5.9 Dewatering of trench with water pump shall be applied when necessary due to

high ground water or surface run off.

1.6.5.10 Surplus excavated materials, earth, rubbish and waste shall be disposed off site

to the approved dumping ground.

1.6.6 Hauling and Handling of Pipe

1.6.6.1 Care shall be taken to ensure that the pipes and fittings are not subject to any

kind of shock or sudden load during hauling and handling.

1.6.6.2 Crane or any approved hoisting machine shall be used to assist in loading and

REF. NO : RWTP-GB-C&S-MST- 000002 Page 9

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

unloading of pipes. Canvas slings shall be used to lift the pipes from the

stockpile area to minimize the damage.

1.6.6.3 The pipes shall be delivered and unloaded along the proposed pipe alignment

using approved hoisting machine such as a lorry-crane or a lorry and a crane.

1.6.6.4 All pipes and fittings shall be thoroughly checked thru for cracks and flaws both

internally and externally immediately prior to laying.

1.6.7 Laying Pipes and Fittings

1.6.7.1 All pipes and fittings shall be laid to the lines and level shown on the construction

/ shop drawings.

1.6.7.2 Trench levels shall be checked and confirmed before filling the trench with

approved sand material and compacted.

1.6.7.3 Levelling and trimming to the final level shall be done carefully. The level of the

sand bedding is then checked and confirmed prior to laying of pipes.

1.6.7.4 Pipes are hoisted with the use of crane of approved hoisting machinery and

canvas slings and lowered into the trench. The pipes are to be placed into

position and the crown levels of pipes shall be checked against the proposed

level. Except for the pipes to be embedded in concrete, all pipes and fittings shall

be placed in their full length and in position ready for jointing.

1.6.7.5 Pipes and fittings to be embedded in concrete shall be held firmly in position and

protected from damage while the concrete is being in placed. Should any pipe

become either partially or fully clogged before final acceptance of the work, it

shall be cleaned out.

1.6.7.6 Trench and pipe details are recorded on pipe laying logs to be confirmed by

PDP/SC representative on site.

1.6.8 Pipe Jointing and Assembly

1.6.8.1 Jointing of Mild Steel (M.S.) Pipe (Welding)

a. For pipes with diameter 700mm and above, end of pipe which to be jointed

shall generally be spigots and sockets for jointing in trench.

b. End of pipe which to be jointed for plain ends shall use welded collars,

mechanical coupling or flange adaptors for pipes and fittings with diameter

REF. NO : RWTP-GB-C&S-MST- 000002 Page 10

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

700mm and above.

c. Welding shall be applied to Mild Steel pipe with diameter above 700mm. The

steel pipes are to be joined by welding internally and externally using

circumferential electric arc welding.

d. Before placing the pipes together, the portion of the sockets and spigots to

be welded shall be cleaned.

e. The spigot end shall then be placed in the socket and forced inside

so that the spherical surfaces are in contact and that the gap

between the pipes at the end of the spigot is nowhere greater than

1.5mm.

f. For longitudinally welded pipes, the longitudinal welds on adjacent

pipes shall be at least 15 degree out of line.

g. Where pipes are to be joined by a steel split collar, the pipe's end

and collar shall be cleaned.

h. The collar shall then be placed on the ends of the pipes and

clamped tightly onto the pipes using lugs and welded longitudinally.

i. Lugs shall be removed once completions of the internal & external

circumferential welding.

j. The weld shall be of the convex full fillet type for lap welded joints

made manually by the metal arc process.

k. Each time the arc is started, it shall be manipulated to obtain

complete fusion of the weld metal with the pipe and any previously

deposited weld metal.

l. After each joint has been welded, it shall be air tested in

accordance to SYABAS specification with the presence of

consultant.

m. After air test, the external sheathing shall be completed to ensure

continuity of protection along the pipeline. The joint area shall be

cleaned to a metallic finish and immediately coated with a primer

solution. As soon as the primer has set, the sheathing shall be

completed by running hot bitumen over the joint with 75mm

overlaps on both sides of joint. The thickness of the sheathing

shall not be less than 10mm.

REF. NO : RWTP-GB-C&S-MST- 000002 Page 11

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

1.6.8.2 Flanged Joints

a. The flanged joints shall be applied to area jointing with the air valves.

b. The end of each pipe shall be wire brushed to remove any dirt or

protuberances prior to the jointing.

c. Carefully fit gasket into position and ensure no damage to the gasket

surface.

d. Install bolt and nuts into all bolt holes of flange end.

e. The bolts shall be tightened in regular sequence starting from opposite sides

of bolt circle and the going around in this way until bolt is tight. Excessive

tightening of flanged joints shall be avoided.

f. Flanged joints located in chambers shall be painted with two coats of

bituminous paint.

1.6.8.3 Flexible Mechanical Coupling

a. Inspect pipe ends and to ensure compliance with the specification.

b. Align the end of pipe which already in position, adjusting the bed of the

trench or other support as necessary.

c. Place flanges over the pipe ends. Mark both pipe ends at a distance of half

the sleeve width plus the width of one flange to aid in central positioning of

the coupling over the gaps.

d. Place sleeve onto the pipe which already in position and insert the adjacent

pipe end into sleeve, adjust gap between pipe ends as necessary.

e. Bring each rubber wedge ring towards the sleeve using the flanges.

f. Bring bolt holes into line and fit bolts all from the same side. Ensure the neck

of the bolt is properly located in the flange hole and fits the nuts tight

1.6.9 Construction of Thrust Block

1.6.9.1 When bends are required to be installed, they shall be secured using thrust

blocks.

1.6.9.2 The dimension of thrust blocks for horizontal and vertical bends as per

construction drawings.

1.6.9.3 The concrete grade of the thrust block as indicated in the construction drawings.

1.6.9.4 Concrete supply from ready mix batching plant shall be the choice for bigger

REF. NO : RWTP-GB-C&S-MST- 000002 Page 12

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

volume. If the volume required is small and the distance and time is

uneconomical to procure the concrete from the batching plant, an alternative

supply shall be considered. Concrete shall be mixed on site for very small

volume.

1.6.9.5 On site mix design and method shall be submitted for approval.

1.6.10 Installation of Pipe S - Bend (Above Ground)

1.6.10.1 When above ground pipe works are required, Mild Steel (MS) pipe and specials

shall be used as S-bend. Jointing shall use MS collars.

1.6.10.2 The collar shall be a single split collar with temporary bolts and lugs. The collar

shall be 1.5mm thicker than the thickness of the pipe. The collar inner surface

shall be in close contact with the outer surface of the pipe/specials to be welded.

1.6.10.3 The outer surface of both pipe end as well as the specials shall be brushed away

and clean from any dirt, rust and earth. The same is carried out on to the inner

surface of the collars.

1.6.10.4 Slide the collar into the MS pipe.

1.6.10.5 Using a crane or any approved lifting machinery with proper slings to lift the

specials and align it into position. Slide the collar out to hold the special in its

position and steadily tighten the bolts and nuts.

1.6.10.6 Ensure that the gap between the split ends of the collar is at minimum when

bolts and nuts are tightened and the specials is in line with the pipeline

alignment.

1.6.10.7 Carry out intermittent butt welding of the collar to the pipe and specials while the

machinery still supporting the specials. The machinery shall be removed once

the weld is sufficiently rigid to hold the specials in its position. Complete

circumference welding of both sides.

1.6.10.8 Ensure that there shall be no defects such as cracks, leaks, lack of penetration

and lack of complete fusion on the welded joint.

1.6.11 Installation of Tees and Valves

1.6.11.1 Tees and valves shall be installed at predetermined locations before the

connection being carried out.

REF. NO : RWTP-GB-C&S-MST- 000002 Page 13

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

1.6.11.2 Pre-fabricated Tee shall be welded at predetermined location of pipe section.

Jointing shall use M.S. collar.

1.6.11.3 The collar shall be a single split collar with temporary bolts and lugs. The collar

shall be 1.5mm thicker than the thickness of the pipe. The collar inner surface

shall be in close contact with the outer surface of the pipe/specials to be welded

1.6.11.4 The outer surface of both pipe end as well as the Tee shall be brushed away and

clean from any dirt, rust and earth. The same is carried out on to the inner

surface of the collar.

1.6.11.5 Slide the collar into the MS pipe.

1.6.11.6 Align the tee and pipe, hold in position, slide the collar to hold the tee in its

position and tighten the bolts and nuts. Carry out intermittent butt welding until

the weld is sufficiently rigid to hold the tee in its position. Complete

circumference welding.

1.6.11.7 Valves shall be installed with flanged joint at predetermined locations.

1.6.11.8 The end of each pipe shall be wire brushed to remove any dirt or protuberances

prior to the jointing.

1.6.11.9 Carefully fit gasket into position and ensure no damage to the gasket surface.

1.6.11.10 Install bolt and nuts into all bolt holes of flange end. The bolts shall be

tightened in regular sequence starting from opposite sides of bolt circle and the

going around in this way until bolt is tight. Excessive tightening of flanged joints

shall be avoided.

1.6.12 Backfilling of Pipe Trenches

1.6.12.1 After pipe laying works have been approved by the consultant and before the

pipelines are tested, only sufficient backfilling of the trenches to maintain the

pipes in position shall be carried out but all joints shall be left exposed.

1.6.12.2 The sand shall be delivered to designated locations adjacent to the actual

work site. If stockpile is not permitted (due to heavy traffic or space

constraint), the sand shall be transferred to work site when needed.

1.6.13 Construction of Valves Chamber

1.6.13.1 Construction of valve chambers shall be carried out within a reasonable period of

time after all valves have been installed. Positions of chambers are pre-

REF. NO : RWTP-GB-C&S-MST- 000002 Page 14

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

determined and pegged out. Incidental excavation shall be carried out with the

use of backhoe.

1.6.13.2 Formation level of the chambers shall be checked during excavations works

before the construction takes place.

1.6.13.3 Detail of valves chamber as per construction drawings.

1.6.13.4 Precast chamber shall be installed where available. If cast in situ of chamber is

required, refer to Method Statement for cast in situ chamber construction.

1.6.14 Pressure and Leakage Test

1.6.14.1 The field pressure and leakage test shall not be carried out until the backfilling of

the pipe trenches have been completed except at the joints. Backfilling at flexible

joints shall be left uncompleted to facilitate inspection joints during testing.

1.6.14.2 Prior to filling the pipe line with clean water, the pipe line shall be thoroughly

inspected jointly with the PDP/SC to ensure that the pipes jointing have been

completed. At each test, the tees for air valves and washouts shall be sealed

with blank flanges.

1.6.14.3 Field Testing for Water Main

a. Air Testing of Welded Joints

The annular space between the two welds shall be air tested to a pressure of

1.7 MPa. While this pressure is maintained for a minimum period of 10

minutes, the welds shall be examined carefully for leakage. Any defective

welding shall be repaired. The screwed plug shall be replaced and welded

after each joint has been satisfactorily tested. The Contractor shall provide all

necessary gauges, equipment, labour and materials for air testing of welded

joints.

b. Pressure Test

The two ends of the test section shall be end cap with steel plates. A pressure

gauge shall be attached to the end of the test section to monitor water

pressure. The pressure gauge shall have a dial of not less than 150mm

diameter and shall be such that maximum field test pressure of pipeline shall

be at 60% to 70% of the gauge range. The test section to be filled with water

of fair quality and free of sediments. During filling, provision shall be made for

REF. NO : RWTP-GB-C&S-MST- 000002 Page 15

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

air to escape from high spots in the section by properly installing air valves

and from the air release vent pipe in the stop end at the higher end of the

section. After the section has been filled with water for a period of not less

than 48 hours, more water shall be pumped into the section to raise the

pressure to 15 bars and hold for 10 minutes. When the pressure gauge shows

no reduction in pressure during the period of 10 minutes, the pressure test is

considered passed. If the above requirements are not satisfied, a thorough

inspection of the section shall be made and all defects shall be repaired and

the test shall be repeated.

c. Leakage Test

Once the pressure test considered pass then the leakage test shall be

proceeded. The pressure shall be reduced from 15 bars to 12 bars and hold

for 24 hours. A re-inspection on the pressure after 24 hours shall be

conducted with the presence of SC and SYABAS representatives. The

leakage test is considered to have been passed if the make-up water pumped

into the section of the main does not exceed the allowable leakage calculated

as : 0.34 litre per cm of pipe diameter per km of pipe per 24 hours per 1.0 bar

of water pressure. If this specified rate of leakage is exceeded, a thorough

inspection of the section of the main shall be made. All leaks discovered shall

be repaired and the section shall be tested again.

1.6.15 Sterilising and Flushing of Pipelines

1.6.15.1 Sterilising and flushing shall be carried out before completion of final connection

to existing SYABAS pipeline. The water from sterilising and flushing shall be

obtained from SYABAS.

1.6.15.2 All necessary equipment and materials e.g. Dosing pump, chemical mixing tank

shall be ready at site prior to sterilise and flushing of pipeline.

1.6.15.3 The section of the pipeline to be sterilised shall be filled with water with a solution

of chloride and chlorine. The calculation of ration for water, chloride and chlorine

will be determined later.

1.6.15.4 The contractor shall have to adopt a dosing system to a system to sterilise the

line effectively. The system shall be provided with a set up of the temporary

REF. NO : RWTP-GB-C&S-MST- 000002 Page 16

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

equipment, chemical tank mixer, dosing pump and other necessary accessories

for the solution to be injected into the lines through air valve tee when portable

water will be introduced gradually.

1.6.15.5 After the pipeline has been filled with chlorinated water, it shall be closed and left

for at least 24 hours. The pipeline shall be deemed to have sterilised if the

samples of water taken from scour chamber on the pipeline shows chlorine

residual of 10.00pm.

1.6.15.6 After the pipeline has been sterilised and the samples water taken from scour

chamber on the pipeline shows chlorine residual of 3.0ppm, it shall be flushed

through the scour point.

2.0 SAFETY AND HEALTH REQUIREMENTS

2.1 Job Safety & Health Analysis

Job Safety & Health Analysis shall be carried on the project site. Cautions and

hazards signs shall be established at location of works. The hazards in a

particular activity and the control measures implemented shall be briefed to the

workers during SHE induction, tool box talk and JSA Briefing. Please refer to the

attached Appendix 5.1.

2.2 Information to Personnel

2.1.1 All workers employed in the project site must have CIDB green card.

2.1.2 All new workers and staff to attend the SHE Training or SHE Induction Course

before commencing works at site and attendances shall be recorded in an

induction checklist.

2.1.3 All site personnel are mandatory wear proper Personnel Protective Equipment

(PPE):

2.1.4 Safety helmets, Safety vest, Safety boots, Hand gloves and any other additional

PPE required in JSA or advised by SHE Department.

2.1.5 Monthly SHE Committee meeting shall be held with all the contractors related to

the works.

2.1.6 All workers are compulsory to attend the daily pre-task briefing and weekly

toolbox meeting conducted by the SHE Department/Representative and

REF. NO : RWTP-GB-C&S-MST- 000002 Page 17

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

attendances shall be recorded.

2.3 Emergency Arrangements

2.3.1 Project Emergency Response Plan and Procedure shall be established.

2.3.2 The potential hazards during Bored Pile Works are as below:

i. Accident due to machinery/equipment failure and movement

ii. Fall from height, contact with sharp edges/protruding rebar and etc.

iii. Fire

2.3.3 An Emergency Response Team shall be formed at the site.

2.3.4 Please refer to the Appendix 5.2 for Safety, Health & Environmental Emergency

Response Flow Chart.

2.3.5 The organization chart, list of emergency contact person and relevant authorities

with their contact numbers shall be showed in the Notice Board.

2.3.6 In the event of emergency, the site management staffs must evaluate the

situation and commence the necessary procedures as follow:

Raise the alarm

Stop works

Remain composed.

Make sure notifications of emergency or evacuation are in place for all

workers surrounding the vicinity.

Make sure all workers are assembled at designated assembly point.

Make sure first aid kits are prepared at assembly point.

All workers are told not to leave the assembly point until clear sign is issued.

Headcount shall be conducted

First aiders shall attend to the injured workers

Prepare assessment reports for the losses.

1.7 Permit Requirements

Person or Authorities in-

No Description Remarks

charge

1 SHE permit to work such as SHE Department

Crane and Lifting Operation

REF. NO : RWTP-GB-C&S-MST- 000002 Page 18

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

permit, Excavation permit, Night

work permit, Hot work permit

and etc.

2.5 Housekeeping

Housekeeping is an essential part of SHE for the daily routine. Housekeeping

would include the following items:

Maintain the access way to all working area.

Proper material arrangement.

Park the machineries in orderly manner.

No littering around the site.

3.0 ENVIRONMENTAL ISSUES

3.5 Environmental Aspects, Impacts & Control Measures

All activities at work site shall comply with requirements stated in Environmental

Management Plan. Work site shall observe potential environmental impacts that

will be generated from activities stated in this method of statement, proposed

control measures, responsible parties’ in-charge and relevant legal applicability.

The significant environmental impacts associated with the Bored Pile Works

have been identified and listed in the Appendix 5.3.

3.5.1 Air Quality and Noise Level

Machineries shall be in well maintain and in good working condition to reduce

emission of soot, smoke and noise.

The following measures shall be implemented if the above mentioned (soot,

smoke and noise) is deteriorating:

Increase maintenance frequency.

Replace to better equipment if necessary.

Switched-off equipment if not in used

Supply workers on-site with proper PPE (i.e. ear plugs and mask).

3.5.2 Water Quality

REF. NO : RWTP-GB-C&S-MST- 000002 Page 19

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

All surface runoff and contaminated water generated from activities stated in this

method of statement, must be channel to temporary earth drain and shall be

channel into sediment basin/ silt trap for further treatment.

3.5.3 Soil Erosion and Sediment Control

Precaution measures of erosion and sediment transport during the surface

preparation, construction, operation and closure phase of project shall comply

with Erosion and Sediment Control Plan (ESCP).

Erosion control such as phasing of works, vegetation buffers, turfing, protection

of slopes and stockpiles to be implemented. Sediment control such as

construction of sediment basin/ silt traps, sump, silt fence, sandbag and wash

trough shall be provided and maintained regularly.

3.5.4 Waste Management

All type of waste must be segregated, stored and disposed of in accordance with

the Construction Waste Management Plan and shall be removed from site

regularly.

Scheduled waste from maintenance works of machineries, vehicles and tools will

be placed in designated areas. Proper oil tray or drum shall be placed to prevent

the oil spillage all over the place. Subsequent waste shall be collected and

transfer to area as assigned.

4.0 QUALITY ASSURANCE & QUALITY CONTROL

4.1 Contractual Requirements

Shall be implemented in accordance with submitted comprehensive IMS plan.

4.2 Inspection and Testing

All inspection shall involve the consulting engineer and client.

REF. NO : RWTP-GB-C&S-MST- 000002 Page 20

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

5.0 APPENDICES

5.1 Job Safety Analysis

REF. NO : RWTP-GB-C&S-MST- 000002 Page 21

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

5.2 Emergency Response Flow Chart

REF. NO : RWTP-GB-C&S-MST- 000002 Page 22

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

REF. NO : RWTP-GB-C&S-MST- 000002 Page 23

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

Emergency Response Flowchart for Fire Emergency

Fire Emergency

Identifier alert

Major Minor

Alert workers/trigger alarm

to inform workers by ERT

Control fire with existing

member.

firefighting equipment

Active ERT and evacuate Set command point.

workers to designated Inform representative

assembly point. authority (BOMBA)

.

Assist authority with

information (if

required)

All clear declaration

from Authority

Emergency

terminates

Debriefing by Conduct

Emergency investigation Finish

commander

REF. NO : RWTP-GB-C&S-MST- 000002 Page 24

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

5.3 Environmental Aspect & Impact

Register

REF. NO : RWTP-GB-C&S-MST- 000002 Page 25

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

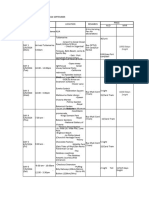

5.4 Inspection & Test Plan

REF. NO : RWTP-GB-C&S-MST- 000002 Page 26

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD

RASAU WATER METHOD STATEMENT

Rev

Project: TREATMENT PLANT ITP for: WATER PIPE RELOCATION 00

:

(RWTP)

Discipline

C&S Ref. No: RWTP-GB-C&S-ITP-000001-00

:

Discipline

REFER TO PROCEDURE Date: 23/08/2022 No of Pages: 1 of 3

code:

N Inspection Point

Activity Controlling Acceptance Frequenc

o Record

Description Document Criteria y CR SC CA

.

Technical Method Prior to Approved

1 Submission of

Specification/C Statement and commence Method of

. Method H R R

onstruction Inspection Test ment of Statement;

0 Statement

Drawing Plan (ITP) work Approved ITP

Method Technical Prior to Comment

2 Submission of

Statement: Specification/Co commence Review Sheet

. Material for H R S

RWTP-GB-C&S- nstruction ment of for Material

0 approval

MST- Drawing work Submission

Material Technical Approved

Submission Specification/Co Material

Approval nstruction Prior to Submission /

3

Material Drawing commence Request for

. H W S

inspection ment of Inspection

0

work (RFI) /

Delivery

Order (D.O.)

Technical As-built Survey Prior to

4

Specification/C data / Record commence

. Setting Out Survey Record H W S

onstruction ment of

0

Drawing work

- Pipe Trench Method Technical

During Work

5 Excavation Statement: Specification/Co

commence Inspection

. - Laying Pipes RWTP-GB-C&S- nstruction H W S

ment of Request

0 - Valve MST- Drawing

work Checklist

Installation

Method Technical During Work

6

Pipe Jointing and Statement: Specification/Co commence Inspection

. H W S

Air Testing RWTP-GB-C&S- nstruction ment of Request

0

MST- Drawing work Checklist

Method Technical During Work

7 Construction of

Statement: Specification/Co commence Inspection

. Valve Chamber & H W S

RWTP-GB-C&S- nstruction ment of Request

0 Thrust Block

MST- Drawing work Checklist

Testing of Method Technical During Work

8

Pipeline Statement: Specification/Co commence Inspection

. H W S

(Pressure & RWTP-GB-C&S- nstruction ment of Request

0

Leakage Test) MST- Drawing work Checklist

RASAU WATER

Rev

Project: TREATMENT PLANT ITP for: SOIL INVESTIGATION 00

:

(RWTP)

Discipline

C&S Ref. No: RWTP-GB-C&S-ITP-000001-00

:

REF. NO : RWTP-GB-C&S-MST- 000002 Page 27

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

H : Hold Point Points where no further works shall proceed without the written approval of the Supervising

Consultant representative

W : Witness Point Points where Supervising Consultant can opt to observe/ or visually examine or participate in the work

operation.

S : Surveillance Points where the SC representative monitor the contractor activities to the degree necessary for

confidences that work process/ method is complying with the established criteria

R: Review Review of the contractor’s ITP records for correctness and completeness

Discipline

REFER TO PROCEDURE Date: 23/08/2022 No of Pages: 2 of 3

code:

N Inspection Point

Activity Controlling Acceptance Frequenc

o Record

Description Document Criteria y CR SC CA

.

Method Technical During Work

9

Sterilizing & Statement: Specification/Co commence Inspection

. H W S

Flushing RWTP-GB-C&S- nstruction ment of Request

0

MST- Drawing work Checklist

1 Method Technical During Work

0 Statement: Specification/Co commence Inspection

Backfilling H W S

. RWTP-GB-C&S- nstruction ment of Request

0 MST- Drawing work Checklist

1 Method

After

1 Statement: Joint survey As-built

As built drawing completio H W S

. RWTP-GB-C&S- data drawing

n work

0 MST-

Remarks:

Inspection Authority:

CR Contractor Representative

SC Supervising Consultant

CA Contract Administrator

Prepared Reviewed Approved

Syerifaizal Bin Chin Sau Lun

Ooi Jeh Tsong

Mustapha (QAQC (Construction

Name (Assistant Manager)

Manager) Manager)

Signature

Date

REF. NO : RWTP-GB-C&S-MST- 000002 Page 28

RWTP

RASAU WATER TREATMENT PLANT

PENGURUSAN AIR SELANGOR

SDN BHD METHOD STATEMENT

REF. NO : RWTP-GB-C&S-MST- 000002 Page 29

You might also like

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- Method Statement - Sheet Piling WorksDocument202 pagesMethod Statement - Sheet Piling WorksWee Chek92% (12)

- Method Statement For Interconnection of Permeate Pipe To The Existing PipeDocument20 pagesMethod Statement For Interconnection of Permeate Pipe To The Existing PipegregNo ratings yet

- Method Statement - Tube Pilling WorkDocument21 pagesMethod Statement - Tube Pilling WorkReza Roseno100% (12)

- Foundation Method Statement: Uganda Electricity Transmission Corporation Limited. UETCLDocument20 pagesFoundation Method Statement: Uganda Electricity Transmission Corporation Limited. UETCLAnonymous CPEha1db7UNo ratings yet

- Method Statement For Testing & Commissioning of Feeder PillarDocument28 pagesMethod Statement For Testing & Commissioning of Feeder PillarhusamNo ratings yet

- RWTP GB CNS MST 000067 00Document61 pagesRWTP GB CNS MST 000067 00slayerzzz22No ratings yet

- RWTP-GB-CNS-MST-000015-01 (Raw Water Pipe Laying)Document61 pagesRWTP-GB-CNS-MST-000015-01 (Raw Water Pipe Laying)slayerzzz22No ratings yet

- RWTP GB MNE MST 000046 - Underground - DuctDocument54 pagesRWTP GB MNE MST 000046 - Underground - Ductslayerzzz22No ratings yet

- RWTP GB MNE MST 000031 Telecommunication SystemDocument60 pagesRWTP GB MNE MST 000031 Telecommunication Systemslayerzzz22No ratings yet

- RWTP-GB-C&S-MST - 000063-00 - General Repair WorkDocument38 pagesRWTP-GB-C&S-MST - 000063-00 - General Repair Workslayerzzz22No ratings yet

- RWTP GB Mne MST 000033 CA SystemDocument45 pagesRWTP GB Mne MST 000033 CA Systemslayerzzz22No ratings yet

- RWTP GB MNE MST 000041 Cable Management & TerminationDocument54 pagesRWTP GB MNE MST 000041 Cable Management & Terminationslayerzzz22No ratings yet

- RWTP GB Mne MST 000037Document69 pagesRWTP GB Mne MST 000037slayerzzz22No ratings yet

- RWTP GB MNE MST 000052 - BusductDocument50 pagesRWTP GB MNE MST 000052 - Busductslayerzzz22No ratings yet

- RWTP GB MNE MST 000050 Switches, Sso and IsolatorsDocument45 pagesRWTP GB MNE MST 000050 Switches, Sso and Isolatorsslayerzzz22No ratings yet

- RWTP GB Mne MST 000042 Pa SystemDocument63 pagesRWTP GB Mne MST 000042 Pa Systemslayerzzz22No ratings yet

- RWTP GB MNE MST 000043 - AV - SystemDocument52 pagesRWTP GB MNE MST 000043 - AV - Systemslayerzzz22No ratings yet

- RWTP-GB-MNE-MST-000051 Lighting System, Exit Signage and Fittings InstallationDocument50 pagesRWTP-GB-MNE-MST-000051 Lighting System, Exit Signage and Fittings Installationslayerzzz22No ratings yet

- RWTP GB CNS MST 000030 00Document45 pagesRWTP GB CNS MST 000030 00slayerzzz22No ratings yet

- RWTP GB Mne MST 000034 Smatv SystemDocument57 pagesRWTP GB Mne MST 000034 Smatv Systemslayerzzz22No ratings yet

- Paew Aiec 1 2017 PQP DraftDocument45 pagesPaew Aiec 1 2017 PQP DraftPopescu OctavianNo ratings yet

- RWTP GB Mne Msa 000049Document44 pagesRWTP GB Mne Msa 000049slayerzzz22No ratings yet

- Ms-021 - Laying of GRP Pipelines For SEWERGAE Pressure Works - DMDocument19 pagesMs-021 - Laying of GRP Pipelines For SEWERGAE Pressure Works - DMruwaaquaNo ratings yet

- Ts 147 Surge MitigationDocument34 pagesTs 147 Surge MitigationChris DamvergisNo ratings yet

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNo ratings yet

- Method Statement For ConcretingDocument23 pagesMethod Statement For ConcretingVinod MasaniNo ratings yet

- 2973 - Method Statement For Cable LayingDocument13 pages2973 - Method Statement For Cable LayingMuhammad SajjadNo ratings yet

- 2014.03.01 RATLE-DBM-DAM-03 - Rev A2 DESIGN BASIS MEMORANDUM FOR DAM & ASSOCIATED WORKS PDFDocument89 pages2014.03.01 RATLE-DBM-DAM-03 - Rev A2 DESIGN BASIS MEMORANDUM FOR DAM & ASSOCIATED WORKS PDFsekharNo ratings yet

- MS-PIPING-001Rev.a, Laying & Jointing DI PipingDocument14 pagesMS-PIPING-001Rev.a, Laying & Jointing DI PipingBiswasNo ratings yet

- Method Statement For DI PipingDocument16 pagesMethod Statement For DI Pipingtomj9104No ratings yet

- MS For Irrigation WorksDocument30 pagesMS For Irrigation Worksmaliksaqlain193No ratings yet

- Lus CP7B QDSBG Inr CV 85502 00Document12 pagesLus CP7B QDSBG Inr CV 85502 00AnwarologyNo ratings yet

- Design Criteria of WASAsDocument55 pagesDesign Criteria of WASAsImran AzizNo ratings yet

- AlbahaDocument173 pagesAlbahasamNo ratings yet

- RWTP GB Mne Msa 000147 SignedDocument26 pagesRWTP GB Mne Msa 000147 Signedslayerzzz22No ratings yet

- VIBRO Replacement (Stone Columns) For Central Reservoir Dammam 5Document63 pagesVIBRO Replacement (Stone Columns) For Central Reservoir Dammam 5mohamed ghalyNo ratings yet

- Mos - Slumb-Aln-Saf-Mst-St-00Document38 pagesMos - Slumb-Aln-Saf-Mst-St-00Saleem MohammedNo ratings yet

- Ground Improvement Procedure Rev.0Document14 pagesGround Improvement Procedure Rev.0Muhammad AfrasiyabNo ratings yet

- Earthworks Technical SpecificationDocument48 pagesEarthworks Technical SpecificationFeng XueNo ratings yet

- AO-SAR-MoS - R2 - Structural WorksDocument11 pagesAO-SAR-MoS - R2 - Structural Worksfloredex005No ratings yet

- Method Statement For RebarDocument8 pagesMethod Statement For RebarEng hassan hussien100% (1)

- JMS For Drainage & Sewage WorksDocument16 pagesJMS For Drainage & Sewage WorksazrulNo ratings yet

- Method Statement: Ministry of Water Supply & Drainage National Water Supply & Drainage BoardDocument13 pagesMethod Statement: Ministry of Water Supply & Drainage National Water Supply & Drainage BoardLakshithaGonapinuwalaWithanageNo ratings yet

- MST Installation of WEHOLITE Pipe - Stormwater - FinalDocument13 pagesMST Installation of WEHOLITE Pipe - Stormwater - FinalShahzaib ShahidNo ratings yet

- Sample Testing & Commissioning MSRA (Complete)Document18 pagesSample Testing & Commissioning MSRA (Complete)Dihar RaviNo ratings yet

- Pumpings Works Installtion MS Dammam-2Document10 pagesPumpings Works Installtion MS Dammam-2Eng hassan hussienNo ratings yet

- R03-C02C02-AAP-MTS-CI-0004 RevDocument20 pagesR03-C02C02-AAP-MTS-CI-0004 Revlike saddamNo ratings yet

- Msra-21 Asphalt WorksDocument44 pagesMsra-21 Asphalt WorksAbdul LatheefNo ratings yet

- RWTP GB Mne Msa 000095 Spring Isolator SignedDocument26 pagesRWTP GB Mne Msa 000095 Spring Isolator Signedslayerzzz22No ratings yet

- Technical Specifications of Kuraz Road Final HG1Document37 pagesTechnical Specifications of Kuraz Road Final HG1ABAMELANo ratings yet

- Corrosion Assessment Guidelines For Aging Pipelines and FlowlinesDocument47 pagesCorrosion Assessment Guidelines For Aging Pipelines and FlowlinesHermanNo ratings yet

- 0279STX N WM PW01 Qa Pro 0011 A02Document12 pages0279STX N WM PW01 Qa Pro 0011 A02praveen 0064No ratings yet

- MS-PIPING-002ev.a, Laying & Jointing HDPE PipingDocument12 pagesMS-PIPING-002ev.a, Laying & Jointing HDPE PipingBiswasNo ratings yet

- Method Statement - Shoring and Excavation For Soakaway Tank - Hub Park RevisedDocument13 pagesMethod Statement - Shoring and Excavation For Soakaway Tank - Hub Park Revisedyaswanth reddy mummadiNo ratings yet

- AO-SAR-MoS - R2 - SL - Mechanical Works - Part ADocument11 pagesAO-SAR-MoS - R2 - SL - Mechanical Works - Part Afloredex005No ratings yet

- SPAN Note Part 1 2013Document47 pagesSPAN Note Part 1 2013wan marzuki100% (1)

- Projek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)Document18 pagesProjek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)fendi azizNo ratings yet

- MOS-008 For Water Leaking TestDocument25 pagesMOS-008 For Water Leaking Testslayerzzz22No ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- RWTP GB Qaqc MPR 000006Document37 pagesRWTP GB Qaqc MPR 000006slayerzzz22No ratings yet

- Case Study StudentDocument24 pagesCase Study Studentslayerzzz22No ratings yet

- RWTP GB Mne Msa 000139 SignedDocument39 pagesRWTP GB Mne Msa 000139 Signedslayerzzz22No ratings yet

- RWTP GB MNE MST 000043 - AV - SystemDocument52 pagesRWTP GB MNE MST 000043 - AV - Systemslayerzzz22No ratings yet

- RWTP GB MNE MST 000046 - Underground - DuctDocument54 pagesRWTP GB MNE MST 000046 - Underground - Ductslayerzzz22No ratings yet

- RWTP GB Cns Msa 000173Document61 pagesRWTP GB Cns Msa 000173slayerzzz22No ratings yet

- RWTP GB MNE MST 000031 Telecommunication SystemDocument60 pagesRWTP GB MNE MST 000031 Telecommunication Systemslayerzzz22No ratings yet

- RWTP-GB-AMS-L-000668-2024 - Reply-Site ObservationCorrective Action Request No. P1-003Document2 pagesRWTP-GB-AMS-L-000668-2024 - Reply-Site ObservationCorrective Action Request No. P1-003slayerzzz22No ratings yet

- Case Study Student AnswerDocument7 pagesCase Study Student Answerslayerzzz22No ratings yet

- Checklist Genenral Concret RepairDocument6 pagesChecklist Genenral Concret Repairslayerzzz22No ratings yet

- Australia Iteanary 2024Document3 pagesAustralia Iteanary 2024slayerzzz22No ratings yet

- RWTP GB CNS Msa 000177Document38 pagesRWTP GB CNS Msa 000177slayerzzz22No ratings yet

- Jlgwvkyfc Gkpxmvbs7Kxdtdymvcrgc Vcvbilbkfcxvnraep: Bill StatementDocument5 pagesJlgwvkyfc Gkpxmvbs7Kxdtdymvcrgc Vcvbilbkfcxvnraep: Bill Statementslayerzzz22No ratings yet

- RWTP GB Mne Msa 000049Document44 pagesRWTP GB Mne Msa 000049slayerzzz22No ratings yet

- RWTP-GB-C&S-MST - 000063-00 - General Repair WorkDocument38 pagesRWTP-GB-C&S-MST - 000063-00 - General Repair Workslayerzzz22No ratings yet

- RWTP GB Mne MST 000034 Smatv SystemDocument57 pagesRWTP GB Mne MST 000034 Smatv Systemslayerzzz22No ratings yet

- AMS QAQC Observation Reply TemplatesDocument1 pageAMS QAQC Observation Reply Templatesslayerzzz22No ratings yet

- RWTP GB Mne Msa 000066Document82 pagesRWTP GB Mne Msa 000066slayerzzz22No ratings yet

- Maybank2u CCPMDocument1 pageMaybank2u CCPMslayerzzz22No ratings yet

- RWTP GB Mne MST 000033 CA SystemDocument45 pagesRWTP GB Mne MST 000033 CA Systemslayerzzz22No ratings yet

- KVMRT-AZSB-SBK-PKG6-BTHS-MST-CIVS-000113.00 - MS Launching of Precast T-BeamDocument39 pagesKVMRT-AZSB-SBK-PKG6-BTHS-MST-CIVS-000113.00 - MS Launching of Precast T-Beamslayerzzz22No ratings yet

- G2101080364-mETAL mUFFDocument2 pagesG2101080364-mETAL mUFFslayerzzz22No ratings yet

- G2102006549 BCRichDocument2 pagesG2102006549 BCRichslayerzzz22No ratings yet

- G2012406439-Washburn DimeDocument2 pagesG2012406439-Washburn Dimeslayerzzz22No ratings yet

- Breakdown of ExpensesDocument2 pagesBreakdown of Expensesslayerzzz22No ratings yet

- G2011240654-Takeuchi FRDocument2 pagesG2011240654-Takeuchi FRslayerzzz22No ratings yet

- G2011006977-ESP PhoenixDocument2 pagesG2011006977-ESP Phoenixslayerzzz22No ratings yet

- G2007906394-ESP Mirage DeluxeDocument2 pagesG2007906394-ESP Mirage Deluxeslayerzzz22No ratings yet

- G2007704588-Boss BCB 6Document2 pagesG2007704588-Boss BCB 6slayerzzz22No ratings yet

- G2008506364-Fernandes Ratt R.crosbyDocument2 pagesG2008506364-Fernandes Ratt R.crosbyslayerzzz22No ratings yet

- Material HandlingDocument54 pagesMaterial HandlingNafiul Alam SnigdhoNo ratings yet

- Standard Tube Map PDFDocument2 pagesStandard Tube Map PDFDiego Ricardo CarriazoNo ratings yet

- Signature Over Printed Name Date and TimeDocument10 pagesSignature Over Printed Name Date and Timeronna robleNo ratings yet

- 34 SunroofDocument9 pages34 SunroofKuba SwkNo ratings yet

- Modern Railways - January 2020Document116 pagesModern Railways - January 2020洪冠No ratings yet

- Military Ordinance 3/2020Document5 pagesMilitary Ordinance 3/2020vpop2010No ratings yet

- Mobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperDocument2 pagesMobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperTEKLEWEYNI TsegayNo ratings yet

- Directive 2023-1 Safe DrivingDocument2 pagesDirective 2023-1 Safe DrivingThe Kansas City StarNo ratings yet

- ChatlogDocument91 pagesChatlogCiprian LuscanNo ratings yet

- Cebu Pacific Print Itinerary PDFDocument4 pagesCebu Pacific Print Itinerary PDFArnold MambaNo ratings yet

- M.Rafee Revaldi Marcell - PWBSDocument1 pageM.Rafee Revaldi Marcell - PWBSRafee RevaldiNo ratings yet

- Method Statement For Installation of Diesel Generator Set - Safe Work Method of StatementDocument5 pagesMethod Statement For Installation of Diesel Generator Set - Safe Work Method of StatementMohamed AliNo ratings yet

- Viktoriia Voloshchuk Lesia Ukrainka 2 UA-77605 SVARYCHIVDocument4 pagesViktoriia Voloshchuk Lesia Ukrainka 2 UA-77605 SVARYCHIVViktoriiaNo ratings yet

- Capoch's Build Orders: Subscribers November Guide 2020Document31 pagesCapoch's Build Orders: Subscribers November Guide 2020Camilo ZuluagaNo ratings yet

- PGBP NotesDocument38 pagesPGBP Noteskryptone 1No ratings yet

- 2x HMK 102s Alpha (Perkins-tr3+Turner+Cr) s090hDocument1,014 pages2x HMK 102s Alpha (Perkins-tr3+Turner+Cr) s090hStrahinja100% (1)

- NCC Service Subject PDFDocument136 pagesNCC Service Subject PDFGaurav100% (1)

- Part 3 - c1.4 Mid-Term TestDocument35 pagesPart 3 - c1.4 Mid-Term TestThu Lê Thị HiềnNo ratings yet

- Pip CVC01015-2019Document25 pagesPip CVC01015-2019antonio diaz100% (1)

- PH3 KWID DetailsDocument5 pagesPH3 KWID DetailsRavi RaiNo ratings yet

- NIE Hyderabad 12-03-2024Document18 pagesNIE Hyderabad 12-03-2024Gdrive 129No ratings yet

- Euro - Ncap Commercial Van Safety 2023 Peugeot Boxer DatasheetDocument5 pagesEuro - Ncap Commercial Van Safety 2023 Peugeot Boxer DatasheetsergioNo ratings yet

- Vehicle SOPS - Ethiopia - April 2020Document28 pagesVehicle SOPS - Ethiopia - April 2020Daniel Tilahun50% (2)

- ANE06 SUR - Booklet.collardDocument324 pagesANE06 SUR - Booklet.collardIsaacNo ratings yet

- Bird StrikeDocument47 pagesBird StrikeMarcelo Kenji DoiNo ratings yet

- VALTRA 87315500 EN PreviewDocument21 pagesVALTRA 87315500 EN PreviewEvandro VitorinoNo ratings yet

- Tour Report On Samtse-Sipsoo RoadDocument35 pagesTour Report On Samtse-Sipsoo RoadSonam TsheringNo ratings yet

- Accessories-7-Electric Diagram of Whole VehicleDocument25 pagesAccessories-7-Electric Diagram of Whole VehicleCarlos TecnicNo ratings yet

- M1 LESSON 3 Classifications Causes Prevention Control and Extinguishments of FireDocument21 pagesM1 LESSON 3 Classifications Causes Prevention Control and Extinguishments of Firehanz31512No ratings yet

- CASE STUDY Energy AuditDocument4 pagesCASE STUDY Energy AuditMinita ManeNo ratings yet