Professional Documents

Culture Documents

101-A-004 Interior Finish Detail-2 (REV 3)

101-A-004 Interior Finish Detail-2 (REV 3)

Uploaded by

ICEDA HumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

101-A-004 Interior Finish Detail-2 (REV 3)

101-A-004 Interior Finish Detail-2 (REV 3)

Uploaded by

ICEDA HumCopyright:

Available Formats

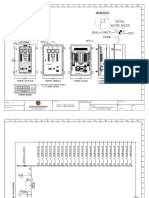

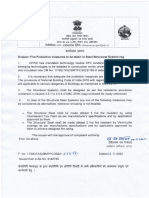

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

L L

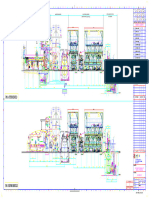

MARK C1 (MF ACOUSTIC TILE) C2 (VINYL PAINT) C3 (SMC PANEL) C4 (ALUMINUM SHEET)

ANCHOR SCREW ANCHOR SCREW

K K

Ø9 HANGER BOLT Ø9 HANGER BOLT

Ø9 HANGER BOLT Ø9 HANGER BOLT

HANGER BOLT HANGER BOLT CARRYING CHANNEL CARRYING CHANNEL KEY PLAN

ANCHOR SCREW ANCHOR SCREW NOTE

WIRE CLIP WIRE CLIP

1. ALL STEEL STRUCTURES SHALL

SECTION RECEIVE AN ANTI-CORROSION

J J

DETAIL COATING CONSISTING OF

READY-MIXED PAINT. THE COATING

SHALL MEET THE PROJECT

M-BAR SPECIFICATIONS AND PROVIDE

CLIP-BAR CLIP-BAR

T-BAR THK12 GYPSUM BOARD 2PLY ADEQUATE PROTECTION FOR THE

MF ACOUSTIC CEILING TILE SMC CEILING PANEL ALUMINUM SHEET INTENDED SERVICE LIFE OF THE

VINYL PAINT STRUCTURE.

(600X600)

AL.TZ MOLDING AL.TZ MOLDING

ALUMINIUM TZ MOLDING 2. THE COLUMNS IN THE ASSEMBLY

SHOP SHALL RECEIVE A COAT OF

I ALUMINIUM TZ MOLDING WALL FINISH WALL FINISH LIQUID COATING OR EMULSION PAINT I

3

AFTER SURFACE TREATMENT.

3. WATER BASED PAINT : STAIN

RESISTANT PAINT FOR OFFICE

THK12 GYPSUM BOARD 2PLY 1 INTERIOR WALL

4. FOR OPTIMAL POLISHING

RESULTS, RECOMMEND USING

LIQUID HARDENER ON POWDER

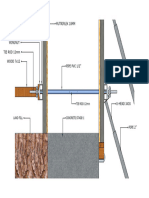

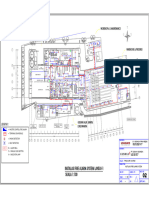

MARK EW1 ASSEMBLY SHOP - EXTERIOR WALL EW2 ASSEMBLY SHOP(OFFICE) - EXTERIOR WALL EW3 ASSEMBLY SHOP(RESTROOM) - EXTERIOR WALL 2ND FLOOR HANGER BOLT + ROOF PURLIN JOINT DETAIL HARDENER. CHOOSE THE

H APPROPRIATE HARDENER BASED H

ON THE SPECIFIC SITE CONDITIONS

SUCH AS SURFACE CONDITION,

TEMPERATURE, AND HUMIDITY.

200 FOLLOW CONSULTING WITH A

288 330 PROFESSIONAL BEFORE

50 150 50 150 76 12 50 150 100 30 ROOF PURLIN SELECTING THE TYPE OF

(LC-150x50x20x3.2 @1000) HARDENER TO USE TO ENSURE

100 40 10

THE BEST OUTCOME.

5. ABBREVIATION

G - MF ACOUSTIC TILE G

: MINERAL FIBER ACOUSTIC TILE

1 - SMC CEILING PANEL

Ø9 HANGER BOLT : SHEET MOLDING COMPOUND

SANDWICH PANEL SANDWICH PANEL THK12 GYPSUM BOARD SANDWICH PANEL CERAMIC TILE

SECTION / WATER BASED PAINT

CEILING PANEL

DETAIL STEEL STUD STEEL STUD STEEL STUD

MORTAR

STEEL STUD CARRYING CHANNEL

F F

URETHANE RUBBER

STEEL PIPE STEEL PIPE STEEL PIPE WATERPROFING

(H=1,200)

CONSTRUCTION DOCUMENTS 2023.

ALC BLOCK 3

REV.3 SEP, 27

CONSTRUCTION DOCUMENTS 2023.

CEILING FINISH 2

REV.2 JUN, 14

1 CONSTRUCTION DOCUMENTS 2023.

E REV.1 APR, 20 E

2 0 CONSTRUCTION DOCUMENTS 2023.

MAR, 31

A DESIGN DEVELOPMENT 2023.

FEB, 28

MARK B1(VINYL SKIRTING) B1(WOODEN SKIRTING) A SCHEMATIC DESIGN 2023.

FEB, 03

REV. DESCRIPTION DRAWN DATE

CLIENT

D D

DESIGN CONSULTANT

DESIGN

WALL FINISH (PER PLAN) WALL FINISH (PER PLAN)

C C

PROJECT TITLE

SECTION 1 1

HYUNDAI ENERGY

VINYL SKIRTING (t=3mm) WOODEN SKIRTING (t=3mm)

DETAIL

(H=100mm) (H=100mm)

INDONESIA BSA PROJECT

3 3 DRAWING TITLE

[ASSEMBLY SHOP]

INTERIOR FINISH DETAIL-2

100

100

FLOOR FINISH WOOD TILE

(PER PLAN) (PER PLAN) SCALE(A1) DAWON GROUP HEC

B NONE DRAWN APPROVED REVIEWED APPROVED B

DATE

2023

SEP, 27

GENERAL CONTRACTOR

DRAWING NO. REV.

101-A-004 3

A A

16 15 14 13 12 11 10 7 6 5 4 3 2 1

You might also like

- Lokotrack ST4.8 GA Drawing 2022 R013Document3 pagesLokotrack ST4.8 GA Drawing 2022 R013Guilherme AssisNo ratings yet

- Suspended Ceiling-Method StatementDocument6 pagesSuspended Ceiling-Method StatementTATATAHERNo ratings yet

- Ateco Tank Geodesic Dome Drawings For Information PDFDocument47 pagesAteco Tank Geodesic Dome Drawings For Information PDFJavierfox98100% (2)

- GYPROCK 500 Red - Book 2011 PDFDocument252 pagesGYPROCK 500 Red - Book 2011 PDFduckeNo ratings yet

- Product Brochure: Passive Fire ProtectionDocument16 pagesProduct Brochure: Passive Fire ProtectionValentin A.No ratings yet

- ARCHITECTURAL DETAILS 2.1-ModelDocument1 pageARCHITECTURAL DETAILS 2.1-ModelRitesh LoharNo ratings yet

- Al Hamd Container Terminal DrawingDocument9 pagesAl Hamd Container Terminal Drawingdickey1976jafriNo ratings yet

- Lighting Outlet Layout: Circuit DiagramDocument1 pageLighting Outlet Layout: Circuit DiagramDonna Rafal GaasNo ratings yet

- Second Floor Plan of Shopping Mall: DN DN DN DN DN DN DNDocument1 pageSecond Floor Plan of Shopping Mall: DN DN DN DN DN DN DNKripasindhu BordoloiNo ratings yet

- Double Wiper SealDocument1 pageDouble Wiper SealJoeNo ratings yet

- Detail A - With Cooler Option: Pro EngineerDocument1 pageDetail A - With Cooler Option: Pro EngineerGonzalo GalvezNo ratings yet

- San Clemente ST 07 PDFDocument1 pageSan Clemente ST 07 PDFMel Frederick MadriagaNo ratings yet

- Generator Room (Tower 01) - Option Exhaust Air-Spml-Dmd-Sd-Mep-Gr-001 (Tower - 01)Document1 pageGenerator Room (Tower 01) - Option Exhaust Air-Spml-Dmd-Sd-Mep-Gr-001 (Tower - 01)Suren VelletheryNo ratings yet

- Construction Schedule Pert/ CPM: Bar Chart and S-CurveDocument1 pageConstruction Schedule Pert/ CPM: Bar Chart and S-CurveEizl Nyce VillanuevaNo ratings yet

- civil-666Document3 pagescivil-666Alaa MansourNo ratings yet

- Nit Raipur Name-Abhishek Kumar Topic-Steel Connection Assignment No. - DATE - 9-4-2017 ROLL NO.-13114903Document1 pageNit Raipur Name-Abhishek Kumar Topic-Steel Connection Assignment No. - DATE - 9-4-2017 ROLL NO.-13114903DOMINICNo ratings yet

- Electrical Plan: LegendDocument1 pageElectrical Plan: LegendDaryl Jay YubalNo ratings yet

- D92-1108.tarea 11-4.HARN-ENGINE ISXE5Document5 pagesD92-1108.tarea 11-4.HARN-ENGINE ISXE5marioNo ratings yet

- MTK4110-1509 - PM-1 Side View General Assy-Before & AfterDocument1 pageMTK4110-1509 - PM-1 Side View General Assy-Before & Afterdelvi.panjaitan097No ratings yet

- 101-A-003 Interior Finish Detail-1 (REV 2)Document1 page101-A-003 Interior Finish Detail-1 (REV 2)ICEDA HumNo ratings yet

- General Notes: Vicinity MapDocument3 pagesGeneral Notes: Vicinity MapKenneth MolinaNo ratings yet

- E50034000 FLUSARC (In)Document2 pagesE50034000 FLUSARC (In)Cristian TintoiuNo ratings yet

- Detail C - Cable Detail D - Height Detail A - : Routing Powertail/FeederDocument1 pageDetail C - Cable Detail D - Height Detail A - : Routing Powertail/Feedervinod 7No ratings yet

- 1 Storey Residential HouseDocument1 page1 Storey Residential HouseCharles SarabilloNo ratings yet

- Forward: Y96-1026S02 Y96-1026S02Document1 pageForward: Y96-1026S02 Y96-1026S02Gonzalo GalvezNo ratings yet

- Legend:: Drawing TitleDocument1 pageLegend:: Drawing TitleSonah AlcarazNo ratings yet

- GCCP1.1 - 6015777 - 9.3B, C13, C15 Cat GCDocument3 pagesGCCP1.1 - 6015777 - 9.3B, C13, C15 Cat GCCarlos U. Callirgos100% (1)

- Pro Engineer: DescriptionDocument1 pagePro Engineer: DescriptionGonzalo GalvezNo ratings yet

- A1 Sheet (P-1) SribalajiDocument1 pageA1 Sheet (P-1) Sribalajisribalaji.d2019No ratings yet

- Aa 036335 001Document1 pageAa 036335 001nisha_khanNo ratings yet

- Construction Schedule Pert/ CPM: Bar Chart and S-CurveDocument1 pageConstruction Schedule Pert/ CPM: Bar Chart and S-CurveEizl Nyce VillanuevaNo ratings yet

- Curtain Cove Promenade BalconyDocument1 pageCurtain Cove Promenade BalconyJefferson De GuiaNo ratings yet

- Finish Floor Line: Reflected Ceiling Plan Reflected Ceiling Plan Reflected Ceiling PlanDocument1 pageFinish Floor Line: Reflected Ceiling Plan Reflected Ceiling Plan Reflected Ceiling PlanDerf Jayson AdanteNo ratings yet

- BB A5 13 BIG BOX SD 16 05 06 2016-Layout July23,2018Document1 pageBB A5 13 BIG BOX SD 16 05 06 2016-Layout July23,2018terryNo ratings yet

- 2 09 22 045 - Rev1Document6 pages2 09 22 045 - Rev1TEC INDIANo ratings yet

- 220602-D-1320 RevB GAD Water Fire-Fighting Locker Type IIIDocument1 page220602-D-1320 RevB GAD Water Fire-Fighting Locker Type IIINambi RajaNo ratings yet

- Project: Codelco El Salvador Rajo Inca 2: Certified For ConstructionDocument1 pageProject: Codelco El Salvador Rajo Inca 2: Certified For ConstructionRoberto RevinsacNo ratings yet

- Five Pile Cap: Plan Showing Piles Reinforcement Plan Showing Pile Cap Reinforcement PlanDocument1 pageFive Pile Cap: Plan Showing Piles Reinforcement Plan Showing Pile Cap Reinforcement PlanVinayakNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- CG LT Motor Catalogue-1Document25 pagesCG LT Motor Catalogue-1lightsonsNo ratings yet

- Front BrakeDocument1 pageFront BrakeManuel MoralesNo ratings yet

- Panel Power Distribution MCCB 125aDocument3 pagesPanel Power Distribution MCCB 125adhimas abdillah putraNo ratings yet

- Living Room.: Produced by An Autodesk Student VersionDocument1 pageLiving Room.: Produced by An Autodesk Student VersionYashwant PatilNo ratings yet

- 3.14 Inch Ansi 150, Ansi 300 X 6Document1 page3.14 Inch Ansi 150, Ansi 300 X 6Andi Ramdan HamdaniNo ratings yet

- G+3 StructureDocument1 pageG+3 StructureMANNANo ratings yet

- fDocument8 pagesfmtauqeer86No ratings yet

- Revised PEB Architecture, GA and LayoutDocument3 pagesRevised PEB Architecture, GA and LayoutDuraid FalihNo ratings yet

- Ac Catalogue 2019bDocument2 pagesAc Catalogue 2019bShaneNo ratings yet

- Plan View Isometric View: RPK-SE-942Document1 pagePlan View Isometric View: RPK-SE-942ajNo ratings yet

- Architectural PlanDocument1 pageArchitectural Planthe ArkiRMPEnPNo ratings yet

- Side Elevation From Upstream: R O A D B R I D G EDocument1 pageSide Elevation From Upstream: R O A D B R I D G EGayan Indunil JayasundaraNo ratings yet

- Ag 002Document1 pageAg 002safety gulferectionNo ratings yet

- 1 Tablas Bolinter, Fittings & Valves-FinalDocument21 pages1 Tablas Bolinter, Fittings & Valves-FinalTIPAZONo ratings yet

- 1400 Feet Existing Camera Proposed Camera: P / Press MT Pool Barrack Sports ComplexDocument1 page1400 Feet Existing Camera Proposed Camera: P / Press MT Pool Barrack Sports ComplexImran AhmedNo ratings yet

- Ign Rfa M SD 41Document1 pageIgn Rfa M SD 41Faqih FadhilaNo ratings yet

- Section Aa: W1 Interior ElevationDocument1 pageSection Aa: W1 Interior ElevationBharani MadamanchiNo ratings yet

- Bant Jain DetailDocument1 pageBant Jain DetailAlok UpadhyayNo ratings yet

- 0219030016new Rudder-ModelDocument1 page0219030016new Rudder-ModelMuhammad Ilham AlfiansyahNo ratings yet

- s0-02 - Abbreviations, Legends, and Reinforcing Bar TablesDocument1 pages0-02 - Abbreviations, Legends, and Reinforcing Bar TablesJason toraldeNo ratings yet

- FP-05 - All Home Cdo - 070317 PDFDocument1 pageFP-05 - All Home Cdo - 070317 PDFLowentan LaxamanaNo ratings yet

- s2Document3 pagess2Alaa MansourNo ratings yet

- Rafter Detail: Roofing InsulationDocument1 pageRafter Detail: Roofing InsulationRODEAN HOPE LACSINo ratings yet

- BoQ Hyunday Project + Back Up DataDocument31 pagesBoQ Hyunday Project + Back Up DataICEDA HumNo ratings yet

- LIST ALAT YG DITINGGAL DI PROYEK SAAT LEBARANDocument2 pagesLIST ALAT YG DITINGGAL DI PROYEK SAAT LEBARANICEDA HumNo ratings yet

- Progres Cosmax New Factory - Retaining Wall & Fence Project 24032024Document9 pagesProgres Cosmax New Factory - Retaining Wall & Fence Project 24032024ICEDA HumNo ratings yet

- Quotation PT - Joowon Indonesia Jepara Additional Work 2024Document17 pagesQuotation PT - Joowon Indonesia Jepara Additional Work 2024ICEDA HumNo ratings yet

- BOQ - Finishing Works-R5 PT.GLOBAL UTAMA ABADI Final 2024.3.12 (재출용)Document3 pagesBOQ - Finishing Works-R5 PT.GLOBAL UTAMA ABADI Final 2024.3.12 (재출용)ICEDA HumNo ratings yet

- Bar Bending Retaining WallDocument12 pagesBar Bending Retaining WallICEDA HumNo ratings yet

- Bekisting 2Document1 pageBekisting 2ICEDA HumNo ratings yet

- BEKISTINGDocument4 pagesBEKISTINGICEDA HumNo ratings yet

- 5.BBS SECTION 14-ADocument1 page5.BBS SECTION 14-AICEDA HumNo ratings yet

- 5.rebar Drawing Section 14-ADocument1 page5.rebar Drawing Section 14-AICEDA HumNo ratings yet

- URS Infrastructure and Utility NEW EC Line R0Document5 pagesURS Infrastructure and Utility NEW EC Line R0ICEDA HumNo ratings yet

- 1.16-01-23 Assembly Purlin AtapDocument7 pages1.16-01-23 Assembly Purlin AtapICEDA HumNo ratings yet

- Format JSA (New)Document2 pagesFormat JSA (New)ICEDA HumNo ratings yet

- Intalasi Fa LT 1 Asbuilt 1 Model 2Document1 pageIntalasi Fa LT 1 Asbuilt 1 Model 2ICEDA HumNo ratings yet

- Daily Report: Classification (직군) Prev. (전일누계) Attend (출석) Absen (결근) Total (누계)Document2 pagesDaily Report: Classification (직군) Prev. (전일누계) Attend (출석) Absen (결근) Total (누계)ICEDA HumNo ratings yet

- User Requirement Specifications Ground TankDocument2 pagesUser Requirement Specifications Ground TankICEDA HumNo ratings yet

- SiTech Putty English TDSDocument3 pagesSiTech Putty English TDSMahmoud MahalawyNo ratings yet

- Improving Workflow and Resource Usage in Construction Schedules Through Location Based Management System LBMSDocument17 pagesImproving Workflow and Resource Usage in Construction Schedules Through Location Based Management System LBMSBhavik UmraliyaNo ratings yet

- Hangboard TrainingDocument2 pagesHangboard TrainingPeter AmatoNo ratings yet

- Hydrofit General Contractors Guide 2012Document79 pagesHydrofit General Contractors Guide 2012Jawad MerhyNo ratings yet

- Fire Protection For Structural SteelDocument12 pagesFire Protection For Structural SteelakhilasatapathyNo ratings yet

- AR Everest IndsDocument187 pagesAR Everest IndsPrakhar SaxenaNo ratings yet

- Hydraulic Elevator Installation Checklist: Schindler 330ADocument4 pagesHydraulic Elevator Installation Checklist: Schindler 330AMMMOH200No ratings yet

- Security G13-02 Secure Demising Wall (SDW) With Steel SheetsDocument14 pagesSecurity G13-02 Secure Demising Wall (SDW) With Steel SheetsnationdrywalllimitedNo ratings yet

- New Home Quality Control FREE Snag ChecklistDocument14 pagesNew Home Quality Control FREE Snag ChecklistVineel BellapuNo ratings yet

- Ceiling SystemsDocument56 pagesCeiling SystemsTheGuroid100% (1)

- Knauf ASTM Partition ManualDocument60 pagesKnauf ASTM Partition ManualShubham SrivastavaNo ratings yet

- Esr-4749 From Icc Report 1Document7 pagesEsr-4749 From Icc Report 1api-46442094No ratings yet

- Cost Guide 2019-20Document46 pagesCost Guide 2019-20Antonio Guillermo CruzNo ratings yet

- Twist A Saw ManualDocument52 pagesTwist A Saw Manual7013131870131318No ratings yet

- Plaster Wall MaterialDocument3 pagesPlaster Wall MaterialAzizah Uniti Brick Sdn. Bhd.No ratings yet

- Fire Door Manual-V-12 Firecore-June2018Document92 pagesFire Door Manual-V-12 Firecore-June2018trickersniperNo ratings yet

- MS - Gypsum Dry Wall Partition WorkDocument14 pagesMS - Gypsum Dry Wall Partition Worklinga2014100% (1)

- Katalog PetraroofDocument48 pagesKatalog PetraroofBogdan BungardiNo ratings yet

- Discharge Calculations Per Ahri 885-08: Ncplot RcplotDocument16 pagesDischarge Calculations Per Ahri 885-08: Ncplot RcplothanyassawyNo ratings yet

- Safe N Silent Data Sheet inDocument2 pagesSafe N Silent Data Sheet inApoorv MahajanNo ratings yet

- 09bill of Quantities (Office-Showroom Fit-Out) PDFDocument15 pages09bill of Quantities (Office-Showroom Fit-Out) PDFChin Xue KeiNo ratings yet

- Fpa101249 BR (A) 001-003Document3 pagesFpa101249 BR (A) 001-003chriscundyNo ratings yet

- Using Gypsum Board For Walls and CeilingsDocument3 pagesUsing Gypsum Board For Walls and CeilingsEmmNo ratings yet

- Molly, B&D, 2013, Fixing SolutionsDocument18 pagesMolly, B&D, 2013, Fixing SolutionsSebaNo ratings yet

- FITOUT WORKS - SummaryDocument24 pagesFITOUT WORKS - SummaryhenmarkNo ratings yet

- 215 - Detailed Installation & MaintenanceDocument84 pages215 - Detailed Installation & MaintenanceFachri Ferdiansyah100% (1)

- JebDocument31 pagesJebMelissa OrlanesNo ratings yet