Professional Documents

Culture Documents

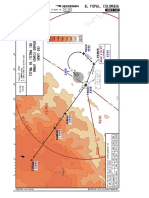

BANG-R5-DTD-PK4-STR-DWG-86992-A0

BANG-R5-DTD-PK4-STR-DWG-86992-A0

Uploaded by

atec atulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BANG-R5-DTD-PK4-STR-DWG-86992-A0

BANG-R5-DTD-PK4-STR-DWG-86992-A0

Uploaded by

atec atulCopyright:

Available Formats

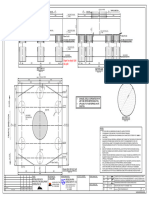

25000 500 7500 500

6.70Tons 7080 7080 6.70Tons

15.30Tons 15.30Tons 15.30Tons 15.30Tons

CL OF EXP. JOINT / PIER CL OF PIER

CL OF BEARING CL OF BEARING

1430 1430

3600

1430 745 460 01 02 03 04

4450

1200 3895 1612 05 06 07 08

1460 09 10 11 12

SECTION A-A

SCALE : 1/75 MID SECTION

SCALE : 1/75

AP-13

AP-12

25.00

5800 (AV.) 5800 (AV.)

7080 7080

1200 3165 1430 1205 1205 1430 3165 1200 7080

1200 3165 1430 1205

01 05 09

118

2855

118 1804 118 118 1804 118

118 1804 118 118 1804 118

2490

2040

1804

02 06 10

VEHICLE-1 VEHICLE-2

2490

2040

2040

2490

118

2790

A A

300

750

300

03 07 11 6.70 Tons 15.30 Tons 15.30 Tons

(AXLE LOAD) (AXLE LOAD)

TYPICAL VEHICAL

2490

2040

2040

2490

VEHICLE-3 VEHICLE-4 SCALE : 1/50

04 08 12

2855

1430 1430

1200 3165 1430 1205 1205 1430 3165 1200

7080 290 7080

SPECIAL NOTES:

1. ALL DIMENSIONS AND DEFLECTIONS ARE IN MILLIMETERS, AND ALL AXLE LOADS ARE IN TONS UNLESS OTHERWISE MENTIONED.

PLAN AT DECK LEVEL 2. THE LOAD TEST SHALL BE CONDUCTED AS PER THE GUIDELINES GIVEN IN IRC:SP:51 & IRC:SP:37.

SCALE : 1/75 3. WEARING COAT, CRASH BARRIER, EJ, ETC., SHALL BE COMPLETED FOR THE SPAN BEFORE

CONDUCTING THE LOAD TEST. HOWEVER IF NOT COMPLETED THAN EQUILENT ADDITIONAL LOAD SHOULD BE PLACED ON

STRUCTURE PRIOR TO CONDUCTING THE LOAD TEST.

25000

4. REDUCED LEVELS AT THE SPECIFIED POINT SHALL BE RECORDED AT AN INTERVAL OF EVERY ONE HOUR, FOR 48 HOURS

IN ORDER TO OBSERVE THE EFFECT OF TEMPARATURE VARIATION.

STAGES OF LOADING & SCHEDULE OF DEFLECTIONS 5. THE LOADS SHOWN IN THIS DRAWING CORRESPOND TO THE DESIGN LIVE LOAD INCLUDING IMPACT AND LANE REDUCTION FACTOR.

Stages Vehicles 01 02 03 04 05 06 07 08 09 10 11 12 6. POSITION OF VEHICAL/AXELS SHALL BE MARKED ON THE CARRIAGEWAY AND VEHICAL SLOWLY BROUGHT IN AT SPEED LESS THEN

REFERENCE DRAWINGS:

10kmph AT THE DESIGNATED LOCATION.

Stage - 1 1 -1.951 -1.637 -1.089 -0.652 -2.691 -2.169 -1.556 -0.96 -1.637 -1.32 -0.984 -0.64 1. FOR GENERAL ARRANGEMENT REFER DRAWING NO. 7. DIAL GAUGE READINGS SHALL BE TAKEN BEFORE ANY VEHICAL IS BROUGHT IN AND AFTER STATIONING. FINAL READING WILL BE

Stage - 2 1+2 -3.603 -2.969 -2.08 -1.295 -5.381 -4.337 -3.111 -1.921 -3.565 -2.938 -2.065 -1.291 BANG-R5-DTD-PK4-STR-DWG-86011 & 86012 TAKEN AFTER ALL VEHICALS ARE IN POSITION. READING SHALL BE TAKEN ALONG WITH CORRESPONDING AMBIENT TEMPERATURE.

Stage - 3 1+2+3 -4.28 -4.098 -3.741 -3.146 -6.372 -5.929 -5.303 -4.536 -4.223 -3.934 -3.384 -2.921 2. FOR STEEL GIRDERS DETAILS REFER DRAWING NO. 8. VEHICALS SHALL BE MAINTAINED IN POSITION FOR 24 HOURS AFTER WHICH AGAIN DEFLECTION MEASUREMENT SHLL BE TAKEN

Stage - 4 1+2+3+4 -6.162 -6.357 -6.314 -5.966 -9.188 -9.385 -9.353 -8.924 -6.099 -6.301 -6.277 -5.942 BANG-R5-DTD-PK4-STR-DWG-86324 TO 86325 VEHICALS SHALL BE THAN BE MOVED OUT OF UNITS.

(-)ve SHOWN DOWNWARD DEFLECTION 9. DEFLECTION SHALL BE RECORDED AFTER ALL VEHICALS ARE MOVED OUT.

10. DURING THE TESTING OPERATIONS THE LOAD DEFLECTION DIAGRAM SHOULD BE PLOTTED AT EVERY STAGE OF LOADING.

11. AFTER THE FINAL STAGE OF LOAD PLACEMENT DEFLECTION OBSERVATION SHOULD BE CONTINUED AND REDUCED LEVELS

SHOULD BE RECORDED FOR 24 HOURS UNDER LOAD.

12. AFTER THE LOAD PLACEMENT OBSERVATION SHOULD ALSO BE MADE FOR DEVELOPMENT OF ANY NEW CRACK OF DEFORMATION

ACCEPTANCE CRITERIA OF BEARING IN EVERY STAGE.

1. MEASURED DEFLECTIONS AT CRITICAL LOCATION SHALL BE EQUAL TO OR LESS THAN WHERE, 13. THE REMOVAL OF TEST LOAD SHALL BE DONE AT SAME STAGES AS THAT OF LOADING AND CORRESPONDING SHOULD BE

THEORETICAL DEFLECTIONS. R1 =INITIAL GAUGE READING. RECORDED ACCORDINGLY.

2. PERCENTAGE RECOVERY OF DEFLECTION, 24 HOURS AFTER REMOVAL OF TEST LOAD = R3-R5 X 100 R3 =DIAL GAUGE READING 24 HRS AFTER APPLYING 100% LOAD. 14. IF THE DEFLECTION OBSERVED EXCEEDS THE LIMIT PRESCRIBED BY THE DESIGNER, FURTHER LOADING SHALL BE STOPPED,

R3-R1 R5 =DIAL GAUGE READING 24 HRS AFTER REMOVING ALL APPLIED LOADS. SUBSEQUENT ACTIONS SHALL BE TAKEN IN CONSULTATION WITH APPROPRIATE AUTHORITIES.

THE MINIMUM PERCENTAGE AGE RECOVERY OF DEFLECTION AT 24 HOURS AFTER REMOVAL OF TEST LOAD SHALL BE 85%, 3. THE CRACKS DEVELOPED , IF ANY, SHALL NOT BE GREATER THAN 0.3MM WIDTH.

15. ACCEPTANCE CRITERIA FOR THIS STRUCTURE IN MINIMUM 85% RECOVERY AFTER 24 HOURS OF LOAD RETENTION.

NOTES : DRAWING REFERENCE : QUALITY ASSURANCE CONSULTANT PROOF CHECKED BMRCL ENDORSEMENT namma

1. ALL DIMENSIONS ARE IN MILLIMETERS & LEVELS The responsibility of control, check and verification of accuracy, BANGALORE METRO RAIL CORPORATION LTD. metro

ARE IN METERS (UNLESS NOTED OTHERWISE) correctness, completeness, integration and full compliance with

2. ALL DIMENSIONS ARE TO BE READ AND NOT design basis parameters lies with the design consultants. SYSTRA MVA CONSULTING (INDIA) PVT.LTD.

MEASURED. 5TH FLOOR, GURU ANGAD BHAWAN, MISCELLANEOUS DETAILS

STRUCTURAL

3. THIS DRAWING MUST BE READ IN CONJUNCTION 71, NEHRU PLACE, NEW DELHI-110019

WITH GAD,GENERAL NOTES, SPAN ARRANGEMENT PH: 26422844, 26413310 FAX: 26224204 SPAN LOAD TEST FOR SPAN AP-12 ~ AP-13

AND OTHER RELATED STRUCTURAL DRAWINGS. SUBSIDIARY OF:

MSJ SYSTRA S.A. - 5 AVENUE DU COQ - PARIS 75009 25M PSC I GIRDER SUPERSTRUCTURE

4. ANY DISCREPANCIES MUST BE BROUGHT TO THE

A0 25/04/2024 ISSUED FOR GFC MSJ SJH PSM

NOTICE OF THE CONSULTANT.

R0 25/03/2024 FIRST ISSUE MSJ SJH PSM

SJH DETAILED DESIGN CONSULTANCY FOR BANG-R5-DTD-PK4-STR-DWG-86992

REACH 5 OF BMRCL PACKAGE- 4

PSM SILK BOARD INTERCHANGE FLYOVER 25/03/2024 --- A0 GFC

You might also like

- 4 Storey Commercial Residential PLANS ELEVATIONSDocument4 pages4 Storey Commercial Residential PLANS ELEVATIONSabet hilario100% (1)

- Ground Floor Electrical Layout Second Floor Electrical LayoutDocument1 pageGround Floor Electrical Layout Second Floor Electrical LayoutDalawa BenteNo ratings yet

- Morph and AllomorphDocument3 pagesMorph and Allomorphyuliati paramitha0% (1)

- PD 1096 Arch Pedro Santos JR PDFDocument342 pagesPD 1096 Arch Pedro Santos JR PDFMonique Gaw33% (3)

- Similarity: Chapter Test Form ADocument15 pagesSimilarity: Chapter Test Form AWalid Mohamed Gadalla100% (1)

- 7.VIE-PC01-STN-BHT-CRS-4003 (R2) SECTION C-Layout1Document1 page7.VIE-PC01-STN-BHT-CRS-4003 (R2) SECTION C-Layout1Ashish BhartiNo ratings yet

- Cafe Pettarani PDFDocument19 pagesCafe Pettarani PDFahmad arwinNo ratings yet

- Desain Cafee TestDocument13 pagesDesain Cafee TestAnkara ArchitectsNo ratings yet

- SVMIDocument20 pagesSVMIGiorgio CalvareseNo ratings yet

- WD18Document2 pagesWD18Anshika KhandelwalNo ratings yet

- Karnaphuli Water Supply Project - Phase 2 (Kwsp2) PlanDocument1 pageKarnaphuli Water Supply Project - Phase 2 (Kwsp2) PlangawtomNo ratings yet

- Pipe 2 Vents 1m Dia.Document1 pagePipe 2 Vents 1m Dia.Jammi NagrajNo ratings yet

- ACHTA-Model.pdf 2Document1 pageACHTA-Model.pdf 2Yaw KrahNo ratings yet

- Classroom and RestroomDocument1 pageClassroom and RestroomPorshia DimarucutNo ratings yet

- PILE PILE CAP & PIER - 25.10.2023-Comments-28-10-23Document5 pagesPILE PILE CAP & PIER - 25.10.2023-Comments-28-10-23Tanveer IqbalNo ratings yet

- 22.290.90 2700 KVA 33-0,8 HERMETICAL-ModelDocument1 page22.290.90 2700 KVA 33-0,8 HERMETICAL-ModelMario TNo ratings yet

- Taloy 3rd FloorDocument1 pageTaloy 3rd Floorktguillermo777No ratings yet

- SBSP - Omni Rwy 17l 17r 35l 35r - Sid - 20210715Document2 pagesSBSP - Omni Rwy 17l 17r 35l 35r - Sid - 20210715Ricardo PalermoNo ratings yet

- Design of Composite Bridge: Project: Assignment No # 1Document3 pagesDesign of Composite Bridge: Project: Assignment No # 1simon maaaklaNo ratings yet

- PANEL SYNCRONE ModelDocument1 pagePANEL SYNCRONE ModelBudi SentosaNo ratings yet

- SECTIONSDocument1 pageSECTIONSEr Navneet JassiNo ratings yet

- Gambar Kerja Jalan PDFDocument1 pageGambar Kerja Jalan PDFMudiasa MadeNo ratings yet

- Convenience Outlet PlanDocument1 pageConvenience Outlet PlanRycca DeeNo ratings yet

- A-TH-A-4-100 D1: First Floor PlanDocument20 pagesA-TH-A-4-100 D1: First Floor Planokdi pranciscoNo ratings yet

- Roof Deck Floor Plan: Adamson University 003Document1 pageRoof Deck Floor Plan: Adamson University 003Ryan Argente QuintanaNo ratings yet

- Al-Zahraa Interchange: General NotesDocument1 pageAl-Zahraa Interchange: General NotesNadher Al-BaghdadiNo ratings yet

- Wooden Pallet - 720x1190x135 REV1Document1 pageWooden Pallet - 720x1190x135 REV1ชาญณรงค์ ชาแท่นNo ratings yet

- Wooden Pallet - 720x1190x135 REV1Document1 pageWooden Pallet - 720x1190x135 REV1ชาญณรงค์ ชาแท่นNo ratings yet

- Megin II M: Lenses LEDDocument2 pagesMegin II M: Lenses LEDnumaionelNo ratings yet

- Skyp/Eyp El Yopal, Colombia: .Rnav - SidDocument1 pageSkyp/Eyp El Yopal, Colombia: .Rnav - SidAlexandra DiazNo ratings yet

- (Colored) Refrigerant 134a P-H Diagram (SI Units)Document1 page(Colored) Refrigerant 134a P-H Diagram (SI Units)Mc Jason LaureteNo ratings yet

- (Colored) Refrigerant 134a P-H Diagram (SI Units) PDFDocument1 page(Colored) Refrigerant 134a P-H Diagram (SI Units) PDFMc Jason LaureteNo ratings yet

- SBKG Adc-Sbkg Adc 20160818Document2 pagesSBKG Adc-Sbkg Adc 20160818CarolNo ratings yet

- Makati - Mandaluyong Bridge: General Section PlanDocument1 pageMakati - Mandaluyong Bridge: General Section PlangregNo ratings yet

- LMCPL-P2023-02-COS-09 Working Platform M-Deck North West BridgeDocument8 pagesLMCPL-P2023-02-COS-09 Working Platform M-Deck North West BridgeAli md YounusNo ratings yet

- PlanDocument1 pagePlanfaithNo ratings yet

- Thangal Station Gowri Ashram Station Thiruvottiyur Station: General Arrangement DrawingDocument6 pagesThangal Station Gowri Ashram Station Thiruvottiyur Station: General Arrangement DrawingAnonymous USbc7XzsA6No ratings yet

- PW 01 - Water SupplyDocument1 pagePW 01 - Water SupplyDileesha RoshaneNo ratings yet

- Proposed Assembly Hall and Toilet and Bath Plan 1 ADocument1 pageProposed Assembly Hall and Toilet and Bath Plan 1 ALionheart GuillermoNo ratings yet

- KS SPRDocument6 pagesKS SPRIhya UlumudinNo ratings yet

- SM 26Document1 pageSM 26MUBASHIRNo ratings yet

- 1700 2700 ManualDocument38 pages1700 2700 ManualArsalan KhanNo ratings yet

- Kanpur Central Rly. Station Jhakar Kati Bus Terminal NayaganjDocument29 pagesKanpur Central Rly. Station Jhakar Kati Bus Terminal NayaganjANKIT DWIVEDINo ratings yet

- Ground Floor Plan Second Floor Plan: KitchenDocument6 pagesGround Floor Plan Second Floor Plan: Kitchenlouie n. gustoNo ratings yet

- Al-Zahraa Interchange: General NotesDocument1 pageAl-Zahraa Interchange: General NotesNadher Al-BaghdadiNo ratings yet

- Ukkong Residence SFDocument1 pageUkkong Residence SFJireh BalisiNo ratings yet

- Airport Information: Details For PALONEGRODocument50 pagesAirport Information: Details For PALONEGRODaniel CalleNo ratings yet

- SBGR pdc-1-sbgr PDC 20200521Document2 pagesSBGR pdc-1-sbgr PDC 20200521Arthur GarciaNo ratings yet

- Roof Level Plan: Larsen & Toubro LTDDocument7 pagesRoof Level Plan: Larsen & Toubro LTDchandru sekarNo ratings yet

- 7 - Pile Layout-Rev00Document1 page7 - Pile Layout-Rev00layaljamal2No ratings yet

- DFG 03Document1 pageDFG 03Rudra MehtaNo ratings yet

- I & D 18.10.17 - Final-ModelDocument1 pageI & D 18.10.17 - Final-Modelraghu kiranNo ratings yet

- Distribution: Ground Level: Vent Shaft Main StaircaseDocument4 pagesDistribution: Ground Level: Vent Shaft Main Staircaseأحمد شوكت100% (1)

- Plan at El (+) 16.200/el (+) 15.500M LevelDocument1 pagePlan at El (+) 16.200/el (+) 15.500M Levelsubramanian SivaNo ratings yet

- Cross SectionDocument1 pageCross SectionsibeshbigalNo ratings yet

- I:/3. SUBANG WORKS 2018/5. MATERI UNSUB/2.SM GENAP/1. STRUKTUR KONTRUKSI 2/2. TUGAS BESAR/unsub Teknik - JPGDocument1 pageI:/3. SUBANG WORKS 2018/5. MATERI UNSUB/2.SM GENAP/1. STRUKTUR KONTRUKSI 2/2. TUGAS BESAR/unsub Teknik - JPGFajar bahariNo ratings yet

- Graphic Plan - Smart West Sby - 230116Document4 pagesGraphic Plan - Smart West Sby - 230116Triya MahayanaNo ratings yet

- Euro Diebold Opteva 328 177528r00Document4 pagesEuro Diebold Opteva 328 177528r00Meta UrsaNo ratings yet

- Mabs OfficeDocument1 pageMabs OfficeAyesha Amie G. De LeonNo ratings yet

- SBFL Rnav-Punod-3a-Rwy14 Sid 20210520Document1 pageSBFL Rnav-Punod-3a-Rwy14 Sid 20210520jose netoNo ratings yet

- Denah SKALA 1:100: Citra Borneo Indah GroupDocument3 pagesDenah SKALA 1:100: Citra Borneo Indah Grouphendrik rustendiNo ratings yet

- SIST-EN-12390-18-2021Document11 pagesSIST-EN-12390-18-2021atec atulNo ratings yet

- 5666Document9 pages5666atec atulNo ratings yet

- %X ,,,PLYWQOD. F-Or General Purposes K. 3 $S+-+R I: Specification8. TDocument10 pages%X ,,,PLYWQOD. F-Or General Purposes K. 3 $S+-+R I: Specification8. Tatec atulNo ratings yet

- Morth Specification Fifth RevisionDocument904 pagesMorth Specification Fifth Revisionatec atulNo ratings yet

- Indian StandardDocument16 pagesIndian Standardatec atulNo ratings yet

- Of Floors: Indian StandardDocument9 pagesOf Floors: Indian Standardatec atulNo ratings yet

- Or On LineDocument10 pagesOr On LinekateNo ratings yet

- 8 M 611502Document100 pages8 M 611502Molnár Eszter100% (7)

- Mage Wars: Variant With No Dice: Basic RulesDocument8 pagesMage Wars: Variant With No Dice: Basic RulesMáté BoaNo ratings yet

- Recounttext 160409104911Document9 pagesRecounttext 160409104911Anif Ough GtuwNo ratings yet

- Roles of Physiotherapy in Intensive Care Unit (Document28 pagesRoles of Physiotherapy in Intensive Care Unit (Chukwuemeka ChidogoNo ratings yet

- Airside Driving HandbookDocument23 pagesAirside Driving HandbookBrandon Wong100% (1)

- Magic SquaresDocument1 pageMagic SquaresplmokmNo ratings yet

- Users' Preference Towards Traditional Banking Versus E-Banking - An Analysis Dr. S. Anthony Rahul GoldenDocument6 pagesUsers' Preference Towards Traditional Banking Versus E-Banking - An Analysis Dr. S. Anthony Rahul GoldenOmotayo AkinpelumiNo ratings yet

- SSP Assignment Problems - FinalDocument2 pagesSSP Assignment Problems - FinalVadivelan AdaikkappanNo ratings yet

- Near Source Fault Effects On The Performance of Base-Isolated Hospital Building vs. A BRBF Hospital BuildingDocument6 pagesNear Source Fault Effects On The Performance of Base-Isolated Hospital Building vs. A BRBF Hospital BuildingJosé Antonio Alarcón LeónNo ratings yet

- Lesson 1 - Plumbing MaterialsDocument18 pagesLesson 1 - Plumbing MaterialsNicholas Bonn SingNo ratings yet

- (REVIEW) KENDALL, Stuart - The Philosophy of Design by Glenn ParsonsDocument5 pages(REVIEW) KENDALL, Stuart - The Philosophy of Design by Glenn ParsonsOmega ZeroNo ratings yet

- Assembly Language Lecture6Document10 pagesAssembly Language Lecture6bmas19692No ratings yet

- Programa FinalDocument63 pagesPrograma Finalpatmos666No ratings yet

- Spesifikasi Oli MesinDocument6 pagesSpesifikasi Oli MesinRichard FebrinoNo ratings yet

- NY B32 Fire Tape 2A FDR - Entire Contents - Transcript - 911 Calls 381Document82 pagesNY B32 Fire Tape 2A FDR - Entire Contents - Transcript - 911 Calls 3819/11 Document Archive100% (3)

- CHUYÊN ĐỀ CHỈ SỰ NHƯỢNG BỘDocument5 pagesCHUYÊN ĐỀ CHỈ SỰ NHƯỢNG BỘĐinh DuyênNo ratings yet

- The Psychological Aspects of Cinematography and Its ImpactDocument21 pagesThe Psychological Aspects of Cinematography and Its Impactanastasiapiven7No ratings yet

- Quarter 3 MAPEH 7Document5 pagesQuarter 3 MAPEH 7Michelle Jane JapsonNo ratings yet

- HI FOG For BuildingsDocument32 pagesHI FOG For BuildingsKaustubh BidkarNo ratings yet

- Hyundai J3 PDFDocument203 pagesHyundai J3 PDFAlexey Kolmakov100% (4)

- Foam Cushioning Instapak SpeedyPacker BrochureDocument4 pagesFoam Cushioning Instapak SpeedyPacker BrochureRodrigo BeltranNo ratings yet

- Bahasa Inggris Lawang SewuDocument12 pagesBahasa Inggris Lawang Sewuaisyah100% (1)

- Spinal StabilizationDocument32 pagesSpinal StabilizationLakshita PrajapatiNo ratings yet

- Sro 565-2006Document44 pagesSro 565-2006Abdullah Jathol100% (1)

- PDS - NA - PRP Repair Data SheetDocument2 pagesPDS - NA - PRP Repair Data SheetHendra AwanNo ratings yet

- LIT - Sullair S-Energy 25-40hp Brochure - SAPSEN2540201904-6 - ENDocument8 pagesLIT - Sullair S-Energy 25-40hp Brochure - SAPSEN2540201904-6 - ENKrist San QNo ratings yet