Professional Documents

Culture Documents

Boeing to build new Apache fuselage (Reinforced Plastics, vol. 42, issue 7) (1998)

Boeing to build new Apache fuselage (Reinforced Plastics, vol. 42, issue 7) (1998)

Uploaded by

recolectorCopyright:

Available Formats

You might also like

- J %ijki: 400 Commonwealth Drive Warrendale, Pa 1S096Document14 pagesJ %ijki: 400 Commonwealth Drive Warrendale, Pa 1S096KaradiasNo ratings yet

- Oaci Exam PDFDocument212 pagesOaci Exam PDFCarlos Raúl YepezNo ratings yet

- Sample PM ChecklistDocument4 pagesSample PM ChecklistmohsinsafiNo ratings yet

- Shape Memory Alloy Based Morphing Aerostructures: Frederick T. Calkins James H. MabeDocument7 pagesShape Memory Alloy Based Morphing Aerostructures: Frederick T. Calkins James H. Mabearifefe99No ratings yet

- Irjet V7i1123456789Document8 pagesIrjet V7i1123456789AbhijeetNo ratings yet

- A36 ElectricalDocument3 pagesA36 ElectricalSantiago Varas SaavedraNo ratings yet

- 787 Restoring The DreamDocument6 pages787 Restoring The DreamDan GriffithsNo ratings yet

- SpiroidDocument2 pagesSpiroidMuthu KumarNo ratings yet

- Mini Case BoeingDocument2 pagesMini Case BoeingwindiNo ratings yet

- Alliant picked to make fuselage for tiltrotor plane (Reinforced Plastics, vol. 42, issue 11) (1998)Document1 pageAlliant picked to make fuselage for tiltrotor plane (Reinforced Plastics, vol. 42, issue 11) (1998)recolectorNo ratings yet

- Falco FurioDocument1 pageFalco Furioranickng1No ratings yet

- 4 PDFDocument1 page4 PDFranickng1No ratings yet

- Composite Fuselage Frames Manufactured by Resin Transfer Mouldin 2004Document4 pagesComposite Fuselage Frames Manufactured by Resin Transfer Mouldin 2004junjie yiNo ratings yet

- 7 FsaeDocument1 page7 FsaeSouhail Mouradi (“ninocity3”)No ratings yet

- Advanced F-18 Super Hornet PDFDocument21 pagesAdvanced F-18 Super Hornet PDFFakhrul-Razi Abu BakarNo ratings yet

- Notes-2 ReviewerDocument6 pagesNotes-2 ReviewerAngelo ConsunjiNo ratings yet

- VALLOTA Katrina AMT 1104-Reciprocating Engine ResearchDocument10 pagesVALLOTA Katrina AMT 1104-Reciprocating Engine ResearchKatrina VallotaNo ratings yet

- Boeing FA-18 2010.teal - Group.december.2010Document18 pagesBoeing FA-18 2010.teal - Group.december.2010Jose Luis Magaña PizarroNo ratings yet

- Jet Engine Materials: Cut-Away View of The GE90 EngineDocument8 pagesJet Engine Materials: Cut-Away View of The GE90 EngineAhmed KhasawnehNo ratings yet

- Next Gen Aerospace 2019Document76 pagesNext Gen Aerospace 2019Vishwajit GaunsNo ratings yet

- Composite Structures: SciencedirectDocument9 pagesComposite Structures: SciencedirectMarko PopovićNo ratings yet

- SAE International SAE Transactions: This Content Downloaded From 160.75.86.201 On Tue, 02 Feb 2021 12:29:37 UTCDocument11 pagesSAE International SAE Transactions: This Content Downloaded From 160.75.86.201 On Tue, 02 Feb 2021 12:29:37 UTCTurk SoloNo ratings yet

- Civil Aircraft Engine Exhaust Systems: Moro MatthieuDocument7 pagesCivil Aircraft Engine Exhaust Systems: Moro MatthieuVishnu RamNo ratings yet

- Tactical Aircraft Aerodynamic IntegrationDocument14 pagesTactical Aircraft Aerodynamic IntegrationMitra100% (1)

- Operator E-Jets News Rel 039Document9 pagesOperator E-Jets News Rel 039jivomirNo ratings yet

- SAEcompetitionAERO TeamDocument1 pageSAEcompetitionAERO TeamKarthik JNo ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument8 pagesSciencedirect Sciencedirect SciencedirectAnand VarmaNo ratings yet

- Automating Aerospace Composites Production With Fibre PlacementDocument6 pagesAutomating Aerospace Composites Production With Fibre PlacementAnalfabetas Vacas Pitas Do Ask e afinsNo ratings yet

- Unmanned Aerial Vehicles: An Armada International SupplementDocument36 pagesUnmanned Aerial Vehicles: An Armada International SupplementГригорий ОмельченкоNo ratings yet

- Lange 2012 Review of Unconventional Aircraft Design ConceptsDocument8 pagesLange 2012 Review of Unconventional Aircraft Design Conceptssanskar.maddiNo ratings yet

- Unmanned Aerial Vehicles: An Armada International SupplementDocument36 pagesUnmanned Aerial Vehicles: An Armada International SupplementSebastian ArdilesNo ratings yet

- Conversion of Production Automotive Engines For Aviation UseDocument14 pagesConversion of Production Automotive Engines For Aviation UseTayfunwNo ratings yet

- Turboshaft Engine: About GE AviationDocument4 pagesTurboshaft Engine: About GE Aviation唐波No ratings yet

- Design of A CFRP Composite Monocoque Simulation ApproachDocument8 pagesDesign of A CFRP Composite Monocoque Simulation ApproachGregory Aguilera LopesNo ratings yet

- KGAL Boeing 737MAX September 2019Document11 pagesKGAL Boeing 737MAX September 2019GrowlerJoeNo ratings yet

- Morgan BrochureDocument8 pagesMorgan BrochurePaper-FaceNo ratings yet

- Composite Landing Gear Components For Aerospace ApplicationsDocument8 pagesComposite Landing Gear Components For Aerospace ApplicationsSabih Ahmad KhanNo ratings yet

- Discover More: Institute of Avionics & AeronauticsDocument2 pagesDiscover More: Institute of Avionics & Aeronauticsfahadfadi48No ratings yet

- Conquest IIDocument6 pagesConquest IILyster75% (4)

- A Family of Small, Low Cost Turbojet Engines For Short Life ApplicationsDocument13 pagesA Family of Small, Low Cost Turbojet Engines For Short Life ApplicationsMorgen Gump100% (1)

- Overview of Aeromechanical Research at KTH Energy TechnologyDocument46 pagesOverview of Aeromechanical Research at KTH Energy TechnologymistrycsNo ratings yet

- Presentasi Bapak Triyoga WaskitoDocument20 pagesPresentasi Bapak Triyoga WaskitoIne IinPoeunyafreddytheaNo ratings yet

- PerusahaanDocument3 pagesPerusahaanFaza InsanNo ratings yet

- (2020) Effect of A Fuselage Boundary Layer Ingesting Propulsor On Airframe Forces and MomentsDocument11 pages(2020) Effect of A Fuselage Boundary Layer Ingesting Propulsor On Airframe Forces and MomentsRulo CuencaNo ratings yet

- Flight International - May 2023Document84 pagesFlight International - May 2023بدر الكبكبيNo ratings yet

- Official Sea Trial Completed For Sox Scrubber-Ready Mac Auxiliary BoilerDocument5 pagesOfficial Sea Trial Completed For Sox Scrubber-Ready Mac Auxiliary BoilerMohammed YcfssNo ratings yet

- Effect of Aircraft Wheel Load and Configuration On Runway DamagesDocument10 pagesEffect of Aircraft Wheel Load and Configuration On Runway DamageshieputcNo ratings yet

- Recuperated Gas Turbine Aeroengines. Part III: Engine Concepts For Reduced Emissions, Lower Fuel Consumption, and Noise AbatementDocument19 pagesRecuperated Gas Turbine Aeroengines. Part III: Engine Concepts For Reduced Emissions, Lower Fuel Consumption, and Noise AbatementsxasxasxNo ratings yet

- Rostami 2020Document10 pagesRostami 2020enes coşkunNo ratings yet

- Ef 2000 TestingDocument12 pagesEf 2000 TestingLeiser HartbeckNo ratings yet

- Numerical Designed Experiment To Optimize A Ported Shroud To Extend The Operability Margin of A Centrifugal CompressorDocument9 pagesNumerical Designed Experiment To Optimize A Ported Shroud To Extend The Operability Margin of A Centrifugal CompressorDhanasekar KNo ratings yet

- Review of Experiences With Ultra Thi9n Asphalt - Arno HeferDocument8 pagesReview of Experiences With Ultra Thi9n Asphalt - Arno HeferRob DamhuisNo ratings yet

- Structural Analysis For VVIP Cabin Compartment Modification STC of Commercial AirplaneDocument10 pagesStructural Analysis For VVIP Cabin Compartment Modification STC of Commercial AirplaneguillermoNo ratings yet

- Body Builders Layout Book: Second Unit Body Mounting IndexDocument10 pagesBody Builders Layout Book: Second Unit Body Mounting IndexSPIN2018No ratings yet

- Drones 05 00101 v2Document19 pagesDrones 05 00101 v2vishal BhoknalNo ratings yet

- Tomorrow's Materials TodayDocument2 pagesTomorrow's Materials TodayShantanu SinghaNo ratings yet

- FSTNR SBSTNDocument6 pagesFSTNR SBSTNAlyssa MaglinteNo ratings yet

- Library: Status Report On The Boeing Model 733-Supersonic TransportDocument8 pagesLibrary: Status Report On The Boeing Model 733-Supersonic TransportDaniel RouareNo ratings yet

- List of DOA Issued by EASA: AustraliaDocument40 pagesList of DOA Issued by EASA: AustraliaRangan SrinivasanNo ratings yet

- betti2007Document17 pagesbetti2007يمني شامخNo ratings yet

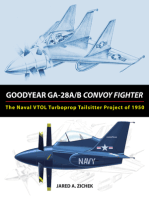

- Goodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandGoodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 4 out of 5 stars4/5 (2)

- Bridge Ergonomic Design A ReviewDocument7 pagesBridge Ergonomic Design A ReviewLibrary Jasaan CampusNo ratings yet

- Heavy Duty FJ 1Document2 pagesHeavy Duty FJ 1gaelNo ratings yet

- Design of PUP (1x7mx4.465m) CH:41+158Document47 pagesDesign of PUP (1x7mx4.465m) CH:41+158Rajan GuptaNo ratings yet

- 10-5.DrThuHanTun MMUDocument11 pages10-5.DrThuHanTun MMUThu Han TunNo ratings yet

- 850J II Crawler Dozer PIN 1BZ850JA C000001 PIN 1BZ850JA D000001 Replacement Parts GuideDocument3 pages850J II Crawler Dozer PIN 1BZ850JA C000001 PIN 1BZ850JA D000001 Replacement Parts GuidesocomgutNo ratings yet

- ExpatsInBrussels 2019Document276 pagesExpatsInBrussels 2019Asmaa CaNo ratings yet

- 6PH04 01R Que 20130613 PDFDocument2 pages6PH04 01R Que 20130613 PDFSamuel Muabia PlānetNo ratings yet

- Smart Transportation Technologies in ChennaiDocument25 pagesSmart Transportation Technologies in Chennaipremsai555No ratings yet

- Desarme Parking Brake Wa600-6Document2 pagesDesarme Parking Brake Wa600-6Oliver ArcosNo ratings yet

- The Impact of Commuting Time On Youth's School Performance: Journal of Regional Science January 2017Document32 pagesThe Impact of Commuting Time On Youth's School Performance: Journal of Regional Science January 2017SahooNo ratings yet

- D 1 - 2 - v4 - 27 - 09 - 2019.docx-1 PDFDocument416 pagesD 1 - 2 - v4 - 27 - 09 - 2019.docx-1 PDF18rosa18No ratings yet

- R1600G Load Haul Dump Operator Familiarization Instructor ModuleDocument25 pagesR1600G Load Haul Dump Operator Familiarization Instructor Modulepaul heberth areche conovilcaNo ratings yet

- ncs0111513 16Document118 pagesncs0111513 16maximus2297No ratings yet

- SSLC Public Exam 2024 Ss Answers 3 MarksDocument11 pagesSSLC Public Exam 2024 Ss Answers 3 MarkspoojarybarghavNo ratings yet

- Cajas AutomaticasDocument12 pagesCajas AutomaticasREYNALDO COPANo ratings yet

- Cooling BedDocument47 pagesCooling BedSubrata ChakrabortyNo ratings yet

- 7.0 Initial Course For Apprentice Technician (Signal) Gr-IiiDocument6 pages7.0 Initial Course For Apprentice Technician (Signal) Gr-IiiAryamn SainiNo ratings yet

- Catalogue & Price ListDocument3 pagesCatalogue & Price ListCINA auto partsNo ratings yet

- Request For VehicleDocument1 pageRequest For VehicleJelyn BujatinNo ratings yet

- Final Pamphlet Class K CTRBDocument30 pagesFinal Pamphlet Class K CTRBArghya BiswasNo ratings yet

- CodesDocument12 pagesCodesCham ArevaloNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument20 pagesDepartment of Transportation Federal Aviation AdministrationIgor MedeirosNo ratings yet

- Owner'S Manual: WesterlyDocument135 pagesOwner'S Manual: WesterlyPH Ph GnsoNo ratings yet

- Loadmasters Customs Services, Inc. v. Glodel Brokerage Corporation, G.R. No. 179446, 10 January 2011, (639 SCRA 69)Document3 pagesLoadmasters Customs Services, Inc. v. Glodel Brokerage Corporation, G.R. No. 179446, 10 January 2011, (639 SCRA 69)Christian Talisay100% (1)

- NCGM XX XX D Aec DR 930 1102Document1 pageNCGM XX XX D Aec DR 930 1102yusufuNo ratings yet

- Aptitude Day4Document42 pagesAptitude Day4Sachindra ManeNo ratings yet

- NORTHWEST AIRLINES Vs Spouses HeshanDocument2 pagesNORTHWEST AIRLINES Vs Spouses Heshanfermo ii ramosNo ratings yet

- Falcon LogisticsDocument31 pagesFalcon LogisticsAwais AhmedNo ratings yet

Boeing to build new Apache fuselage (Reinforced Plastics, vol. 42, issue 7) (1998)

Boeing to build new Apache fuselage (Reinforced Plastics, vol. 42, issue 7) (1998)

Uploaded by

recolectorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boeing to build new Apache fuselage (Reinforced Plastics, vol. 42, issue 7) (1998)

Boeing to build new Apache fuselage (Reinforced Plastics, vol. 42, issue 7) (1998)

Uploaded by

recolectorCopyright:

Available Formats

APPLICAT

V@

Boeing to build new Apache fuselage GE awards

A FOUR-year, $15.9 mil- Apache helicopters. Boeing improvements, the Apache engine inlet

lion agreement to design, is currently remanufacturing helicopter could remain in device contract

manufacture and flight test a AH-64A Apaches into the military service well into the

new centre fuselage section advanced AH-64D Apache next century. A FIVE-year, $65 million

fabricated in com- In addition contract from GE Aircraft

posite for Apache Phantom Works Engines, to produce com-

helicopters has will use Boeing posite inlet devices, has

been awarded to developed com- been awarded to Marion

The Boeing Co. posite techniques Composites, a division of

The composite sec- that replace tradi- Advanced Technical Pro-

tion, essentially tional metal fas- ducts Inc.

from the aft cock- teners with a In the first five years of

pit of the aircraft stitching process the contract, Marion Com-

to just behind the leading to greater posites is expected to pro-

engines, will be structural integri-

duce composite inlet devices

lighter, stronger ty and lower man-

for the GE F414-400 turbo-

and easier to ufacturing cost.

fan engine, powering

manufacture than The award was

the Boeing/US Navy

the existing metal granted under the

F/A- 18E/F Super Hornet

structure. Rotary Wings

Aircraft.

The award is a Structures Tech-

The inlet device is a

significant mile- nology Demon-

stone for the com- stration ,p;;;h high temperature, bonded

pany’s Phantom ramme, ’ composite structure that

Works and for the funds cost and mounts in the aircraft air

Apache develop- weight reduction inlet just forward of the

ment programme. The AH-G4D Apache Longbow helicopter. initiatives for the engine to enhance aircraft

Successful comple- Army’s existing survivability.

tion of the agreement poten- Longbow configuration. By and future helicopter fleet. Facility and equipment

tially allows for the length- incorporating the composite Ken Jensen, Boeing; startup, risk reduction hard-

ening of the service life of fuselage section and other tel:+l-602-891-2119. ware fabrication, and source

substantiation evaluation

will begin in 19%.

Deliveries are expected

to begin at a rate of one unit

Lincoln wins contract for composite natural gas fuel tank per month and are predict-

THE LINCOLN Com- Continuous spools of carbon The tank has been ed to reach a peak rate of up

posites division of Advanced and glass fibre are combined certified to meet the fuel to ten units per month in

Technical Products Inc has with an epoxy resin and over tank standard set by mid-2002 for the US

been awarded a contract by wrapped onto a high-density the US Department of Navy’s high priority FIA-

Mitsui Plastics Inc, polyethylene liner with alu- Transportation. 18E/F development and

California, USA, to design minum end fittings. The “During the past four procurement programme.

and produce an all compos- resulting composite structure years we have worked hard The current production

ite natural gas vehicle is then heated to cure the to ensure that the Tuffshell plan for the twin engine jet

(NGV) fuel tank for Honda resin. Each finished part is tank meets the demands is to produce a minimum of

of America’s 1998 model individually tested to a pres- of original equipment man- 548 aircraft each including

Civic GX. sure 50% greater than its ser- ufacturers”, says Lincoln’s two inlet devices.

Honda will individually vice pressure. president Jim Fuller. “More “This contract will

mount the 450 .mm diame- The tank design is virtu- importantly, we have increase our previously

ter by 925 mm long tanks in ally identical to the 16 000 focused on ensuring that announced first quarter

the boot of the vehicle. The TuffshellTM fuel tanks that industry certification such 1997 backlog to over

tanks, some of which will be Lincoln has delivered to as the NGV-2, IS0 DIS $600 million”, says Garret

exported for sale in Japan, transit bus manufacturers in 11439 and Canadian B-5 1 L. Dominy, chief finan-

will be used on cars built in Canada and the USA since standards, reflect the need cial officer at Marion

Honda’s Ohio plant and 1992 for use by fleet opera- to improve industry safety Composites.

sold in the US market. tors, gas utilities and shuttle and product integrity.” Marion Composites;

The tank is produced and package delivery Lincoln Composites Inc; teL:+l-800-662-9044;

using filament winding. services. tel: + I - 402-464-821 I. fm:+l-540-783-9667.

Reinforced Plastics July/August 1998

You might also like

- J %ijki: 400 Commonwealth Drive Warrendale, Pa 1S096Document14 pagesJ %ijki: 400 Commonwealth Drive Warrendale, Pa 1S096KaradiasNo ratings yet

- Oaci Exam PDFDocument212 pagesOaci Exam PDFCarlos Raúl YepezNo ratings yet

- Sample PM ChecklistDocument4 pagesSample PM ChecklistmohsinsafiNo ratings yet

- Shape Memory Alloy Based Morphing Aerostructures: Frederick T. Calkins James H. MabeDocument7 pagesShape Memory Alloy Based Morphing Aerostructures: Frederick T. Calkins James H. Mabearifefe99No ratings yet

- Irjet V7i1123456789Document8 pagesIrjet V7i1123456789AbhijeetNo ratings yet

- A36 ElectricalDocument3 pagesA36 ElectricalSantiago Varas SaavedraNo ratings yet

- 787 Restoring The DreamDocument6 pages787 Restoring The DreamDan GriffithsNo ratings yet

- SpiroidDocument2 pagesSpiroidMuthu KumarNo ratings yet

- Mini Case BoeingDocument2 pagesMini Case BoeingwindiNo ratings yet

- Alliant picked to make fuselage for tiltrotor plane (Reinforced Plastics, vol. 42, issue 11) (1998)Document1 pageAlliant picked to make fuselage for tiltrotor plane (Reinforced Plastics, vol. 42, issue 11) (1998)recolectorNo ratings yet

- Falco FurioDocument1 pageFalco Furioranickng1No ratings yet

- 4 PDFDocument1 page4 PDFranickng1No ratings yet

- Composite Fuselage Frames Manufactured by Resin Transfer Mouldin 2004Document4 pagesComposite Fuselage Frames Manufactured by Resin Transfer Mouldin 2004junjie yiNo ratings yet

- 7 FsaeDocument1 page7 FsaeSouhail Mouradi (“ninocity3”)No ratings yet

- Advanced F-18 Super Hornet PDFDocument21 pagesAdvanced F-18 Super Hornet PDFFakhrul-Razi Abu BakarNo ratings yet

- Notes-2 ReviewerDocument6 pagesNotes-2 ReviewerAngelo ConsunjiNo ratings yet

- VALLOTA Katrina AMT 1104-Reciprocating Engine ResearchDocument10 pagesVALLOTA Katrina AMT 1104-Reciprocating Engine ResearchKatrina VallotaNo ratings yet

- Boeing FA-18 2010.teal - Group.december.2010Document18 pagesBoeing FA-18 2010.teal - Group.december.2010Jose Luis Magaña PizarroNo ratings yet

- Jet Engine Materials: Cut-Away View of The GE90 EngineDocument8 pagesJet Engine Materials: Cut-Away View of The GE90 EngineAhmed KhasawnehNo ratings yet

- Next Gen Aerospace 2019Document76 pagesNext Gen Aerospace 2019Vishwajit GaunsNo ratings yet

- Composite Structures: SciencedirectDocument9 pagesComposite Structures: SciencedirectMarko PopovićNo ratings yet

- SAE International SAE Transactions: This Content Downloaded From 160.75.86.201 On Tue, 02 Feb 2021 12:29:37 UTCDocument11 pagesSAE International SAE Transactions: This Content Downloaded From 160.75.86.201 On Tue, 02 Feb 2021 12:29:37 UTCTurk SoloNo ratings yet

- Civil Aircraft Engine Exhaust Systems: Moro MatthieuDocument7 pagesCivil Aircraft Engine Exhaust Systems: Moro MatthieuVishnu RamNo ratings yet

- Tactical Aircraft Aerodynamic IntegrationDocument14 pagesTactical Aircraft Aerodynamic IntegrationMitra100% (1)

- Operator E-Jets News Rel 039Document9 pagesOperator E-Jets News Rel 039jivomirNo ratings yet

- SAEcompetitionAERO TeamDocument1 pageSAEcompetitionAERO TeamKarthik JNo ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument8 pagesSciencedirect Sciencedirect SciencedirectAnand VarmaNo ratings yet

- Automating Aerospace Composites Production With Fibre PlacementDocument6 pagesAutomating Aerospace Composites Production With Fibre PlacementAnalfabetas Vacas Pitas Do Ask e afinsNo ratings yet

- Unmanned Aerial Vehicles: An Armada International SupplementDocument36 pagesUnmanned Aerial Vehicles: An Armada International SupplementГригорий ОмельченкоNo ratings yet

- Lange 2012 Review of Unconventional Aircraft Design ConceptsDocument8 pagesLange 2012 Review of Unconventional Aircraft Design Conceptssanskar.maddiNo ratings yet

- Unmanned Aerial Vehicles: An Armada International SupplementDocument36 pagesUnmanned Aerial Vehicles: An Armada International SupplementSebastian ArdilesNo ratings yet

- Conversion of Production Automotive Engines For Aviation UseDocument14 pagesConversion of Production Automotive Engines For Aviation UseTayfunwNo ratings yet

- Turboshaft Engine: About GE AviationDocument4 pagesTurboshaft Engine: About GE Aviation唐波No ratings yet

- Design of A CFRP Composite Monocoque Simulation ApproachDocument8 pagesDesign of A CFRP Composite Monocoque Simulation ApproachGregory Aguilera LopesNo ratings yet

- KGAL Boeing 737MAX September 2019Document11 pagesKGAL Boeing 737MAX September 2019GrowlerJoeNo ratings yet

- Morgan BrochureDocument8 pagesMorgan BrochurePaper-FaceNo ratings yet

- Composite Landing Gear Components For Aerospace ApplicationsDocument8 pagesComposite Landing Gear Components For Aerospace ApplicationsSabih Ahmad KhanNo ratings yet

- Discover More: Institute of Avionics & AeronauticsDocument2 pagesDiscover More: Institute of Avionics & Aeronauticsfahadfadi48No ratings yet

- Conquest IIDocument6 pagesConquest IILyster75% (4)

- A Family of Small, Low Cost Turbojet Engines For Short Life ApplicationsDocument13 pagesA Family of Small, Low Cost Turbojet Engines For Short Life ApplicationsMorgen Gump100% (1)

- Overview of Aeromechanical Research at KTH Energy TechnologyDocument46 pagesOverview of Aeromechanical Research at KTH Energy TechnologymistrycsNo ratings yet

- Presentasi Bapak Triyoga WaskitoDocument20 pagesPresentasi Bapak Triyoga WaskitoIne IinPoeunyafreddytheaNo ratings yet

- PerusahaanDocument3 pagesPerusahaanFaza InsanNo ratings yet

- (2020) Effect of A Fuselage Boundary Layer Ingesting Propulsor On Airframe Forces and MomentsDocument11 pages(2020) Effect of A Fuselage Boundary Layer Ingesting Propulsor On Airframe Forces and MomentsRulo CuencaNo ratings yet

- Flight International - May 2023Document84 pagesFlight International - May 2023بدر الكبكبيNo ratings yet

- Official Sea Trial Completed For Sox Scrubber-Ready Mac Auxiliary BoilerDocument5 pagesOfficial Sea Trial Completed For Sox Scrubber-Ready Mac Auxiliary BoilerMohammed YcfssNo ratings yet

- Effect of Aircraft Wheel Load and Configuration On Runway DamagesDocument10 pagesEffect of Aircraft Wheel Load and Configuration On Runway DamageshieputcNo ratings yet

- Recuperated Gas Turbine Aeroengines. Part III: Engine Concepts For Reduced Emissions, Lower Fuel Consumption, and Noise AbatementDocument19 pagesRecuperated Gas Turbine Aeroengines. Part III: Engine Concepts For Reduced Emissions, Lower Fuel Consumption, and Noise AbatementsxasxasxNo ratings yet

- Rostami 2020Document10 pagesRostami 2020enes coşkunNo ratings yet

- Ef 2000 TestingDocument12 pagesEf 2000 TestingLeiser HartbeckNo ratings yet

- Numerical Designed Experiment To Optimize A Ported Shroud To Extend The Operability Margin of A Centrifugal CompressorDocument9 pagesNumerical Designed Experiment To Optimize A Ported Shroud To Extend The Operability Margin of A Centrifugal CompressorDhanasekar KNo ratings yet

- Review of Experiences With Ultra Thi9n Asphalt - Arno HeferDocument8 pagesReview of Experiences With Ultra Thi9n Asphalt - Arno HeferRob DamhuisNo ratings yet

- Structural Analysis For VVIP Cabin Compartment Modification STC of Commercial AirplaneDocument10 pagesStructural Analysis For VVIP Cabin Compartment Modification STC of Commercial AirplaneguillermoNo ratings yet

- Body Builders Layout Book: Second Unit Body Mounting IndexDocument10 pagesBody Builders Layout Book: Second Unit Body Mounting IndexSPIN2018No ratings yet

- Drones 05 00101 v2Document19 pagesDrones 05 00101 v2vishal BhoknalNo ratings yet

- Tomorrow's Materials TodayDocument2 pagesTomorrow's Materials TodayShantanu SinghaNo ratings yet

- FSTNR SBSTNDocument6 pagesFSTNR SBSTNAlyssa MaglinteNo ratings yet

- Library: Status Report On The Boeing Model 733-Supersonic TransportDocument8 pagesLibrary: Status Report On The Boeing Model 733-Supersonic TransportDaniel RouareNo ratings yet

- List of DOA Issued by EASA: AustraliaDocument40 pagesList of DOA Issued by EASA: AustraliaRangan SrinivasanNo ratings yet

- betti2007Document17 pagesbetti2007يمني شامخNo ratings yet

- Goodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandGoodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 4 out of 5 stars4/5 (2)

- Bridge Ergonomic Design A ReviewDocument7 pagesBridge Ergonomic Design A ReviewLibrary Jasaan CampusNo ratings yet

- Heavy Duty FJ 1Document2 pagesHeavy Duty FJ 1gaelNo ratings yet

- Design of PUP (1x7mx4.465m) CH:41+158Document47 pagesDesign of PUP (1x7mx4.465m) CH:41+158Rajan GuptaNo ratings yet

- 10-5.DrThuHanTun MMUDocument11 pages10-5.DrThuHanTun MMUThu Han TunNo ratings yet

- 850J II Crawler Dozer PIN 1BZ850JA C000001 PIN 1BZ850JA D000001 Replacement Parts GuideDocument3 pages850J II Crawler Dozer PIN 1BZ850JA C000001 PIN 1BZ850JA D000001 Replacement Parts GuidesocomgutNo ratings yet

- ExpatsInBrussels 2019Document276 pagesExpatsInBrussels 2019Asmaa CaNo ratings yet

- 6PH04 01R Que 20130613 PDFDocument2 pages6PH04 01R Que 20130613 PDFSamuel Muabia PlānetNo ratings yet

- Smart Transportation Technologies in ChennaiDocument25 pagesSmart Transportation Technologies in Chennaipremsai555No ratings yet

- Desarme Parking Brake Wa600-6Document2 pagesDesarme Parking Brake Wa600-6Oliver ArcosNo ratings yet

- The Impact of Commuting Time On Youth's School Performance: Journal of Regional Science January 2017Document32 pagesThe Impact of Commuting Time On Youth's School Performance: Journal of Regional Science January 2017SahooNo ratings yet

- D 1 - 2 - v4 - 27 - 09 - 2019.docx-1 PDFDocument416 pagesD 1 - 2 - v4 - 27 - 09 - 2019.docx-1 PDF18rosa18No ratings yet

- R1600G Load Haul Dump Operator Familiarization Instructor ModuleDocument25 pagesR1600G Load Haul Dump Operator Familiarization Instructor Modulepaul heberth areche conovilcaNo ratings yet

- ncs0111513 16Document118 pagesncs0111513 16maximus2297No ratings yet

- SSLC Public Exam 2024 Ss Answers 3 MarksDocument11 pagesSSLC Public Exam 2024 Ss Answers 3 MarkspoojarybarghavNo ratings yet

- Cajas AutomaticasDocument12 pagesCajas AutomaticasREYNALDO COPANo ratings yet

- Cooling BedDocument47 pagesCooling BedSubrata ChakrabortyNo ratings yet

- 7.0 Initial Course For Apprentice Technician (Signal) Gr-IiiDocument6 pages7.0 Initial Course For Apprentice Technician (Signal) Gr-IiiAryamn SainiNo ratings yet

- Catalogue & Price ListDocument3 pagesCatalogue & Price ListCINA auto partsNo ratings yet

- Request For VehicleDocument1 pageRequest For VehicleJelyn BujatinNo ratings yet

- Final Pamphlet Class K CTRBDocument30 pagesFinal Pamphlet Class K CTRBArghya BiswasNo ratings yet

- CodesDocument12 pagesCodesCham ArevaloNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument20 pagesDepartment of Transportation Federal Aviation AdministrationIgor MedeirosNo ratings yet

- Owner'S Manual: WesterlyDocument135 pagesOwner'S Manual: WesterlyPH Ph GnsoNo ratings yet

- Loadmasters Customs Services, Inc. v. Glodel Brokerage Corporation, G.R. No. 179446, 10 January 2011, (639 SCRA 69)Document3 pagesLoadmasters Customs Services, Inc. v. Glodel Brokerage Corporation, G.R. No. 179446, 10 January 2011, (639 SCRA 69)Christian Talisay100% (1)

- NCGM XX XX D Aec DR 930 1102Document1 pageNCGM XX XX D Aec DR 930 1102yusufuNo ratings yet

- Aptitude Day4Document42 pagesAptitude Day4Sachindra ManeNo ratings yet

- NORTHWEST AIRLINES Vs Spouses HeshanDocument2 pagesNORTHWEST AIRLINES Vs Spouses Heshanfermo ii ramosNo ratings yet

- Falcon LogisticsDocument31 pagesFalcon LogisticsAwais AhmedNo ratings yet