Professional Documents

Culture Documents

960C-SOP-112-R2 - Compressed Air and Air Hoses_2022-04-10

960C-SOP-112-R2 - Compressed Air and Air Hoses_2022-04-10

Uploaded by

amonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

960C-SOP-112-R2 - Compressed Air and Air Hoses_2022-04-10

960C-SOP-112-R2 - Compressed Air and Air Hoses_2022-04-10

Uploaded by

amonCopyright:

Available Formats

STANDARD OPERATING PROCEDURE

Compressed Air and Air Hoses Document Number: 960C-SOP-112

Original Approval Date: Mar 31, 2010 Revision Number: 2 Page 1 of 5

Latest Revision Date: Apr 10, 2022 Next Revision Date: Apr 10, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

COMPRESSED AIR AND AIR HOSES

2 APP Apr 10, 2022 Approved Matthew MacIsaac Tammy Siver Gilbert Schreyer

1 APP Mar 31, 2010 Approved Ken Morran Stan Miller Stan Miller

Rev Status Rev. Date Status Description Prepared by Reviewed by Approved by

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Compressed Air and Air Hoses Document Number: 960C-SOP-112

Original Approval Date: Mar 31, 2010 Revision Number: 2 Page 2 of 5

Latest Revision Date: Apr 10, 2022 Next Revision Date: Apr 10, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

The following is a step by step procedure on how to complete a specific task or meet a facility specific requirement.

Standard Operating Procedures (SOPs) are written for all identified critical tasks. By virtue of the hazard or

complexity associated with critical tasks it is paramount that the SOP be followed as written. SOPs contain a listing

of high-level hazards associated with the task, for detailed hazard analysis reference the applicable Task Hazard

Assessments. SOPs do not replace the requirements contained in the company Standards, Codes, and Processes

nor does it replace the need to comply with required legislation. Section 8.0 references documentation that the

worker shall understand before work commences.

1.0 PURPOSE

• To establish a company standard to safely and effectively carry out work as it applies to using compressed

air and air hoses.

2.0 SCOPE AND APPLICATION

• This document applies to all company Heavy Construction Mining operations. Ensure all site-specific

requirements are being met or exceeded before performing the task.

3.0 HAZARDS AND CONTROLS

• Injuries or damage due to failing hoses, clamps and couplings which may be damaged or unsuitable for the

equipment or task.

o Inspect hoses for damage, wear, and defects prior to use. Do not use bare hands to locate a leak.

o Hoses should be kept clean of grease, oil, dirt and debris

o Ensure hoses are rated for the amount of pressure to be used. Inspect clamps for damage, wear,

and secure connection to hose. Hoses should be visibly labelled with the maximum pressure rating

to ensure compliance at all times.

o Ensure “quick connect” fittings are securely connected and locked prior to using air tool.

o Ensure “Chicago” fittings are locked and pinned with approved pins (absolutely no wire to be used).

o Ensure “Chicago” connections are fitted with whip check cables.

o Ensure the locking springs on the hose reel are working effectively.

o Hoses should be kept organized, out of the way of walkways, and should never be bent or kinked,

during or after operation.

o If an air hose should burst, do not attempt to grab it. Follow the line back to its end and trace the

pipe supply until you find a shut-off valve.

o Use only crimp style hose clamps.

• Striking people or equipment with material or debris moved by compressed air.

o Ensure air compressors are in proper working order prior to use.

o Ensure portable compressors are on level ground and secured against movement prior to start-up.

o Review and follow appropriate machine “start-up” and “shut-down” procedures as per

manufacturer.

o Ensure pressure regulators are in proper working order and set to deliver safe working pressures

as defined by manufacturer of tool to be attached to compressor.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Compressed Air and Air Hoses Document Number: 960C-SOP-112

Original Approval Date: Mar 31, 2010 Revision Number: 2 Page 3 of 5

Latest Revision Date: Apr 10, 2022 Next Revision Date: Apr 10, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

o Ensure the valve(s) to the hose connectors are closed.

o Do not use compressed air to clean dust or debris from yourself or others.

o Ensure pressure is relieved from connected hoses and tools prior to disconnecting.

• Exposure to electrical shocks causing bodily injury or damage to the compressor.

o If an outlet isn’t grounded correctly, it can result in electrical shocks and significant damage to the

compressor.

o Pay close attention to your air compressor’s voltage. If repairs are needed, power down the

machine, lock and tag out all power sources and release all pressure from the compressor.

o If the compressor is designed for indoor use, don’t use it outdoors, as rain or wet conditions can

cause electrical problems.

o Before performing maintenance work, shut off the machine and disconnect it from all power

sources.

• Hazardous fumes generated from gasoline and diesel operated compressors.

o Gas-powered and diesel-powered compressors produce dangerous fumes, so it’s important that

you only use them outside or in an area with ventilation extraction.

o Only smoke in designated smoking areas, away from potential ignition sources.

• Sparks created from the electrical contacts of an electric compressor.

o Always operate the compressor in a well-ventilated area free of combustible materials, gasoline

and vapors.

• Portable air compressors placed on unstable ground.

o Locate a flat, stable work area for your air compressor. Do not place the air compressor on a surface

that is unstable or uneven.

• Starting fires or puncturing airlines with grinding slag when air arcing or gouging.

o Remove all flammable / combustible materials from the path of grinding slag.

o Utilize barriers such as weld screens to contain the slag/grindings.

• Compromised air tank damages such as rust or puncture damage.

o Inspect air tank as part of daily inspection. If it appears damaged, bleed the tank of air, and have

an authorized dealer determine examine it so they can recommend the proper course of action.

• Noise exposure.

o Wear hearing protection suitable to the occupational noise exposure limit as defined by the

jurisdiction. In most situations, single hearing protection may be required. However, double hearing

protection may be required depending on the task. Review task with supervisor to determine the

appropriate level of hearing protection.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Compressed Air and Air Hoses Document Number: 960C-SOP-112

Original Approval Date: Mar 31, 2010 Revision Number: 2 Page 4 of 5

Latest Revision Date: Apr 10, 2022 Next Revision Date: Apr 10, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

o Utilize mufflers / diffusers.

o Direct air stream and control the air release to minimize the volume and force.

• Incorrect maintenance or upkeep of the compressor and air hoses

o Pressure-regulating equipment should never be changed, replaced, or adjusted by anyone other

than competent personnel.

o Follow manufacturer recommendations for servicing and maintenance.

4.0 CHECKLIST

Attend all preparatory meetings (IE: daily PSI; job scope; review of JSA’s and SOP’s for the job).

Complete FLRA cards before starting the work.

Ensure all personnel involved in the task are aware of the hazards and the controls to be used, as

identified in the SOP’s; JSA’s; and FLRA’s

Conduct a pre-job inspection of all equipment to be worked on and tools to be used.

Standard of Training required for working on this job: On-the job training.

5.0 DEFINITIONS

5.1 Company

Means North American Construction Group Ltd. (NACG) and all directly or indirectly owned subsidiary companies,

including joint ventures.

5.2 Company Personnel

Includes the Company’s employees, officers, directors, agents, associates, consultants/contractors, temporary

employees and third-party processors.

5.3 HSE

Refers to the Health, Safety & Environment department.

5.4 Compressed Air

Compressed air is air kept under a pressure that is greater than atmospheric pressure. Compressed air is an

important medium for transfer of energy in industrial processes and is used for power tools such as air hammers,

drills, wrenches and others, as well as to atomize paint, to operate air cylinders for automation, and can also be

used to propel vehicles.

5.5 Air Hose

An airline is a tube, or hose, that contains and carries a compressed air supply.

5.6 Air Compressor

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor

is a specific type of gas compressor. Compressors are similar to pumps: both increase the pressure on a fluid or

gas, and both can transport the fluid or gas through a pipe.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Compressed Air and Air Hoses Document Number: 960C-SOP-112

Original Approval Date: Mar 31, 2010 Revision Number: 2 Page 5 of 5

Latest Revision Date: Apr 10, 2022 Next Revision Date: Apr 10, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

6.0 PROCEDURE

1) Complete a hazard assessment (i.e. FLRA) for the task and determine the type of equipment to be

used. Notify supervision if unsure of task or how to use equipment or if there are hazards outside of the

worker’s control.

2) Inspect all components of the air compressor and air hose. Tagout and remove from service any

defective or damaged equipment. Report to supervisor.

3) Inspect the immediate work area to ensure ventilation is in place.

4) Unreel or uncoil enough air hose to reach the work point

5) Start the compressor noting the pressure gauge increase and the cut-in / cut-out pressure levels.

6) Listen for any air leaks from all airlines or hoses. Do not continue if there are any leaks.

7) Adjust the pressure regulator to suit the particular work requirements.

8) Continue to check pressures at regular intervals during normal operation.

7.0 NOTES

If this task is to be done by a method different than described in this SOP, the work must STOP and the alternate

method must be DOCUMENTED with an adequate hazard assessment tool such as a JSA. The document must be

APPROVED by a supervisor before such procedures are implemented.

8.0 REFERENCES

• Alberta Occupational Health and Safety Act, Regulation and Code – {Part 10 Fire and Explosion Hazards}

• Alberta Occupational Health and Safety Act, Regulation and Code – {Part 25 Tools, Equipment and

Machinery}

• Tools and compressor manufacturers’ operating manual

• 950C-C-045 Power Tools Code

• 950C-C-028 Hazardous Energy Isolation Code

• 960C-SOP-500 Rad Gun Operation

• 960C-SOP-502 Safe Use of Grinders

• 960C-SOP-505 Powered Hand Tools

• 960C-SOP-308 Air Arcing – Gouging Metal

9.0 APPENDICES

• No appendices.

Form 999C-F-003_Rev2 Aug 16, 2016

You might also like

- Operating & Maintenance Procedure For Air Cooler Heat ExchangerDocument10 pagesOperating & Maintenance Procedure For Air Cooler Heat Exchangerrahim_33516285678% (9)

- RMS Installation Instructions 016-14-607v01Document7 pagesRMS Installation Instructions 016-14-607v01NileshgordeNo ratings yet

- PARTS LIST FOR MANITOU MT 1840 SERIES (00000002)Document3 pagesPARTS LIST FOR MANITOU MT 1840 SERIES (00000002)amonNo ratings yet

- Mould Change, Storage and Maintenance ProcedureDocument10 pagesMould Change, Storage and Maintenance ProcedureTechnicians SIM100% (1)

- Flanged Basket Strainers IOMDocument4 pagesFlanged Basket Strainers IOMSteve NewmanNo ratings yet

- Dresser Roots Tri-Nado TM 1125 DVJ Tri-Lobe Blower - ManualDocument10 pagesDresser Roots Tri-Nado TM 1125 DVJ Tri-Lobe Blower - Manualpablo.matulic9471No ratings yet

- Air Leak TestingDocument5 pagesAir Leak Testingkusdiyanta75% (4)

- Aero 80FP Operator ManualDocument48 pagesAero 80FP Operator ManualTimmyNo ratings yet

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaNo ratings yet

- Ethics Chapter 5Document7 pagesEthics Chapter 5mine2515100% (1)

- Aug 9 Sbi4u Answers Quiz 4Document3 pagesAug 9 Sbi4u Answers Quiz 4api-216300751No ratings yet

- 960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use ofDocument5 pages960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use ofamonNo ratings yet

- Mechanical Integrity Exchanger Tube BundleDocument9 pagesMechanical Integrity Exchanger Tube BundleirvansyahNo ratings yet

- 960C-SOP-502-R2 - Safe use of Grinders_2022-04-04Document10 pages960C-SOP-502-R2 - Safe use of Grinders_2022-04-04amonNo ratings yet

- S-04-HCW-M-40-V001-001 - SA Fan PDFDocument48 pagesS-04-HCW-M-40-V001-001 - SA Fan PDFElsadig Elkhair100% (1)

- Unicon v100 Globe ValvesDocument19 pagesUnicon v100 Globe ValvesEduardo GarridoNo ratings yet

- Operating & Maintenance manual-RM-290AC'J'Document33 pagesOperating & Maintenance manual-RM-290AC'J'faqdaniNo ratings yet

- Regulators: Certifi Ed ISO 9001Document16 pagesRegulators: Certifi Ed ISO 9001HUBERT GERMAN BRIOSO BARRENECHEANo ratings yet

- Pa Series: Air Operated Food Grade Piston PumpsDocument20 pagesPa Series: Air Operated Food Grade Piston PumpsvikramchowdaryNo ratings yet

- Method Statement For ChillersDocument8 pagesMethod Statement For ChillersFark Off100% (1)

- Air Compressor Air Compressor: (Small) (Small)Document1 pageAir Compressor Air Compressor: (Small) (Small)alcrosalitaNo ratings yet

- Method Statement For Installation and T - C of Split UnitsDocument4 pagesMethod Statement For Installation and T - C of Split Unitsمحمد بدر الدين العمامي100% (1)

- Operating & Maintenance Manual-RM-180ACDocument33 pagesOperating & Maintenance Manual-RM-180ACfaqdani100% (1)

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- 960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06Document4 pages960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06amonNo ratings yet

- Corrosion Coupon Installation Procedure PDFDocument31 pagesCorrosion Coupon Installation Procedure PDFtrichysayeeNo ratings yet

- Rotary Air Blower RM450 WCTRDocument39 pagesRotary Air Blower RM450 WCTRShahNo ratings yet

- Check-Valves-3Document8 pagesCheck-Valves-3GordinhorsNo ratings yet

- Industrial Air Technology Corp Centrifugal Fans Blowers Installation Operation Maintenance ManualDocument8 pagesIndustrial Air Technology Corp Centrifugal Fans Blowers Installation Operation Maintenance Manualcristobal pascuaNo ratings yet

- Sop for Gas Cutting-01Document4 pagesSop for Gas Cutting-01Subhra RanjanNo ratings yet

- PRES-M-08 Rotating Equipment - Compressors PackageDocument2 pagesPRES-M-08 Rotating Equipment - Compressors PackagesalamlinNo ratings yet

- 23-022 Installation Procedures ValvesDocument6 pages23-022 Installation Procedures ValvesAli Khalid QureshiNo ratings yet

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivani100% (1)

- Sopladores Urai Manual PDFDocument28 pagesSopladores Urai Manual PDFJohanna RojasNo ratings yet

- VHS30-03B - Valvula de Segurança Manual Serie Vhs-A-B - SMCDocument16 pagesVHS30-03B - Valvula de Segurança Manual Serie Vhs-A-B - SMCRafael EspositoNo ratings yet

- Boss 11T-107 Installation Manual A 0Document54 pagesBoss 11T-107 Installation Manual A 0Ardi WiranataNo ratings yet

- Overhauling of TransformersDocument9 pagesOverhauling of TransformersVibhor Gaur100% (5)

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocument20 pagesFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNo ratings yet

- Method Statement Form - Diaphragm ValveDocument6 pagesMethod Statement Form - Diaphragm ValveSmith SuwanNo ratings yet

- 090 R01Document72 pages090 R0118085012No ratings yet

- C.1.3 Method Statement For Sand BlastingDocument7 pagesC.1.3 Method Statement For Sand Blastingagbon johnNo ratings yet

- Facilities For Corrosion Monitoring in Process Equipment - Engineering Guide EG 19-6-1.1Document3 pagesFacilities For Corrosion Monitoring in Process Equipment - Engineering Guide EG 19-6-1.1aminNo ratings yet

- Manual DPCVDocument8 pagesManual DPCVbhaaskarNo ratings yet

- Kelvion Searle Coolers Installation 1Document50 pagesKelvion Searle Coolers Installation 1Yutt WattNo ratings yet

- Wilkerson F16 FilterDocument2 pagesWilkerson F16 FilterCDFlohrNo ratings yet

- Cms-2 Detector de MonoxidoDocument17 pagesCms-2 Detector de MonoxidoJORGEALEXERNo ratings yet

- Method Statement For WellDocument7 pagesMethod Statement For WellDeffous AbdelhadiNo ratings yet

- 960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06Document9 pages960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06amonNo ratings yet

- Jphil Bolting and Unbolting Procedure Rev 1Document21 pagesJphil Bolting and Unbolting Procedure Rev 1Mark Darrel AranasNo ratings yet

- MJR For 30M Maintenance Check of Check ValvesDocument9 pagesMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Hollo BlastDocument16 pagesHollo BlastBraz Pataro NetoNo ratings yet

- Construction Method of Statement: Submitted By: Mega Air EnterprisesDocument12 pagesConstruction Method of Statement: Submitted By: Mega Air Enterprisesallen bernabeNo ratings yet

- Ump Fan-Air Om Manual - Rev Dec 2014Document12 pagesUmp Fan-Air Om Manual - Rev Dec 2014api-252481722No ratings yet

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDocument16 pagesSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- CO2 System Installation InspectionDocument3 pagesCO2 System Installation InspectionJun AballeNo ratings yet

- User Manual: WSPC U I M WSC ™Document72 pagesUser Manual: WSPC U I M WSC ™Matheus KraemerNo ratings yet

- Q&M GeneralDocument0 pagesQ&M GeneralPhu NguyenNo ratings yet

- SOP For Condenser Rubber Ball Cleaning System HBSDocument8 pagesSOP For Condenser Rubber Ball Cleaning System HBSAbeer arifNo ratings yet

- MSA-10 and MSA-100 Air Operated Pump: Instruction - Installation and PartsDocument18 pagesMSA-10 and MSA-100 Air Operated Pump: Instruction - Installation and PartsArtu MezaNo ratings yet

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Confined Space Blowers: Users ManualDocument17 pagesConfined Space Blowers: Users ManualRandhir RanaNo ratings yet

- Mechanical PlugsDocument6 pagesMechanical Plugskategord0% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- maintenance-210502124530 (3)Document17 pagesmaintenance-210502124530 (3)amonNo ratings yet

- Noblelft FD20-35 Operation & Maintenance ManualDocument176 pagesNoblelft FD20-35 Operation & Maintenance ManualamonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- PT Parts - VBeltsDocument25 pagesPT Parts - VBeltsamonNo ratings yet

- Automotive Lamp Guide – BulbAmericaDocument1 pageAutomotive Lamp Guide – BulbAmericaamonNo ratings yet

- Wa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)Document2 pagesWa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)amonNo ratings yet

- Gsw415v 2011 (Alt.m) Acp FrameDocument4 pagesGsw415v 2011 (Alt.m) Acp FrameamonNo ratings yet

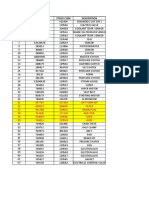

- IC Stock Inventory Control 8566 V1Document7 pagesIC Stock Inventory Control 8566 V1amonNo ratings yet

- CRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARDocument3 pagesCRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARamonNo ratings yet

- Datasheet - HK pm24024-110 4671240Document2 pagesDatasheet - HK pm24024-110 4671240amonNo ratings yet

- Sinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

- Section 2 - General: 2-8 - JLG Lift - 3121290Document1 pageSection 2 - General: 2-8 - JLG Lift - 3121290amonNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- 692734Document44 pages692734amonNo ratings yet

- Caterpillar Preventive Maintenance Products For On-Highway Engines and TransmissionsDocument3 pagesCaterpillar Preventive Maintenance Products For On-Highway Engines and Transmissionsamon100% (1)

- Volume Changes of ConcreteDocument17 pagesVolume Changes of ConcreteAljawhara AlnadiraNo ratings yet

- Manual TLDocument59 pagesManual TLSebastian OlayaNo ratings yet

- Das Consultants: Design of 1000KL Capacity OHTDocument19 pagesDas Consultants: Design of 1000KL Capacity OHTPrashant GargNo ratings yet

- Booking Report 6-23-2021Document2 pagesBooking Report 6-23-2021WCTV Digital Team0% (1)

- Possible Failure Mechanisms BabcockDocument10 pagesPossible Failure Mechanisms Babcockanh thoNo ratings yet

- Research Final OutputDocument35 pagesResearch Final Outputgersyl avilaNo ratings yet

- QC Case StudyDocument77 pagesQC Case StudyBibhudutta mishraNo ratings yet

- Cep Sop KSKDocument11 pagesCep Sop KSKSonrat100% (1)

- HydroPlus Information Website PDFDocument1 pageHydroPlus Information Website PDFTere CastellanosNo ratings yet

- LECTURE 6-Forming and Shaping of Plastics and CompositesDocument52 pagesLECTURE 6-Forming and Shaping of Plastics and CompositesM.k. VarmaNo ratings yet

- Reflective Writing 2Document4 pagesReflective Writing 2Noriel GirayNo ratings yet

- Rocks and Minerals WorksheetDocument4 pagesRocks and Minerals WorksheetPwiladNo ratings yet

- Harvard Risk Management Career OpportunityDocument7 pagesHarvard Risk Management Career OpportunityLeo Kolbert100% (1)

- 74781-Civil Degree PDFDocument14 pages74781-Civil Degree PDFCgpscAspirantNo ratings yet

- Chap 3 - Reading Essentials Nicholas CeballosDocument5 pagesChap 3 - Reading Essentials Nicholas CeballosNicholasNo ratings yet

- Integrated Pest Management in Early Care & Education ProgramsDocument46 pagesIntegrated Pest Management in Early Care & Education Programsrain hoNo ratings yet

- 14 - Manual Motor WeichaiDocument220 pages14 - Manual Motor WeichaiJoão Paulo Gobbo AugustoNo ratings yet

- Advantages and Disadvantages of Organic FarmingDocument25 pagesAdvantages and Disadvantages of Organic Farmingshankar_shrivastav018No ratings yet

- Raw Mix DesignDocument8 pagesRaw Mix DesignkazamNo ratings yet

- Clisis 14Document18 pagesClisis 14fortroniNo ratings yet

- Boilar Mounting and AccessoriesDocument44 pagesBoilar Mounting and AccessoriesSyam RajuNo ratings yet

- The Odyssey of Homer PDFDocument370 pagesThe Odyssey of Homer PDFNeha VarshneyNo ratings yet

- Siddharth Group of Institutions:: Puttur: Unit - IDocument6 pagesSiddharth Group of Institutions:: Puttur: Unit - Ikrishnareddy_chintalaNo ratings yet

- EN ISO 11064-3 - Ergonomic Design of Control Centres - Part 3: Control Room LayoutDocument4 pagesEN ISO 11064-3 - Ergonomic Design of Control Centres - Part 3: Control Room Layoutsoares_alexNo ratings yet

- 2003 - Biodiesel Production From Waste Cooking Oil - ProcessDocument16 pages2003 - Biodiesel Production From Waste Cooking Oil - ProcessKaoutar SefriouiNo ratings yet

- Jordan Hartley Health Snack Recipe E-BookDocument25 pagesJordan Hartley Health Snack Recipe E-BookMandi Lee100% (1)

- Substation Senior EngineerDocument3 pagesSubstation Senior Engineer999saitama 999No ratings yet

- The Right To Sexual Orientation, CG ProjectDocument9 pagesThe Right To Sexual Orientation, CG ProjecttanayaNo ratings yet