Professional Documents

Culture Documents

960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use of

960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use of

Uploaded by

amonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use of

960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use of

Uploaded by

amonCopyright:

Available Formats

STANDARD OPERATING PROCEDURE

Hydraulic Bead Breakers and Rams; Use of Document Number: 960C-SOP-800

Original Approval Date: FEB 03, 2010 Revision Number: 4 Page 1 of 5

Latest Revision Date: MAR 09, 2022 Next Revision Date: MAR 09, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

HYDRAULIC BEAD BREAKERS AND RAMS; USE OF

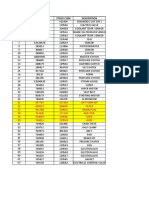

4 APP MAR 09, 2022 Approved L. Norris T. Siver T. Siver

S. Kucher / T.

3 APP DEC 18, 2015 Approved H. Lau G. Schreyer

Siver

Rev Status Rev. Date Status Description Prepared by Reviewed by Approved by

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Hydraulic Bead Breakers and Rams; Use of Document Number: 960C-SOP-800

Original Approval Date: FEB 03, 2010 Revision Number: 4 Page 2 of 5

Latest Revision Date: MAR 09, 2022 Next Revision Date: MAR 09, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

The following is a step-by-step procedure on how to complete a specific task or meet a facility specific

requirement. Standard Operating Procedures (SOPs) are written for all identified critical tasks. By virtue of the

hazard or complexity associated with critical tasks it is paramount that the SOP be followed as written. SOPs

contain a listing of high-level hazards associated with the task, for detailed hazard analysis reference the

applicable Task Hazard Assessments. SOPs do not replace the requirements contained in the company

Standards, Codes, and Processes nor does it replace the need to comply with required legislation. Section 8.0

references documentation that the worker shall understand before work commences.

1.0 PURPOSE

• To establish a Company standard to safely and effectively carry out work as it applies to ensuring the

safe use of hydraulic bead breakers and rams.

2.0 SCOPE AND APPLICATION

• This document applies to all Company Heavy Construction and Mining operations. Ensure all site-specific

requirements are being met or exceeded before performing the task.

3.0 HAZARDS AND CONTROLS

• Tool failure.

o Inspect all tools prior to task and ensure they have been calibrated as required.

o Examine bead breakers for worn parts such as puller bolt, claws and wedges. Replace if

necessary.

o Check hydraulic pumps for proper fluid levels and hose conditions prior to use.

o Ensure bead breakers are set up correctly and locked at a right-angle position to the rim. The

bead breaker clevis must be snug with the rim and both feet should be touching the side ring

flange.

o Always attach the portable air hydraulic pump to the bead breaker prior to connecting the airline

to the pump.

o Ensure hoses are OEM rated.

• Injuries caused by using bead breaker (bead breaker not seated properly and ejects from rim/wheel

assembly contacting personnel; hydraulic oil injection into body parts; hand injuries when placed near

pressurized bead breakers).

o Do not stand in line of fire or in front of bead breaker when using. Never place hands on or near

pressurized bead breakers.

o Do not hold onto pressurized bead breaker hoses; ruptured hoses can cause oil injection injuries.

o Wear hearing protection.

o Never push on flange rings near the weld in the flange. Never over pressure any spot.

o Keep work area clear of unnecessary tools and equipment.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Hydraulic Bead Breakers and Rams; Use of Document Number: 960C-SOP-800

Original Approval Date: FEB 03, 2010 Revision Number: 4 Page 3 of 5

Latest Revision Date: MAR 09, 2022 Next Revision Date: MAR 09, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

4.0 CHECKLIST

Attend all preparatory meetings (IE: daily PSI; job scope; review of JSA’s and SOP’s for the job)

Complete FLRA cards before starting the work.

Ensure all personnel involved in the task are aware of the hazards and the controls to be used, as

identified in the SOP’s; JSA’s; and FLRA’s

Conduct a pre-job inspection of all equipment to be worked on and tools to be used.

Standard of Training required for working on this job: On-the job training.

5.0 DEFINITIONS

5.1 Company

Means North American Construction Group Ltd. (NACG) and all directly or indirectly owned subsidiary

companies, including joint ventures.

5.2 Company Personnel

Includes the Company’s employees, officers, directors, agents, associates, consultants/contractors, temporary

employees and third-party processors.

5.3 HSE

Refers to the Health, Safety & Environment department

6.0 PROCEDURE

6.1 Using Bead Breaker on Five Piece Wheel

(a) Inspect bead breaker for damaged, worn or loose parts and replace, if necessary, prior to use.

(b) Inspect hydraulic pump and hoses for leaks or hose wear. Ensure hoses are OEM rated.

(c) Check fluid level in pump.

(d) Attach hose from hydraulic pump to fitting on bead breaker and tighten.

(e) Ensure bead breaker is in the fully depressurized position and install hook or adjustable screw under

step or pocket in back side of wheel or bead seat band.

(f) Slowly engage the pump activation valve until the bead breaker begins to grab the bead seat band or

wheel. Recheck for proper alignment. Release the pump and adjust bead breaker fit if necessary.

(g) Stand clear of the line of fire of the bead breaker and activate the pump incrementally until the bead

breaker is fully extended or the bead seat band or back section of wheel breaks free from the tire.

Monitor the bead breaker from a safe distance to ensure proper alignment. Reposition bead breaker

around rim until components are completely separated.

(h) If the bead breaker fully extends without breaking the bead, release the pump pressure and reposition

the bead breaker to a new location on the wheel assembly and repeat steps (e) - (g).

(i) Once bead breaks, release the pump pressure and remove the bead breaker.

6.2 Using Bead Breaker on Three Piece Wheels

(a) Complete steps (a) – (d) from Using Bead Breaker on Five Piece Wheel.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Hydraulic Bead Breakers and Rams; Use of Document Number: 960C-SOP-800

Original Approval Date: FEB 03, 2010 Revision Number: 4 Page 4 of 5

Latest Revision Date: MAR 09, 2022 Next Revision Date: MAR 09, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

(b) Ensure bead breaker is in the fully depressurized position and install wedge under the flange ring

while ensuring the claw on the bead breaker is positioned appropriately on the wheel.

(c) Hold the bead breaker in position with both hands, using your foot to operate the pump until the bead

breaker is under enough pressure to ensure the wedge and claw are properly seated.

(d) Stand clear of the line of fire of the bead breaker and activate the pump incrementally until the bead

breaker is fully extended or the bead seat band or back section of wheel breaks free from the tire.

Monitor the bead breaker from a safe distance to ensure proper alignment.

(e) If the bead breaker fully extends without breaking the bead, release the pump pressure and reposition

the bead breaker to a new location on the wheel assembly and repeat steps (b) – (d).

(f) Once the bead breaks, release the pump pressure and remove the bead breaker.

6.3 Using Hydraulic Rams (for back bead of mounted wheel/tire assembly)

(a) Inspect ram for damaged, worn, or loose parts and replace, if necessary, prior to use.

(b) Inspect hydraulic pump and hoses for leaks or hose wear. Ensure hoses are OEM rated.

(c) Check fluid level in pump.

(d) Attach hose from hydraulic pump to fitting on ram and tighten.

(e) Ensure ram is in the fully depressurized position.

(f) Connect airline to pump.

(g) Position the ram against a strong section on the frame of the vehicle adjacent to the flange ring of the

wheel assembly under repair.

(h) Hold the ram in position with both hands and operate the pump with your foot until the ram contacts

the flange ring and there is enough pressure to hold the ram in place.

(i) Stand clear of the line of fire of the ram and activate the pump incrementally until the bead breaks or

the ram is fully extended.

(j) If the ram fully extends without breaking the bead, release the pump pressure and reposition the ram

in a new location on the flange ring. Repeat steps (g) – (i) until bead breaks.

(k) Once the bead breaks, release the pressure on the pump and remove the ram.

7.0 NOTES

If this task is to be done by a method different than described in this SOP, the work must STOP, and the alternate

method must be DOCUMENTED with an adequate hazard assessment tool such as a JSA. The document must

be APPROVED by a supervisor before such procedures are implemented.

8.0 REFERENCES

• Alberta Occupational Health and Safety Act, Regulation and Code – Part 12, Section 193, Tire Servicing

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Hydraulic Bead Breakers and Rams; Use of Document Number: 960C-SOP-800

Original Approval Date: FEB 03, 2010 Revision Number: 4 Page 5 of 5

Latest Revision Date: MAR 09, 2022 Next Revision Date: MAR 09, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

• Alberta Occupational Health and Safety Act, Regulation and Code – Part 14, Sections 208 & 209, Lifting

and Handling Loads

• Tire Industry Association Earth Mover Tire Service Training Program

• 960C-SOP-824 Torquing of Tire-Wheel Assemblies

• 960C-SOP-504 Hand Tools; Use of

• 950C-C-028 Hazardous Energy Isolation Code

9.0 APPENDICES

• No appendices.

Form 999C-F-003_Rev2 Aug 16, 2016

You might also like

- Numerology Personality Decoder - Marijan Orbovic PDFDocument44 pagesNumerology Personality Decoder - Marijan Orbovic PDFMarijan OrbovicNo ratings yet

- Sop For Set Up & Operation of Concrete PumpDocument3 pagesSop For Set Up & Operation of Concrete Pumplelu ojhaNo ratings yet

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Booty by Bret Month 63Document16 pagesBooty by Bret Month 63moniquesmith90100% (2)

- Lashes PDFDocument7 pagesLashes PDFsamanthaNo ratings yet

- PARTS LIST FOR MANITOU MT 1840 SERIES (00000002)Document3 pagesPARTS LIST FOR MANITOU MT 1840 SERIES (00000002)amonNo ratings yet

- Greenlee Pipe and Tube Bender 782 IM823REV08Document18 pagesGreenlee Pipe and Tube Bender 782 IM823REV08Leonard100% (1)

- Plunger Pump ManualDocument23 pagesPlunger Pump Manualgovindharajalu75% (4)

- CementumDocument47 pagesCementumpratikl12345No ratings yet

- 960C-SOP-112-R2 - Compressed Air and Air Hoses_2022-04-10Document5 pages960C-SOP-112-R2 - Compressed Air and Air Hoses_2022-04-10amonNo ratings yet

- 960C-SOP-502-R2 - Safe use of Grinders_2022-04-04Document10 pages960C-SOP-502-R2 - Safe use of Grinders_2022-04-04amonNo ratings yet

- POSITIVECHOKEMANUALDocument11 pagesPOSITIVECHOKEMANUALsambhajiNo ratings yet

- Work Instruction: General Overhauling of Centrifugal Pump OSCS-IMS-WI - 020Document8 pagesWork Instruction: General Overhauling of Centrifugal Pump OSCS-IMS-WI - 020MahmoudNo ratings yet

- Hydraulic Cylinder & Servomotor: Hydrosystems Pvt. LTDDocument6 pagesHydraulic Cylinder & Servomotor: Hydrosystems Pvt. LTDPratik MoreNo ratings yet

- 960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06Document4 pages960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06amonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- Ump Fan-Air Om Manual - Rev Dec 2014Document12 pagesUmp Fan-Air Om Manual - Rev Dec 2014api-252481722No ratings yet

- Single Acting, Low Profile Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIDocument8 pagesSingle Acting, Low Profile Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSITitanplyNo ratings yet

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- Bhr240n Iom Rev 0Document60 pagesBhr240n Iom Rev 0Saipavan ChanduNo ratings yet

- 6-Mobile Crane inspection-FO-GL-HAL-HSE-0420BDocument2 pages6-Mobile Crane inspection-FO-GL-HAL-HSE-0420BMonaya Djank'aNo ratings yet

- Booster Pump Agiba PDFDocument518 pagesBooster Pump Agiba PDFhamadaNo ratings yet

- Foot ValveDocument12 pagesFoot ValvesusphedNo ratings yet

- MS For Installation - Hypochlorination 23.10.07 HamdyDocument8 pagesMS For Installation - Hypochlorination 23.10.07 HamdyunnicyriacNo ratings yet

- Method Statement For Gravel Surfacing Around New Lift Station IW-10ADocument6 pagesMethod Statement For Gravel Surfacing Around New Lift Station IW-10ANazirNo ratings yet

- Greenlee Dobladora de TubosDocument16 pagesGreenlee Dobladora de TuboswilfredoNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- 960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26Document6 pages960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26amonNo ratings yet

- IOM - iHTDocument50 pagesIOM - iHTkarun agrawalNo ratings yet

- Float Valve Operational GuidelinesDocument13 pagesFloat Valve Operational GuidelinesAzriel Naufal Fadilah100% (1)

- Installation Manual SKC Series Pump-1Document26 pagesInstallation Manual SKC Series Pump-1Huraira AliNo ratings yet

- BVA H Series Manual 55 & 100 Ton ModelsDocument12 pagesBVA H Series Manual 55 & 100 Ton ModelsTitanplyNo ratings yet

- PROCEDURE BOLT TIGHTENING - Rev0Document15 pagesPROCEDURE BOLT TIGHTENING - Rev0DanielLeeNo ratings yet

- 23-019 Installation Procedures Mechanical WtemplateDocument7 pages23-019 Installation Procedures Mechanical WtemplateAli Khalid QureshiNo ratings yet

- Axial Split Volute Case PumpsDocument21 pagesAxial Split Volute Case Pumpshardik sakariya100% (1)

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- W SER 0502 AD Manual Flange Torque TighteningDocument8 pagesW SER 0502 AD Manual Flange Torque TighteningAnonymous IJBjI0No ratings yet

- Nto 01 CDocument11 pagesNto 01 CubermonzonNo ratings yet

- GDN 218Document25 pagesGDN 218Vasant Kumar Varma100% (1)

- Bomba PattersonDocument26 pagesBomba PattersonJorge Inostroza100% (1)

- Pipe Bend Procedure SA-4200-70621Document7 pagesPipe Bend Procedure SA-4200-70621mohd as shahiddin jafri100% (1)

- Fiberstrong Wavistrong Flange GuideDocument52 pagesFiberstrong Wavistrong Flange Guidemuhammedemraan100% (1)

- Rotary Air Blower RM450 WCTRDocument39 pagesRotary Air Blower RM450 WCTRShahNo ratings yet

- Chapter (4) Pump InstallationDocument21 pagesChapter (4) Pump Installationkarioke mohaNo ratings yet

- 960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06Document9 pages960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06amonNo ratings yet

- Pneumatic Slide GateDocument7 pagesPneumatic Slide Gateemad sabriNo ratings yet

- JC 2648 Seal IOM Manual PDFDocument4 pagesJC 2648 Seal IOM Manual PDFRené Mora-CasalNo ratings yet

- RP 205Document30 pagesRP 205Vasant Kumar VarmaNo ratings yet

- Mos-Replacement Gasket For PP Piping - 2024Document6 pagesMos-Replacement Gasket For PP Piping - 2024habibullah.centroironNo ratings yet

- Machine Test ProcedureDocument69 pagesMachine Test ProcedurekbldamNo ratings yet

- Operation Manual: & Parts ListDocument62 pagesOperation Manual: & Parts ListanggieNo ratings yet

- Single Acting, Pull Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIDocument8 pagesSingle Acting, Pull Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSITitanplyNo ratings yet

- Rotating Equipment Installation ProcedureDocument2 pagesRotating Equipment Installation ProcedureathithancapeNo ratings yet

- OPS019 Rig-Up & Instalation of Coiled Tubing Lift Frame & Injector HeadDocument8 pagesOPS019 Rig-Up & Instalation of Coiled Tubing Lift Frame & Injector HeadsamanNo ratings yet

- Torque Value PDFDocument8 pagesTorque Value PDF7761430No ratings yet

- Operation and Maintenance Instructions: Outside Collar Hydraulic Nut HNOC-C064-3600Document0 pagesOperation and Maintenance Instructions: Outside Collar Hydraulic Nut HNOC-C064-3600LoveNo ratings yet

- Skimming Job GeneralDocument5 pagesSkimming Job Generalvishal bailurNo ratings yet

- Operation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyDocument25 pagesOperation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyvaisakhpillaiNo ratings yet

- Sidetie B SeriesDocument36 pagesSidetie B Seriesnadeem4ahmed-805026No ratings yet

- MJR For 30M Maintenance Check of Check ValvesDocument9 pagesMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Warning: Inspection, Testing, Preventive Maintenance and Special Operating Instructions For Planetary HoistsDocument8 pagesWarning: Inspection, Testing, Preventive Maintenance and Special Operating Instructions For Planetary HoistsPedro RiveraNo ratings yet

- Braden - Service BulletinDocument5 pagesBraden - Service BulletinRafael MonteiroNo ratings yet

- MOS-09-Generator Set Installation-Rev-0 (05, Jan)Document42 pagesMOS-09-Generator Set Installation-Rev-0 (05, Jan)Muhammad IrfanNo ratings yet

- Instruction and Maintenance Manual: IndexDocument11 pagesInstruction and Maintenance Manual: IndexskodgeNo ratings yet

- maintenance-210502124530 (3)Document17 pagesmaintenance-210502124530 (3)amonNo ratings yet

- Noblelft FD20-35 Operation & Maintenance ManualDocument176 pagesNoblelft FD20-35 Operation & Maintenance ManualamonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- PT Parts - VBeltsDocument25 pagesPT Parts - VBeltsamonNo ratings yet

- Automotive Lamp Guide – BulbAmericaDocument1 pageAutomotive Lamp Guide – BulbAmericaamonNo ratings yet

- Wa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)Document2 pagesWa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)amonNo ratings yet

- Gsw415v 2011 (Alt.m) Acp FrameDocument4 pagesGsw415v 2011 (Alt.m) Acp FrameamonNo ratings yet

- IC Stock Inventory Control 8566 V1Document7 pagesIC Stock Inventory Control 8566 V1amonNo ratings yet

- CRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARDocument3 pagesCRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARamonNo ratings yet

- Datasheet - HK pm24024-110 4671240Document2 pagesDatasheet - HK pm24024-110 4671240amonNo ratings yet

- Sinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

- Section 2 - General: 2-8 - JLG Lift - 3121290Document1 pageSection 2 - General: 2-8 - JLG Lift - 3121290amonNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- 692734Document44 pages692734amonNo ratings yet

- Caterpillar Preventive Maintenance Products For On-Highway Engines and TransmissionsDocument3 pagesCaterpillar Preventive Maintenance Products For On-Highway Engines and Transmissionsamon100% (1)

- Prospectus - 2022 Admission: M. Phil Course in Clinical Epidemiology (Part-Time) CourseDocument5 pagesProspectus - 2022 Admission: M. Phil Course in Clinical Epidemiology (Part-Time) CourseDr.Minu C MathewsNo ratings yet

- Nigeria Country Profile - 0Document4 pagesNigeria Country Profile - 0Nden SohbutNo ratings yet

- Body Composition Physical Fitness PhysicDocument8 pagesBody Composition Physical Fitness PhysicsunnybeaNo ratings yet

- CBT WorkbookDocument5 pagesCBT WorkbookninoNo ratings yet

- Fulltext01 PDFDocument90 pagesFulltext01 PDFBrenda Sequeiros AyllónNo ratings yet

- Artificial Intelligence For Blood AnalysisDocument14 pagesArtificial Intelligence For Blood AnalysisKIPNGENO EMMANUELNo ratings yet

- Notes On CommunicationDocument8 pagesNotes On CommunicationSWAPNIL MISHRANo ratings yet

- Curriculum Committee LetterDocument2 pagesCurriculum Committee Letterariana villarrealNo ratings yet

- 005-Line British Paints Exterior Varnish Gloss: Safety Data SheetDocument9 pages005-Line British Paints Exterior Varnish Gloss: Safety Data SheetLaura SalmonteNo ratings yet

- Residual Ridge Resorption in Complete Denture WearersDocument5 pagesResidual Ridge Resorption in Complete Denture WearersFiru LgsNo ratings yet

- Recommendation: Osteoporosis To Prevent Fractures: Screening - United States Preventive Services TaskforceDocument22 pagesRecommendation: Osteoporosis To Prevent Fractures: Screening - United States Preventive Services TaskforceNonoy JoyaNo ratings yet

- The Hollow of Three Hills NotesDocument4 pagesThe Hollow of Three Hills NotesMNo ratings yet

- Eye Tracking Metrics To Screen and Assess Cognitive Impairment in Patients With Neurological DisordersDocument8 pagesEye Tracking Metrics To Screen and Assess Cognitive Impairment in Patients With Neurological DisordersSyed Abdul Qadir GilaniNo ratings yet

- Aranda, Law - 2007 - Tales of Sociology and The Nursing Curriculum Revisiting The DebatesDocument7 pagesAranda, Law - 2007 - Tales of Sociology and The Nursing Curriculum Revisiting The DebatesaliaNo ratings yet

- MCQs On Employees Provident Fund & Miscellaneous Provisions Act 1952Document4 pagesMCQs On Employees Provident Fund & Miscellaneous Provisions Act 1952sandeep kumarNo ratings yet

- Proposal Business PlanDocument13 pagesProposal Business PlanM Yusuf MaulanaNo ratings yet

- BORLAND Douglas Infuluenza PDFDocument18 pagesBORLAND Douglas Infuluenza PDFJxson GomezNo ratings yet

- SBM Accomplishment ReportDocument17 pagesSBM Accomplishment ReportCarmela SalvadorNo ratings yet

- Jeffrey DahmerDocument3 pagesJeffrey DahmerAMERICA DAYANA PORTILLO FIERRONo ratings yet

- NCP-post-op 2Document2 pagesNCP-post-op 2Eyanah Delos ReyesNo ratings yet

- Dr. A. SAMHARI BASWEDAN, MPA SwissBelInn Desember 2015Document36 pagesDr. A. SAMHARI BASWEDAN, MPA SwissBelInn Desember 2015Arfiana TalitaNo ratings yet

- 102 - SCO8048A-Alert - Fixings-FinalDocument3 pages102 - SCO8048A-Alert - Fixings-FinalO SNo ratings yet

- Dogs Make Better Companions Than CatsDocument2 pagesDogs Make Better Companions Than CatsJonabel AlinsootNo ratings yet

- Salinan ISO 14155 - 2020Document31 pagesSalinan ISO 14155 - 2020regulatory ransNo ratings yet

- Week 14. Spinal Cord InjuryDocument1 pageWeek 14. Spinal Cord InjuryMary Joy RoqueNo ratings yet

- Healthcare Provider Letter To Mag: Rescind Endorsement of Rich Mccormick, MDDocument7 pagesHealthcare Provider Letter To Mag: Rescind Endorsement of Rich Mccormick, MDPeter M. HeimlichNo ratings yet