Professional Documents

Culture Documents

960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26

960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26

Uploaded by

amonCopyright:

Available Formats

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Ansi A10 - 12Document49 pagesAnsi A10 - 12RonaldVictorLazaroTacoNo ratings yet

- Lifting Tools & TacklesDocument44 pagesLifting Tools & Tacklesbalajirajasekaran100% (2)

- Non Complex Method Statement For OffloadingDocument5 pagesNon Complex Method Statement For OffloadingDaniel Cryer100% (1)

- Estimatingcalculation MalaysiaDocument136 pagesEstimatingcalculation MalaysiaAbdulBari100% (1)

- PARTS LIST FOR MANITOU MT 1840 SERIES (00000002)Document3 pagesPARTS LIST FOR MANITOU MT 1840 SERIES (00000002)amonNo ratings yet

- SUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDocument17 pagesSUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDavid O'BrienNo ratings yet

- MCBU - Lifting & Rigging Questions and AnswersDocument15 pagesMCBU - Lifting & Rigging Questions and AnswersBhaiJan59No ratings yet

- Lifting PlanDocument66 pagesLifting Planklibi100% (7)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- 5810 ManualDocument50 pages5810 ManualkrmchariNo ratings yet

- QTZ125 (6018) EnglishDocument72 pagesQTZ125 (6018) Englishivansuryawan94100% (2)

- Construction Cost MonitoringDocument13 pagesConstruction Cost MonitoringOng George Sammy100% (1)

- Demag - Jib CranesDocument22 pagesDemag - Jib CranesGogyNo ratings yet

- 960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06Document9 pages960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06amonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- Dynamic Compaction Operation Safety Training - ECTDocument4 pagesDynamic Compaction Operation Safety Training - ECTgayanNo ratings yet

- Crane and Rigging OperationDocument94 pagesCrane and Rigging OperationJust singingNo ratings yet

- 960C-SOP-006-R4_Safe Use of Ladders and Stairs_2022-06-06Document12 pages960C-SOP-006-R4_Safe Use of Ladders and Stairs_2022-06-06amonNo ratings yet

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pages9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- Material Handling Equipment Test Method Rev. 2 (Dood)Document8 pagesMaterial Handling Equipment Test Method Rev. 2 (Dood)ThomasNo ratings yet

- Safe Work Practices - CraneDocument22 pagesSafe Work Practices - CranepentianNo ratings yet

- Crane and Rigging Policy: Potential Fatal Risks PolicyDocument3 pagesCrane and Rigging Policy: Potential Fatal Risks PolicyAlex Sandro Borges PereiraNo ratings yet

- 960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06Document4 pages960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06amonNo ratings yet

- 6.1.6 Loading and Unloading When Using Load CarriersDocument37 pages6.1.6 Loading and Unloading When Using Load Carriersmirano81No ratings yet

- Care & Use Assembly Instructions: Gantry CranesDocument12 pagesCare & Use Assembly Instructions: Gantry CranesThein MaungNo ratings yet

- DCA-FRM-MATL-016 R1 Forklift Operator Evaluation FormDocument3 pagesDCA-FRM-MATL-016 R1 Forklift Operator Evaluation FormchoadleyNo ratings yet

- Crane SafetyDocument4 pagesCrane SafetyUsman MinhasNo ratings yet

- Safe Work Method Statement PDFDocument6 pagesSafe Work Method Statement PDFsuli permita100% (1)

- Health and Safety FCX-HS32Document8 pagesHealth and Safety FCX-HS32berry trisnamuktiNo ratings yet

- SWP 04 Lifting OperationDocument4 pagesSWP 04 Lifting Operationমমিন মানবNo ratings yet

- Cranes Hoists Truck CranesDocument26 pagesCranes Hoists Truck Cranesrajesh_jeev100% (1)

- Lifting Plan Checklist and Method Statement SkeletonDocument7 pagesLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesNo ratings yet

- Course Material For Rigger-Latest - Final CHVR 2010Document138 pagesCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- Lifting Procedure and PlanDocument7 pagesLifting Procedure and PlanEngr Muslim KhanNo ratings yet

- 962C-SOP-002-R3 - Dump Stockpile ManagementDocument7 pages962C-SOP-002-R3 - Dump Stockpile ManagementAmsal SinagaNo ratings yet

- Lifting Plan AgcDocument8 pagesLifting Plan Agcragesh p rNo ratings yet

- SAFETY ALERT 2019 - OCT - CRANE IncidentDocument2 pagesSAFETY ALERT 2019 - OCT - CRANE Incidentvikrant911No ratings yet

- Craneblock WulDocument2 pagesCraneblock WulZachNo ratings yet

- 960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use ofDocument5 pages960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use ofamonNo ratings yet

- Lifting OperationDocument6 pagesLifting OperationOchulor IsaacNo ratings yet

- General Lifting MethodDocument3 pagesGeneral Lifting MethodNaukhez A. KashifNo ratings yet

- Crane OperationDocument2 pagesCrane OperationnoniebellNo ratings yet

- Ehv SWP Form SpaceringDocument3 pagesEhv SWP Form SpaceringSn AhsanNo ratings yet

- SOP 13 Slew Crane OperationsDocument6 pagesSOP 13 Slew Crane OperationsakhmadbayNo ratings yet

- Lifting Procedure PDFDocument25 pagesLifting Procedure PDFAhmad Husnul MutaqinNo ratings yet

- 1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForDocument6 pages1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForAnwar MohamedNo ratings yet

- RT09 Forward Tipping DumperDocument5 pagesRT09 Forward Tipping DumperDuncanNo ratings yet

- Safe LiftingDocument22 pagesSafe LiftingMahmoud Abdallah67% (3)

- Fassi Crane: Use and MaintenanceDocument55 pagesFassi Crane: Use and MaintenanceJaime Sua100% (1)

- Slewing Jib Cranes SI 18.3Document2 pagesSlewing Jib Cranes SI 18.3reda mesbahNo ratings yet

- HHB 58CFR SWP-4 Lifting Equipment, Appliances & GearsDocument5 pagesHHB 58CFR SWP-4 Lifting Equipment, Appliances & GearsSelwyn GohNo ratings yet

- RT60 Mobile CraneDocument6 pagesRT60 Mobile CraneNithin DevNo ratings yet

- Cranes and Lifting GearDocument3 pagesCranes and Lifting GearSundar_1975No ratings yet

- Liftingoperationsafetyppt 230220111908 487c851eDocument39 pagesLiftingoperationsafetyppt 230220111908 487c851emamuNo ratings yet

- Procedure For Instalattion of VesselDocument6 pagesProcedure For Instalattion of Vesselyayan hNo ratings yet

- HASCO Crane and Lifting Campaign July 2022Document18 pagesHASCO Crane and Lifting Campaign July 2022shahid052No ratings yet

- Erection Method Statement - Birla White (Gotan)Document15 pagesErection Method Statement - Birla White (Gotan)SEPL SEPLNo ratings yet

- Mobile Gantries SI 20.3Document2 pagesMobile Gantries SI 20.3reda mesbahNo ratings yet

- CAREC Road Safety Engineering Manual 2: Safer Road WorksFrom EverandCAREC Road Safety Engineering Manual 2: Safer Road WorksNo ratings yet

- maintenance-210502124530 (3)Document17 pagesmaintenance-210502124530 (3)amonNo ratings yet

- Noblelft FD20-35 Operation & Maintenance ManualDocument176 pagesNoblelft FD20-35 Operation & Maintenance ManualamonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- PT Parts - VBeltsDocument25 pagesPT Parts - VBeltsamonNo ratings yet

- Automotive Lamp Guide – BulbAmericaDocument1 pageAutomotive Lamp Guide – BulbAmericaamonNo ratings yet

- Wa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)Document2 pagesWa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)amonNo ratings yet

- Gsw415v 2011 (Alt.m) Acp FrameDocument4 pagesGsw415v 2011 (Alt.m) Acp FrameamonNo ratings yet

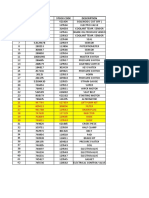

- IC Stock Inventory Control 8566 V1Document7 pagesIC Stock Inventory Control 8566 V1amonNo ratings yet

- CRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARDocument3 pagesCRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARamonNo ratings yet

- Datasheet - HK pm24024-110 4671240Document2 pagesDatasheet - HK pm24024-110 4671240amonNo ratings yet

- Sinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

- Section 2 - General: 2-8 - JLG Lift - 3121290Document1 pageSection 2 - General: 2-8 - JLG Lift - 3121290amonNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- 692734Document44 pages692734amonNo ratings yet

- Caterpillar Preventive Maintenance Products For On-Highway Engines and TransmissionsDocument3 pagesCaterpillar Preventive Maintenance Products For On-Highway Engines and Transmissionsamon100% (1)

- Bhushan Power & Steel Ltd.Document17 pagesBhushan Power & Steel Ltd.navdeeplakheraNo ratings yet

- Condition Assessment of Water Control Gates Task Committee of The Hydropower Technical Committee of The Energy Division of ASCE (2012) PDFDocument406 pagesCondition Assessment of Water Control Gates Task Committee of The Hydropower Technical Committee of The Energy Division of ASCE (2012) PDFDimitar100% (1)

- Group 4 Removal and Installation: 1. ForksDocument9 pagesGroup 4 Removal and Installation: 1. ForksBaciu NicolaeNo ratings yet

- Wire Rope Hoist AustrDocument11 pagesWire Rope Hoist AustrJESUSCALVILLONo ratings yet

- Crosby Lifting ClampsDocument18 pagesCrosby Lifting ClampsBaihaki StNo ratings yet

- Konecranes Industrial Cranes 2018 PDFDocument25 pagesKonecranes Industrial Cranes 2018 PDFChen QingNo ratings yet

- Pivot ProDocument20 pagesPivot Proaiyubi2No ratings yet

- ER2 Manual 125kg 5t - 04Document144 pagesER2 Manual 125kg 5t - 04Muhammed ShamseerNo ratings yet

- Angle-Of-Lift (Tension Increase, Reduced Capacity)Document1 pageAngle-Of-Lift (Tension Increase, Reduced Capacity)Mohamed HadjkacemNo ratings yet

- 1 Technical Specification For ERSDocument16 pages1 Technical Specification For ERSipraoNo ratings yet

- As 1418.7-1999 Cranes (Including Hoists and Winches) - Builders' Hoists and Associated EquipmentDocument50 pagesAs 1418.7-1999 Cranes (Including Hoists and Winches) - Builders' Hoists and Associated Equipmentfovod74255No ratings yet

- 40tonx58 Span-CraneDocument7 pages40tonx58 Span-CraneKoresh KhalpariNo ratings yet

- Straight Lifting MonorailDocument4 pagesStraight Lifting MonorailMahesh SavandappaNo ratings yet

- MUSE ED Elevator: Installation ManualDocument16 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Steel Body - Lever Hoists: A e B A e B A e BDocument1 pageSteel Body - Lever Hoists: A e B A e B A e BtylerlhsmithNo ratings yet

- Company Introduction EBM 2021Document16 pagesCompany Introduction EBM 2021putramahandhikaNo ratings yet

- Factories ActDocument120 pagesFactories ActCefi JohnNo ratings yet

- Yale KELC YL1006 0107Document2 pagesYale KELC YL1006 0107Sarah PerezNo ratings yet

- Ch165a 25120 01Document8 pagesCh165a 25120 01surya jaya bearingNo ratings yet

- Safe Working Load CalculationsDocument3 pagesSafe Working Load CalculationsShanAlanNo ratings yet

- Yale HoistDocument94 pagesYale Hoistjohn_tigerNo ratings yet

- Pedestal Crane SpecDocument21 pagesPedestal Crane SpecYinka Akinkunmi100% (1)

- Norms and Standards For Sizing and Calculation of A Coke Cutting System Paul Ruhrpumpen DCU Dusseldorf 2011Document39 pagesNorms and Standards For Sizing and Calculation of A Coke Cutting System Paul Ruhrpumpen DCU Dusseldorf 2011최승원100% (1)

- Chain Hoist PDFDocument12 pagesChain Hoist PDFAnton HariwangsaNo ratings yet

960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26

960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26

Uploaded by

amonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26

960C-SOP-407-R2 - Crane Operation-Rubber Tire Gantry Crane_2022-05-26

Uploaded by

amonCopyright:

Available Formats

STANDARD OPERATING PROCEDURE

Crane Operation – Rubber Tire Gantry Crane Document Number: 960C-SOP-407

Original Approval Date: Apr 09, 2018 Revision Number: 2 Page 1 of 6

Latest Revision Date: May 26, 2022 Next Revision Date: May 26, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

CRANE OPERATION – RUBBER TIRE GANTRY CRANE

2 APP May 26, 2022 Approved Tammy Siver

1 APP Apr 09, 2018 Approved T. Siver P. Judge S. Miller

Rev Status Rev. Date Status Description Prepared by Reviewed by Approved by

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Crane Operation – Rubber Tire Gantry Crane Document Number: 960C-SOP-407

Original Approval Date: Apr 09, 2018 Revision Number: 2 Page 2 of 6

Latest Revision Date: May 26, 2022 Next Revision Date: May 26, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

The following is a step-by-step procedure on how to complete a specific task or meet a facility specific

requirement. Standard Operating Procedures (SOPs) are written for all identified critical tasks. By virtue of the

hazard or complexity associated with critical tasks it is paramount that the SOP be followed as written. SOPs

contain a listing of high-level hazards associated with the task, for detailed hazard analysis reference the

applicable Task Hazard Assessments. SOPs do not replace the requirements contained in the company

Standards, Codes, and Processes nor does it replace the need to comply with required legislation. Section 8.0

references documentation that the worker shall understand before work commences.

1.0 PURPOSE

• To establish a North American Construction Group Standard to safely and effectively carry out work as it

applies to using a Rubber Tire Gantry Crane.

2.0 SCOPE AND APPLICATION

• This document applies to all NACG Heavy Construction and Mining operations. Ensure all site specific

requirements are being met or exceeded before performing the task.

3.0 HAZARDS AND CONTROLS

• Unstable loads causing crane upset or damage.

o Never lift a load using only the rear or front hoists. Always support the load between the front and

rear hoists and distribute the load equally between the hoists.

o Ensure gantry crane is set up on relatively firm, level ground. Where possible use concrete,

asphalt or hard-packed gravel. A firm, well graded pad is sufficient as well.

o Line up trolley with centre markers on bridge when lifting the load.

• Loads and or crane and rigging components shifting or swinging while crane is travelling.

o Avoid sudden stops and quick starts. Operate all controls in a slow and steady manner.

o Use the low speed range when transporting loads.

o Ensure bridge and spreader bar are fully retracted into support saddles and centered on bridge if

travelling without a load. Rigging cannot be attached when travelling.

• Loads exceeding lifting capacity of cranes.

o Do not attempt to hoist a load if it is beyond the capacity of the machine. Confirm rated load

capacity on the machine’s identification plate.

o Use the load indicator device to confirm the load is within lifting limits.

o Do not shock load the machine. If the machine or its components have been shock loaded, it

must be removed from service until such time that it has been inspected by a qualified person

and re-certified for lifting.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Crane Operation – Rubber Tire Gantry Crane Document Number: 960C-SOP-407

Original Approval Date: Apr 09, 2018 Revision Number: 2 Page 3 of 6

Latest Revision Date: May 26, 2022 Next Revision Date: May 26, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

• Contact between crane and objects or personnel when crane is travelling.

o Inspect travel route before moving crane to ensure there is adequate room and that the path is

firm and level.

o Use spotters; ensure primary spotter is identified with reflective arm band. Review hand and

communication signals with all personnel before the task.

o Use lighting plants as required for extra visibility.

o Ground personnel are not permitted under trolleys while crane is travelling and must stay out of

the line of travel.

o Ground personnel are not permitted under suspended load.

o Ensure load is lifted high enough to avoid contacting ground when travelling. Take into

consideration elevation changes.

• Improper operation of crane.

o Only trained, competent personnel are permitted to operate the gantry crane.

o Do not drag a load. All loads must be lifted and carried.

o When picking a load, ensure both wire ropes are in the vertical position. Do not place both hooks

at the centre of a load; use a spreader bar as required to ensure centre of gravity is maintained.

o Do not push or tow the gantry crane while it is under load.

o Do not drive the gantry crane up an incline.

o Do not use erratic or jerky movements when raising or lowering loads as this can break or

damage hoist components.

o Do not raise or lower more that 25% of the rated load in high speed.

• Falling while mounting or dismounting crane.

o Always use 4x3 contact when mounting or dismounting the crane.

o Do not carry anything while mounting or dismounting.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Crane Operation – Rubber Tire Gantry Crane Document Number: 960C-SOP-407

Original Approval Date: Apr 09, 2018 Revision Number: 2 Page 4 of 6

Latest Revision Date: May 26, 2022 Next Revision Date: May 26, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

• Inadequate or improper set up of rigging.

o Inspect rigging, shackles, slings and lift pins; remove damaged or defective equipment.

o Ensure rigging, shackles and slings are sufficient for the load being lifted.

o Use softeners when slings are connected to sharp edges.

o Make sure all pins and connections are secure before lifting.

o Set rigging to proper spreader bar holes to safely maintain correct angle of sling to load being

lifted. Follow lift plan.

• Pinch points and hand injuries when setting up rigging.

o Wear gloves while handling rigging. Do not put fingers or hands between slings and lifting

lugs/shackles.

• Unauthorized personnel in work area.

o Flag or barricade the work area to ensure unauthorized personnel do not enter the area.

o Only required personnel working on the task are permitted in the area.

o No personnel are permitted under a suspended load.

• Contact with overhead hazards.

o Inspect travel route before travelling with crane and ensure the crane can maintain a safe

distance from powerlines and other overhead hazards.

• Unplanned or unintentional movement of crane.

o Use wheel chocks on gantry crane when not in use and when crane is stationary while workers

are setting up rigging.

o Ensure parking brake is applied when crane is stationary or parked.

4.0 CHECKLIST

Attend all preparatory meetings (IE: daily PSI; job scope; review of JSA’s and SOP’s for the job)

Complete FLRA cards before starting the work.

Ensure all personnel involved in the task are aware of the hazards and the controls to be used, as

identified in the SOP’s; JSA’s; and FLRA’s.

Conduct a pre-job inspection of all equipment to be worked on and tools to be used.

Standard of Training required for working on this job: On-the job training.

5.0 DEFINITIONS

5.1 Company

Means North American Construction Group Ltd. (NACG) and all directly or indirectly owned subsidiary

companies, including joint ventures.

5.2 Company Personnel

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Crane Operation – Rubber Tire Gantry Crane Document Number: 960C-SOP-407

Original Approval Date: Apr 09, 2018 Revision Number: 2 Page 5 of 6

Latest Revision Date: May 26, 2022 Next Revision Date: May 26, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

Includes the Company’s employees, officers, directors, agents, associates, consultants/contractors, temporary

employees and third-party processors.

5.3 HSE

Refers to the Health, Safety & Environment department.

5.4 Gantry Crane

A bridge crane in which the beam or bridge is carried at each end by a trestle that travels on tracks on the ground.

5.5 Shock Load

With respect to a lifting device or its components, a sudden application of force or release of load. Any shock load

requires the lifting device to be removed from service and re-certified for further lifting applications.

6.0 PROCEDURE

1) Prepare lift plan for the two (2) crane lift if using the gantry crane for a lift. Review JSA for task and

complete FLRA.

2) Inspect rigging and ensure it is adequate size for task. Remove all damaged or defective rigging.

Confirm load weights.

3) Inspect travel route (if travelling with crane) and ensure the ground is firm, level and free from

obstacles. Confirm there are no overhead hazards or powerlines. Ensure there is a minimum of 40

feet width clearance to allow safe travel of crane.

4) Complete pre use inspection and walk around. Observe tires, cables, sheaves and drums as well as

leaks or loose/missing/broken parts. Check to make sure emergency stop buttons are not pressed in

and that wheels have been aligned. Document inspection in gantry crane logbook.

5) Use 4x3 contact to mount or dismount the gantry crane. Do not have anything in hands.

6) Fasten seatbelt and ensure parking brake is engaged. Sound horn, wait 5 seconds then start

machine. Allow 2-3 minute warm-up period at low idle before applying load. Test steering, brakes and

machine operation.

7) Using spotter(s), align crane with load being lifted. Ensure trolley has been lined up with centre

markers on bridge. Once aligned, park crane and apply wheel chocks.

8) Attach rigging to load following JSA and lift plan specific to load being lifted.

9) Clear area of ground personnel; ensure no one is within trolleys or travel path of crane.

10) Using the load indicator display panel, confirm load is within machine limits. Select hoist speed and

begin to raise load. Do not raise more than 25% of rated load in high speed. Both front and read

hoists can be operated simultaneously or one at a time. Raise load high enough for the task.

Form 999C-F-003_Rev2 Aug 16, 2016

STANDARD OPERATING PROCEDURE

Crane Operation – Rubber Tire Gantry Crane Document Number: 960C-SOP-407

Original Approval Date: Apr 09, 2018 Revision Number: 2 Page 6 of 6

Latest Revision Date: May 26, 2022 Next Revision Date: May 26, 2025 Document Approval Level: 4

*This document is not controlled if printed.*

11) Confirm trolleys are still aligned with centre markers on bridge. Set engine throttle to ¾ to full throttle.

Confirm ground personnel are not in travel path. Sound horn once for travelling forward and twice for

travelling in reverse. Release park brake and using controlled, slow movements begin travelling crane

in forward or reverse to designated location. Ensure constant communication with primary spotter.

Crane must stop if sight of primary spotter is lost at any time.

12) Once at designated location, stop crane and set park brake. Ground personnel will install wheel

chocks. Using spotters, lower load onto designated location and remove rigging.

13) Ensure bridge and spreader bar are fully retracted into support saddles and centered on bridge

before moving if travelling without a load. Rigging must be removed before travelling.

7.0 NOTES

If this task is to be done by a method different than described in this SOP, the work must STOP and the alternate

method must be DOCUMENTED with an adequate hazard assessment tool such as a JSA. The document must

be APPROVED by a supervisor before such procedures are implemented.

8.0 REFERENCES

• Alberta Occupational Health and Safety Act, Regulation and Code – {Part 6, Cranes, Hoists and Lifting

Devices}

• 950C-C-008 Cranes, Hoists and Rigging Code

• 960C-SOP-403 Crane Operation – Shop Bridge Type

9.0 APPENDICES

No appendices.

Form 999C-F-003_Rev2 Aug 16, 2016

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Ansi A10 - 12Document49 pagesAnsi A10 - 12RonaldVictorLazaroTacoNo ratings yet

- Lifting Tools & TacklesDocument44 pagesLifting Tools & Tacklesbalajirajasekaran100% (2)

- Non Complex Method Statement For OffloadingDocument5 pagesNon Complex Method Statement For OffloadingDaniel Cryer100% (1)

- Estimatingcalculation MalaysiaDocument136 pagesEstimatingcalculation MalaysiaAbdulBari100% (1)

- PARTS LIST FOR MANITOU MT 1840 SERIES (00000002)Document3 pagesPARTS LIST FOR MANITOU MT 1840 SERIES (00000002)amonNo ratings yet

- SUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDocument17 pagesSUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDavid O'BrienNo ratings yet

- MCBU - Lifting & Rigging Questions and AnswersDocument15 pagesMCBU - Lifting & Rigging Questions and AnswersBhaiJan59No ratings yet

- Lifting PlanDocument66 pagesLifting Planklibi100% (7)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- 5810 ManualDocument50 pages5810 ManualkrmchariNo ratings yet

- QTZ125 (6018) EnglishDocument72 pagesQTZ125 (6018) Englishivansuryawan94100% (2)

- Construction Cost MonitoringDocument13 pagesConstruction Cost MonitoringOng George Sammy100% (1)

- Demag - Jib CranesDocument22 pagesDemag - Jib CranesGogyNo ratings yet

- 960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06Document9 pages960C-SOP-212-R5 - Field Servicing of Equipment_2022-04-06amonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- Dynamic Compaction Operation Safety Training - ECTDocument4 pagesDynamic Compaction Operation Safety Training - ECTgayanNo ratings yet

- Crane and Rigging OperationDocument94 pagesCrane and Rigging OperationJust singingNo ratings yet

- 960C-SOP-006-R4_Safe Use of Ladders and Stairs_2022-06-06Document12 pages960C-SOP-006-R4_Safe Use of Ladders and Stairs_2022-06-06amonNo ratings yet

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pages9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- Material Handling Equipment Test Method Rev. 2 (Dood)Document8 pagesMaterial Handling Equipment Test Method Rev. 2 (Dood)ThomasNo ratings yet

- Safe Work Practices - CraneDocument22 pagesSafe Work Practices - CranepentianNo ratings yet

- Crane and Rigging Policy: Potential Fatal Risks PolicyDocument3 pagesCrane and Rigging Policy: Potential Fatal Risks PolicyAlex Sandro Borges PereiraNo ratings yet

- 960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06Document4 pages960C-SOP-019-R3 - Slip Trip and Fall Hazard Prevention_2022-07-06amonNo ratings yet

- 6.1.6 Loading and Unloading When Using Load CarriersDocument37 pages6.1.6 Loading and Unloading When Using Load Carriersmirano81No ratings yet

- Care & Use Assembly Instructions: Gantry CranesDocument12 pagesCare & Use Assembly Instructions: Gantry CranesThein MaungNo ratings yet

- DCA-FRM-MATL-016 R1 Forklift Operator Evaluation FormDocument3 pagesDCA-FRM-MATL-016 R1 Forklift Operator Evaluation FormchoadleyNo ratings yet

- Crane SafetyDocument4 pagesCrane SafetyUsman MinhasNo ratings yet

- Safe Work Method Statement PDFDocument6 pagesSafe Work Method Statement PDFsuli permita100% (1)

- Health and Safety FCX-HS32Document8 pagesHealth and Safety FCX-HS32berry trisnamuktiNo ratings yet

- SWP 04 Lifting OperationDocument4 pagesSWP 04 Lifting Operationমমিন মানবNo ratings yet

- Cranes Hoists Truck CranesDocument26 pagesCranes Hoists Truck Cranesrajesh_jeev100% (1)

- Lifting Plan Checklist and Method Statement SkeletonDocument7 pagesLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesNo ratings yet

- Course Material For Rigger-Latest - Final CHVR 2010Document138 pagesCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- Lifting Procedure and PlanDocument7 pagesLifting Procedure and PlanEngr Muslim KhanNo ratings yet

- 962C-SOP-002-R3 - Dump Stockpile ManagementDocument7 pages962C-SOP-002-R3 - Dump Stockpile ManagementAmsal SinagaNo ratings yet

- Lifting Plan AgcDocument8 pagesLifting Plan Agcragesh p rNo ratings yet

- SAFETY ALERT 2019 - OCT - CRANE IncidentDocument2 pagesSAFETY ALERT 2019 - OCT - CRANE Incidentvikrant911No ratings yet

- Craneblock WulDocument2 pagesCraneblock WulZachNo ratings yet

- 960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use ofDocument5 pages960C-SOP-800-R4 - Hydraulic Bead Breakers and Rams Use ofamonNo ratings yet

- Lifting OperationDocument6 pagesLifting OperationOchulor IsaacNo ratings yet

- General Lifting MethodDocument3 pagesGeneral Lifting MethodNaukhez A. KashifNo ratings yet

- Crane OperationDocument2 pagesCrane OperationnoniebellNo ratings yet

- Ehv SWP Form SpaceringDocument3 pagesEhv SWP Form SpaceringSn AhsanNo ratings yet

- SOP 13 Slew Crane OperationsDocument6 pagesSOP 13 Slew Crane OperationsakhmadbayNo ratings yet

- Lifting Procedure PDFDocument25 pagesLifting Procedure PDFAhmad Husnul MutaqinNo ratings yet

- 1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForDocument6 pages1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForAnwar MohamedNo ratings yet

- RT09 Forward Tipping DumperDocument5 pagesRT09 Forward Tipping DumperDuncanNo ratings yet

- Safe LiftingDocument22 pagesSafe LiftingMahmoud Abdallah67% (3)

- Fassi Crane: Use and MaintenanceDocument55 pagesFassi Crane: Use and MaintenanceJaime Sua100% (1)

- Slewing Jib Cranes SI 18.3Document2 pagesSlewing Jib Cranes SI 18.3reda mesbahNo ratings yet

- HHB 58CFR SWP-4 Lifting Equipment, Appliances & GearsDocument5 pagesHHB 58CFR SWP-4 Lifting Equipment, Appliances & GearsSelwyn GohNo ratings yet

- RT60 Mobile CraneDocument6 pagesRT60 Mobile CraneNithin DevNo ratings yet

- Cranes and Lifting GearDocument3 pagesCranes and Lifting GearSundar_1975No ratings yet

- Liftingoperationsafetyppt 230220111908 487c851eDocument39 pagesLiftingoperationsafetyppt 230220111908 487c851emamuNo ratings yet

- Procedure For Instalattion of VesselDocument6 pagesProcedure For Instalattion of Vesselyayan hNo ratings yet

- HASCO Crane and Lifting Campaign July 2022Document18 pagesHASCO Crane and Lifting Campaign July 2022shahid052No ratings yet

- Erection Method Statement - Birla White (Gotan)Document15 pagesErection Method Statement - Birla White (Gotan)SEPL SEPLNo ratings yet

- Mobile Gantries SI 20.3Document2 pagesMobile Gantries SI 20.3reda mesbahNo ratings yet

- CAREC Road Safety Engineering Manual 2: Safer Road WorksFrom EverandCAREC Road Safety Engineering Manual 2: Safer Road WorksNo ratings yet

- maintenance-210502124530 (3)Document17 pagesmaintenance-210502124530 (3)amonNo ratings yet

- Noblelft FD20-35 Operation & Maintenance ManualDocument176 pagesNoblelft FD20-35 Operation & Maintenance ManualamonNo ratings yet

- 960C SOP 213 R1 Automotive Servicing 2024-02-26Document10 pages960C SOP 213 R1 Automotive Servicing 2024-02-26amonNo ratings yet

- PT Parts - VBeltsDocument25 pagesPT Parts - VBeltsamonNo ratings yet

- Automotive Lamp Guide – BulbAmericaDocument1 pageAutomotive Lamp Guide – BulbAmericaamonNo ratings yet

- Wa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)Document2 pagesWa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)amonNo ratings yet

- Gsw415v 2011 (Alt.m) Acp FrameDocument4 pagesGsw415v 2011 (Alt.m) Acp FrameamonNo ratings yet

- IC Stock Inventory Control 8566 V1Document7 pagesIC Stock Inventory Control 8566 V1amonNo ratings yet

- CRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARDocument3 pagesCRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARamonNo ratings yet

- Datasheet - HK pm24024-110 4671240Document2 pagesDatasheet - HK pm24024-110 4671240amonNo ratings yet

- Sinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

- Section 2 - General: 2-8 - JLG Lift - 3121290Document1 pageSection 2 - General: 2-8 - JLG Lift - 3121290amonNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- 692734Document44 pages692734amonNo ratings yet

- Caterpillar Preventive Maintenance Products For On-Highway Engines and TransmissionsDocument3 pagesCaterpillar Preventive Maintenance Products For On-Highway Engines and Transmissionsamon100% (1)

- Bhushan Power & Steel Ltd.Document17 pagesBhushan Power & Steel Ltd.navdeeplakheraNo ratings yet

- Condition Assessment of Water Control Gates Task Committee of The Hydropower Technical Committee of The Energy Division of ASCE (2012) PDFDocument406 pagesCondition Assessment of Water Control Gates Task Committee of The Hydropower Technical Committee of The Energy Division of ASCE (2012) PDFDimitar100% (1)

- Group 4 Removal and Installation: 1. ForksDocument9 pagesGroup 4 Removal and Installation: 1. ForksBaciu NicolaeNo ratings yet

- Wire Rope Hoist AustrDocument11 pagesWire Rope Hoist AustrJESUSCALVILLONo ratings yet

- Crosby Lifting ClampsDocument18 pagesCrosby Lifting ClampsBaihaki StNo ratings yet

- Konecranes Industrial Cranes 2018 PDFDocument25 pagesKonecranes Industrial Cranes 2018 PDFChen QingNo ratings yet

- Pivot ProDocument20 pagesPivot Proaiyubi2No ratings yet

- ER2 Manual 125kg 5t - 04Document144 pagesER2 Manual 125kg 5t - 04Muhammed ShamseerNo ratings yet

- Angle-Of-Lift (Tension Increase, Reduced Capacity)Document1 pageAngle-Of-Lift (Tension Increase, Reduced Capacity)Mohamed HadjkacemNo ratings yet

- 1 Technical Specification For ERSDocument16 pages1 Technical Specification For ERSipraoNo ratings yet

- As 1418.7-1999 Cranes (Including Hoists and Winches) - Builders' Hoists and Associated EquipmentDocument50 pagesAs 1418.7-1999 Cranes (Including Hoists and Winches) - Builders' Hoists and Associated Equipmentfovod74255No ratings yet

- 40tonx58 Span-CraneDocument7 pages40tonx58 Span-CraneKoresh KhalpariNo ratings yet

- Straight Lifting MonorailDocument4 pagesStraight Lifting MonorailMahesh SavandappaNo ratings yet

- MUSE ED Elevator: Installation ManualDocument16 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Steel Body - Lever Hoists: A e B A e B A e BDocument1 pageSteel Body - Lever Hoists: A e B A e B A e BtylerlhsmithNo ratings yet

- Company Introduction EBM 2021Document16 pagesCompany Introduction EBM 2021putramahandhikaNo ratings yet

- Factories ActDocument120 pagesFactories ActCefi JohnNo ratings yet

- Yale KELC YL1006 0107Document2 pagesYale KELC YL1006 0107Sarah PerezNo ratings yet

- Ch165a 25120 01Document8 pagesCh165a 25120 01surya jaya bearingNo ratings yet

- Safe Working Load CalculationsDocument3 pagesSafe Working Load CalculationsShanAlanNo ratings yet

- Yale HoistDocument94 pagesYale Hoistjohn_tigerNo ratings yet

- Pedestal Crane SpecDocument21 pagesPedestal Crane SpecYinka Akinkunmi100% (1)

- Norms and Standards For Sizing and Calculation of A Coke Cutting System Paul Ruhrpumpen DCU Dusseldorf 2011Document39 pagesNorms and Standards For Sizing and Calculation of A Coke Cutting System Paul Ruhrpumpen DCU Dusseldorf 2011최승원100% (1)

- Chain Hoist PDFDocument12 pagesChain Hoist PDFAnton HariwangsaNo ratings yet