Professional Documents

Culture Documents

Cast Iron Strongcast

Cast Iron Strongcast

Uploaded by

Takul ThongyooCopyright:

Available Formats

You might also like

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- 490N High Tensile Strength Steel_7010Document1 page490N High Tensile Strength Steel_7010Takul ThongyooNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Cast Iron_Ni Cast 55Document1 pageCast Iron_Ni Cast 55Takul ThongyooNo ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Hardfacing - Catalog H-650Document1 pageHardfacing - Catalog H-650Takul ThongyooNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Stick Electrode For Mild Steel: ClassificationDocument1 pageStick Electrode For Mild Steel: Classificationmohamed AdelNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- Applications Characteristics: For Inter-Metallic AbrasionDocument1 pageApplications Characteristics: For Inter-Metallic AbrasionThanuja PereraNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- Applications: For Repairing of Cast Iron ProductsDocument1 pageApplications: For Repairing of Cast Iron ProductsLasandu WanniarachchiNo ratings yet

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 pageL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55No ratings yet

- Low Hydrogen High Tensile: Electrocito 7018Document1 pageLow Hydrogen High Tensile: Electrocito 7018mohamed AdelNo ratings yet

- For Mild Steel: Electroweld 6013Document1 pageFor Mild Steel: Electroweld 6013mohamed AdelNo ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Welding Electrodes CatalogueDocument7 pagesWelding Electrodes CatalogueFiroj Al HasanNo ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- EN12073T19123L PC/Mi: - Chemical Composition of All-Weld MetalDocument1 pageEN12073T19123L PC/Mi: - Chemical Composition of All-Weld Metalmohamed AdelNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- Super Tensile Blue Data SheetDocument1 pageSuper Tensile Blue Data Sheetdapp.70No ratings yet

- Select Arc Catalogue Part 2Document10 pagesSelect Arc Catalogue Part 2lionheartedNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12No ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- SMAW Electrodes: Product FeaturesDocument1 pageSMAW Electrodes: Product FeaturesIgur EuiNo ratings yet

- Pipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionDocument1 pagePipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshNo ratings yet

- Kobel Hard EdgeDocument1 pageKobel Hard EdgeBHARAT KNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

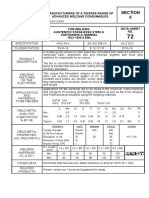

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Ama 23ak - enDocument1 pageAma 23ak - enmohamed AdelNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- HL 202308 Report No 5652917Document5 pagesHL 202308 Report No 5652917Takul ThongyooNo ratings yet

- 03 Welding Imperfections & Materilal Inspection+Notes+AnsDocument42 pages03 Welding Imperfections & Materilal Inspection+Notes+AnsTakul ThongyooNo ratings yet

- 02 Terms and Definitions+Notes+AnsDocument27 pages02 Terms and Definitions+Notes+AnsTakul ThongyooNo ratings yet

- Storage and Handling Recommandations ConsumableDocument20 pagesStorage and Handling Recommandations ConsumableTakul ThongyooNo ratings yet

- AWS - A5.1 Specification For Carbon Steel ElectrodeDocument62 pagesAWS - A5.1 Specification For Carbon Steel ElectrodeTakul ThongyooNo ratings yet

Cast Iron Strongcast

Cast Iron Strongcast

Uploaded by

Takul ThongyooCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cast Iron Strongcast

Cast Iron Strongcast

Uploaded by

Takul ThongyooCopyright:

Available Formats

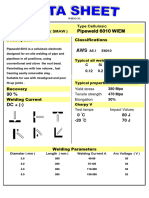

YAWATA Strongcast For Cast Iron

Classification

AWS A 5.15 : ~ESt

Applications

For welding, surfacing, and joining of cast iron to mild and low carbon steel. It is suitable

for most repair jobs and is recommended to repair defects and cracks in foundries.

Characteristics

YAWATA Strongcast is a basic electrode that has mild steel core wire and is specially design-

ed for cold welding of cast iron. The electrode is especially suitable for very dirty castings,

but it gives non-machineable weld deposits which provide an excellent colour match and

rust the cast iron. It is best used for non-critical applications.

Typical Chemical Composition of Deposited Metal (%)

C Si Mn P S

0.10 0.38 0.72 0.011 0.008

Typical Mechanical Properties of Deposited Metal

Tensile Strength Enlongation

N/mm 2 (kgf/mm2 ) %

490 (50) 33

Sizes & Recommended Current Range (AC or DC +)

Diameter/ Length (mm) 3.2/350 4.0/400 5.0/400

Welding Position Current (A)

All 70~110 100~140 150~180

Guideline in Usage

1. Use dry electrodes only. Damp electrodes should be re-dried at 80~120℃ for 60

minutes before use.

2. A pretending of 450~500℃ should be uniformly applied to the casting and after welding

it should be allowed to cool very slowly.

Welding Positions

All positions, except vertical down

You might also like

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- 490N High Tensile Strength Steel_7010Document1 page490N High Tensile Strength Steel_7010Takul ThongyooNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Cast Iron_Ni Cast 55Document1 pageCast Iron_Ni Cast 55Takul ThongyooNo ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Hardfacing - Catalog H-650Document1 pageHardfacing - Catalog H-650Takul ThongyooNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Stick Electrode For Mild Steel: ClassificationDocument1 pageStick Electrode For Mild Steel: Classificationmohamed AdelNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- Applications Characteristics: For Inter-Metallic AbrasionDocument1 pageApplications Characteristics: For Inter-Metallic AbrasionThanuja PereraNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- Applications: For Repairing of Cast Iron ProductsDocument1 pageApplications: For Repairing of Cast Iron ProductsLasandu WanniarachchiNo ratings yet

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 pageL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55No ratings yet

- Low Hydrogen High Tensile: Electrocito 7018Document1 pageLow Hydrogen High Tensile: Electrocito 7018mohamed AdelNo ratings yet

- For Mild Steel: Electroweld 6013Document1 pageFor Mild Steel: Electroweld 6013mohamed AdelNo ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Welding Electrodes CatalogueDocument7 pagesWelding Electrodes CatalogueFiroj Al HasanNo ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- EN12073T19123L PC/Mi: - Chemical Composition of All-Weld MetalDocument1 pageEN12073T19123L PC/Mi: - Chemical Composition of All-Weld Metalmohamed AdelNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- Super Tensile Blue Data SheetDocument1 pageSuper Tensile Blue Data Sheetdapp.70No ratings yet

- Select Arc Catalogue Part 2Document10 pagesSelect Arc Catalogue Part 2lionheartedNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12No ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- SMAW Electrodes: Product FeaturesDocument1 pageSMAW Electrodes: Product FeaturesIgur EuiNo ratings yet

- Pipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionDocument1 pagePipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshNo ratings yet

- Kobel Hard EdgeDocument1 pageKobel Hard EdgeBHARAT KNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Ama 23ak - enDocument1 pageAma 23ak - enmohamed AdelNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- HL 202308 Report No 5652917Document5 pagesHL 202308 Report No 5652917Takul ThongyooNo ratings yet

- 03 Welding Imperfections & Materilal Inspection+Notes+AnsDocument42 pages03 Welding Imperfections & Materilal Inspection+Notes+AnsTakul ThongyooNo ratings yet

- 02 Terms and Definitions+Notes+AnsDocument27 pages02 Terms and Definitions+Notes+AnsTakul ThongyooNo ratings yet

- Storage and Handling Recommandations ConsumableDocument20 pagesStorage and Handling Recommandations ConsumableTakul ThongyooNo ratings yet

- AWS - A5.1 Specification For Carbon Steel ElectrodeDocument62 pagesAWS - A5.1 Specification For Carbon Steel ElectrodeTakul ThongyooNo ratings yet