Professional Documents

Culture Documents

1F1-1F2 Maint

1F1-1F2 Maint

Uploaded by

Michael HunterCopyright:

Available Formats

You might also like

- John Deere 4055 4255 4455 4555 4755 4955 Shopmanual Sec WatDocument20 pagesJohn Deere 4055 4255 4455 4555 4755 4955 Shopmanual Sec Watdoris97% (32)

- Haval-H6 2022 EN Service 98f4452a68Document7 pagesHaval-H6 2022 EN Service 98f4452a68Jairo PizarroNo ratings yet

- Service Schedule: Chevrolet UtilityDocument5 pagesService Schedule: Chevrolet UtilityJamie Whittle100% (2)

- Haval H6 3rd Gen Service ScheduleDocument1 pageHaval H6 3rd Gen Service Schedulekhalil louizNo ratings yet

- Ford Shop Manual 2Document300 pagesFord Shop Manual 2fl100% (1)

- Tb45 Gasoline Engine (Ecu) : Service ManualDocument25 pagesTb45 Gasoline Engine (Ecu) : Service ManualZiad Mubarak100% (1)

- S2E-S6E2 Operation ManualDocument34 pagesS2E-S6E2 Operation ManualJOHON SANCHEZNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Cat 3126 Spec Sheet Abby PDFDocument14 pagesCat 3126 Spec Sheet Abby PDFMao TorresNo ratings yet

- Manual Jlem MotorsDocument35 pagesManual Jlem MotorsJesus FernandezNo ratings yet

- Toyota Surf Maint SchedDocument2 pagesToyota Surf Maint SchedPaolo A. AguilaNo ratings yet

- Piaggio 400 500 Service ScheduleDocument1 pagePiaggio 400 500 Service Schedulemilemajor2308No ratings yet

- B5 Lubrication System: To IndexDocument9 pagesB5 Lubrication System: To Indexwei fooNo ratings yet

- Inspection, Lubrication and Periodic Replacement PartsDocument6 pagesInspection, Lubrication and Periodic Replacement PartsMalcolmNo ratings yet

- Chevrolet Spark Beat 1.2 M300Document3 pagesChevrolet Spark Beat 1.2 M300SixtoNo ratings yet

- HOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckDocument3 pagesHOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckRPaiva100% (3)

- Industrial Diesel Engine: TNV IDI SeriesDocument2 pagesIndustrial Diesel Engine: TNV IDI SeriesJohn GarnetNo ratings yet

- NP300Document8 pagesNP300sfsman1100% (1)

- Periodic Replacement PartsDocument2 pagesPeriodic Replacement PartsJesuz GrüberNo ratings yet

- 30d-7sa Operator's ManualDocument79 pages30d-7sa Operator's Manualafolayan josephNo ratings yet

- Models J05C-TD, J08C-TP and J08C-TRDocument20 pagesModels J05C-TD, J08C-TP and J08C-TRKomatsu Perkins HitachiNo ratings yet

- Xrvs 1000 Service PDFDocument10 pagesXrvs 1000 Service PDFpowermanagerNo ratings yet

- Intake and Exhaust SystemDocument2 pagesIntake and Exhaust SystemPopescu IonNo ratings yet

- PDF Om 13 Rescue Boatpdf DLDocument17 pagesPDF Om 13 Rescue Boatpdf DLRendra Anggi SaputraNo ratings yet

- 45rfe 545rfe 65rfe 66rfe 68rfe Zip-11k-InDocument1 page45rfe 545rfe 65rfe 66rfe 68rfe Zip-11k-InHenry SilvaNo ratings yet

- MAN B&W ME Type EngineDocument95 pagesMAN B&W ME Type EngineUjjwal SinghNo ratings yet

- Exhaust Valve System (Maj 2015)Document21 pagesExhaust Valve System (Maj 2015)roydsouza87No ratings yet

- 02 Periodic MaintenanceDocument23 pages02 Periodic MaintenanceVincent RoyNo ratings yet

- Good Oil Sampling Guide v5 - CompressedDocument12 pagesGood Oil Sampling Guide v5 - CompressedВиталий БезверскийNo ratings yet

- 08 Exhaust Valve System (Maj 2015)Document42 pages08 Exhaust Valve System (Maj 2015)Alexandru AlexNo ratings yet

- Matrix CM EXC102-4Document10 pagesMatrix CM EXC102-4Ahmat RamadaniNo ratings yet

- 08 Exhaust Valve SystemDocument16 pages08 Exhaust Valve SystemTimmyJuri100% (1)

- Pressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02ADocument1 pagePressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02Aflash_24014910No ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- Job Schedule Sheet: Machine Component Job Description Planned by Wo NoDocument8 pagesJob Schedule Sheet: Machine Component Job Description Planned by Wo NoYudha RafiNo ratings yet

- Maintenance - HR-V 1.5 HybridDocument1 pageMaintenance - HR-V 1.5 Hybridzaekin2011No ratings yet

- ME Engine (Intelligent Engine)Document95 pagesME Engine (Intelligent Engine)Mahesh More100% (2)

- B&W Alpha LubricationDocument4 pagesB&W Alpha Lubricationimmyself94% (17)

- Service Estimation PersonaDocument1 pageService Estimation PersonaAwalJefriNo ratings yet

- All Dynamic Acera Hydraulic Components Part NºKSMH-VI-REV.3Document25 pagesAll Dynamic Acera Hydraulic Components Part NºKSMH-VI-REV.3julianNo ratings yet

- Co2 PDFDocument29 pagesCo2 PDFdonhan91No ratings yet

- Maintenance - City 1.5 HybridDocument1 pageMaintenance - City 1.5 HybridMohamed HafizNo ratings yet

- PC 1250 500 HR Service SheetDocument5 pagesPC 1250 500 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Arriel - 2B 2B1 2D - en - L1 - 05 11 - PD13 1 201 436Document236 pagesArriel - 2B 2B1 2D - en - L1 - 05 11 - PD13 1 201 436Alejandro SánchezNo ratings yet

- Juke Maintenenace IntervalsDocument12 pagesJuke Maintenenace Intervalscybertech34 HDNo ratings yet

- pg_si_0072_en_webDocument4 pagespg_si_0072_en_webΜΠΑΜΠΗΣ ΛΙΑΤΟΣNo ratings yet

- MAG Pneumatic Grease Lubricator: FeaturesDocument1 pageMAG Pneumatic Grease Lubricator: FeaturesDmitry DauhalNo ratings yet

- PC 1250 250 HR Service SheetDocument4 pagesPC 1250 250 HR Service SheetJamyansuren Tseveendorj100% (1)

- Dorin H2Document6 pagesDorin H2frigoremontNo ratings yet

- Ect AccentDocument1 pageEct Accentwilliamchavez17No ratings yet

- VVT VR6 EnglishDocument30 pagesVVT VR6 EnglishvereseNo ratings yet

- Auxiliary Mechanical: SectionDocument17 pagesAuxiliary Mechanical: SectionRavi Kiran MNo ratings yet

- TVS Jive Maintenance ScheduleDocument5 pagesTVS Jive Maintenance ScheduleSanNo ratings yet

- Schedule of Inspection and Maintenance ServicesDocument2 pagesSchedule of Inspection and Maintenance ServicesAnton FortovNo ratings yet

- 7 Speed DSG VW 0AM - 0CW - DQ200 and Repair Measures - Sheng Hai Au182338Document12 pages7 Speed DSG VW 0AM - 0CW - DQ200 and Repair Measures - Sheng Hai Au182338Nitin Patil100% (2)

- Serviceinformation Serviceinformation: Troubleshooting On The Exhaust Gas Recirculation SystemDocument5 pagesServiceinformation Serviceinformation: Troubleshooting On The Exhaust Gas Recirculation SystemNascu AndreiNo ratings yet

- PC 1250 1000 HR Service SheetDocument5 pagesPC 1250 1000 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Wheeloader 980HDocument8 pagesWheeloader 980HAdie PranataNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- $R8RKNIXDocument1 page$R8RKNIXMichael HunterNo ratings yet

- MaintenanceDocument66 pagesMaintenanceMichael HunterNo ratings yet

- Maintenance: A/C MOTOR REPAIR S/N A474N03000L S/N A497N030000L S/N D801N02161L S/N E826N01917LDocument24 pagesMaintenance: A/C MOTOR REPAIR S/N A474N03000L S/N A497N030000L S/N D801N02161L S/N E826N01917LMichael HunterNo ratings yet

- Capacities and Specifications: MaintenanceDocument12 pagesCapacities and Specifications: MaintenanceMichael HunterNo ratings yet

- Wire Driver Manual: MaintenanceDocument20 pagesWire Driver Manual: MaintenanceMichael HunterNo ratings yet

- Guide Wire Installation: MaintenanceDocument26 pagesGuide Wire Installation: MaintenanceMichael HunterNo ratings yet

- HMC 2.4L LPGDocument104 pagesHMC 2.4L LPGMichael HunterNo ratings yet

- Yale, Hyster 3 Wheel CodesDocument1 pageYale, Hyster 3 Wheel CodesMichael HunterNo ratings yet

- Part Unit PDFDocument8 pagesPart Unit PDFOgy Tirta PerdanaNo ratings yet

- Dexter Axles Sway Control Service ManualDocument30 pagesDexter Axles Sway Control Service Manualgearhead1No ratings yet

- Cxt-10 Parts List: Key No Parts No Parts Name Key No Parts No Parts NameDocument1 pageCxt-10 Parts List: Key No Parts No Parts Name Key No Parts No Parts NameGergely IvánovicsNo ratings yet

- A Whole New Way To Move: Owners ManualDocument36 pagesA Whole New Way To Move: Owners ManualFrancesco CauzNo ratings yet

- VSPS COMBINED CATALOG ١Document16 pagesVSPS COMBINED CATALOG ١mezo catNo ratings yet

- Manual Xj350 PeruDocument115 pagesManual Xj350 PeruVctorEritkPMNo ratings yet

- Build Your Own Car That Gets 100 Miles Per Gallon: Subscribe (/cta-Sub-Landing)Document11 pagesBuild Your Own Car That Gets 100 Miles Per Gallon: Subscribe (/cta-Sub-Landing)mraNo ratings yet

- 01 Air CleanerDocument2 pages01 Air Cleanerronieka.pNo ratings yet

- Iitj Bus ScheduleDocument1 pageIitj Bus ScheduleGeeteshGuptaNo ratings yet

- UFMENDocument136 pagesUFMENMarko PalekaNo ratings yet

- Agentur H. Willems: Tel.: +49-421-52009-0 List of Manufacturers Fax: +49-421-545858Document5 pagesAgentur H. Willems: Tel.: +49-421-52009-0 List of Manufacturers Fax: +49-421-545858Trần Minh NhậtNo ratings yet

- Yumak Air Compressor Catalogue v.1.1.9Document744 pagesYumak Air Compressor Catalogue v.1.1.9Yassine BoulhendNo ratings yet

- Ape City March 2013Document60 pagesApe City March 2013DEEPAKNo ratings yet

- Bpcrules 1Document4 pagesBpcrules 1SKPSANTOSHNo ratings yet

- Vdru02 01GBDocument1,312 pagesVdru02 01GBmaNo ratings yet

- MF260 II Series - Partscatalog - CEL - EDocument48 pagesMF260 II Series - Partscatalog - CEL - EvvosaratNo ratings yet

- Air Operated Hydraulic Press Parts List 6-250-6-450 - 01.2022Document9 pagesAir Operated Hydraulic Press Parts List 6-250-6-450 - 01.2022grantNo ratings yet

- Techno-Commercial Proposal - Slitting Machine - Rev 01Document9 pagesTechno-Commercial Proposal - Slitting Machine - Rev 01Chandru ChristurajNo ratings yet

- Elevador SC GasBoostersDocument20 pagesElevador SC GasBoostersmaliNo ratings yet

- Form 124-13 Supercedes Form 124-10Document1,308 pagesForm 124-13 Supercedes Form 124-10البريكي لقطع الغيار100% (2)

- Parts Manual - WGD185Document8 pagesParts Manual - WGD185Francisco Fernandez-Davila SainzNo ratings yet

- 2Document9 pages2stathiss11No ratings yet

- MediaTek - MediaTek - New Dimensity Auto Cockpit Platforms, in Partnership With NVIDIA DRIVE TechnologyDocument2 pagesMediaTek - MediaTek - New Dimensity Auto Cockpit Platforms, in Partnership With NVIDIA DRIVE Technology4whyjys4qhNo ratings yet

- Va - 500 - Series SEMPELLDocument12 pagesVa - 500 - Series SEMPELLtri_purwadiNo ratings yet

- Cooling System: Description and OperationDocument26 pagesCooling System: Description and Operationrodolfodiaz100% (1)

- Touran No. 204 / 1: Position of Relays and Fuses Electronics Box Low, From May 2005Document18 pagesTouran No. 204 / 1: Position of Relays and Fuses Electronics Box Low, From May 2005Dariaxa Sos CarsNo ratings yet

- Continental at Overhaul 100% Parts Replacement List Engine Model: TSIO 520 BB, DB, EB, JB, KB, LB, NB, UB, VB, WBDocument2 pagesContinental at Overhaul 100% Parts Replacement List Engine Model: TSIO 520 BB, DB, EB, JB, KB, LB, NB, UB, VB, WBRik AraujNo ratings yet

- Service Bulletin: Kolberg-Pioneer, IncDocument26 pagesService Bulletin: Kolberg-Pioneer, Inci Soluciones100% (1)

1F1-1F2 Maint

1F1-1F2 Maint

Uploaded by

Michael HunterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1F1-1F2 Maint

1F1-1F2 Maint

Uploaded by

Michael HunterCopyright:

Available Formats

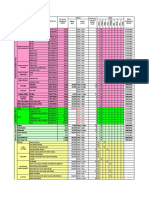

MAINTENANCE SCHEDULE

Periodic Maintenance and Lubrication Schedule for Emission Control

System (Cont’d)

Interval

Months 1 2 3 4 5 6 7 8 9 10 11 12 18 How to

Inspection Items

check

100s

of hours

2 4 6 8 10 12 14 16 18 20 22 24 36

Intake & exhaust valve

Test/

Engine Compartment Maintenance

clearance (operating A A A A A A

Adjust

temp)

(Except LPG Fuel System)

Drive belt tension I I I I I I I I I I I I I Visual

Engine oil R R R R R R R Replace

Oil filter R R R R R R R Replace

Engine Coolant (LLC) R Replace

K21/K25, GK21/GK25 Engine

Visual/

Air cleaner element I I I I I I I I I I I R R

Replace

Spark plugs I I I I I I I I I I I I R Visual

PCV Valve I I I I I Visual

Piping or pipe

connector portion

I I I I I I I I I I I I I Visual

(Except LPG Fuel System)

for gas leakage and

Engine Compartment

damage

Maintenance

Tar in vaporizer D D D D D D D D D D D D D Drain

Visual/

LPG Fuel Filters C C C R C

Replace

Injection screen C C C C C Visual

Check LPG cylinder

holder for looseness I I I I I I I I I I I I I Visual

or damage

NOTE:

• When the LPG Cylinder is replaced, inspect pipe connectors for gas leakage with soapy water.

• UCA recommends a complete tear down, inspection and resealing of the vaporizer before 6,000 hours or 30 months of operation,

whichever comes first. This maintenance is necessary for all units even if the recommended HD5 grade is being used. The

conditions in your area and the quality of the LPG may dictate a more stringent maintenance schedule.

Interval

Months 1 2 3 4 5 6 7 8 9 10 11 12 18 How to

Inspection Items

check

100s

of hours

2 4 6 8 10 12 14 16 18 20 22 24 36

Intake & exhaust

valve clearance A A A A A A Adjust

Engine Compartment Maintenance

(operating temp)

Drive belt tension I I I I I I I I I I I I I Visual

Engine oil R R R R R R R R R R R R R Replace

QD32 Engine

Oil filter R R R R R R R R R R R R R Replace

Engine coolant (LLC) R Replace

Visual/

Air cleaner element I I R I I R I I R I I R R

Replace

Water separator D D D D R D Drain

Engine idle rpm A A A A A A A A A A A A A Adjust

Nozzle I I I Visual

NOTE:

• If Engine power decreases, black exhaust smoke is emitted or Engine noise increases before the maintenance period expires,

check and, if necessary, adjust the fuel injection nozzle starting pressure and the fuel spray pattern.

Abbreviations: I: Inspect (correct or replace if necessary), D: Drain, R: Replacement, A: Adjustment, C: Clean, T: Retighten,

L: Lubricate/Grease

MA-10

You might also like

- John Deere 4055 4255 4455 4555 4755 4955 Shopmanual Sec WatDocument20 pagesJohn Deere 4055 4255 4455 4555 4755 4955 Shopmanual Sec Watdoris97% (32)

- Haval-H6 2022 EN Service 98f4452a68Document7 pagesHaval-H6 2022 EN Service 98f4452a68Jairo PizarroNo ratings yet

- Service Schedule: Chevrolet UtilityDocument5 pagesService Schedule: Chevrolet UtilityJamie Whittle100% (2)

- Haval H6 3rd Gen Service ScheduleDocument1 pageHaval H6 3rd Gen Service Schedulekhalil louizNo ratings yet

- Ford Shop Manual 2Document300 pagesFord Shop Manual 2fl100% (1)

- Tb45 Gasoline Engine (Ecu) : Service ManualDocument25 pagesTb45 Gasoline Engine (Ecu) : Service ManualZiad Mubarak100% (1)

- S2E-S6E2 Operation ManualDocument34 pagesS2E-S6E2 Operation ManualJOHON SANCHEZNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Cat 3126 Spec Sheet Abby PDFDocument14 pagesCat 3126 Spec Sheet Abby PDFMao TorresNo ratings yet

- Manual Jlem MotorsDocument35 pagesManual Jlem MotorsJesus FernandezNo ratings yet

- Toyota Surf Maint SchedDocument2 pagesToyota Surf Maint SchedPaolo A. AguilaNo ratings yet

- Piaggio 400 500 Service ScheduleDocument1 pagePiaggio 400 500 Service Schedulemilemajor2308No ratings yet

- B5 Lubrication System: To IndexDocument9 pagesB5 Lubrication System: To Indexwei fooNo ratings yet

- Inspection, Lubrication and Periodic Replacement PartsDocument6 pagesInspection, Lubrication and Periodic Replacement PartsMalcolmNo ratings yet

- Chevrolet Spark Beat 1.2 M300Document3 pagesChevrolet Spark Beat 1.2 M300SixtoNo ratings yet

- HOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckDocument3 pagesHOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckRPaiva100% (3)

- Industrial Diesel Engine: TNV IDI SeriesDocument2 pagesIndustrial Diesel Engine: TNV IDI SeriesJohn GarnetNo ratings yet

- NP300Document8 pagesNP300sfsman1100% (1)

- Periodic Replacement PartsDocument2 pagesPeriodic Replacement PartsJesuz GrüberNo ratings yet

- 30d-7sa Operator's ManualDocument79 pages30d-7sa Operator's Manualafolayan josephNo ratings yet

- Models J05C-TD, J08C-TP and J08C-TRDocument20 pagesModels J05C-TD, J08C-TP and J08C-TRKomatsu Perkins HitachiNo ratings yet

- Xrvs 1000 Service PDFDocument10 pagesXrvs 1000 Service PDFpowermanagerNo ratings yet

- Intake and Exhaust SystemDocument2 pagesIntake and Exhaust SystemPopescu IonNo ratings yet

- PDF Om 13 Rescue Boatpdf DLDocument17 pagesPDF Om 13 Rescue Boatpdf DLRendra Anggi SaputraNo ratings yet

- 45rfe 545rfe 65rfe 66rfe 68rfe Zip-11k-InDocument1 page45rfe 545rfe 65rfe 66rfe 68rfe Zip-11k-InHenry SilvaNo ratings yet

- MAN B&W ME Type EngineDocument95 pagesMAN B&W ME Type EngineUjjwal SinghNo ratings yet

- Exhaust Valve System (Maj 2015)Document21 pagesExhaust Valve System (Maj 2015)roydsouza87No ratings yet

- 02 Periodic MaintenanceDocument23 pages02 Periodic MaintenanceVincent RoyNo ratings yet

- Good Oil Sampling Guide v5 - CompressedDocument12 pagesGood Oil Sampling Guide v5 - CompressedВиталий БезверскийNo ratings yet

- 08 Exhaust Valve System (Maj 2015)Document42 pages08 Exhaust Valve System (Maj 2015)Alexandru AlexNo ratings yet

- Matrix CM EXC102-4Document10 pagesMatrix CM EXC102-4Ahmat RamadaniNo ratings yet

- 08 Exhaust Valve SystemDocument16 pages08 Exhaust Valve SystemTimmyJuri100% (1)

- Pressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02ADocument1 pagePressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02Aflash_24014910No ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- Job Schedule Sheet: Machine Component Job Description Planned by Wo NoDocument8 pagesJob Schedule Sheet: Machine Component Job Description Planned by Wo NoYudha RafiNo ratings yet

- Maintenance - HR-V 1.5 HybridDocument1 pageMaintenance - HR-V 1.5 Hybridzaekin2011No ratings yet

- ME Engine (Intelligent Engine)Document95 pagesME Engine (Intelligent Engine)Mahesh More100% (2)

- B&W Alpha LubricationDocument4 pagesB&W Alpha Lubricationimmyself94% (17)

- Service Estimation PersonaDocument1 pageService Estimation PersonaAwalJefriNo ratings yet

- All Dynamic Acera Hydraulic Components Part NºKSMH-VI-REV.3Document25 pagesAll Dynamic Acera Hydraulic Components Part NºKSMH-VI-REV.3julianNo ratings yet

- Co2 PDFDocument29 pagesCo2 PDFdonhan91No ratings yet

- Maintenance - City 1.5 HybridDocument1 pageMaintenance - City 1.5 HybridMohamed HafizNo ratings yet

- PC 1250 500 HR Service SheetDocument5 pagesPC 1250 500 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Arriel - 2B 2B1 2D - en - L1 - 05 11 - PD13 1 201 436Document236 pagesArriel - 2B 2B1 2D - en - L1 - 05 11 - PD13 1 201 436Alejandro SánchezNo ratings yet

- Juke Maintenenace IntervalsDocument12 pagesJuke Maintenenace Intervalscybertech34 HDNo ratings yet

- pg_si_0072_en_webDocument4 pagespg_si_0072_en_webΜΠΑΜΠΗΣ ΛΙΑΤΟΣNo ratings yet

- MAG Pneumatic Grease Lubricator: FeaturesDocument1 pageMAG Pneumatic Grease Lubricator: FeaturesDmitry DauhalNo ratings yet

- PC 1250 250 HR Service SheetDocument4 pagesPC 1250 250 HR Service SheetJamyansuren Tseveendorj100% (1)

- Dorin H2Document6 pagesDorin H2frigoremontNo ratings yet

- Ect AccentDocument1 pageEct Accentwilliamchavez17No ratings yet

- VVT VR6 EnglishDocument30 pagesVVT VR6 EnglishvereseNo ratings yet

- Auxiliary Mechanical: SectionDocument17 pagesAuxiliary Mechanical: SectionRavi Kiran MNo ratings yet

- TVS Jive Maintenance ScheduleDocument5 pagesTVS Jive Maintenance ScheduleSanNo ratings yet

- Schedule of Inspection and Maintenance ServicesDocument2 pagesSchedule of Inspection and Maintenance ServicesAnton FortovNo ratings yet

- 7 Speed DSG VW 0AM - 0CW - DQ200 and Repair Measures - Sheng Hai Au182338Document12 pages7 Speed DSG VW 0AM - 0CW - DQ200 and Repair Measures - Sheng Hai Au182338Nitin Patil100% (2)

- Serviceinformation Serviceinformation: Troubleshooting On The Exhaust Gas Recirculation SystemDocument5 pagesServiceinformation Serviceinformation: Troubleshooting On The Exhaust Gas Recirculation SystemNascu AndreiNo ratings yet

- PC 1250 1000 HR Service SheetDocument5 pagesPC 1250 1000 HR Service SheetJamyansuren TseveendorjNo ratings yet

- Wheeloader 980HDocument8 pagesWheeloader 980HAdie PranataNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- $R8RKNIXDocument1 page$R8RKNIXMichael HunterNo ratings yet

- MaintenanceDocument66 pagesMaintenanceMichael HunterNo ratings yet

- Maintenance: A/C MOTOR REPAIR S/N A474N03000L S/N A497N030000L S/N D801N02161L S/N E826N01917LDocument24 pagesMaintenance: A/C MOTOR REPAIR S/N A474N03000L S/N A497N030000L S/N D801N02161L S/N E826N01917LMichael HunterNo ratings yet

- Capacities and Specifications: MaintenanceDocument12 pagesCapacities and Specifications: MaintenanceMichael HunterNo ratings yet

- Wire Driver Manual: MaintenanceDocument20 pagesWire Driver Manual: MaintenanceMichael HunterNo ratings yet

- Guide Wire Installation: MaintenanceDocument26 pagesGuide Wire Installation: MaintenanceMichael HunterNo ratings yet

- HMC 2.4L LPGDocument104 pagesHMC 2.4L LPGMichael HunterNo ratings yet

- Yale, Hyster 3 Wheel CodesDocument1 pageYale, Hyster 3 Wheel CodesMichael HunterNo ratings yet

- Part Unit PDFDocument8 pagesPart Unit PDFOgy Tirta PerdanaNo ratings yet

- Dexter Axles Sway Control Service ManualDocument30 pagesDexter Axles Sway Control Service Manualgearhead1No ratings yet

- Cxt-10 Parts List: Key No Parts No Parts Name Key No Parts No Parts NameDocument1 pageCxt-10 Parts List: Key No Parts No Parts Name Key No Parts No Parts NameGergely IvánovicsNo ratings yet

- A Whole New Way To Move: Owners ManualDocument36 pagesA Whole New Way To Move: Owners ManualFrancesco CauzNo ratings yet

- VSPS COMBINED CATALOG ١Document16 pagesVSPS COMBINED CATALOG ١mezo catNo ratings yet

- Manual Xj350 PeruDocument115 pagesManual Xj350 PeruVctorEritkPMNo ratings yet

- Build Your Own Car That Gets 100 Miles Per Gallon: Subscribe (/cta-Sub-Landing)Document11 pagesBuild Your Own Car That Gets 100 Miles Per Gallon: Subscribe (/cta-Sub-Landing)mraNo ratings yet

- 01 Air CleanerDocument2 pages01 Air Cleanerronieka.pNo ratings yet

- Iitj Bus ScheduleDocument1 pageIitj Bus ScheduleGeeteshGuptaNo ratings yet

- UFMENDocument136 pagesUFMENMarko PalekaNo ratings yet

- Agentur H. Willems: Tel.: +49-421-52009-0 List of Manufacturers Fax: +49-421-545858Document5 pagesAgentur H. Willems: Tel.: +49-421-52009-0 List of Manufacturers Fax: +49-421-545858Trần Minh NhậtNo ratings yet

- Yumak Air Compressor Catalogue v.1.1.9Document744 pagesYumak Air Compressor Catalogue v.1.1.9Yassine BoulhendNo ratings yet

- Ape City March 2013Document60 pagesApe City March 2013DEEPAKNo ratings yet

- Bpcrules 1Document4 pagesBpcrules 1SKPSANTOSHNo ratings yet

- Vdru02 01GBDocument1,312 pagesVdru02 01GBmaNo ratings yet

- MF260 II Series - Partscatalog - CEL - EDocument48 pagesMF260 II Series - Partscatalog - CEL - EvvosaratNo ratings yet

- Air Operated Hydraulic Press Parts List 6-250-6-450 - 01.2022Document9 pagesAir Operated Hydraulic Press Parts List 6-250-6-450 - 01.2022grantNo ratings yet

- Techno-Commercial Proposal - Slitting Machine - Rev 01Document9 pagesTechno-Commercial Proposal - Slitting Machine - Rev 01Chandru ChristurajNo ratings yet

- Elevador SC GasBoostersDocument20 pagesElevador SC GasBoostersmaliNo ratings yet

- Form 124-13 Supercedes Form 124-10Document1,308 pagesForm 124-13 Supercedes Form 124-10البريكي لقطع الغيار100% (2)

- Parts Manual - WGD185Document8 pagesParts Manual - WGD185Francisco Fernandez-Davila SainzNo ratings yet

- 2Document9 pages2stathiss11No ratings yet

- MediaTek - MediaTek - New Dimensity Auto Cockpit Platforms, in Partnership With NVIDIA DRIVE TechnologyDocument2 pagesMediaTek - MediaTek - New Dimensity Auto Cockpit Platforms, in Partnership With NVIDIA DRIVE Technology4whyjys4qhNo ratings yet

- Va - 500 - Series SEMPELLDocument12 pagesVa - 500 - Series SEMPELLtri_purwadiNo ratings yet

- Cooling System: Description and OperationDocument26 pagesCooling System: Description and Operationrodolfodiaz100% (1)

- Touran No. 204 / 1: Position of Relays and Fuses Electronics Box Low, From May 2005Document18 pagesTouran No. 204 / 1: Position of Relays and Fuses Electronics Box Low, From May 2005Dariaxa Sos CarsNo ratings yet

- Continental at Overhaul 100% Parts Replacement List Engine Model: TSIO 520 BB, DB, EB, JB, KB, LB, NB, UB, VB, WBDocument2 pagesContinental at Overhaul 100% Parts Replacement List Engine Model: TSIO 520 BB, DB, EB, JB, KB, LB, NB, UB, VB, WBRik AraujNo ratings yet

- Service Bulletin: Kolberg-Pioneer, IncDocument26 pagesService Bulletin: Kolberg-Pioneer, Inci Soluciones100% (1)