Professional Documents

Culture Documents

BBTCSX_BBTCSYZ Instructions 3-28-2010

BBTCSX_BBTCSYZ Instructions 3-28-2010

Uploaded by

assistenteintegradorCopyright:

Available Formats

You might also like

- Voest DAT ManualDocument52 pagesVoest DAT ManualRobert Spencer80% (5)

- Story. The Tale of Three TreesDocument2 pagesStory. The Tale of Three TreesAlwin Asuncion100% (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Kiwiprop K4 Boss Assembly v2.4Document15 pagesKiwiprop K4 Boss Assembly v2.4adul sungkatinNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Dividing HeadDocument40 pagesDividing HeadChristopher Ruben100% (3)

- BOP 4116 15kDocument44 pagesBOP 4116 15koswaldo58100% (2)

- Mini Lathe CNC ConversionDocument7 pagesMini Lathe CNC ConversioneFalegname100% (5)

- Garden Tractor Plans PDFDocument11 pagesGarden Tractor Plans PDFLucian LeonteNo ratings yet

- Falk Quadrive Shaft Mounted Drive - Interchange Guide 371810Document12 pagesFalk Quadrive Shaft Mounted Drive - Interchange Guide 371810Anonymous ntE0hG2TPNo ratings yet

- 1150 InstDocument5 pages1150 InstMohammad NorooziNo ratings yet

- A2ZUpgradesForSherlineMillExplainedDocument4 pagesA2ZUpgradesForSherlineMillExplainedassistenteintegradorNo ratings yet

- Accessories: Scan These QR CodesDocument12 pagesAccessories: Scan These QR CodesAnonymous D5QForitcNo ratings yet

- How To: Index The Spark Plugs On A Ficht / Direct Injection OutboardDocument4 pagesHow To: Index The Spark Plugs On A Ficht / Direct Injection OutboardrfffffNo ratings yet

- 2014 Right Foot Performance Products CatalogDocument54 pages2014 Right Foot Performance Products CatalogbudzodesignsNo ratings yet

- FF Primary InstructionsDocument12 pagesFF Primary InstructionsKevin VillagranNo ratings yet

- Trailer Buddy VaultDocument10 pagesTrailer Buddy VaultjeffNo ratings yet

- B 4600Document6 pagesB 4600sergioarrayaNo ratings yet

- Avk Butterfly Valves, Centric With Loose Liner: Series 820Document6 pagesAvk Butterfly Valves, Centric With Loose Liner: Series 820utzu_yooNo ratings yet

- Atlas Copco Secoroc: Reverse Circulation EquipmentDocument12 pagesAtlas Copco Secoroc: Reverse Circulation EquipmentSergio Perez100% (1)

- Atv PlansDocument90 pagesAtv PlansK Scott Wyatt100% (6)

- Apex Catlogue A43010-MinDocument24 pagesApex Catlogue A43010-Minfaisal kingNo ratings yet

- VQ35DEDocument18 pagesVQ35DEJorge MirandaNo ratings yet

- Bearing Ina Lit - 167 - Us - Us PDFDocument16 pagesBearing Ina Lit - 167 - Us - Us PDFbatman2054No ratings yet

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDocument39 pagesTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Bath Tube 3997d3df 9c44 4dfd b1b6 7f4eb028eef9Document17 pagesBath Tube 3997d3df 9c44 4dfd b1b6 7f4eb028eef9nam nguyenNo ratings yet

- Atlanta Servo Drive System 060812Document85 pagesAtlanta Servo Drive System 060812Anonymous JGugvoz1No ratings yet

- 371 810 Falk Quadrive Shaft Mounted Drive Interchange GuideDocument12 pages371 810 Falk Quadrive Shaft Mounted Drive Interchange GuideVirginia Venus Visuette MarínNo ratings yet

- WorkBee Screw Assembly Manual 2019Document40 pagesWorkBee Screw Assembly Manual 2019CsíkJúliusNo ratings yet

- Drive Coupling SKFDocument19 pagesDrive Coupling SKFFrank MwafulirwaNo ratings yet

- Getrag 256 PrepDocument7 pagesGetrag 256 PrepInes LopesNo ratings yet

- 600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)Document8 pages600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)LeonardNo ratings yet

- Pennbarry SX Catalogue TS v9bDocument34 pagesPennbarry SX Catalogue TS v9bjacaNo ratings yet

- Assembly Instructions: Retrofit For Bridgeport Series 1 MillsDocument4 pagesAssembly Instructions: Retrofit For Bridgeport Series 1 MillsDustin_JanesNo ratings yet

- Design Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsDocument30 pagesDesign Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsCora XuNo ratings yet

- Bosch Rexroth Fusos EsferasDocument164 pagesBosch Rexroth Fusos EsferasjomiseferNo ratings yet

- SKF CouplingDocument16 pagesSKF CouplingmatchutNo ratings yet

- Redlands Ingles Manual Junta GiratoriaDocument10 pagesRedlands Ingles Manual Junta GiratoriaTarcilio FonsecaNo ratings yet

- Efk 1Document4 pagesEfk 1Jennifer YuanNo ratings yet

- Equipements de Positionnement14601Document18 pagesEquipements de Positionnement14601techspawNo ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- Vtec - Grinding and Lapping - ORBIT - 0101 - V1Document3 pagesVtec - Grinding and Lapping - ORBIT - 0101 - V1Hugo AbreuNo ratings yet

- General Twin Seal 4 Way IOM 2002 PDFDocument16 pagesGeneral Twin Seal 4 Way IOM 2002 PDFtxlucky80No ratings yet

- Manual Pexto 137 Foot ShearDocument10 pagesManual Pexto 137 Foot Shearrubens072No ratings yet

- Installation Instructions For Vilter 25972Document8 pagesInstallation Instructions For Vilter 25972jorge castilloNo ratings yet

- High-Performance Sealed Brushless Motor Fans & Blowers: 12V - 24V DC/CCDocument64 pagesHigh-Performance Sealed Brushless Motor Fans & Blowers: 12V - 24V DC/CCSaid El AmmNo ratings yet

- Rock Roller BitDocument8 pagesRock Roller Bitdwinanda fortuna warmanNo ratings yet

- Pushrod Accessories & Rev KitsDocument6 pagesPushrod Accessories & Rev Kitscrower_scribdNo ratings yet

- Flight Model Sbach 342 50ccDocument61 pagesFlight Model Sbach 342 50ccyuntanakaNo ratings yet

- SKF Shaft CouplingsDocument24 pagesSKF Shaft CouplingsEmilio PortelaNo ratings yet

- Cadenas Forjadas 4B PDFDocument5 pagesCadenas Forjadas 4B PDFCésar VásquezNo ratings yet

- ZSpeed CMAK Install Instructions 8 8 19 UpdatedDocument7 pagesZSpeed CMAK Install Instructions 8 8 19 UpdatedSteeve GosselinNo ratings yet

- BFV2MANUALDocument16 pagesBFV2MANUALDanny Olmedo TorresNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Porsche 356: The Engine Handbook: An Engine Assembly GuideFrom EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNo ratings yet

- HSRS1AA_HeadstockRiser_AdjusterMountHoleDrawingDocument1 pageHSRS1AA_HeadstockRiser_AdjusterMountHoleDrawingassistenteintegradorNo ratings yet

- Laserati-Manual-EN_2Document55 pagesLaserati-Manual-EN_2assistenteintegradorNo ratings yet

- FlashCut CNC Guia de Hardware do Gerador de SinaisDocument21 pagesFlashCut CNC Guia de Hardware do Gerador de SinaisassistenteintegradorNo ratings yet

- Pro Series Servo Controller ManualDocument65 pagesPro Series Servo Controller ManualassistenteintegradorNo ratings yet

- FlashCut CNC 501A Manual do gerador de sinaisDocument36 pagesFlashCut CNC 501A Manual do gerador de sinaisassistenteintegradorNo ratings yet

- FlashCut CNC Stepper Drive Box Manual de configuraçãoDocument19 pagesFlashCut CNC Stepper Drive Box Manual de configuraçãoassistenteintegradorNo ratings yet

- Forkardt_Betriebsanleitung_Spannzylinder_PZR_DDocument20 pagesForkardt_Betriebsanleitung_Spannzylinder_PZR_DassistenteintegradorNo ratings yet

- Forkardt HRC ARC UR2M & URPC Modelos de Cilindro Rotativo Manual de InstruçõesDocument8 pagesForkardt HRC ARC UR2M & URPC Modelos de Cilindro Rotativo Manual de InstruçõesassistenteintegradorNo ratings yet

- Forkardt ID & OD Grip Collet Chucks Manual de instalação e serviçoDocument8 pagesForkardt ID & OD Grip Collet Chucks Manual de instalação e serviçoassistenteintegradorNo ratings yet

- Diafragmas Forkardt WoodworthDocument1 pageDiafragmas Forkardt WoodworthassistenteintegradorNo ratings yet

- Handicrafts of GoaDocument2 pagesHandicrafts of Goanishma shemyNo ratings yet

- ScrollSaw Woodworking & Crafts #64 - Fall 2016 (Gnv64)Document92 pagesScrollSaw Woodworking & Crafts #64 - Fall 2016 (Gnv64)Jose Francisco Torquato100% (1)

- TLE-IA6 - q0 - Mod2 - Creative and Innovative Ways of EnhancingDecorating Products - v3Document24 pagesTLE-IA6 - q0 - Mod2 - Creative and Innovative Ways of EnhancingDecorating Products - v3PAUL JIMENEZNo ratings yet

- Basic Tec 2Document36 pagesBasic Tec 2TMTM MediaNo ratings yet

- Traditional FurnitureDocument130 pagesTraditional Furniturearquivoslivros100% (2)

- Paper Towel HolderDocument5 pagesPaper Towel HoldermchiovettaNo ratings yet

- The Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsDocument211 pagesThe Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsAmmad Ahmad100% (2)

- Concrete Construction Article PDF Form ReuseDocument3 pagesConcrete Construction Article PDF Form ReuseiveyNo ratings yet

- Optimization of Process Parameters in Turning and Threading Operation-A ReviewDocument5 pagesOptimization of Process Parameters in Turning and Threading Operation-A ReviewIJRASETPublicationsNo ratings yet

- Lecture 3-Tool Life, Tools, Machine Parts-F-19!8!14Document20 pagesLecture 3-Tool Life, Tools, Machine Parts-F-19!8!14hari0118No ratings yet

- Cordless Drill Charge Station Cut List and Plans Hertoolbelt 1Document6 pagesCordless Drill Charge Station Cut List and Plans Hertoolbelt 1kent neitzkeNo ratings yet

- c5 Lathe 120203152613 Phpapp02Document30 pagesc5 Lathe 120203152613 Phpapp02Preavin Kutty Thamotharan100% (1)

- Flow Hive Assembly Guide Combined AU PRINT 310517Document12 pagesFlow Hive Assembly Guide Combined AU PRINT 310517José FrazãoNo ratings yet

- Mechanical Engineering Module 2Document28 pagesMechanical Engineering Module 2gubavinNo ratings yet

- Carpentry FINALDocument8 pagesCarpentry FINALSJ BatallerNo ratings yet

- DIY Router Table: InstructablesDocument18 pagesDIY Router Table: Instructablesjack100% (1)

- Flooring Materials, Walling Materials, Ceiling and Acoustical Materials, & Roofing MaterialsDocument58 pagesFlooring Materials, Walling Materials, Ceiling and Acoustical Materials, & Roofing MaterialsGio Padilla100% (1)

- Types of Flooring: Materials and Priciples of ConstructionDocument26 pagesTypes of Flooring: Materials and Priciples of ConstructionSanjay KumarNo ratings yet

- Descriptions of Tools in InmatproDocument6 pagesDescriptions of Tools in InmatproArabella PASAHOLNo ratings yet

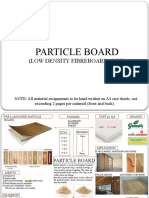

- Particle Board: (Low Density Fibreboard - LDF)Document3 pagesParticle Board: (Low Density Fibreboard - LDF)Bmssa 2017BNo ratings yet

- Bangladesh Industrial Technical Assistance CenterDocument38 pagesBangladesh Industrial Technical Assistance CenterJunaed Ahmed SaifNo ratings yet

- July26 TreasurechestDocument5 pagesJuly26 Treasurechestapi-376979181No ratings yet

- BÀI TẬP LỚP 12 Tues 20 7 2021Document9 pagesBÀI TẬP LỚP 12 Tues 20 7 2021Thiên TrangNo ratings yet

- Measure in Inch and CMDocument1 pageMeasure in Inch and CMIrena Agatha SimanjuntakNo ratings yet

- Ews Lab 01Document4 pagesEws Lab 01Aamir Ali DayoNo ratings yet

- Tle 7 A.F.A. Plant Production Quarter 1 Module 2 MataDocument10 pagesTle 7 A.F.A. Plant Production Quarter 1 Module 2 Mataio100% (1)

- Ra 1141Document104 pagesRa 1141Jesus DavalosNo ratings yet

BBTCSX_BBTCSYZ Instructions 3-28-2010

BBTCSX_BBTCSYZ Instructions 3-28-2010

Uploaded by

assistenteintegradorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BBTCSX_BBTCSYZ Instructions 3-28-2010

BBTCSX_BBTCSYZ Instructions 3-28-2010

Uploaded by

assistenteintegradorCopyright:

Available Formats

A2Z CNC Ball Bearing Thrust Collar for Sherline

The A2Z CNC Ball Bearing Thrust Collar system requires your X (and Y for mill) leadscrews to

use Sherline’s newer end system that has been standard since about 2000. You can identify this

version by the 5-40 cap screw screwed into the central axis of the screw and holding a top hat

style adapter onto the end of the screw. If your machine has the older system which used a clip

onto the leadscrew, you will need to replace the screw with the following Sherline part numbers:

X Inch Y Inch Z Inch X Metric Y Metric Z Metric

5X00 Mill 50171 50161 67028 51171 51161 67029

54X0 Mill 50171 54161 67028 51171 54170 67029

20X0 Mill 50171 56161 67030 51171 56151 67031

4X00 Lathe 44211 67024 44221 67025

44X0 Lathe 67210 67026 67221 67027

You will need to replace your Z axis screw with the CNC version that uses the 30 deg taper and

5-40 cap screw to mate with our leadscrew adapter. The Sherline part numbers are listed in the

table above.

To install A2Z CNC Ball Bearing Thrust Collars on Sherline lathe or mill:

1 - Remove the hand wheel, factory thrust collar, and leadscrew adapter.

2 - Install the new leadscrew adapter using the included 5-40x1-1/4” cap screw. Do not use any

loctite on the 5-40 screw.

3 - Slide the Thrust Collar Body with bearings installed onto the leadscrew adapter. The recessed

bearing faces towards the leadscrew.

4 - Secure the Thrust Collar Body to the table/base/slide using the included 8-32 cap screws.

5 - Install your handwheel. You adjust the preload on the bearings by squeezing the handwheel

and leadscrew together and then securing the handwheel.

Thrust Collar Bod'

Bearings

•5-40x1-1/4

Socket Cap Screw

Leadscrew Adapter

A2Z IS. Sc

I CNC I

www.A2ZCNC.com

www.Peck-Polymers.com

www.lndoorModelSupply.com Indoor Balsa .com

www.A2ZCorp.us

QUALITY PRODUCTS MADE IN THE USA Mar 2010

You might also like

- Voest DAT ManualDocument52 pagesVoest DAT ManualRobert Spencer80% (5)

- Story. The Tale of Three TreesDocument2 pagesStory. The Tale of Three TreesAlwin Asuncion100% (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Kiwiprop K4 Boss Assembly v2.4Document15 pagesKiwiprop K4 Boss Assembly v2.4adul sungkatinNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Dividing HeadDocument40 pagesDividing HeadChristopher Ruben100% (3)

- BOP 4116 15kDocument44 pagesBOP 4116 15koswaldo58100% (2)

- Mini Lathe CNC ConversionDocument7 pagesMini Lathe CNC ConversioneFalegname100% (5)

- Garden Tractor Plans PDFDocument11 pagesGarden Tractor Plans PDFLucian LeonteNo ratings yet

- Falk Quadrive Shaft Mounted Drive - Interchange Guide 371810Document12 pagesFalk Quadrive Shaft Mounted Drive - Interchange Guide 371810Anonymous ntE0hG2TPNo ratings yet

- 1150 InstDocument5 pages1150 InstMohammad NorooziNo ratings yet

- A2ZUpgradesForSherlineMillExplainedDocument4 pagesA2ZUpgradesForSherlineMillExplainedassistenteintegradorNo ratings yet

- Accessories: Scan These QR CodesDocument12 pagesAccessories: Scan These QR CodesAnonymous D5QForitcNo ratings yet

- How To: Index The Spark Plugs On A Ficht / Direct Injection OutboardDocument4 pagesHow To: Index The Spark Plugs On A Ficht / Direct Injection OutboardrfffffNo ratings yet

- 2014 Right Foot Performance Products CatalogDocument54 pages2014 Right Foot Performance Products CatalogbudzodesignsNo ratings yet

- FF Primary InstructionsDocument12 pagesFF Primary InstructionsKevin VillagranNo ratings yet

- Trailer Buddy VaultDocument10 pagesTrailer Buddy VaultjeffNo ratings yet

- B 4600Document6 pagesB 4600sergioarrayaNo ratings yet

- Avk Butterfly Valves, Centric With Loose Liner: Series 820Document6 pagesAvk Butterfly Valves, Centric With Loose Liner: Series 820utzu_yooNo ratings yet

- Atlas Copco Secoroc: Reverse Circulation EquipmentDocument12 pagesAtlas Copco Secoroc: Reverse Circulation EquipmentSergio Perez100% (1)

- Atv PlansDocument90 pagesAtv PlansK Scott Wyatt100% (6)

- Apex Catlogue A43010-MinDocument24 pagesApex Catlogue A43010-Minfaisal kingNo ratings yet

- VQ35DEDocument18 pagesVQ35DEJorge MirandaNo ratings yet

- Bearing Ina Lit - 167 - Us - Us PDFDocument16 pagesBearing Ina Lit - 167 - Us - Us PDFbatman2054No ratings yet

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDocument39 pagesTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Bath Tube 3997d3df 9c44 4dfd b1b6 7f4eb028eef9Document17 pagesBath Tube 3997d3df 9c44 4dfd b1b6 7f4eb028eef9nam nguyenNo ratings yet

- Atlanta Servo Drive System 060812Document85 pagesAtlanta Servo Drive System 060812Anonymous JGugvoz1No ratings yet

- 371 810 Falk Quadrive Shaft Mounted Drive Interchange GuideDocument12 pages371 810 Falk Quadrive Shaft Mounted Drive Interchange GuideVirginia Venus Visuette MarínNo ratings yet

- WorkBee Screw Assembly Manual 2019Document40 pagesWorkBee Screw Assembly Manual 2019CsíkJúliusNo ratings yet

- Drive Coupling SKFDocument19 pagesDrive Coupling SKFFrank MwafulirwaNo ratings yet

- Getrag 256 PrepDocument7 pagesGetrag 256 PrepInes LopesNo ratings yet

- 600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)Document8 pages600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)LeonardNo ratings yet

- Pennbarry SX Catalogue TS v9bDocument34 pagesPennbarry SX Catalogue TS v9bjacaNo ratings yet

- Assembly Instructions: Retrofit For Bridgeport Series 1 MillsDocument4 pagesAssembly Instructions: Retrofit For Bridgeport Series 1 MillsDustin_JanesNo ratings yet

- Design Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsDocument30 pagesDesign Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsCora XuNo ratings yet

- Bosch Rexroth Fusos EsferasDocument164 pagesBosch Rexroth Fusos EsferasjomiseferNo ratings yet

- SKF CouplingDocument16 pagesSKF CouplingmatchutNo ratings yet

- Redlands Ingles Manual Junta GiratoriaDocument10 pagesRedlands Ingles Manual Junta GiratoriaTarcilio FonsecaNo ratings yet

- Efk 1Document4 pagesEfk 1Jennifer YuanNo ratings yet

- Equipements de Positionnement14601Document18 pagesEquipements de Positionnement14601techspawNo ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- Vtec - Grinding and Lapping - ORBIT - 0101 - V1Document3 pagesVtec - Grinding and Lapping - ORBIT - 0101 - V1Hugo AbreuNo ratings yet

- General Twin Seal 4 Way IOM 2002 PDFDocument16 pagesGeneral Twin Seal 4 Way IOM 2002 PDFtxlucky80No ratings yet

- Manual Pexto 137 Foot ShearDocument10 pagesManual Pexto 137 Foot Shearrubens072No ratings yet

- Installation Instructions For Vilter 25972Document8 pagesInstallation Instructions For Vilter 25972jorge castilloNo ratings yet

- High-Performance Sealed Brushless Motor Fans & Blowers: 12V - 24V DC/CCDocument64 pagesHigh-Performance Sealed Brushless Motor Fans & Blowers: 12V - 24V DC/CCSaid El AmmNo ratings yet

- Rock Roller BitDocument8 pagesRock Roller Bitdwinanda fortuna warmanNo ratings yet

- Pushrod Accessories & Rev KitsDocument6 pagesPushrod Accessories & Rev Kitscrower_scribdNo ratings yet

- Flight Model Sbach 342 50ccDocument61 pagesFlight Model Sbach 342 50ccyuntanakaNo ratings yet

- SKF Shaft CouplingsDocument24 pagesSKF Shaft CouplingsEmilio PortelaNo ratings yet

- Cadenas Forjadas 4B PDFDocument5 pagesCadenas Forjadas 4B PDFCésar VásquezNo ratings yet

- ZSpeed CMAK Install Instructions 8 8 19 UpdatedDocument7 pagesZSpeed CMAK Install Instructions 8 8 19 UpdatedSteeve GosselinNo ratings yet

- BFV2MANUALDocument16 pagesBFV2MANUALDanny Olmedo TorresNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Porsche 356: The Engine Handbook: An Engine Assembly GuideFrom EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNo ratings yet

- HSRS1AA_HeadstockRiser_AdjusterMountHoleDrawingDocument1 pageHSRS1AA_HeadstockRiser_AdjusterMountHoleDrawingassistenteintegradorNo ratings yet

- Laserati-Manual-EN_2Document55 pagesLaserati-Manual-EN_2assistenteintegradorNo ratings yet

- FlashCut CNC Guia de Hardware do Gerador de SinaisDocument21 pagesFlashCut CNC Guia de Hardware do Gerador de SinaisassistenteintegradorNo ratings yet

- Pro Series Servo Controller ManualDocument65 pagesPro Series Servo Controller ManualassistenteintegradorNo ratings yet

- FlashCut CNC 501A Manual do gerador de sinaisDocument36 pagesFlashCut CNC 501A Manual do gerador de sinaisassistenteintegradorNo ratings yet

- FlashCut CNC Stepper Drive Box Manual de configuraçãoDocument19 pagesFlashCut CNC Stepper Drive Box Manual de configuraçãoassistenteintegradorNo ratings yet

- Forkardt_Betriebsanleitung_Spannzylinder_PZR_DDocument20 pagesForkardt_Betriebsanleitung_Spannzylinder_PZR_DassistenteintegradorNo ratings yet

- Forkardt HRC ARC UR2M & URPC Modelos de Cilindro Rotativo Manual de InstruçõesDocument8 pagesForkardt HRC ARC UR2M & URPC Modelos de Cilindro Rotativo Manual de InstruçõesassistenteintegradorNo ratings yet

- Forkardt ID & OD Grip Collet Chucks Manual de instalação e serviçoDocument8 pagesForkardt ID & OD Grip Collet Chucks Manual de instalação e serviçoassistenteintegradorNo ratings yet

- Diafragmas Forkardt WoodworthDocument1 pageDiafragmas Forkardt WoodworthassistenteintegradorNo ratings yet

- Handicrafts of GoaDocument2 pagesHandicrafts of Goanishma shemyNo ratings yet

- ScrollSaw Woodworking & Crafts #64 - Fall 2016 (Gnv64)Document92 pagesScrollSaw Woodworking & Crafts #64 - Fall 2016 (Gnv64)Jose Francisco Torquato100% (1)

- TLE-IA6 - q0 - Mod2 - Creative and Innovative Ways of EnhancingDecorating Products - v3Document24 pagesTLE-IA6 - q0 - Mod2 - Creative and Innovative Ways of EnhancingDecorating Products - v3PAUL JIMENEZNo ratings yet

- Basic Tec 2Document36 pagesBasic Tec 2TMTM MediaNo ratings yet

- Traditional FurnitureDocument130 pagesTraditional Furniturearquivoslivros100% (2)

- Paper Towel HolderDocument5 pagesPaper Towel HoldermchiovettaNo ratings yet

- The Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsDocument211 pagesThe Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsAmmad Ahmad100% (2)

- Concrete Construction Article PDF Form ReuseDocument3 pagesConcrete Construction Article PDF Form ReuseiveyNo ratings yet

- Optimization of Process Parameters in Turning and Threading Operation-A ReviewDocument5 pagesOptimization of Process Parameters in Turning and Threading Operation-A ReviewIJRASETPublicationsNo ratings yet

- Lecture 3-Tool Life, Tools, Machine Parts-F-19!8!14Document20 pagesLecture 3-Tool Life, Tools, Machine Parts-F-19!8!14hari0118No ratings yet

- Cordless Drill Charge Station Cut List and Plans Hertoolbelt 1Document6 pagesCordless Drill Charge Station Cut List and Plans Hertoolbelt 1kent neitzkeNo ratings yet

- c5 Lathe 120203152613 Phpapp02Document30 pagesc5 Lathe 120203152613 Phpapp02Preavin Kutty Thamotharan100% (1)

- Flow Hive Assembly Guide Combined AU PRINT 310517Document12 pagesFlow Hive Assembly Guide Combined AU PRINT 310517José FrazãoNo ratings yet

- Mechanical Engineering Module 2Document28 pagesMechanical Engineering Module 2gubavinNo ratings yet

- Carpentry FINALDocument8 pagesCarpentry FINALSJ BatallerNo ratings yet

- DIY Router Table: InstructablesDocument18 pagesDIY Router Table: Instructablesjack100% (1)

- Flooring Materials, Walling Materials, Ceiling and Acoustical Materials, & Roofing MaterialsDocument58 pagesFlooring Materials, Walling Materials, Ceiling and Acoustical Materials, & Roofing MaterialsGio Padilla100% (1)

- Types of Flooring: Materials and Priciples of ConstructionDocument26 pagesTypes of Flooring: Materials and Priciples of ConstructionSanjay KumarNo ratings yet

- Descriptions of Tools in InmatproDocument6 pagesDescriptions of Tools in InmatproArabella PASAHOLNo ratings yet

- Particle Board: (Low Density Fibreboard - LDF)Document3 pagesParticle Board: (Low Density Fibreboard - LDF)Bmssa 2017BNo ratings yet

- Bangladesh Industrial Technical Assistance CenterDocument38 pagesBangladesh Industrial Technical Assistance CenterJunaed Ahmed SaifNo ratings yet

- July26 TreasurechestDocument5 pagesJuly26 Treasurechestapi-376979181No ratings yet

- BÀI TẬP LỚP 12 Tues 20 7 2021Document9 pagesBÀI TẬP LỚP 12 Tues 20 7 2021Thiên TrangNo ratings yet

- Measure in Inch and CMDocument1 pageMeasure in Inch and CMIrena Agatha SimanjuntakNo ratings yet

- Ews Lab 01Document4 pagesEws Lab 01Aamir Ali DayoNo ratings yet

- Tle 7 A.F.A. Plant Production Quarter 1 Module 2 MataDocument10 pagesTle 7 A.F.A. Plant Production Quarter 1 Module 2 Mataio100% (1)

- Ra 1141Document104 pagesRa 1141Jesus DavalosNo ratings yet