Professional Documents

Culture Documents

TA1000-0039EN

TA1000-0039EN

Uploaded by

Miguel CastellanosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TA1000-0039EN

TA1000-0039EN

Uploaded by

Miguel CastellanosCopyright:

Available Formats

TA 1000-0039

Securing GE Jenbacher modules during

transport by truck

Technical Instruction

© GE Jenbacher GmbH & Co OG

Achenseestr. 1-3

A-6200 Jenbach (Austria)

www.gejenbacher.com

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

1 Scope ............................................................................................................................................................ 2

2 Purpose ........................................................................................................................................................ 2

3 Relevant documents.................................................................................................................................. 2

4 Minimum requirements for the transport of modules (without accessories)................................. 2

5 Loading ........................................................................................................................................................ 3

5.1 General ............................................................................................................................................................................ 3

5.2 Lifting, moving and setting down ....................................................................................................................... 3

5.3 Positioning on the transport vehicle.................................................................................................................. 3

6 Securing during transport........................................................................................................................ 5

6.1 General ............................................................................................................................................................................ 5

6.2 Anti-slip mats................................................................................................................................................................ 5

6.3 Lashing straps.............................................................................................................................................................. 6

6.4 Lashing forces.............................................................................................................................................................. 6

7 Attachment points on the module.......................................................................................................... 8

8 Restraining the module in the direction of travel................................................................................ 8

9 Attachment points and restraints for Type 2 modules....................................................................... 9

10 Attachment points and restraints for Type 4 modules .................................................................... 10

11 Attachment points and restraints for Type J624 modules .............................................................. 13

12 Generator attachment points and restraints .................................................................................... 15

13 Checklist .................................................................................................................................................... 15

14 Revision code............................................................................................................................................ 16

The target recipients of this document are:

Customer, Service Partner, Commissioning Partner, Subsidiaries/Branches, Location Jenbach

GE proprietary information: CONFIDENTIAL

The information contained in this document is General Electric Company proprietary information and is

disclosed in confidence. It is the property of GE and shall not be used, disclosed to others or reproduced

without the express written consent of GE. This includes but not limited to use for the creation, manufacture,

development or derivation of any repairs, modifications, spare parts, designs or configuration changes, or for

obtaining government or regulatory approval to do so. If consent is given for reproduction in whole or in part,

this notice and the notice set forth on each page of this document shall appear in any such reproduction in

whole or in part.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

See TI 2300-0005 for safety instructions!

NOTICE

Observance of the conditions of this Technical Instruction and performance of the

activities described therein is the basis of safe and efficient transport of the plant.

Non-observance of the conditions of this Technical Instruction and/or non-performance of the

prescribed activities or any departure from the prescribed activities shall result in the loss of

guarantee rights. This shall not be the case if the operator/carrier shows that although the Tech-

nical Instruction was observed, defects already existed at the time of handover or commission-

ing,

The activities and conditions defined in this Technical Instruction shall be performed and/or ob-

served by the plant operator. This shall not apply if this Technical Instruction is expressly alloca-

ted to the area of responsibility of GE Jenbacher or a contractual agreement between the opera-

tor/carrier and GE Jenbacherprovides for a different arrangement.

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 1/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

1 Scope

This Technical Instruction applies to all GE modules with Type 2, 3, 4 and 6 engines.

2 Purpose

This Technical Instruction expands the information in TI 1000-0042 and TI 1000-0046 by adding instructions on

securing GE Jenbacher modules during transport by truck.

It does not cover:

▪ transport in containers

▪ transport in crates, boxes or other rigid packing

Modules with Type 9 engines are treated separately and are subject to their own transport specifications.

3 Relevant documents

The following documents must also be observed:

TI 1000-0042 Lifting and transporting GE Jenbacher modules and positioning them in engine rooms

TI 1000-0046 Lifting and transporting GE Jenbacher modules and positioning them in engine rooms

DIN EN 12195 Load restraining on road vehicles - Safety

VDI 2700 Securing of loads on road vehicles

4 Minimum requirements for the transport of modules (without accessories)

▪ Closed truck

Type 2 and 3 engines and generators:

▪ 12 lashing straps with at least LC 2,500 including edge protection

▪ 2 anti-slip mats of 200 mm x 6,000 mm x 12 mm

Type 4 engines:

▪ 10 lashing straps with at least LC 2,500 including edge protection

▪ 2 shackles with WLL 8.5 t pin, DM 28 mm, inside width 43 mm

▪ 2 anti-slip mats of 200 mm x 6,500 mm x 12 mm

Type 6 engines:

▪ 14 lashing straps with at least LC 2 500 including edge protection

▪ 4 shackles with WLL 8.5 t pin, DM 28 mm, inside width 43 mm

▪ 2 anti-slip mats of 200 mm x 7,000 mm x 12 mm

Type 624 engines:

▪ 8 lashing chains with at least LC 4,000 including edge protection

▪ 2 lashing straps with at least LC 2,500 including edge protection

▪ 4 shackles with WLL 8.5 t pin, DM 28 mm, inside width 43 mm

▪ 2 anti-slip mats of 200 mm x 9,800 mm x 12 mm

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 2/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

5 Loading

5.1 General

Loading must be carried out by an experienced and trained loader holding all the necessary training

certificates. The loader in this context is the person operating the lifting equipment used to load the truck,

regardless of whether they are an employee of GE Jenbacher or the carrier (truck driver or person responsible

for loading) The following are permissible for loading GE Jenbacher modules on to trucks:

▪ Forklift trucks with adequate lifting capacity, height and reach if permitted by the relevant TI for the engine

type.

▪ Mobile cranes

▪ Stationary cranes

When loading with this lifting equipment, all the work and safety instructions of the manufacturer of the lifting

equipment and those laid down by law must be observed. The loader must familiarise himself with these in

advance.

5.2 Lifting, moving and setting down

The instructions in TI 1000-0046 for type 2, 3 and 4 engines and in TI 1000-0042 for Type 6 engines must

always be observed when lifting, moving and setting down. Modules must be lifted carefully, and the

permissible acceleration in the Z-direction of 0.2 g must not be exceeded. No movement in the X and Y

directions is permissible when lifting. The load must not be moved until lifting is completed.

When moving, pay strict attention to ensuring that no damage occurs to either the load or the truck, and that

no personal injury is suffered. The loader must make sure before the start of loading that the planned load path

is clear and there are no persons or objects obstructing the module and lifting gear; this must be continuously

checked during loading. If this not possible for technical reasons or reasons to do with the building, a loading

assistant must be called in to monitor the area out of the loader's field of view and to assist the loader by

means of optical or acoustic signals. The load must be moved carefully; jerky movements, speeds over 0.8 m/s

(3 km/h, half walking pace) and longitudinal and transverse accelerations of more than 0.1 g, e.g. when

negotiating bends, must be avoided at all costs.

Make sure before setting down that anti-slip measures have been taken where the module is to be placed.

Setting down itself must be carried out with extreme caution, and any impact on the module or transport

equipment must be avoided. The maximum permissible acceleration in the Z-direction is 0.2 g; horizontal

movement is inadmissible. It must also be ensured that once set down, the module frame sits flush on the

vehicle floor surface, and that the cargo cannot tip over and stands straight and has been positioned in

accordance with the instructions under "Positioning on the transport vehicle". If this is not the case, the loading

procedure (separated into horizontal and vertical procedures) must be repeated until the requirements are met

in full. The loader is responsible for compliance.

5.3 Positioning on the transport vehicle

The module must be positioned longitudinally in the middle of the load surface and parallel to the vehicle

longitudinal axis. The cargo must be positioned transversely on the vehicle so that the axle loads are as even

as possible; under no circumstances may the permissible individual axle or wheel loads be exceeded. Make

sure that there is sufficient clearance between the module and walls or tarpaulins so that no contact and

resulting damage to the module or the vehicle can occur during transport, and access to the lashing points on

the vehicle cargo floor is guaranteed.

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 3/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Fig. 1: Module positioning on the cargo floor viewed from the rear

Fig. 2: Module positioning on the cargo floor viewed from the left

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 4/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

6 Securing during transport

6.1 General

GE Jenbacher modules must be secured during

transport by truck in accordance with the regulations

and guidelines of EN 12195 and VDI 2700. Securing

using friction-locking alone and combined friction and

positive locking are both permissible. The carrier is

under an obligation to ensure that the driver given the

job is familiar with all the rules and regulations and

has been trained in them. The appropriate lashing

equipment must be provided by the carrier and

presented to the person responsible for despatch at

GE Jenbacher before loading is commenced. The

lashing equipment must be in good condition, be

completely undamaged and bear the manufacturer's

test notice.

Fig. 3: Test notice for lashing equipment as per EN

12195-2

Lashing equipment which is missing or does not comply with legal requirements will result in loading being

refused until the required equipment is presented. The complaint and resultant delay must be noted in the

delivery note. Any costs incurred by the delay or total refusal to load, including consequential costs, shall be

borne by the carrier. GE Jenbacher further reserves the right to claim against the carrier for any penalty

payments resulting from late delivery of the module to the customer, should a justified refusal to load for the

above reasons be the cause of the delayed delivery.

6.2 Anti-slip mats

To reduce the lashing forces it is required to use anti-slip mats according to VDI 2700 Part 15 for every single

transport. These will be provided by GE Jenbacher or its logistics partner, the firm of Geb. Weiss, to every carrier

before the start of loading.

The anti-slip mats must be positioned on the vehicle cargo floor (while observing the prohibition against

working under suspended loads) so that the two longitudinal beams of the module frame sit flush on the anti-

slip mats and no part of the module is in direct contact with the vehicle cargo floor.

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 5/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

6.3 Lashing straps

Heavy-duty lashing straps with the following properties are prescribed for lashing down GE Jenbacher

modules:

▪ Lashing strap according to EN 12195-2

▪ Width at least 50 mm

▪ at least LC 2,500 daN

▪ SHF 50 daN

▪ STF 300 daN

▪ Max. elongation 5%

▪ Carabiner or triangle hooks with safety latches (claw hooks only permissible after approval by the GE Jen-

bacher person responsible for despatch, and if loosening or becoming undone during transport can be

ruled out)

or

▪ Lashing strap according to EN 12195-2

▪ Width at least 50 mm

▪ at least LC 5,000 daN

▪ SHF 50 daN

▪ STF 400 daN

▪ Max. elongation 5%

▪ Carabiner or triangle hook with safety latch

If a carabiner or triangle hook cannot be attached directly to the module, suitable aids or intermediate

equipment such as shackles or heavy-duty carabiners must be used.

Restraining chains must be used to secure GE Jenbacher modules with type J624 engines.

6.4 Lashing forces

The lashing provides a restraint against acceleration forces during transport. These generally result in tipping

around the longitudinal axis of the module-vehicle due to the narrow support triangle, and slipping in the

longitudinal direction.

Fig. 4: Support triangles in the longitudinal and transverse directions

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 6/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

The module must be restrained in principle as shown in Figs. 5 or 6. The number and position of the lashings

will depend on the weight of the module and the accessibility of the lashing points on the vehicle.

Restraints must always run directly between the attachment point on the module and the load bearing point

on the vehicle, i.e. the lashing strap must run in a straight line between these two points without touching any

other components. In particular, it must be ensured that no other components are subjected to any forces from

the restraints which could deform or damage them, and that no components can deform during transport with

the result that the restraints can become loose or undone.

Fig. 5: Fastening lashings to the module, schematic, four-point fixing

① Module centre of gravity

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 7/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Fig. 6: Fastening lashings to the module, schematic, six-point fixing

① Module centre of gravity

7 Attachment points on the module

Modules have different attachment points where the restraints have to be attached, depending on the engine

type and the scope of supply. The attachment points, their position on the module and the correct position of

the lashings for the individual engine types are shown in Figs. 7 to 25. The lashings must be checked before

transport is approved and started.

8 Restraining the module in the direction of travel

The fundamental rule is:

▪ The module must be restrained in backward direction (to prevent slipping forwards) with at least 60% of

the weight of the load.

▪ The module must be restrained in forward direction (to prevent slipping backwards) with at least 40% of

the weight of the load.

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 8/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

9 Attachment points and restraints for Type 2 modules

Fig. 7: Position of the attachment points, Type 2, left

Fig. 8: Position of the attachment points, Type 2, right

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 9/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Fig. 9: Detail of attachment point 1 Fig. 10: Detail of attachment point 2

Fig. 11: Detail of attachment point 3 Fig. 12: Detail of attachment point 4

10 Attachment points and restraints for Type 4 modules

Use a shackle when lashing down at the lifting lugs - see Fig. 16

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 10/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Fig. 13: Position of the attachment points, Type 4, left

Fig. 14: Position of the attachment points, Type 4, right

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 11/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Fig. 15: Detail of attachment point 1 Fig. 16: Detail of attachment point 2

Fig. 17: Detail of attachment point 3, Type 4

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 12/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

11 Attachment points and restraints for Type J624 modules

Fig. 18: Position of the attachment points, Type J624, right

Fig. 19: Detail of attachment point 1, J624

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 13/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Fig. 20: Detail of attachment point 2, J624

Fig. 22: Detail of attachment point 4, J624

Fig. 21: Detail of attachment point 3, J624

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 14/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

12 Generator attachment points and restraints

Fig. 23: Position of the generator attachment points, right

Fig. 24: Detail of generator attachment point 1 Fig. 25: Detail of generator attachment point 2

13 Checklist

The following checklist must be filled in completely before transport is commenced and question 17 must be

answered with YES before transport approval can be given by GE Jenbacher.

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 15/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

TA 1000-0039

Securing GE Jenbacher modules during transport by truck

Task description Person responsible Com Date and Signature

plet time

ed

(Y/N)

1 Transport order present, transport responsible

person, carrier and driver checked?

2 Cargo provided in accordance with transport

order?

3 Dimensions and exact weight of the cargo

known, checked and noted on the delivery note?

4 Vehicle suitable for transport as regards tonnage

and dimensions?

5 Carrier familiar with necessary regulations,

guidelines and GE Work Instructions?

6 Loader in possession of all necessary

qualification certificates and documents for

loading?

7 Vehicle cargo floor prepared as per VDI 2700?

8 Lashing equipment as per EN ISO 12195 present

and in perfect condition?

9 Anti-slip mats present and in perfect condition?

10 Cargo placed in the longitudinal and transverse

centre of the vehicle?

11 Cargo sitting flush on the anti-slip mats?

12 Enough lashing eyes in the vehicle cargo floor

and are they accessible?

13 Lashing carried out in accordance with

Technical Instruction?

14 Straps running in a straight line to the vehicle

cargo floor (no diversion caused by obstructing/

deformable module components)?

15 Straps clear (no danger of chafing), if not:

chafing protection fitted?

16 Straps tensioned crosswise to maximum manual

force (SHT value)?

17 Transport approval given?

14 Revision code

Revision history

Index Date Description/Revision summary Creator

Auditor

1 29.08.2014 Erstausgabe / First issue Kecht S.

SprungMarke!!!8458608011

Wolf S.

Author: Kecht S. Responsible: Wolf S. Release date: 29/08/2014

Index: 1 Page No.: 16/16

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

You might also like

- Reference Guide Parameters GHG14GHG17Document108 pagesReference Guide Parameters GHG14GHG17waleed azzawi60% (5)

- Kioti DK4810 (H, HS), DK5310 (H, HS), DK5810 (H, HS) Tractor Operator's ManualDocument15 pagesKioti DK4810 (H, HS), DK5310 (H, HS), DK5810 (H, HS) Tractor Operator's ManualLisakolyNo ratings yet

- VRT200 Transmission Service ManualDocument160 pagesVRT200 Transmission Service Manualgerallazo29100% (3)

- YALE (D879) GLC155VX LIFT TRUCK Service Repair Manual PDFDocument35 pagesYALE (D879) GLC155VX LIFT TRUCK Service Repair Manual PDFjkdmsmemmd67% (3)

- Ktron ManualDocument42 pagesKtron Manualdakalo83100% (3)

- Tms800e Om Ctrl132-03Document134 pagesTms800e Om Ctrl132-03Qike FlowersNo ratings yet

- Uno DM 3.3 3.8 4.6 5.0 TL Plus Us Product Manual en Reva (M000037ag)Document155 pagesUno DM 3.3 3.8 4.6 5.0 TL Plus Us Product Manual en Reva (M000037ag)Fernando Machado FerreiraNo ratings yet

- E06-017 Rev 1 EIV Manual PDFDocument29 pagesE06-017 Rev 1 EIV Manual PDFPalomino VergaraNo ratings yet

- Aerial Work Platform Business Study For Pakistan Market.Document17 pagesAerial Work Platform Business Study For Pakistan Market.TasneemNo ratings yet

- TA1000-0004ENDocument22 pagesTA1000-0004ENMiguel CastellanosNo ratings yet

- 1000-0039 enDocument50 pages1000-0039 enMohammad SajjidNo ratings yet

- Gcl-2 Operation Manual 06 VerDocument300 pagesGcl-2 Operation Manual 06 VerNatthakoon PhutchongNo ratings yet

- PD3000 Operating Manual CompressedDocument112 pagesPD3000 Operating Manual CompressedMUHAMAD SAUKINo ratings yet

- Kt9625 PtoDocument140 pagesKt9625 PtoDenial ImoNo ratings yet

- Clutch Compressor Service Manual For VolvoDocument36 pagesClutch Compressor Service Manual For Volvox100% (2)

- Operator's Manual - Spare Parts List Conveyor TRDocument46 pagesOperator's Manual - Spare Parts List Conveyor TRvalle verdeNo ratings yet

- Cigweldaeb Transtig 220acdc, 300acdc (S) 0-5292 - AbDocument104 pagesCigweldaeb Transtig 220acdc, 300acdc (S) 0-5292 - AbRobert Case0% (1)

- KM3000 KM4000 104075 E EnglishCompressedDocument122 pagesKM3000 KM4000 104075 E EnglishCompressedazharzebNo ratings yet

- T22 Mounting InstructionsDocument64 pagesT22 Mounting InstructionsHMI SERVERNo ratings yet

- Register Now Jetzt Registrieren: and Benefit! Und Profitieren!Document53 pagesRegister Now Jetzt Registrieren: and Benefit! Und Profitieren!cartigosaNo ratings yet

- Service & Maintenance Manual: Model EC600SJ, H600SJ, EC600SJP, H600SJPDocument544 pagesService & Maintenance Manual: Model EC600SJ, H600SJ, EC600SJP, H600SJPAlfredoNo ratings yet

- Yale Mpe 060vg - (A292) Lift Truck Service Repair ManualDocument35 pagesYale Mpe 060vg - (A292) Lift Truck Service Repair ManualSul Bases GustavoNo ratings yet

- Operator ManualDocument352 pagesOperator ManualRajeevanNo ratings yet

- Status Stamp: Sp-Proj-07-5 Vendor Doccover Sheet - Word Rev 04 18-09-18 - E003534 - Sp0793-P102.00-G05-0039Document56 pagesStatus Stamp: Sp-Proj-07-5 Vendor Doccover Sheet - Word Rev 04 18-09-18 - E003534 - Sp0793-P102.00-G05-0039enrique polarNo ratings yet

- Service User InterfaceDocument60 pagesService User InterfaceLuis Arcudia100% (3)

- Alternadores GPW Gpa GPF GSW Gsa GSF en 02Document39 pagesAlternadores GPW Gpa GPF GSW Gsa GSF en 02Gesiel SoaresNo ratings yet

- Kioti dk4510Document188 pagesKioti dk4510Rijal Furqaan MardhatillahNo ratings yet

- YALE A888 ERP12RCF LIFT TRUCK Service Repair Manual PDFDocument8 pagesYALE A888 ERP12RCF LIFT TRUCK Service Repair Manual PDFsekfsekmdddeNo ratings yet

- Yale g807 Erp18vt Lift Truck (Europe) Service Repair ManualDocument32 pagesYale g807 Erp18vt Lift Truck (Europe) Service Repair ManualSARAMQR50% (2)

- SM LM1330 LM1333 ENDocument415 pagesSM LM1330 LM1333 ENAfterek100% (1)

- WEG Turbogenerator 10174576 Manual English PDFDocument59 pagesWEG Turbogenerator 10174576 Manual English PDFjosaos76No ratings yet

- Manual de Operación y Mantenimiento PDFDocument49 pagesManual de Operación y Mantenimiento PDFJairresistenciagt123No ratings yet

- CompressorDocument93 pagesCompressorliliana06macarenaNo ratings yet

- Installation and Maintenance Manual: Centrifugal Fans At-As-Ash-Rsh-Adh-RdhDocument31 pagesInstallation and Maintenance Manual: Centrifugal Fans At-As-Ash-Rsh-Adh-Rdhshahzad32552372No ratings yet

- WEG Low and High Voltage Three Phase Induction Motors Squirrel Cage Rotor Vertical 11371757 Manual English DCDocument59 pagesWEG Low and High Voltage Three Phase Induction Motors Squirrel Cage Rotor Vertical 11371757 Manual English DCFrancisco OliveiraNo ratings yet

- CM6200 63674 CompressedDocument334 pagesCM6200 63674 CompressedazharzebNo ratings yet

- Corona PDFDocument98 pagesCorona PDFrosanateamoNo ratings yet

- EMMT As Operating Instr 2023 09f 8201373g1Document14 pagesEMMT As Operating Instr 2023 09f 8201373g1smoan14No ratings yet

- Fendt 200v - F - P Vario Operators ManualDocument158 pagesFendt 200v - F - P Vario Operators ManualgabrielNo ratings yet

- TORO Reelmaster 3100-DDocument306 pagesTORO Reelmaster 3100-Ddalidelia100% (1)

- New Holland Telehandlers Lm1060 en Service ManualDocument20 pagesNew Holland Telehandlers Lm1060 en Service Manualkent100% (51)

- MN 225008 enDocument48 pagesMN 225008 enCae FueNo ratings yet

- GLP/GDP60VX, GLP/GDP70VX (E878) Service Manual ContentsDocument15 pagesGLP/GDP60VX, GLP/GDP70VX (E878) Service Manual ContentsJonathan FullumNo ratings yet

- L2 - RXE 8000 EN Manual 11 - 200828Document64 pagesL2 - RXE 8000 EN Manual 11 - 200828Apurbaa SarmaNo ratings yet

- GS-200 Operation Manual 10 VerDocument466 pagesGS-200 Operation Manual 10 VersunhuynhNo ratings yet

- Niftylift OperationDocument38 pagesNiftylift OperationJay MobNo ratings yet

- SEWDocument64 pagesSEWCasHeerNo ratings yet

- Newholland Telehandlers Lm1340 Workshop ManualDocument20 pagesNewholland Telehandlers Lm1340 Workshop Manualclara100% (57)

- Battery CarrierDocument48 pagesBattery CarrierMarko StuparNo ratings yet

- Yale j813gp-glp-gdp110vx Lift Truck Service Repair ManualDocument57 pagesYale j813gp-glp-gdp110vx Lift Truck Service Repair Manualdeena.karan5281No ratings yet

- 117 4416568 Rev04 PDFDocument24 pages117 4416568 Rev04 PDFharvey89No ratings yet

- Installation & Service Manual Intermittor Roller Dial Index DrivesDocument30 pagesInstallation & Service Manual Intermittor Roller Dial Index Driveslucas rolanNo ratings yet

- Synergic Pulse 320spDocument161 pagesSynergic Pulse 320spwshopNo ratings yet

- Yale g807 Erp040vt Lift Truck Service Repair ManualDocument56 pagesYale g807 Erp040vt Lift Truck Service Repair ManualSul Bases GustavoNo ratings yet

- UNO-DM-6.0-TL-PLUS-US-Product Manual EN-RevADocument154 pagesUNO-DM-6.0-TL-PLUS-US-Product Manual EN-RevADiego SouzaNo ratings yet

- Champion 100624 Log SPlitter ENDocument31 pagesChampion 100624 Log SPlitter ENTenny SupNo ratings yet

- J1-Siemens 8WL5510-0Document22 pagesJ1-Siemens 8WL5510-0Victor Manuel BonettoNo ratings yet

- JunghairDocument577 pagesJunghairRadovanTrninic100% (2)

- Mom RT530 PDFDocument86 pagesMom RT530 PDFCesar Antonio AntillancaNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Form 21 PDFDocument1 pageForm 21 PDFSridharan VenkatNo ratings yet

- Site Plan Name of Work:-Proposed Construction of 90Mtr. Span Steel Giirder Bridge On Tapovan-Karchho Motor Road at K.M. 02 Plan - A & BDocument1 pageSite Plan Name of Work:-Proposed Construction of 90Mtr. Span Steel Giirder Bridge On Tapovan-Karchho Motor Road at K.M. 02 Plan - A & Bakshay kothiyalNo ratings yet

- FM200 Presentation (Corporate Overview) - 3Document108 pagesFM200 Presentation (Corporate Overview) - 3Gian Guaz33% (3)

- 05 10 03 PDFDocument2 pages05 10 03 PDFAnonymous 298xlo3uUNo ratings yet

- Brochure Saf HollandDocument818 pagesBrochure Saf HollandRodion KamyshenkoNo ratings yet

- University Design GuidelinesDocument29 pagesUniversity Design Guidelinesar.vaaniNo ratings yet

- Catalogue-Liyang Industry2021Document6 pagesCatalogue-Liyang Industry2021ЗинаNo ratings yet

- Electronic Throttle Control System-Intelligence (ETCS-i)Document19 pagesElectronic Throttle Control System-Intelligence (ETCS-i)DoDuyBac50% (2)

- Charlevoix County News - December 01, 2011Document12 pagesCharlevoix County News - December 01, 2011Dave BaragreyNo ratings yet

- Indian ATCS SystemDocument22 pagesIndian ATCS SystemAtul SaikumarNo ratings yet

- Puducherry Draft Mobility Plan - PresentationDocument101 pagesPuducherry Draft Mobility Plan - PresentationNathar ShaNo ratings yet

- Directions-Prepositions RESUELTODocument2 pagesDirections-Prepositions RESUELTOEdita PachecoNo ratings yet

- Interview CGSE 2022 en 141122Document10 pagesInterview CGSE 2022 en 141122divyanshNo ratings yet

- Pacific Basin Fleet ListDocument2 pagesPacific Basin Fleet ListRocio Piñero BernalNo ratings yet

- Case 9040BDocument6 pagesCase 9040BOleg080No ratings yet

- Egnm-Lemg OfpDocument70 pagesEgnm-Lemg OfpJoshNo ratings yet

- Aluminium Alloys - Aluminium 6063 Properties, Fabrication and Applications, Supplier Data by AalcDocument4 pagesAluminium Alloys - Aluminium 6063 Properties, Fabrication and Applications, Supplier Data by AalcatiquegeeNo ratings yet

- Lab 3 Running Speed Oel1Document4 pagesLab 3 Running Speed Oel12021884518No ratings yet

- Ppts. Dangerous17 SEAM III Dangerous 2-3Document345 pagesPpts. Dangerous17 SEAM III Dangerous 2-3Jun Briones100% (1)

- (1903) History of The United States Marine CorpsDocument484 pages(1903) History of The United States Marine CorpsHerbert Hillary Booker 2nd100% (2)

- Commendation Pmaj Fernando Tanguilan Manuel JR: SubjectDocument2 pagesCommendation Pmaj Fernando Tanguilan Manuel JR: SubjectJomarNo ratings yet

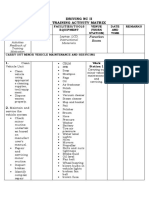

- Training Activity MatrixDocument6 pagesTraining Activity MatrixMaMerlinaJosue100% (2)

- Jet Airways Web Booking ETicket (PLTPWV) - LoboDocument3 pagesJet Airways Web Booking ETicket (PLTPWV) - LoboAamir KhanNo ratings yet

- NY mv21-mcDocument54 pagesNY mv21-mcAres RomanNo ratings yet

- Shyam Steel Industries LTD EnglishDocument14 pagesShyam Steel Industries LTD EnglishbalaasenthilNo ratings yet

- Master Circular Master Circular No. 10 Special Casual LeaveDocument18 pagesMaster Circular Master Circular No. 10 Special Casual LeaveAbhi ShakyNo ratings yet

- Seafarers Happiness Index Q1 2024Document25 pagesSeafarers Happiness Index Q1 2024Samuel ChanNo ratings yet

- Morocco: GMMM - Casablanca FirDocument9 pagesMorocco: GMMM - Casablanca FirRyan LeslieNo ratings yet