Professional Documents

Culture Documents

project rajeev1234

project rajeev1234

Uploaded by

shivajee559Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

project rajeev1234

project rajeev1234

Uploaded by

shivajee559Copyright:

Available Formats

RVS COLLEGE OF ENGINEERING

AND TECHNOLOGY, JAMSEDPUR

Session: 2022-2026

DEPARTMENT OF electrical ENGINEERING

VOCATIONAL TRAINING REPORT TGS, GAMHARIA

PROJECT NAME: Principle & Operation of switchyard

equipment and protection system

Guide By: MR Siripuram Mahender / MR Suraj Sharma

132/33kV TSUISL Substation, Submitted By: Rajeev Kumar

Inside TGS, Gamharia Reg No. 22013475010

Sign:-__________________________ Roll No. EEE/515/23L(4th Sem)

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

ACKNOWLEDGEMENT

This is to acknowledge the help & corporation that I have received make this training

period a great success. Power system, one of the important branch subjects demand

a practical approach and as a trainee at TATA STEEL UTILITIES AND

INFRASTRUCTURE SERVICES, I have received a deep insight of what actually

happens in 132/33kV substation, the equipment in the substation and various other

aspects related to the process which have been summarized in this report.

Before we go any further, I would like to present a gesture of gratitude towards

MR. SIRIPURAM MAHENDER SR MANAGER and J.E MR. NEERAJ

KUMAR THAKUR and my esteemed mentors who ensured a friendly,

motivational, and learning environment. I would also like to thank other TATA steel

utilities and infrastructure services employees, who constantly helped in our learning

during in-Plant training. I owe my gratitude to all of them.

INSTITUTE NAME: RVS COLLEGE OF ENGINEERING AND TECHNOLOGY,

JAMSHEDPUR

RAJEEV KUMAR (EEE/515/23L)

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

INDEX

A. SUBSTATION EQUIPMENTS

1. . TRANSFORMER

•1.1 conservator tank

•1.2 Transformer oil

•1.3 MOG

•1.4 Buchholz Relay

•1.5 Breather

•1.6 PRV

•1.7 Terminals and Bushing

•1.8 Radiators and Fans

•1.9 WTI,OTI

•1.10 Oil Level Indicator

•1.11 OLTC ( On Load Tap Changer )

•1.12 Marshalling Box

2. Current Transformer

3. Capacitor Voltage Transformer

4. Wave Trap

5. Lighting Arrester

6. Circuit Breaker

7. Isolator

8. Insulator

9. Bus Bar

10. Protection Relay

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

SUBSTATION EQUIPMENT AND

TRANSFROMER

An electrical substation is an integral part of a generation, transmission and distribution

system. A substation can interrupt or establish electrical circuit, change the voltage,

frequency or other characteristics of electrical energy flowing in the circuit.

In this article you will learn different types of substations, their functions and different

equipment used in them.

❖ Substation….

A substation is a key component of an

electrical generation, transmission, and

distribution system. It transforms voltage

levels, enabling the efficient transfer of

electrical power from power plants to

consumers. Here's a detailed overview of

substations:

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Types of Substations

installation

Functions of a Substation

A substation performs a major role in our power system. The functions of a substation

may include one or more of the following:

• To isolate a faulted element from the rest of the utility system.

• To allow an element to be disconnected from the rest of the utility system for

maintenance or repair.

• To change or transform voltage levels from one part of the utility system to

another.

• To control power flow in the utility system by switching elements into or out of

the utility system.

• To provide sources of reactive power for power factor correction or voltage

control.

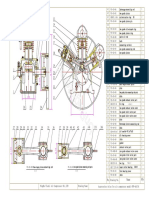

Substation Equipment / Components

An electrical substation contains many types of equipment. Substation generally

comprises the following equipment

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

. Isolator

1. TRANSFORMER

Transformers are essential electrical devices used to transfer electrical energy between

two or more circuits through electromagnetic induction. They play a crucial role in

power generation, transmission, and distribution systems by adjusting voltage levels to

meet different needs. Here's a detailed overview of transformers:

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Principle of Operation

A transformer works on the principle of

electromagnetic induction. When an

alternating current flows in the primary

winding of a transformer, a varying

electromagnetic field is generated which

induces EMF in the secondary winding.

The magnitude of the induced EMF is

proportional to the turn’s ratio.

Parts of a Transformer

following are the various transformer parts:

1. Conservator tank

2. Transformer oil

3. Magnetic oil gauge (MOG)

4. Buchholz relay

5. Breather

6. Pressure relief valve (PRV)

7. Terminals and bushings

8. Radiators and fans

10 WTI, OTI

11 Cooling tubes

12 Tap changer

1.1 Conservator Tank

Definition :-

This is a cylindrical tank mounted on supporting structure on the roof the

transformer main tank. The main function of conservator tank of transformer is to

provide adequate space for expansion of oil inside the transformer. It is connected

to the main tank through a pipe

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Conservator Main tank

OLTC (On Load Tap Changer)

Function of Conservator Tank of a Transformer :-

When transformer is loaded and when ambient temperature rises, the volume of oil

inside transformer increases. A conservator tank of transformer provides adequate space

to this expanded transformer oil. It also acts as a reservoir for transformer insulating

oil.

Construction of Conservator Tank :-

This is a cylindrical shaped oil container closed from both ends. One large inspection

cover is provided on either side of the container to facilitate maintenance and cleaning

inside of the conservator.

Conservator pipe, i.e., pipe comes from main transformer tank, is projected inside the

conservator from bottom portion. Head of the conservator pipe inside the conservator

is provided with a cap. This pipe is projected as well as provided with a cap because

this design prevents oil sludge and sediment to enter into main tank from conservator.

Generally, silica gel breather fixing pipe enters into the conservator from

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

top. If it enters

from bottom, it should be projected

well above the level of oil inside the

conservator. This arrangement ensure

that oil does not enter the silica gel

breather even at highest operating

level.

conservator tank parts

Conservator to main tank connections (parts)

• silica gel breather

• MOG,

• Drain Valves,

• Air Pockets

• Main tank connection through Buchholz relay

Working of Conservator Tank

When volume of transformer insulating oil

increases due to load and ambient

temperature, the vacant space above the oil

level inside the conservator is partially

occupied by the expanded oil.

Consequently, corresponding quantity of air

of that space is pushed away through breather.

On other hand, when load of transformer

decreases, the transformer is switched off and

when the ambient temperature decreases, the

oil inside the transformer contracts. This

causes outside air to enter in the conservator tank of transformer through silica gel

breather.

Types

There are two types of conservator tanks of a transformer which include the following.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

• Atmo seal Type Conservator

• Diaphragm Sealed Conservator

➢ Atmo seal Type Conservator :-

In this type conservator of

transformer, an air cell made of

NBR material is fitted inside the

conservator reservoir. The

silica gel breather is connected at

the top of this air cell. The oil level

in the power transformer rises and

falls according to this air cell

deflated and inflated. When the air

cell gets deflated the air inside the

air cell comes out via breather and

on the other hand if the cell is

inflated the outside air

comes in through

breather.

This arrangement prevents direct contact of oil with air, thereby reduces ageing effect

of oil.

The space available outside the cell in conservator

tank is totally filled by oil. Air vents are provided on

the top of the conservator for venting accumulated air

outside the air cell. The pressure inside the air cell

must be maintained (0.069bar)

1.1. Protection relay

A protection relay is an electrical device designed to detect faults in electrical circuits

and initiate appropriate protective actions. These devices are essential in maintaining

the reliability and safety of electrical power systems. Here's a brief overview of

protection relays.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

➢ Diaphragm Sealed Conservator :-

Here diaphragm is used as a barrier between transformer oil and atmospheric air. In this

case the conservator of transformer is made

of two semicircular halves as shown below.

The diaphragm is held between the two

halves and bolted. As oil expands it pushes

up the diaphragm. The position of the

diaphragm is indicated by the oil level

indicator i.e., magnetic oil gauge as the rod

of this MOG is connected to the diaphragm.

When the oil level falls down in the

conservator, the diaphragm deflects and the

atmospheric air fills the vacant place. This air is sucked through silica gel breather

which is connected to the top middle of conservator tank of transformer. This type of

conservator has one advantage over air cell conservator. If gas is pressurized to a high

level, it gets dissolved in oil. Over a period of time the amount of gas in oil reaches the

saturation point. If at this stage, the load of transformer is suddenly dropped or the

ambient temperature falls severely, the pressure falls, oil becomes supersaturated and

the gas bubbles will be evolved. If there is a pimp connected in the cooling circuit, it

will help generating bubbles. These bubbles may cause insulation failure in the region

of strong fields.

1.2. Transformer Oil

In all oil-immersed transformers, transformer oil provides added insulation between

the conducting parts, better heat dissipation, and fault detection features. Hydro-

carbon mineral oil is used as transformer oil

Oil Level

Maintaining the transformer oil level within the conservator tank is not important but

there must be some amount of oil for proper operation. So, the oil tank should not

overflow or empty in the process because, in low load conditions, the empty tank must

be avoided whereas, in full load condition, the overload must be avoided. Here, the

level of transformer oil mainly depends on the temperature of oil, solar radiation,

transformer loading, ambient temperature, etc. The design of this tank mainly depends

on the change in the transformer oil level. According to the International

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Electrotechnical Commission (IEC), conservator tank design must use the temperature

which ranges from -25°C to +110°C.

1.3. Magnetic Oil Gauge

A Magnetic Oil Level Gauge (MOG) is a device used to indicate the position of

transformer insulating oil level in conservator of a transformer. This is a mechanical

device. A mog in a transformer consists some main parts, like float arm, oil indicator

etc

Construction & Working:

The Construction & Working of MOG is given below. The magnet of MOG consists

inside the conservator drives and the magnet positioned is fixed outside of the

conservator tank of power transformer. The driving magnet rotates and acquires position

corresponding to height of oil level as it is link with the float. The float is hinged and

swings up or down when oil level rises or falls. This rise or falls rotates the driving

magnet clockwise or anticlockwise with the help of bevel gear. The follower magnet

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

carries a pointer & a cam. The pointer reads oil level and cam is set to operate the switch

of predetermined low level

Calibration:

The standard calibration of dial of MOG are Empty, ¼, ½, ¾, and Full. Calibration of

marks Empty & Full is done after leaving 65 mm from bottom and top of conservator

to avoid striking of float to conservator wall.

Mounting:

Indicator can be mounted in titled position towards ground (max 300C) for easy viewing

by fixing mounting pad at desired angle or the indicator can be mounted by keeping

dial and mounting pad in vertical position. The position of indicator on the conservator

can be selected to suit site condition. Alarm Circuit: One normally open mercury switch

is provided for annunciation low level Alarm.

1.4. Buchholz Relay

• The Buchholz relay is a gas actuated relay installed

in oil emerged Transformers for protection against

many kinds of faults such as overheating winding

falls short circuit incipient fault etc.

• 1st implemented in 1921 by max Buchholz.

• It is placed between transformer main tank and

conservator tank

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Working

Whenever a small fault happens within

the electrical device, heat is made by the

fault currents. The made heat causes

decomposition of electrical device oil

and gas bubbles are made. These gas

bubbles run in the upward direction and

obtain collected within the Buchholz

relay.

The collected gas relocates the oil in Buchholz relay and therefore the displacement

is similar to the amount of gas collected. The dislocation of

oil causes the higher float to shut the higher mercury switch to connect an alarm circuit.

Hence, once a small fault happens, then the alarm will be activated. The collected

quantity of gas specifies the harshness of the error occurred. Throughout minor faults,

the making of gas is not enough to move the lower float. Hence, throughout small faults,

the lower float will not be changed.

During main faults, like the section of earth short, the heat generated is high and an

outsized quantity of gas is made. This massive quantity of gas can equally flow

upwards, however, its motion is high sufficient to tilt the minor float within the

Buchholz relay. During this case, the lower float can source the lower mercury switch

which can trip the transformer from the supply.

1.5. Breather (Moisture contained silica gel)

Breather is present in all oil-immersed transformers that have a conservator tank. It is

necessary to keep the oil-free from moisture. As the temperature variations cause the

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

transformer oil to expand and contact, air flows in and out of the conservator tank. This

air should be free from moisture. Breather serves this purpose.

• Silica gel in the breather will be blue when installed.

• They turn to pink color when they absorb moisture which indicates the crystals

should be replaced.

1.6. Pressure Relief Valve

A (PRV) is a type of valve used to release stored gas in various equipment in order to

maintain an optimal pressure level. PRV opens gradually as pressure builds up in

order to release the necessary amount of press

1.7. Terminals and Bushing

For connecting incoming and outgoing cables, terminals are present in transformers.

They are mounted upon the bushings and is connected to the ends of the windings.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Bushings are insulators that forms a barrier between the terminals and the tank. They

are mounted over the transformer tanks. They serve as a safe passage for the

conductors connecting terminals to the windings.

1.8. Radiators and Fans

The power lost in the transformer is dissipated in the form of heat. Dry transformers are

mostly natural air-cooled. But when it comes to oil-immersed transformers, a variety of

cooling methods are followed. Depending on the kVA rating, power losses, and level of

cooling requirements, radiators and cooling fans are mounted on the transformer tank.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Cooling Fan

Radiator

The heat generated in the core and winding is passed to the surrounding transformer oil.

This heat is dissipated at the radiator. In larger transformer forced cooling is achieved

with the help of cooling fans fitted to the radiators.

The working principle of radiator is very simple. It just increases the surface area for

dissipating heat of the oil.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

1.09. OTI, WTI

The sensor bulb and capacity tube are fitted with an evaporation liquid. The vapor

pressure varies with temperature and is transmitted to a bourdon tube inside the dial

thermometer, which moves in accordance with the changes in pressure, which is

proportional to the temperature.

Winding Temperature Indicator (WTI)

It measures the winding temperature of

transformer

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

1.10. Cooling Tubes

The main function of the cooling tubes is to transfer heat from the transformer core

and coils to the environment. The heated transformer oil circulates through the

cooling tubes where the heat radiates out by natural airflow and hence cooling the

transformer oil.

1.11.Tap Changer

In transmission and distribution systems there can be voltage

fluctuations (i.e., increase or decrease in voltage levels) when the

load on the system varies. These fluctuations can also be caused due

to a voltage drop in the distribution system. Sometimes these

variations in voltage levels can result in quite unsatisfactory

performance.

In order to maintain a constant voltage or to maintain within the

prescribed limits transformer tap-changing is used. In tapchanging,

the tapings on the coils of the transformer are placed so that by

varying the turn-ratio voltage induced can be varied.

This is done by connecting to a number of access points known as taps

along either the primary or secondary winding.

There are two types of tap-changing transformers

• Off-Load Tap-Changing Transformer

• On-Load Tap-Changing Transformer.

Off-Load Tap-Changing Transformer:

The below figure shows the off-load tap-changing transformer provided with tapings (1

to 5) on the secondary winding. The position of the movable arm on the first stud will

give minimum secondary voltage and on the fifth stud will give maximum voltage

across secondary.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

During the light load

period, the movable arm is

placed on the first stud and

with an increase in load, the

movable arm is taken to a

stud (2, 3, 4, or 5) giving a

higher turnsratio so that

voltage drop in the line is

compensated and the output

secondary voltage is

maintained. The disadvantage of this scheme is whenever the tapping is to change load

must be disconnected first from the transformer thus it is referred to as offload tap-

changing. This type of tap-changing cannot be used where continuity of the supply to

the load is the main priority and it is limited where there will be a need for only slight

changes in the turn ratio.

On-Load Tap-Changing Transformer:

The drawback of off-load tap-changing can be overcome by using a special arrangement

of coil connections to the transformer known as the on-load tapchanging of the

transformer. The transformer connection for on-load tapchanging is shown below.

Here, the coils of the winding in

which tapings are to be done are

divided into two parallel

sections with equal tapping on

both sections of the coil. This

forms the two winding A & B as

shown above.

Under normal operating

conditions both the switches (Sa

& Sb) are in the closed (short-circuit) condition with identical tapings (i.e., 1 & 1'). As

the winding is divided into parallel sections the total current will be the sum of the

currents in winding A and B.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

When the tapings are to be changed, to maintain the continuity of the supply the tap-

changing process is made in such a way that,

• At first, any one of the windings (either A or B) from the parallel section is to be

disconnected by opening the respective switch.

• Now, the tap-changing is to be done to the disconnected winding.

• At this instant, the full-load current will pass through the connected winding (i.e.,

double its rated current).

• After changing the tapping to the disconnected winding is reconnected by closing

the switch.

• At this moment there will be an unequal share of the load on both windings due

to their different turn ratios.

• Now the other winding is disconnected and tapping is to be changed (which is

equal to the tapping of previously disconnected winding).

• So that there will be an equal amount of load share on both the windings (A &

B).

In this way, the continuity of the supply is maintained and more turn-ratio of tap-

changing can possibly compare to off-load tap-changing of the transformer. Care must

be taken to prevent the short-circuit with the windings while the tap-changing process.

1.12. Marshalling Box

The Marshalling box is the master control panel for protection

devices. This panel comes with a seethrough glass door to

allow easy visibility of the instruments and their readings.

The panel is situated next to the transformer.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

2. Current Transformer

A current transformer (CT) is a type of transformer that is used to measure AC. It

produces an alternating current (AC) in its secondary which is proportional to the AC

current in its primary.

The Current Transformer is one of the substation equipment used to convert the primary

power signal to manageable values for metering systems, recording systems, protective

relay systems, power generation, plant monitoring systems, SCADA and load control.

Current transformers are used extensively for measuring current and monitoring the

operation of the power grid.

Current transformer

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

The primary winding of a current transformer is connected in series with the high-

voltage conductor. The magnitude of amperes flowing in the high-voltage circuit is

reduced proportionately by the ratio of the transformer windings. The secondary

winding of the current transformer is insulated from the high voltage to permit it to be

connected to low-voltage metering circuits. Current and potential transformers supply

the intelligence for measuring power flows and the electrical inputs for the operation of

protective relays associated with the transmission and distribution circuits or equipment

such as power transformers

3. Capacitor Voltage Transformer

DEFINATION: -

The capacitive voltage transformer stepdown the high voltage input signals and

provide the low voltage signals which can easily measure through the measuring

instrument. The Capacitive voltage transformer (CVT) is also called capacitive

potential transformer

The capacitive potential divider, inductive element and the auxiliary transformer are

the three main parts of the capacitive potential transformer.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

What is the need of CVT?

For measuring high voltage (above 100kV)

the high insulated transformer is required.

The highly insulated transformer is quite

expensive as compared to the normal

transformer. For reducing the cost, the

capacitive potential transformer is used in

the system. The CVT is cheap, and their

performance is not much inferior to the

highly insulated transformer

Capacitive Voltage Transformer

Working

The capacitive potential divider is used in

combination with the auxiliary transformer

and the inductive element. The capacitive potential divider stepdown the extra high

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

voltage signals into a low voltage signal. The output voltage of the capacitive potential

transformer is further step-down by the help of the auxiliary transformer.

Consider the circuit diagram of the capacitive potential transformer.

4. Wave Trap

The line trap or wave trap is a device that is used

to protect the switchyard equipment from the

high-frequency carrier signals. The wave trap is a

filtering cum protective device that filters the

highfrequency signals and pass low-frequency

signal and give protection against surge voltage.

we can understand the concept and function of the

line trap if we know about the communication

system in the transmission line.

In a high voltage (above 132KV) electrical power

transmission system, PLCC

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

(Power Line Carrier Communication) System is used to communicate between two

substations. This carrier signal has a frequency from 3 kHz to 800KHz. But we know

our electrical system works with 50HZ or 60Hz frequency. So, when the substation is

communicating with high-frequency carrier signals the switchyard equipment will be

damaged. That is why an equipment that is called Wave Trap or Line trap is connected

in series with the transmission line.

This line trap prevents the high-frequency signal

and allows only the 50Hz frequency signal to the

switchyard equipment. This line trap also helps to

protect the switchyard equipment from the surge

voltage.

The working function of the

wave trap

Wave trap functions as a low-pass filter to stop high-frequency waveform.

The two ends of the Transmission line (The transmitting end and receiving end) are

mounted with a wave trap. The wave trap is a device capable of creating high impedance

to the carrier frequencies. The wave trap act like a big size choke coil. It allows only

low frequency (50 Hz) to the desired components.

The inductor and capacitor in the line-trap circuit are low-pass filters. The engineers

design the circuit of the wave trap to provide a low impedance path to power frequency

(50Hz) and high impedance to the carrier communication frequency (3kHz to 250 kHz).

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

5. Lightening Arrester

The lightning arresters are another important substation switchgear equipment that

protects the electric system and the substation equipment from lightning strikes and

switching surges.

The lightning arresters are installed in a substation near the termination of aerial circuits

and close to the more valuable pieces of equipment, such as power transformers.

The power transformer has lightning arresters mounted on the radiators which are

connected to transformer bushings. Lightning

arresters contain semiconductor blocks, which

limit the magnitude of highsurge voltages,

permit the large-surge currents to pass

harmlessly to the ground, and interrupt the

power-follow current after the surge is

eliminated.

Metal-oxide surge arresters’ function like a

ceramic capacitor at normal line voltage,

limiting the flow of current to ground.

When a high voltage begins to build up across

the semiconductor blocks, they provide a low-

impedance path to ground, which permits the

surge current to flow to ground, limiting the

voltage buildup and preventing the equipment

from being damaged. The semiconductor

blocks in the arresters are manufactured using

zinc oxide material.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

6. Circuit Breakers

A circuit breaker is a mechanical switching

device, capable of making, carrying and

breaking currents under normal circuit

conditions and also making, carrying for a

specified time and breaking currents under

specified abnormal circuit conditions such

as those of short circuit.

The contacts of the circuit breakers are

opened and closed by mechanical linkages

manufactured from insulating materials and

utilizing energy from compressed air,

electric magnets, or charged springs.

A Hybrid Circuit Breaker. (This adopts a

conventional air-insulated way of busbar

connection to GIS. This smartly overcome

the disadvantages of conventional

AIS equipment)

Some of the high-voltage circuit breakers utilize compressed air to operate the contacts

and interrupt the current flow when the contacts are open.

Operation of the circuit breakers is initiated, utilizing dc circuits, by manually operating

a switch, by remote operation of supervisory control equipment, or by relays that

automatically recognize predetermined abnormal conditions or electrical failures in the

system.

Various types of circuit breakers used in high voltage substations are.

1. SF6 Circuit Breaker 2. Oil Circuit Breaker 3. Air Blast Circuit Breaker 4. Vacuum

Circuit Breaker

There are low voltage circuit breakers like MCB and GFCI that are not normally used

in high voltage substations. MCBs are used inside the control panels.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

7. Isolator

Disconnectors (Isolators) are devices

that are generally operated off-load

to provide isolation of main plant

items for maintenance, on to isolate

faulted equipment from other live

equipment.

Air Insulated or open terminal

disconnectors are available in several

forms for different applications.

At the lower voltages, single break

types are usual with either ‘rocker’

type or single end rotating post types

being predominant.

At higher voltages, rotating center

post, double end rotating post, vertical

break, and pantograph type

disconnectors are more common. Air

brake switches are used in lower voltage to disconnect on load. Disconnectors are

usually interlocked with the associated circuit breaker to prevent any attempt being

made to interrupt load current.

Most disconnectors are available with either a manual drive mechanism or motor

operated drive mechanism and the appropriate drive method must be selected for a

particular disconnector in a particular substation.

For example, in a remotely controlled unmanned double busbar substation the busbar

selector disconnectors would be motor operated to allow ‘on load’ busbar changes

without a site visit being required.

Disconnector mechanisms incorporate a set of auxiliary switches for remote indication

of disconnector position, electrical interlocking and current transformer switching for

busbar protection.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

8.Insulator

An insulator is a material that restricts the flow of electric current or heat. In electrical

applications, insulators are used to protect against electric shock and to ensure the

proper functioning of electrical devices by confining the current to designated paths. In

thermal applications, insulators reduce heat transfer, helping maintain desired

temperatures.

❖ Types Of Insulator :-

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

9. Bus Bar

It is one of the most important elements in an electrical power substation. It is a type of

conductor carrying an electrical current to which many connections are made. In order

words, bus-bar is a type of electrical junction in which the incoming and outgoing of

electrical current take place.

When the fault occurs in the bus- bar, then all the circuit equipment connected to that

section must be tripped out to give complete isolation in the shortest possible time e.g.

(60ms) so that the damage is avoided to the installation due to heating of conductors.

10. Protection Relay

A protection relay is an essential component in electrical power systems designed to

detect faults and initiate the operation of circuit breakers to isolate the faulty section

from the rest of the network. Here are the key points about protection relays:

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

11.1. Types of Protection Relay

➢ Electromechanical Relays :- Use mechanical motion to trip the circuit breaker.

They are robust but have a slower response time and limited functionality

compared to modern relays.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

➢ Numerical Relays :- An advanced form of digital relays that perform multiple

protection functions and provide extensive data logging and communication

features.

11.2. Working of Protection Relay

A protection relay mainly works as a sensor. It may find out the fault location and then

signal the operation of the circuit breaker.

The circuit breaker cuts off the faulty system from the rest of the system and the

continuity of the electrical supply is not hampered. The faulty times are also reduced,

which ensures that the system can work smoothly again in the least time.

The new combination protection relays that may include many different sensors and

the protective relay varieties may sense a variety of faults and issues. No wonder these

are the most common systems employed today in a variety of scenarios.

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

❖ Types Of Protection

1. 50/51 O/C Protection

2. 50N / 51N E/F Protection

3. 87 Differential Protection

4. Line Differential Protection

5. LBB ( Local Breaker Backup ) Protection

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

Conclusion

It was a wonderful learning experience at TATA STEEL GROWTH SHOP, TSUISL site

of 132kv substation Project for one month at gamharia . I gained a lot of insight

regarding almost every aspect of site. I was given exposure in almost all the departments

at the site. The friendly welcome from all the employees is appreciating, sharing their

experience and giving their peace of wisdom which, they have gained in long journey

of work. I am very much thankful for the wonderful accommodation facility from TGS.

I hope this experience will surely help me in my future and also in shaping my career.

THANK YOU

VOCATIONAL TRAINING REPORT RVS COLLEGE RAJEEV KUMAR EEE/515/23L

You might also like

- Guidelines For Rla of TransformersDocument9 pagesGuidelines For Rla of TransformersJanmejaya Mishra100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Vatsa - Vatsa (2009) - Discrete Mathematics, 4th Edition PDFDocument315 pagesVatsa - Vatsa (2009) - Discrete Mathematics, 4th Edition PDFMultimediostv En directo80% (5)

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Kel Industrial Training ReportDocument21 pagesKel Industrial Training ReportVineet JobNo ratings yet

- Distribution Transformer Dry Oven: Core Winding Assembly For OveningDocument18 pagesDistribution Transformer Dry Oven: Core Winding Assembly For OveningJashandeep SinghNo ratings yet

- Training Report Indian RailwayDocument44 pagesTraining Report Indian RailwayHimanand Raj BharatNo ratings yet

- SYLLABUS For Field Study 1 - The Learner's Development and Environment by Prof. Eric Datu AgustinDocument5 pagesSYLLABUS For Field Study 1 - The Learner's Development and Environment by Prof. Eric Datu AgustinRoxane Rivera83% (12)

- tsl1Document35 pagestsl1shivajee559No ratings yet

- Maintenance of TRansformer 1 PDFDocument20 pagesMaintenance of TRansformer 1 PDFVinoth Stratumpc100% (1)

- 440kv GSSDocument37 pages440kv GSSready2cheerNo ratings yet

- INTERNSHIP REPORT NEWDocument29 pagesINTERNSHIP REPORT NEWyashbhuva79967No ratings yet

- Project Report On Transformer TestingDocument19 pagesProject Report On Transformer TestingShakil AhammadNo ratings yet

- High Voltage Substation ReportDocument35 pagesHigh Voltage Substation ReportSewandeep SharmaNo ratings yet

- Jusco Gaurav KumarDocument23 pagesJusco Gaurav KumarGaurav KumarNo ratings yet

- Parts of A Power Transformer - OwlcationDocument5 pagesParts of A Power Transformer - OwlcationYirga MelesewNo ratings yet

- Internship ReportDocument36 pagesInternship ReportDhruv Patel100% (1)

- Lab Manual of Ac MachinesDocument34 pagesLab Manual of Ac MachinesArdalan KhoshnawNo ratings yet

- Valentine SlidesCarnivalDocument21 pagesValentine SlidesCarnivalfbfcbbhxNo ratings yet

- Sanjay Kar Chowdhury Cbip 2006Document7 pagesSanjay Kar Chowdhury Cbip 2006Gunadevan ChandrasekaranNo ratings yet

- Chapter - 1 Transformer: 1.1introduction OftransformerDocument30 pagesChapter - 1 Transformer: 1.1introduction OftransformerpraneethNo ratings yet

- Transformer Athar IqbalDocument27 pagesTransformer Athar IqbalAthar WATTUNo ratings yet

- Protection of Substation: 3.1. Lightning ArrestorsDocument4 pagesProtection of Substation: 3.1. Lightning ArrestorsMuhammad Asif IqbalNo ratings yet

- 220/132 KV Sub-Station Bhilai-3: Training Report ONDocument24 pages220/132 KV Sub-Station Bhilai-3: Training Report ONKalyani ShuklaNo ratings yet

- 10 Equipment You MUST Recognize in Every Distribution SubstationDocument12 pages10 Equipment You MUST Recognize in Every Distribution SubstationAhmed BoussoffaraNo ratings yet

- Maintenance of Transformers: Part 1Document32 pagesMaintenance of Transformers: Part 1Ravi PexelsNo ratings yet

- A Summer Trainingreport On Utteer Pradesh Power Transmission Corporationlimited 132/33Kv Substation, Manaure AllahabadDocument31 pagesA Summer Trainingreport On Utteer Pradesh Power Transmission Corporationlimited 132/33Kv Substation, Manaure AllahabadkairaNo ratings yet

- PS Lab Manual2Document53 pagesPS Lab Manual2krcdewanewNo ratings yet

- TransformerDocument64 pagesTransformerRaja Vignesh100% (1)

- Transformer Training (Compatibility Mode)Document181 pagesTransformer Training (Compatibility Mode)Mukund Gawale100% (1)

- Protection of Transformer by Efficient Cooling AND Voltage Control Through BessDocument17 pagesProtection of Transformer by Efficient Cooling AND Voltage Control Through BessArnav BirlaNo ratings yet

- Assignment: Name: Okegbile Olawale Emmanuel MATRIC NO: MEE/18/6973 Department: Mee Course Code: Eee 351Document6 pagesAssignment: Name: Okegbile Olawale Emmanuel MATRIC NO: MEE/18/6973 Department: Mee Course Code: Eee 351Okegbile OlawaleNo ratings yet

- Oil Filled Transformers: More Information On The Design of An Oil Filled TransformerDocument16 pagesOil Filled Transformers: More Information On The Design of An Oil Filled Transformery_larryNo ratings yet

- MantaienanceDocument22 pagesMantaienancePallavi PatilNo ratings yet

- Trish UlDocument25 pagesTrish UlnoteselecteicalNo ratings yet

- 1EE 8301 Elec.mach.PPT 1 Unit 2TransformerDocument35 pages1EE 8301 Elec.mach.PPT 1 Unit 2TransformerRAMESH BABU EEENo ratings yet

- Presentation On Electrical EquipmentDocument48 pagesPresentation On Electrical EquipmentSandip Kumar100% (1)

- Guidelines For Rla of Transformers PDFDocument9 pagesGuidelines For Rla of Transformers PDFMohammad AsifNo ratings yet

- Summer Training Report NTPCDocument45 pagesSummer Training Report NTPCChetan MeenaNo ratings yet

- Bep 2Document4 pagesBep 2RK KNo ratings yet

- Tata Power Delhi Distribution LimitedDocument31 pagesTata Power Delhi Distribution LimitedVinay SehwagNo ratings yet

- Thermal Report AnkitDocument42 pagesThermal Report Ankitankursharma1490No ratings yet

- Project Report On Transformer Protection Using Numerical RelayDocument85 pagesProject Report On Transformer Protection Using Numerical RelayIhsan Ullah100% (4)

- Transformer ProtectionDocument18 pagesTransformer ProtectionTanmayNo ratings yet

- MALAPPURAM BakiDocument22 pagesMALAPPURAM BakiFayis PulloorNo ratings yet

- Sub StationDocument31 pagesSub Stationkundum santosh100% (1)

- Electrical Power Generation, Transmission & Protection: Project Report OnDocument29 pagesElectrical Power Generation, Transmission & Protection: Project Report OnAmit TripathiNo ratings yet

- Presented By: Kapil Sahani 10EGIEE029 Presented To: Mr. Shakti Singh Shekhawat Head of The Department Electrical EngineeringDocument28 pagesPresented By: Kapil Sahani 10EGIEE029 Presented To: Mr. Shakti Singh Shekhawat Head of The Department Electrical Engineeringkapil97827No ratings yet

- TCL Project ReportDocument41 pagesTCL Project ReportJeremiah PhoenixNo ratings yet

- TFDocument26 pagesTFSarang AbadagireNo ratings yet

- O & M of Sub-Station Equipment: Narender Kumar Me Mba MieDocument31 pagesO & M of Sub-Station Equipment: Narender Kumar Me Mba MiewaleedalzaidiNo ratings yet

- Assignment-Maintenance of Circuit BreakerDocument54 pagesAssignment-Maintenance of Circuit Breakerbwiremtani3No ratings yet

- Practical Approach For Detection of Failure of Distribution Transformers and Their RemidiesDocument4 pagesPractical Approach For Detection of Failure of Distribution Transformers and Their RemidiesIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- DLWDocument3 pagesDLWrockeygreatNo ratings yet

- Synchronous Generator Protection: AnswerDocument26 pagesSynchronous Generator Protection: AnswerLuka YannamNo ratings yet

- Transformer Health Monitoring SystemDocument10 pagesTransformer Health Monitoring SystemPavan Kumar A GNo ratings yet

- Electrical Engineer Interview Questions: Ahmed M ZakariaDocument19 pagesElectrical Engineer Interview Questions: Ahmed M ZakariaБахром АбдуразаковNo ratings yet

- The Maintenanceofa TransformerDocument10 pagesThe Maintenanceofa TransformerRUEL RABANDABANNo ratings yet

- Constructional Details of TransformerDocument16 pagesConstructional Details of TransformerAravind NNo ratings yet

- Power Supply InstallationDocument659 pagesPower Supply InstallationShashi KumarNo ratings yet

- Power Transf DesignDocument4 pagesPower Transf Designرامى ناصرNo ratings yet

- ANSYS AutodynDocument4 pagesANSYS AutodynJaiveer YadavNo ratings yet

- RBLDocument19 pagesRBLD J GamingNo ratings yet

- Manufacturing Process For A PenDocument7 pagesManufacturing Process For A PenFeIipe MunozNo ratings yet

- Control Commands: Model No. PT-LB423 PT-LB383 PT-LB353 PT-LW373 PT-LW333 PT-LB303 PT-TW351R PT-TW350 PT-TW410 PT-TW320Document1 pageControl Commands: Model No. PT-LB423 PT-LB383 PT-LB353 PT-LW373 PT-LW333 PT-LB303 PT-TW351R PT-TW350 PT-TW410 PT-TW3201015646541610312No ratings yet

- China in A Changing Global Environment enDocument97 pagesChina in A Changing Global Environment enEskindirGirmaNo ratings yet

- CASE REPORT Vertigo PutriDocument20 pagesCASE REPORT Vertigo PutriRizqina PutriNo ratings yet

- European Ict Professional Role Profiles: Part 2: User GuideDocument37 pagesEuropean Ict Professional Role Profiles: Part 2: User GuideDaniele BalloNo ratings yet

- El Comercio Informal en La Region de HuanucoDocument5 pagesEl Comercio Informal en La Region de HuanucoJayro CMNo ratings yet

- 57e4d64a5ae56 1317890 SampleDocument32 pages57e4d64a5ae56 1317890 Samplemanaswini sharma B.G.100% (2)

- Automatic Fire Control System in Railways 1Document44 pagesAutomatic Fire Control System in Railways 1RAJ50% (2)

- Strategic Human Resource Management Canadian 2Nd Edition Noe Solutions Manual Full Chapter PDFDocument58 pagesStrategic Human Resource Management Canadian 2Nd Edition Noe Solutions Manual Full Chapter PDFrowanariel26r2100% (9)

- .. Thesis Title .Document31 pages.. Thesis Title .Tanut VongsoontornNo ratings yet

- Safety Plan 2023Document4 pagesSafety Plan 2023Raphy BrionesNo ratings yet

- Play Format ExampleDocument3 pagesPlay Format ExamplemegbenignoNo ratings yet

- Bennett 2003Document8 pagesBennett 2003Emir OkucuNo ratings yet

- List of Required Documents For The UNFCCC Observer StatusDocument1 pageList of Required Documents For The UNFCCC Observer StatussweetchildPNo ratings yet

- 2017 Acacia Annual Report AccountsDocument180 pages2017 Acacia Annual Report AccountsDeus SindaNo ratings yet

- Extract, Transform, Load: Inmon BillDocument11 pagesExtract, Transform, Load: Inmon BillLuntian Amour JustoNo ratings yet

- Promc GuideDocument69 pagesPromc GuideChijioke Zion OkabieNo ratings yet

- Icse Timetable For 2008Document6 pagesIcse Timetable For 2008ReshmabsrNo ratings yet

- Mexicali! A Mini-Gem Guide To Surgery in Baja, CaliforniaDocument127 pagesMexicali! A Mini-Gem Guide To Surgery in Baja, CaliforniaK. EcklandNo ratings yet

- Optical MSRDocument2 pagesOptical MSRexarchos26100% (2)

- Can You Dribble The Ball Like A ProDocument4 pagesCan You Dribble The Ball Like A ProMaradona MatiusNo ratings yet

- 03 Big Data Concepts - Providing Stucture To Unstructured DataDocument26 pages03 Big Data Concepts - Providing Stucture To Unstructured DataLow Wai LeongNo ratings yet

- Indian Institute of Insurance Surveyors and Loss Assessors: (Promoted by IRDA, Govt. of India)Document2 pagesIndian Institute of Insurance Surveyors and Loss Assessors: (Promoted by IRDA, Govt. of India)Sachin PrajapatiNo ratings yet

- GL Period CloseDocument12 pagesGL Period CloseMd MuzaffarNo ratings yet

- Cwf-60-30air CompressorDocument2 pagesCwf-60-30air CompressorHuy Lễ NguyễnNo ratings yet

- What Are Dependency Properties?Document27 pagesWhat Are Dependency Properties?eniranjanreddyNo ratings yet