Professional Documents

Culture Documents

PQR NTL-2

PQR NTL-2

Uploaded by

Susmita SahaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQR NTL-2

PQR NTL-2

Uploaded by

Susmita SahaCopyright:

Available Formats

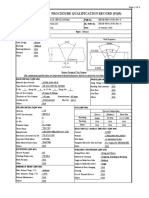

QW - 483 (Back)

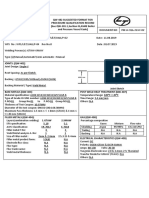

PQR NO. NTLSTEEL/GMAW/PQR-001 DTD. 10.05.2024

Tensile Test (QW - 150)

Specimen No. G. Dia C.S Area Breaking Load in Ultimate Unit Location of

MM2 KN Stress in Mpa Breaking Remarks

e 15.4x19.4 298.76 143 479 Broken outside the SATISFACTORY

f 15.5x19.5 302.25 142 470 weldment SATISFACTORY

Guided-Bend Tests (QW - 160)

Type and Figure No. Result

SATISFACTORY

SIDEBEND TEST - 04 NOS.

(SPECIMEN NO. a, b, c, d )

Toughness Tests (QW - 170)

Specimen No. North Impact Valves

Test Temp. Drop Weight Break (Y/N)

& Size Location Ft. Ibs. % Shear Mils

N/A

Comments : N/A

Fillet - Weld Test (QW-180)

Result - Satisfactory: Yes / No N/A No Penetration Into Parent Metal: Yes / No N/A

Macro - Results N/A

Other Tests

Type of Test Radiography Test (R.T.) - Satisfactory

Report No.: IRC/M/1793/B/2011-2012 Dtd.28.04.2012

M/s.IRC Industrial Research & Consultancy Pvt.Ltd. and Q.C. Group, Howrah - 711113, West Bengal

Deposit Analysis N/A

Other N/A

Welder's Name: Muktikant Ray Clock No. N/A Stamp No. MK001

Tests Conducted by:M/s.IRC Industrial Reasearch & Consultancy Laboratory Test No. DT/24/E9/4 dt. 11.05.24

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in

accordance with the requirements of Setion IX of the 2021 Edition, ASME BOILER AND PRESSURE VESSEL CODE.

Date : 30.04.2012 Manufacturer NTL STEEL LTD

PREPARED BY ( NTL STEEL) REVIEWED BY: Approved By

Signature : Signature :

Name : S. Mazumder Name :

Date :

You might also like

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- KP WPS PQR GTAW FCAWDocument1 pageKP WPS PQR GTAW FCAWwahyuNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Gmaw PQR SampleDocument5 pagesGmaw PQR SampleRakesh MenonNo ratings yet

- FORM QW-483 (Back) : ASME BPVC - IX-2015Document1 pageFORM QW-483 (Back) : ASME BPVC - IX-2015Anonymous 0rt9KWmNNo ratings yet

- QW-483 (Yellow) PQR No.: Tme 355Document1 pageQW-483 (Yellow) PQR No.: Tme 355Sudhir KotkarNo ratings yet

- Wps 1Document1 pageWps 1Sudhir KotkarNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- QW-483 (Black) PQR No.: Tme 356Document1 pageQW-483 (Black) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- QW-483 (BACK) PQR No.: Tme 356Document1 pageQW-483 (BACK) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- QW-483 (Green) PQR No.: Tme 356Document1 pageQW-483 (Green) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- PQR 2Document1 pagePQR 2janardan.sfeNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- 07-04 Welder Performance Qualification RecordDocument1 page07-04 Welder Performance Qualification RecordMo ZeroNo ratings yet

- WPQ 양식 김정균 (DSHI Rev.0)Document5 pagesWPQ 양식 김정균 (DSHI Rev.0)이훈No ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- Asme Sec Ix 2019 381Document1 pageAsme Sec Ix 2019 381Balkishan DyavanapellyNo ratings yet

- Welder Performance Qualification (WPQ)Document1 pageWelder Performance Qualification (WPQ)JBStringerNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- SampleDocument5 pagesSample이훈No ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormTegar OktoberNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

- Welder CertificateDocument1 pageWelder CertificatePaul H TampubolonNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Fir Ris-Am-116Document1 pageFir Ris-Am-116ansarmulla711No ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- Acfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Document6 pagesAcfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Daniel CamposNo ratings yet

- PQR ForDocument3 pagesPQR ForAkash Singh TomarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- Procedure Qualification Records (PQR)Document2 pagesProcedure Qualification Records (PQR)amine algNo ratings yet

- WPQ 2Document1 pageWPQ 2FirozNo ratings yet

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- RSW WOPQ REV. 2010a Interactive FormDocument1 pageRSW WOPQ REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 pagesWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- A-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW-483 (Back) : ASME BPVC - IX-2019Document1 pageQW-483 (Back) : ASME BPVC - IX-2019Balkishan DyavanapellyNo ratings yet

- 1.911.032 WPQ Smaw Astm A36Document1 page1.911.032 WPQ Smaw Astm A36Felipe Carrasco sepulvedaNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- Form PQR 2 AsmeDocument6 pagesForm PQR 2 AsmeZam Zam NoorNo ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- Case Study - Welder WPQ - 2Document6 pagesCase Study - Welder WPQ - 2MOHAMED SALEH ABDALLAH ARAFATNo ratings yet

- Thread Rolling Blank DiameterDocument6 pagesThread Rolling Blank DiameterSusmita SahaNo ratings yet

- Supplementary-Spec-to-API-Spec-20E-Subsea-Fasteners-Alloy-and-Carbon-Steel-Bolting-S-724v2020-09Document37 pagesSupplementary-Spec-to-API-Spec-20E-Subsea-Fasteners-Alloy-and-Carbon-Steel-Bolting-S-724v2020-09Susmita SahaNo ratings yet

- Quotation Debo Engg-001 19-10-20Document2 pagesQuotation Debo Engg-001 19-10-20Susmita SahaNo ratings yet

- Stud SpecnDocument1 pageStud SpecnSusmita SahaNo ratings yet

- Anchor Certification, HH..Document5 pagesAnchor Certification, HH..Susmita SahaNo ratings yet

- Is 5517Document12 pagesIs 5517Susmita Saha100% (1)

- Enquiry 01.10.22Document1 pageEnquiry 01.10.22Susmita SahaNo ratings yet

- Ulink-Specn-Fl SmithDocument1 pageUlink-Specn-Fl SmithSusmita SahaNo ratings yet

- Foundation BoltDocument4 pagesFoundation BoltSusmita SahaNo ratings yet

- Shelf Life CertificateDocument1 pageShelf Life CertificateSusmita SahaNo ratings yet

- ANSI C-136.2 Load Test of PoleDocument8 pagesANSI C-136.2 Load Test of PoleSusmita SahaNo ratings yet

- ChallanDocument1 pageChallanSusmita SahaNo ratings yet

- TsofDocument2 pagesTsofPratik RatwaniNo ratings yet

- Our Best-Selling Platform Lift: Aritco 7000Document2 pagesOur Best-Selling Platform Lift: Aritco 7000Lê Văn HoạtNo ratings yet

- Asset Management Presentation1787Document56 pagesAsset Management Presentation1787cvijica635No ratings yet

- Artistic AnalysisDocument6 pagesArtistic AnalysisMirela SinghNo ratings yet

- PITE Ground Fault Locator GFL3836-User-manualDocument33 pagesPITE Ground Fault Locator GFL3836-User-manualMarinda FebriNo ratings yet

- The Evoltuion of High Maturity (Slides)Document28 pagesThe Evoltuion of High Maturity (Slides)陈豪No ratings yet

- DS-2CD2T83G2-2I 4I Datasheet V5.5.113 20220601Document6 pagesDS-2CD2T83G2-2I 4I Datasheet V5.5.113 20220601ansar89No ratings yet

- 16216l5 16494Document2 pages16216l5 16494Saul AlbertoNo ratings yet

- Wlna9ce - Parts ManualDocument24 pagesWlna9ce - Parts Manualsclaveau20No ratings yet

- Tulsi Tanti Profile: Indian EntrepreneursDocument6 pagesTulsi Tanti Profile: Indian EntrepreneursSuhasNo ratings yet

- A Meta Model of ChangeDocument25 pagesA Meta Model of Changeraminabk100% (1)

- Kisi Kisi Kelas XiDocument15 pagesKisi Kisi Kelas Xihana zhr0% (1)

- Scania: Gearbox ModelsDocument4 pagesScania: Gearbox ModelsWilliam BernardinoNo ratings yet

- CH 18Document9 pagesCH 18Julie Nix FrazierNo ratings yet

- Elements of Chemical Reaction Engineering 4th Ed Fogler Solution ManualDocument2 pagesElements of Chemical Reaction Engineering 4th Ed Fogler Solution ManualHafizh IlyasaNo ratings yet

- SketchUp Tutorial 1 - TableDocument19 pagesSketchUp Tutorial 1 - TablenphilippNo ratings yet

- DC SwitchgearDocument10 pagesDC SwitchgearpjchauhanNo ratings yet

- HYDROPOWER MCQsDocument9 pagesHYDROPOWER MCQsAlexis MUHIRWANo ratings yet

- Grade 3 Science Curriculum MapDocument19 pagesGrade 3 Science Curriculum MapRodel YapNo ratings yet

- Original Research Paper Geography: M.A Geography, UGC NET-JRF (Government P.G College Badli, Haryana)Document4 pagesOriginal Research Paper Geography: M.A Geography, UGC NET-JRF (Government P.G College Badli, Haryana)neeraj kumarNo ratings yet

- Chemistry Final Exam PracticeDocument22 pagesChemistry Final Exam PracticeRida Muhammad RazaNo ratings yet

- Expo-2023-Doha sr10 EngDocument8 pagesExpo-2023-Doha sr10 Engeyad alamreenNo ratings yet

- 03 Chemical Formulae & EquationDocument15 pages03 Chemical Formulae & EquationSathya RauNo ratings yet

- A Place You Want To Stay at On Your Next TripDocument4 pagesA Place You Want To Stay at On Your Next TripĐoàn Thanh Chúc (FGW HN)No ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- A WatermarkedDocument12 pagesA WatermarkedMaintenanceNo ratings yet

- Texasinstruments Ds90ub960q1evm Datasheets 4805Document60 pagesTexasinstruments Ds90ub960q1evm Datasheets 4805BB minNo ratings yet

- I Survive The Blizzard ofDocument2 pagesI Survive The Blizzard ofRyle DyNo ratings yet

- SJT224Document4 pagesSJT224Shrishty RawatNo ratings yet

- Aem 499 Final Powerpoint Andrewdelili 4-28-2021Document20 pagesAem 499 Final Powerpoint Andrewdelili 4-28-2021api-548751501No ratings yet