Professional Documents

Culture Documents

HIP-TWLA (October 1st October 15th ,2021)

HIP-TWLA (October 1st October 15th ,2021)

Uploaded by

Sajjad AfzalCopyright:

Available Formats

You might also like

- Eumig Projector Mark S 810 810D 810D LUX User ManualDocument29 pagesEumig Projector Mark S 810 810D 810D LUX User ManualAstronauta Mecanico100% (2)

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- The Freelance Content Marketing Writer Find Your Perfect Clients, Make Tons of Money and Build A Business You Love (Gregory Jennifer Goforth) (Z-Library)Document219 pagesThe Freelance Content Marketing Writer Find Your Perfect Clients, Make Tons of Money and Build A Business You Love (Gregory Jennifer Goforth) (Z-Library)Mara Relunia-Ayen100% (1)

- RA For Sump PumpsDocument9 pagesRA For Sump PumpsAnonymous ubta67y6eNo ratings yet

- Proposal Indonesia International Travel Show 2018Document21 pagesProposal Indonesia International Travel Show 2018farid_maxiorg100% (1)

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Practical 1 HIRARC (1) CompleteDocument13 pagesPractical 1 HIRARC (1) Completehafiezy77100% (3)

- HIP CPP for NGCP PipelinesDocument15 pagesHIP CPP for NGCP PipelinesSajjad AfzalNo ratings yet

- HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024Document12 pagesHAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024Sajjad AfzalNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- HIRA Boiler Pressure Part Risk AssessmentDocument15 pagesHIRA Boiler Pressure Part Risk AssessmentHARSHAL100% (2)

- HSE Accident Handling, Investigation and ReportingDocument11 pagesHSE Accident Handling, Investigation and ReportingbenNo ratings yet

- 4.1.2 Covid-19 Risk AssessmentDocument41 pages4.1.2 Covid-19 Risk AssessmentaceNo ratings yet

- RA Bored Cast in Situ PileDocument38 pagesRA Bored Cast in Situ PileAnonymous zsBCtskz100% (1)

- Hazard and Risk Register Template: The South Australian Mining and Quarrying Occupational Health and Safety CommitteeDocument14 pagesHazard and Risk Register Template: The South Australian Mining and Quarrying Occupational Health and Safety Committeearunshan1984100% (1)

- RA-IM-12A - Launching Girder - Marine-Rev-02Document52 pagesRA-IM-12A - Launching Girder - Marine-Rev-02Planning C7No ratings yet

- Transport 21 Robert Kamb PresentationDocument55 pagesTransport 21 Robert Kamb PresentationGoran JurisicNo ratings yet

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- Risk Assessment FormDocument4 pagesRisk Assessment Formbeshoy100% (2)

- RA002 Transport, and Offloading The Piling RigDocument15 pagesRA002 Transport, and Offloading The Piling RigNonhleNo ratings yet

- Hirarc SlideDocument19 pagesHirarc SlideKrishnan Mudaliar Bopalan100% (1)

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- PHA-Template-Chemical Feeding SystemDocument8 pagesPHA-Template-Chemical Feeding Systemdilip matalNo ratings yet

- Risk Assessment / Job Hazard Analysis (Jha) FormDocument7 pagesRisk Assessment / Job Hazard Analysis (Jha) FormZameel KhanNo ratings yet

- 07 Scaffolding ErectionDocument2 pages07 Scaffolding ErectionWong See PohNo ratings yet

- Hazards Identification Plan (HIP) Based on Two weeks Look Ahead Plan (Aug 16th – Aug 31st,2022).Document55 pagesHazards Identification Plan (HIP) Based on Two weeks Look Ahead Plan (Aug 16th – Aug 31st,2022).Sajjad AfzalNo ratings yet

- Fire Risk Assessment - 2Document6 pagesFire Risk Assessment - 2PMSIL 2018100% (3)

- Covid-19 Risk AssessmentDocument40 pagesCovid-19 Risk AssessmentaceNo ratings yet

- Case Study: Hazard Identification, Risk Assesment and Risk Control (HIRARC)Document8 pagesCase Study: Hazard Identification, Risk Assesment and Risk Control (HIRARC)F2013 NorfadzilahNo ratings yet

- Risk MatrixDocument3 pagesRisk MatrixyounasNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- Stefanutti Stocks Building: Site: Date CompiledDocument5 pagesStefanutti Stocks Building: Site: Date CompiledPinto MendesNo ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- Risk AssesmentDocument3 pagesRisk AssesmentYogesh bhatNo ratings yet

- SFSDFDocument6 pagesSFSDFali shahNo ratings yet

- 16 HAZOP Basics3Document24 pages16 HAZOP Basics3BharatNo ratings yet

- Hazard Identification Risk Assessment and Risk Control Register HIRARC Review / Revision Control SheetDocument38 pagesHazard Identification Risk Assessment and Risk Control Register HIRARC Review / Revision Control Sheetusman4428No ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. Ahmad100% (1)

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- SWMS Safe-Wrk-Mthd-Statement-Sample-Pump MaintenanceDocument3 pagesSWMS Safe-Wrk-Mthd-Statement-Sample-Pump Maintenancetilet26128No ratings yet

- Econpile (M) SDN BHD: Hazard Identification Risk Assessment Risk ControlDocument3 pagesEconpile (M) SDN BHD: Hazard Identification Risk Assessment Risk Controlalam dooNo ratings yet

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliNo ratings yet

- Aspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Document6 pagesAspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Kevin ColmoNo ratings yet

- Table 1 Risk Assessment Matrix: Health and Safety MatrixDocument17 pagesTable 1 Risk Assessment Matrix: Health and Safety MatrixZulu198005No ratings yet

- MSDS Lead Plates ConcordeDocument3 pagesMSDS Lead Plates Concordeyağmur turanNo ratings yet

- Risk Assessment Fitout SalonDocument19 pagesRisk Assessment Fitout SalonVision ConceptNo ratings yet

- Spray Booth Risk AssessmentDocument3 pagesSpray Booth Risk AssessmentJohn Geddes100% (1)

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Form HIRADC K3Document1 pageForm HIRADC K3Airlangga AirlanggaNo ratings yet

- Site Risk RADocument14 pagesSite Risk RAJohn GeddesNo ratings yet

- Case Study 2 SubmissionDocument6 pagesCase Study 2 SubmissionJahanzaib CSNo ratings yet

- Electrical WorksDocument3 pagesElectrical WorksSaleem Basha50% (2)

- Matrik Risk Rank KPCDocument1 pageMatrik Risk Rank KPCRoy RahadianNo ratings yet

- NEW Form JHA-Road Works (27-03-2018) FinalDocument34 pagesNEW Form JHA-Road Works (27-03-2018) FinalKarthik babu100% (3)

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- Risk Assessment Format For SampleDocument3 pagesRisk Assessment Format For SampleSaqib RasoolNo ratings yet

- Critical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents, Accidents and DisastersFrom EverandCritical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents, Accidents and DisastersNo ratings yet

- Ch#_40,_41,_42 (1)Document5 pagesCh#_40,_41,_42 (1)Sajjad AfzalNo ratings yet

- HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024Document12 pagesHAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024Sajjad AfzalNo ratings yet

- 4. HAZARD IDENTIFICATION PLAN (HIP) REV-06 (1)Document116 pages4. HAZARD IDENTIFICATION PLAN (HIP) REV-06 (1)Sajjad AfzalNo ratings yet

- HIP CPP for NGCP PipelinesDocument15 pagesHIP CPP for NGCP PipelinesSajjad AfzalNo ratings yet

- CSM IV-4 AviationDocument4 pagesCSM IV-4 AviationSajjad AfzalNo ratings yet

- Changing HRM Practices With Firm Growth: Bernice Kotey and Alison SheridanDocument12 pagesChanging HRM Practices With Firm Growth: Bernice Kotey and Alison SheridanAhmed KhanNo ratings yet

- Design To PDFDocument78 pagesDesign To PDFMark John PeñaNo ratings yet

- VMware Overview of L1 Terminal Fault' (L1TF) Speculative-Execution Vulnerabilities in Intel Processors - CVE-2018-3646, CVE-2018-3620, and CVE-2018-3615 (55636)Document2 pagesVMware Overview of L1 Terminal Fault' (L1TF) Speculative-Execution Vulnerabilities in Intel Processors - CVE-2018-3646, CVE-2018-3620, and CVE-2018-3615 (55636)Priyank RajNo ratings yet

- Dr. M. Syed Jamil Asghar: Paper Published: 80Document6 pagesDr. M. Syed Jamil Asghar: Paper Published: 80Awaiz NoorNo ratings yet

- Angela Duckworth Grit ScaleDocument3 pagesAngela Duckworth Grit ScaleErsa ShasqiaNo ratings yet

- Cerumen ImpactionDocument29 pagesCerumen Impactionratu pelaksanaNo ratings yet

- Akbar2015Document33 pagesAkbar2015DEDY KURNIAWANNo ratings yet

- Corrected ReportDocument70 pagesCorrected ReportCurtis IsraelNo ratings yet

- Pump SelectionDocument4 pagesPump SelectionmhmdjdgmailcomNo ratings yet

- A Practical Approach To Truck Dispatch For Open Pit Mines: January 2011Document14 pagesA Practical Approach To Truck Dispatch For Open Pit Mines: January 2011Miloš SimonovićNo ratings yet

- SAEJ30Document38 pagesSAEJ30Jose Luis AusinNo ratings yet

- Finding M in The Network: A Matlab Program and Application: Aximum FlowDocument5 pagesFinding M in The Network: A Matlab Program and Application: Aximum FlowFahad IzharNo ratings yet

- 6469 4 Sun-Protection DigitalDocument2 pages6469 4 Sun-Protection DigitalMohammed sabatinNo ratings yet

- Updating Your Device Via Wialon EN PDFDocument16 pagesUpdating Your Device Via Wialon EN PDFДмитрий ДмитриевичNo ratings yet

- Executive Diploma in Network & Cyber SecurityDocument10 pagesExecutive Diploma in Network & Cyber SecurityKYAW SHWE WINNo ratings yet

- Data Transmission Over Inmarsat in TCP/IP EnvironmentDocument7 pagesData Transmission Over Inmarsat in TCP/IP EnvironmentpankajlangadeNo ratings yet

- Accessibility - Delfont Mackintosh TheatresDocument5 pagesAccessibility - Delfont Mackintosh TheatresLomon SamNo ratings yet

- Smart Sprinkler System Using Basic StampDocument22 pagesSmart Sprinkler System Using Basic StampdiegoNo ratings yet

- Detection of Potholes, Humps and Measuring Distance Between Two Vehicles Using Ultrasonic Sensor and AccelerometerDocument6 pagesDetection of Potholes, Humps and Measuring Distance Between Two Vehicles Using Ultrasonic Sensor and AccelerometerGRD JournalsNo ratings yet

- North Country AutoDocument9 pagesNorth Country AutoSamu BorgesNo ratings yet

- The 6 Quality Basics - Rework Under ControlDocument5 pagesThe 6 Quality Basics - Rework Under Controlpatima_sv4875No ratings yet

- CCJ Issue 49 PDFDocument132 pagesCCJ Issue 49 PDFsleepanon4362No ratings yet

- Machines 07 00042 PDFDocument21 pagesMachines 07 00042 PDFguterresNo ratings yet

- MBA 111 - ControllingDocument39 pagesMBA 111 - ControllingJhoia BesinNo ratings yet

- The 73 TOPIK (Test of Proficiency in Korean) NoticeDocument2 pagesThe 73 TOPIK (Test of Proficiency in Korean) NoticeNilufar YunusovaNo ratings yet

- The Quest For Convenience InfographicDocument1 pageThe Quest For Convenience InfographicDuy Nguyen Ho ThienNo ratings yet

- Cuizon V RamoleteDocument2 pagesCuizon V RamoleteHazel BarbaronaNo ratings yet

HIP-TWLA (October 1st October 15th ,2021)

HIP-TWLA (October 1st October 15th ,2021)

Uploaded by

Sajjad AfzalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIP-TWLA (October 1st October 15th ,2021)

HIP-TWLA (October 1st October 15th ,2021)

Uploaded by

Sajjad AfzalCopyright:

Available Formats

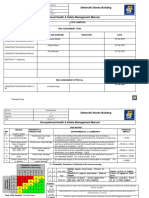

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINES

BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP)

BASED ON TWO WEEKS LOOK AHEAD

(October 1st - 15th ,2021)

DATE October 5, 2021 PREPARED BY REVIEWED BY APPROVED BY

REVISION 00

CONSTRUCTION MANAGER HSE MANAGER PROJECT MANAGER

STATUS IFI

RICK LUMANLAN MUHAMMAD SHAHZAD KAHAWAJA ZHANG WENJIANG

CONTRACT NO.: 6600042306 DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-26

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS

REV 00 STATUS IFI

LOOK AHEAD

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 2 of 45

1.0 INTRODUCTION

This Hazard Identification Plan is not intended to replace and or repeat the

content of the Project Hazard Identification Plan but only to focus on main

hazards and controls to focus on for the coming month.

These hazards, controls, barriers and safeguards are triggered by the

construction activities to be undertaken, environmental factors, current

issues, recent incidents or assessments.

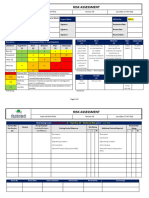

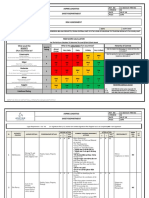

2.0 HAZARD CLASSIFICATION

When identifying hazards associated with the listed activity first determine

what the realistic consequence is, then identify what the probability of that

consequence occurring is. By plotting these two in the A3 worksheet you will

come up with Higher and Medium risk activities.

DEFINITION Severity Consequence

SAFETY / ENVIRONMENTAL DEFINITION

HEALTH IMPACT IMPACT 1 2 3 4 5

1 No injury or No or slight effect 1 Very Low - Never heard of in the industry 5 25

damage to health 5 10 15 20

CONSEQUENCE CATEGORY

PROBABILITY CATEGORY

2 Treatment beyond Minor contamination 2 Low - Some instances in the industry 4 20

First Aid 4 8 12 16

Probability

3 Lost time or Localized event 3 Medium - Incident has happened in the 3 15

restricted work company 3 6 9 12

4 Single fatality or No significant lasting 4 High - Happens several times a year in 2 10

permanent consequence the company 2 4 6 8

disability

5 Multiple fatalities Lasting 5 Very High - Happens several times a 1 5

consequence year in the facility 1 2 3 4

3.0 AUDIENCE

This Hazard Identification Plan is developed by the contractor and the

intended audience are the Contractor Leads/Supervisors. SAPMT should

also be made aware of the hazards involved and the controls that should

be put in place to ensure an incident free work place, SAPMT will use this

Hazard Identification Plan as reference for Safety Walks and Site Visits.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 3 of 45

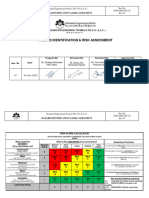

4.0 ROLES & RESPONSIBILITES

The Roles & Responsibilities involved in executing this Hazard Identification Plan are detailed in the RACI Chart

below:

Contractor

Contractor Contractor Discipline Contractor Contractor SAPMT SAPMT

Const Mgr WHO?? Lead HSE DC SPE Engineer

Develop Hazard Identification Plan

based on the Three Week A R - - -

Lookahead Schedule

Determine activities for each craft

A R - - -

Identify potential hazards

A R C

Assess the level of risk

R C

(consequence x probability)

Identify controls barriers &

safeguards to eliminate/reduce

R C

consequence/severity of an

incident

Disseminate to Craft Supervisors

R

Transmit to SAPMT

A R I

Assign to SAPMT Engineer to

verify that controls barriers &

R I

safeguards listed have been

implemented

SAPMT Engineer to verify that

controls barriers & safeguards A R

listed have been implemented

Communicate any gaps to the

I A R

Contractor WHO???

R = Responsible, A = Accountable, C = Consult, I = Informed

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 4 of 45

Responsible Person

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

HWYH LSS AREA (SOUTH HAWIYAH)

(Syed K Ahmed),

Pipe loading and unloading, erecting pipe (Haitham Alshammari),

1 HWYH GK MAGE

spools and supports, flange joint bolt torquing (Themba Zibi)

HWYH OPTF

1088,1093,1134,1076,1 (Syed K Ahmed),

Excavation and Installation of foundation & 079,1067,206,1072,934 Fayyaz

2 Site Foremen CPP (Haitham Alshammari),

pipe spools ,1065,1071,975, 1055. 0581733632

(Themba Zibi)

CJ,209,1087,1092,1036

,942

HWYH (Syed K Ahmed),

Excavation, Fit-up welding, lowering, lifting, 206,201,1023,1067,109 Azeem Ullah

3 Supervisor CPP (Haitham Alshammari),

NDT, Cleaning 6,1072,1069,952, CJ- 0558535191

(Themba Zibi)

RH

HWYH (Syed K Ahmed),

206,201,1023,1067,109

4 Welding, fit-up, lifting, NDT REN Site supervisor CPP (Haitham Alshammari),

6,1072,1069,952, CJ-

(Themba Zibi)

RH

HWYH (Syed K Ahmed),

Nizam

5 Excavation and Rock breaking 206,201,1023,1067,107 Site Foremen CPP (Haitham Alshammari),

0539270046

2,1069,952, CJ, EJ (Themba Zibi)

HWYH (Syed K Ahmed),

6 Excavation and Rock breaking 206,201,1023,1067,109 ALEX Site Foremen CPP (Haitham Alshammari),

6,1072,1069,952, CJ, EJ (Themba Zibi)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 5 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

HWYH (Syed K Ahmed),

7 Excavation and Rock breaking, BACKFILLING 206,201,1023,1067,109 Suhag Site Foremen CPP (Haitham Alshammari),

6,1072,1069, CJ (Themba Zibi)

HWYH (Syed K Ahmed),

206,201,1023,1067,109 Waqar

8 Coating, Wrapping, Holiday test, backfilling Site supervisor CPP (Haitham Alshammari),

6,1072,1069, 952, CJ- 0594285160

(Themba Zibi)

RH

(Syed K Ahmed),

9 Drilling for Rock blasting HWYH 1023, LSS1 Ajmal Site supervisor CPP (Haitham Alshammari),

(Themba Zibi)

HWYH (Syed K Ahmed),

Ahmed

10 Welding, fit-up, lifting, NDT 206,201,1023,1067,109 Site Foremen CPP (Haitham Alshammari),

0580862361

6,1072,1069, CJ,952 (Themba Zibi)

HWYH (Syed K Ahmed),

Excavation, Fit-up welding, lowering, lifting, Zafar

11 206,201,1023,1067,109 Supervisor CPP (Haitham Alshammari),

NDT, Cleaning 0583272894

6,1072,1069, CJ,952 (Themba Zibi)

HWYH (Syed K Ahmed),

206,201,1023,1067,109

12 Welding, fit-up, lifting, NDT Faridul Site Foreman CPP (Haitham Alshammari),

6,1072,1069, CJ,952 &

(Themba Zibi)

RISER

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 6 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

HWYH (Syed K Ahmed),

13 Welding, fit-up, lifting, NDT 206,201,1023,1067,109 Zhang Site Foreman CPP (Haitham Alshammari),

6,1072,1069, CJ,952, EJ (Themba Zibi)

HWYH (Syed K Ahmed),

Excavation, exposing, cable laying, bonding, Asif

14 206,201,1023,1067,109 CP Supervisor CPP (Haitham Alshammari),

install anode for thrust anchor 0596233501

6,1072,1069, CJ (Themba Zibi)

Anchor welding ,Excavation, RTR Installation, (Syed K Ahmed),

Xiang hong

15 Pipeline cleaning, water filling, Hydro-testing, 8"-HWYHLSS-HWGCP-1 Site Foreman CPP (Haitham Alshammari),

0553521039

BREM (Themba Zibi)

(Syed K Ahmed),

HAO HONG TAO

16 Sand Backfilling and Berm, anchor coating 8"-HWYHLSS-HWGCP-1 Site Foreman CPP (Haitham Alshammari),

0536227716

(Themba Zibi)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, PEI GUOTAO

17 HWYH BK-GGM 16" Site Foreman CPP (Haitham Alshammari),

Backfilling, Welding, Excavation 0580678547

(Themba Zibi)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, PEI GUOTAO

18 HWYH LSS-GGM 16" Site Foreman CPP (Haitham Alshammari),

Backfilling, Welding, Excavation 0580678547

(Themba Zibi)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 7 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, HAO HONG TAO

19 BK HWYH RK Site Foreman CPP (Haitham Alshammari),

Backfilling 0536227716

(Themba Zibi)

Conduit Installation for switch rack, cable (Syed K Ahmed),

Tabriz

20 gland and termination, cad welding, HWYH EJ & HK Site In-charge HARISCO (Haitham Alshammari),

0554848032

excavation of trench for lv cable (Themba Zibi)

(Syed K Ahmed),

Excavation of trench, asphalt cutting, cable Tabriz

21 HWYH GGM Site In-charge HARISCO (Haitham Alshammari),

laying and backfilling 0554848032

(Themba Zibi)

(Syed K Ahmed),

Excavation of trench for LV cable, grounding Raj

22 HWYH CJ Site In-charge CPP (Haitham Alshammari),

cable and backfilling 0580253610

(Themba Zibi)

(Syed K Ahmed),

Excavation for FOC trench & HDPE Installation Mutasim

23 HWYH CJ /EJ Supervisor CPP (Haitham Alshammari),

/ sub duct installation and FOC laying 0595658148

(Themba Zibi)

(Syed K Ahmed),

HWYH Li kangkang

24 Cutting, polishing, Fit-up, Welding Supervisor Sinopec (Haitham Alshammari),

RH-CK 0583384032

(Themba Zibi)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 8 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

HWYH Guo Zhongsheng

25 Cutting, polishing, Fit-up, Welding Supervisor Sinopec (Haitham Alshammari),

RH-FK 0592069348

(Themba Zibi)

Cleaning, Gauging, Hydro testing, Drying, Pre- (Syed K Ahmed),

Amjad Kamal

26 Caliper Survey, Swabbing & Nitrogen Purging HWYH-1066-973 Commissioning Trans Asia (Haitham Alshammari),

0554371331

8" Flow line Engineer (Themba Zibi)

Cleaning, Gauging, Hydro testing, Drying, Pre- (Syed K Ahmed),

Amjad Kamal

27 Caliper Survey, Swabbing & Nitrogen Purging HWYH-2243-2104 Commissioning Trans Asia (Haitham Alshammari),

0554371331

8" Flow line Engineer (Themba Zibi)

Pre- (Syed K Ahmed),

Amjad Kamal CPP/Trans

28 Caliper Survey, Swabbing & Nitrogen Purging HW-RH-IK, HW-1093 Commissioning (Haitham Alshammari),

0554371331 Asia

Engineer (Themba Zibi)

Pre- (Syed K Ahmed),

HW-RH-CJ, HW-1102- Amjad Kamal CPP/Trans

29 Caliper Survey, Swabbing & Nitrogen Purging Commissioning (Haitham Alshammari),

HW-1023 0554371331 Asia

Engineer (Themba Zibi)

Pre- (Syed K Ahmed),

HW-RH-CK, HW-1092- Amjad Kamal CPP/Trans

30 Caliper Survey, Swabbing & Nitrogen Purging Commissioning (Haitham Alshammari),

HW-209 0554371331 Asia

Engineer (Themba Zibi)

HWYH GGM AREA (North HAWIYAH)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 9 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

HWYH GGM TO GCP-1 (Syed K Ahmed),

1 Backfilling, Burming TR/LINES, EK-RH,1082, Sami- Site supervisor MSCC (Haitham Alshammari),

HK-RH T/L, CJ, EJ T/L (Badar Al Bashar)

HWYH 1114 F/L TO EK- (Syed K Ahmed),

Excavation, Fit-up welding, lowering, lifting, RH, HWYH GGM TO Zafar

2 Supervisor CPP (Haitham Alshammari),

NDT, Cleaning GCP-1 TR/LINES, HWYH 0583272894

(Badar Al Bashar)

1074,1089,2231

HWYH HK-RH T/L &

HWYH GGM TRNS (Syed K Ahmed),

Excavation, Fit-up welding, lowering, lifting, LINES, UTMN- Azeem Ullah

3 Supervisor CPP (Haitham Alshammari),

NDT, Cleaning 2252,2243CJ, EJ 0558535191

(Badar Al Bashar)

T/L,1089,2237,2231,11

14,1074

HWYH GGM (Syed K Ahmed),

Excavation, exposing, cable laying, bonding,

TR/LINES,2238,2231,22 Asif

4 install anode for thrust anchor, Potential CP Supervisor CPP (Haitham Alshammari),

33,2229,2245,2252-HK- 0596233501

testing (Badar Al Bashar)

RH, FK-RH, EK-RH T/L

HWYH GGM TO GCP-1 ((Syed K Ahmed),

TR/LINES,1082,2243,11 Aminur

5 Excavation and Rock breaking Site Supervisor CPP (Haitham Alshammari),

14,1074, EK-RH, HK-RH, 0590437479

(Badar Al Bashar)

DJ-RH

HWYH GGM TO GCP-1 ((Syed K Ahmed),

TR/LINES & EK-

6 Welding, fit-up, lifting, NDT REN Site Supervisor CPP (Haitham Alshammari),

RH,1114,1074,2252,22

(Badar Al Bashar)

43

HWYH GGM TO GCP-1 ((Syed K Ahmed),

7 Welding, fit-up, lifting, NDT TR/LINES,1082 F/L, CJ, Ahmed Ibrahim Site Supervisor CPP (Haitham Alshammari),

EJ,1089,2237 (Badar Al Bashar)

HWYH GGM TO GCP-1 ((Syed K Ahmed),

8 Welding, fit-up, lifting, NDT TR/LINES,1074,2235,11 Nasrullah Site Supervisor CPP (Haitham Alshammari),

14,1082 (Badar Al Bashar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 10 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

HWYH GGM TO GCP-1 ((Syed K Ahmed),

TR/LINES,2234,2235,22 Waqar

9 Coating, Wrapping, Holiday test, backfilling Site Supervisor CPP (Haitham Alshammari),

38,1082.1114,1074,225 0594285160

(Badar Al Bashar)

2.1089

HWYH 1082 TO 994

F/L, HWYH 1114 F/L, ((Syed K Ahmed),

Nizam

10 Excavation and Rock breaking HWYH 1074 F/L, UTMN Site Foremen CPP (Haitham Alshammari),

0539270046

2252,2231,2237, EK- (Badar Al Bashar)

RH,2243, EK, HK

((Syed K Ahmed),

HWYH GGM TO GCP-1 Aminur

11 Manual Excavation and pipe exposing Site Supervisor CPP (Haitham Alshammari),

TR/LINES.EK-RH, CJ, EJ 0590437479

(Badar Al Bashar)

HWYH GGM TO GCP-1 ((Syed K Ahmed),

TR/LINES, HWYH Ahmed

12 Welding, fit-up, lifting, NDT Site Foremen CPP (Haitham Alshammari),

1074,1114, CJ, EJ, HK, 0580862361

(Febelito)

EK-RH,2243

HWYH GGM TO

HWGCP-1 ((Syed K Ahmed),

Hammed

13 Loading & Unloading Pipes Preservation TR/LINES,1089,1082,22 Site Foremen CPP (Haitham Alshammari),

0597813521

43,2252,2238,1114,107 (Badar Al Bashar)

4, 2235, EK, HK

((Syed K Ahmed),

UTMN 2237,2231,

14 Excavation for trench and Anchor ALEX Site Foremen CPP (Haitham Alshammari),

HWYH 1089, CJ, EJ HDD

(Badar Al Bashar)

HWYH 1082 F/L, HWYH ((Syed K Ahmed),

1114 F/L, HWYH 1074

15 Welding, fit-up, lifting, NDT Faridul Site Foremen CPP (Haitham Alshammari),

F/L,2252,968,1089,108

(Badar Al Bashar)

2

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 11 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

((Syed K Ahmed),

16 Drilling for Rock blasting HWYH 1074 F/L Ajmal Site Supervisor CPP (Haitham Alshammari),

(Badar Al Bashar)

HWGCP-1 THRUST ((Syed K Ahmed),

ANCHOR, UTMN

17 Excavation and Rock breaking, BACKFILLING Haris Site Foremen CPP (Haitham Alshammari),

2231,2237, EK-

(Badar Al Bashar)

RH,2238,2104

HWGCP-1 THRUST ((Syed K Ahmed),

ANCHOR, UTMN 2252

18 Excavation and Rock breaking, BACKFILLING ALI RAZA Site Foremen CPP (Haitham Alshammari),

F/L,2243 T HK-RH F/L,

(Badar Al Bashar)

EJ & CJ

((Syed K Ahmed),

HWYH GGM TR/LINES

19 Manual Excavation and pipe exposing Sohag Site Foremen CPP (Haitham Alshammari),

TO HWGCP-1

(Badar Al Bashar)

HWYH GGM TR/L-1- (Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, Nasir

20 SWEET - HWYHGCP-1 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation 0599163350

24" (Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, HWYH GGM TR/L-2 - Nasir

21 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation HWYHGCP-1 24" 0599163350

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, HWYHGGM-HWGCP1 Nasir

22 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation 36" TL1/TL2/SWEET 0599163350

(Badar Al Bashar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 12 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, Liu Bin

23 BJ HWYH RK Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation 0581507316

(Badar Al Bashar)

HWYH1098-UTMN2219 (Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, ZHANG GANG

24 8" Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding 0591370922

LK HWYH RK (Badar Al Bashar)

HWYH 955-UTMN2239 (Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, HAO HONG TAO

25 8" Site Foremen CPP (Haitham Alshammari),

Backfilling 0536227716

BJ HWYH RK (Badar Al Bashar)

HWYH 1066 - (Syed K Ahmed),

HAO HONG TAO

26 CP, Coating, Holiday Inspection, Backfilling HWYH973 8" Site Foremen CPP (Haitham Alshammari),

0536227716

BJ HWYH RK (Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, BJ HWYH RK Liu Bin

27 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation HWYH 2239 -8" 0581507316

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, BJ HWYH RK PEI GUOTAO

28 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation HWYH 1122-200 -6" 0580678547

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, EK HWYH RK PEI GUOTAO

29 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation HWYH 1095-EK -6" 0580678547

(Badar Al Bashar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 13 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

BJ HWYH RK (Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, Liu Bin

30 UTMN2247- Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation 0581507316

UTMN2231 8" (Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, BJ HWYH RK Liu Bin

31 Site Foremen CPP (Haitham Alshammari),

Backfilling Welding HWYH 1065-969 8" 0581507316

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, EK HWYH RK Liu Bin

32 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation HWYH 2201-EK 10" 0581507316

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, EK HWYH RK WU YANHUI

33 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation UTMN2245-2201 8" 0580682925

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, HK HWYH RK PEI GUOTAO

34 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation UTMN2232-2229 8" 0580678547

(Badar Al Bashar)

(Syed K Ahmed),

CP, Coating, Holiday Inspection, Lowering, HK HWYH RK PEI GUOTAO

35 Site Foremen CPP (Haitham Alshammari),

Backfilling, Welding, Excavation UTMN2229-HK 8" 0580678547

(Badar Al Bashar)

(Syed K Ahmed),

DJ HWYH RH Liu Bin

36 Welding, Excavation Site Foremen CPP (Haitham Alshammari),

UTMN2205-2103 8" 0581507316

(Badar Al Bashar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 14 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

DJ HWYH RH Liu Bin

37 Welding, Excavation Site Foremen CPP (Haitham Alshammari),

UTMN2233-DJ 8" 0581507316

(Badar Al Bashar)

(Syed K Ahmed),

BJ HWYH RH Liu Bin

38 Welding, Excavation Site Foremen CPP (Haitham Alshammari),

HWYH1107-BJ 8" 0581507316

(Badar Al Bashar)

(Syed K Ahmed),

Pole Installation and accessories installation, HW GCP1 TO HWYH Harold

39 Site Engineer MAGE (Haitham Alshammari),

MV underground Installation & Stringing LSS 0552391610

(Badar Al Bashar)

Demolishing of existing pole, its accessories, (Syed K Ahmed),

Harold

40 acsr cable and fence of existing cable and HWY GGM BY PASS Site Engineer MAGE (Haitham Alshammari),

0552391610

loading of material (Badar Al Bashar)

(Syed K Ahmed),

Excavation of trench for MV cable, cable laying HW GCP1 TO HWYH Glen AL-

41 Site Engineer (Haitham Alshammari),

and backfilling LSS 0557123807 AWADH

(Badar Al Bashar)

(Syed K Ahmed),

Pole and anchor hole excavation, rebar Ahmed

42 HWYH DJ Site Engineer PPCO (Haitham Alshammari),

installation, cable trench excavation 0597058203

(Badar Al Bashar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 15 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

Pole Dressing & ACSR Stringing and Cable SUNIL

43 HWYH BK /HWYHH EJ Site Engineer PACOST (Haitham Alshammari),

pulling & MV cable excavation 0596743385

(Badar Al Bashar)

(Syed K Ahmed),

Steel structure erection, Shim Pad fabrication HWYH Li Haibao

44 Supervisor Sinopec (Haitham Alshammari),

& Curing Alignment, bolt tightening RH-GGM 0595653125

(Badar Al Bashar)

(Syed K Ahmed),

HWYH Li Kangkang

45 Cutting, Polishing, Fit-up, Welding Supervisor Sinopec (Haitham Alshammari),

RH-GGM 0583384032

(Badar Al Bashar)

(Syed K Ahmed),

HWYH Li Kangkang

46 Cutting, Polishing, Fit-up, Welding Supervisor Sinopec (Haitham Alshammari),

RH-BJ 0583384032

(Badar Al Bashar)

FDN works and SSB works (FDN installation,

Survey, Concrete, Surface preparation, Rebar (Syed K Ahmed),

and formworks installation and coating works, Sarfraz

47 HWYH-GGM Civil Engineer CPP (Haitham Alshammari),

Asphalt cutting, manual Excavation, 0592957000

(Badar Al Bashar)

Backfilling) Marl Material mixing and anchor

block

FDN works (Pouring concrete, FDN (Syed K Ahmed),

Installation, Surface preparation, Manual and Asad

48 HWYH-EJ Civil Foreman CPP (Haitham Alshammari),

mechanical Excavation, rebar installation 0583926104

(Badar Al Bashar)

formworks, Backfilling and coating works)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 16 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

Kumud

49 FDN works (Excavation, Lifting backfilling) HWYH-CK Civil Foreman CPP (Haitham Alshammari),

0595196942

(Badar Al Bashar)

(Syed K Ahmed),

Yasir

50 FDN works (Excavation, Lifting backfilling) HWYH-RH-BJ Civil Foreman CPP (Haitham Alshammari),

0582329340

(Badar Al Bashar)

(Syed K Ahmed),

Yasir

51 FDN works (Excavation, Lifting backfilling) HWYH-RH-DJ Civil Foreman CPP (Haitham Alshammari),

0582329340

(Badar Al Bashar)

Anchor Block Work (Syed K Ahmed),

Mudassar

52 (Compaction, Rebar, formwork installation HWYH-GGM Civil Supervisor CPP (Haitham Alshammari),

0597543878

and concrete works) (Badar Al Bashar)

(Syed K Ahmed),

Anchor Block Work (Compaction, Rebar, Mudassar

53 HWYH-OPTF-206 Civil Supervisor CPP (Haitham Alshammari),

formwork installation and concrete works) 0597543878

(Badar Al Bashar)

(Syed K Ahmed),

Anchor Block Work (Compaction, Rebar, Usman

54 HWYH-OPTF-2232 Civil Supervisor CPP (Haitham Alshammari),

formwork installation and concrete works) 0581168411

(Badar Al Bashar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 17 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

Anchor Block Work (Compaction, Rebar, Usman

55 HWYH-OPTF-2233 Civil Supervisor CPP (Haitham Alshammari),

formwork installation and concrete works) 0581168411

(Badar Al Bashar)

(Syed K Ahmed),

2-pcs Anchor Block Work (Compaction, Rebar, Usman

56 HWYH-OPTF-2229 Civil Supervisor CPP (Haitham Alshammari),

formwork installation and concrete works) 0581168411

(Badar Al Bashar)

2pcs- Anchor Block Work (Compaction, Rebar, (Syed K Ahmed),

Usman

57 formwork installation and concrete works) HWYH-OPTF-2201 Civil Supervisor CPP (Haitham Alshammari),

0581168411

(Badar Al Bashar)

(Syed K Ahmed),

Anchor Block Work (Compaction, Rebar, Usman

58 HWYH-OPTF-2103 Civil Supervisor CPP (Haitham Alshammari),

formwork installation and concrete works) 0581168411

(Badar Al Bashar)

(Syed K Ahmed),

Anchor Block Work (Compaction, Rebar, Mudassar

59 HWYH-RH-EK Civil Supervisor CPP (Haitham Alshammari),

formwork installation and concrete works) 0597543878

(Badar Al Bashar)

HWYH GCP AREA

Cutting, Polishing, Fit-up, Welding HWYH Li Kangkang (Syed K Ahmed),

Supervisor Sinopec

1 Piping installation RH-EJ 0583384032 (Haitham Alshammari),

(Hasham Al Nasar)

Piping Cutting, welding HWYH Li Kangkang (Syed K Ahmed),

Supervisor Sinopec

2 Piping installation RH-BK 0583384032 (Haitham Alshammari),

(Hasham Al Nasar)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 18 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

Manual excavation of trenches for Instrument HwGCP-1 Azar Instrument

3 CPP (Haitham Alshammari),

cables, cable laying and backfilling. HWYH-GGM (0583417510) Engineer

(Hasham Al Nasar)

N. HARDH GGM AREA

((Syed K Ahmed),

Install Anode cad weld cable laying potential HDGCP-2 TO N HRDH Asif

1 CP Supervisor CPP (Hashem Al Nasser),

test, Bonding GGM 30" 0596233501

(Syed Z Rizvi)

((Syed K Ahmed),

Welding, fit-up, lifting, NDT, Excavation Rock 30" N. HRDH GGM TO

2 Liu Site Foreman CPP (Hashem Al Nasser),

breaking HDGCP-2

(Syed Z Rizvi)

((Syed K Ahmed),

Welding, fit-up, lifting, NDT, Excavation Rock 24" HRDH K3 RH TR/L

3 Liu Site Foreman CPP (Hashem Al Nasser),

breaking TO HDGCP-2

(Syed Z Rizvi)

((Syed K Ahmed),

Welding, fit-up, lifting, NDT, Excavation Rock N. HRDH GGM TO

4 Liu Site Foreman CPP (Hashem Al Nasser),

breaking HDGCP-1 TR/L 1 & 2

(Syed Z Rizvi)

Welding, CP, Joint-Coating, Holiday Inspection, ((Syed K Ahmed),

HAO HONG TAO

5 Lowering, Backfilling HRDH RH-CK Site Foreman CPP (Hashem Al Nasser),

0536227716

8"-HRDH-611-CK-RH (Syed Z Rizvi)

(Syed K Ahmed),

excavation anchor, CP, Coating, Backfilling HAO HONG TAO

6 HRDH RH-AK Site Foreman CPP (Hashem Al Nasser),

8"-HRDH-1309-HRDH-918 0536227716

(Syed Z Rizvi)

Welding, excavation anchor, CP, Coating, (Syed K Ahmed),

HAO HONG TAO

7 Backfilling HRDH RH-CK Site Foreman CPP (Hashem Al Nasser),

0536227716

8"-HRDH-1135-HRDH-1118 (Syed Z Rizvi)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 19 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

(Syed K Ahmed),

Coating Backfilling HAO HONG TAO

8 HRDH RH-GK Site Foreman CPP (Hashem Al Nasser),

8"-HRDH-1146-HRDH-1108 0536227716

(Syed Z Rizvi)

(Syed K Ahmed),

Azhar

9 FDN works, Welding, lifting, cleaning CPP yard Civil Foreman CPP (Hashem Al Nasser),

0582018630

(Syed Z Rizvi)

FDN works (Pouring concrete, FDN (Syed K Ahmed),

Installation, Surface preparation, Manual and Bilal

10 HD-RH-DK Site Supervisor CPP (Hashem Al Nasser),

mechanical Excavation, rebar installation 0507062378

(Syed Z Rizvi)

formworks and coating works)

FDN works (Pouring concrete, FDN (Syed K Ahmed),

Installation, Surface preparation, Manual and Bilal

11 HD-RH-GK Site Supervisor CPP (Hashem Al Nasser),

mechanical Excavation, rebar installation 0507062378

(Syed Z Rizvi)

formworks and coating works)

FDN works and SSB works (FDN installation,

Survey, Concrete, Surface preparation, Rebar (Syed K Ahmed),

and formworks installation and coating works, Umar

12 HRDH-GGM Site Foreman CPP (Hashem Al Nasser),

Asphalt cutting, manual Excavation, 0591254427

(Syed Z Rizvi)

Backfilling) Marl Material mixing and anchor

block

FDN works (Pouring concrete, FDN (Syed K Ahmed),

Installation, Surface preparation, Manual and Ghulam

13 HD-GCP2 Site Supervisor CPP (Hashem Al Nasser),

mechanical Excavation, rebar installation 0592878230

(Syed Z Rizvi)

formworks and coating works)

Pre- (Syed K Ahmed),

Caliper Survey, Swabbing & Nitrogen Purging HRDH-RH-DK, HWYH- Amjad Kamal CPP/Trans

14 Commissioning (Hashem Al Nasser),

1115 0554371331 Asia

Engineer (Syed Z Rizvi)

HRDH-RH-GK, HRDH- (Syed K Ahmed),

Pre-

Caliper Survey, Swabbing & Nitrogen Purging 1122, HRDH-1117, Amjad Kamal CPP/Trans

15 Commissioning (Hashem Al Nasser),

HRDH-1145, HRDH- 0554371331 Asia

Engineer (Syed Z Rizvi)

1162, HRDH-1157-1075

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 20 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

Pre- (Syed K Ahmed),

HRDH-RH-HK, HRDH- Amjad Kamal CPP/Trans

16 Caliper Survey, Swabbing & Nitrogen Purging Commissioning (Hashem Al Nasser),

1153 0554371331 Asia

Engineer (Syed Z Rizvi)

Pre- (Syed K Ahmed),

HRDH-RH-CK, HRDH- Amjad Kamal CPP/Trans

17 Caliper Survey, Swabbing & Nitrogen Purging Commissioning (Hashem Al Nasser),

1306, HRDH-1023 0554371331 Asia

Engineer (Syed Z Rizvi)

HRDH-RH-BK, HRDH- Pre- (Syed K Ahmed),

Amjad Kamal CPP/Trans

18 Caliper Survey, Swabbing & Nitrogen Purging 1172, HRDH-1023- Commissioning (Hashem Al Nasser),

0554371331 Asia

1061, HRDH-1314-920 Engineer (Syed Z Rizvi)

N.HARDH GGM AREA INSIDE FACILITY

((Syed K Ahmed),

XIE CHUNQING

1 Skid Installation HRDH RH-HK Site Foreman CPP (Hashem Al Nasser),

0580699843

(Oliver)

((Syed K Ahmed),

XIE CHUNQING

2 Skid Installation HRDH RH-K3 Site Foreman CPP (Hashem Al Nasser),

0580699843

(Oliver)

((Syed K Ahmed),

Excavation, FND install, backfilling Fence Nasir

3 HRDH RH-AK Site Foreman CPP (Hashem Al Nasser),

remove & install 0599163350

(Oliver)

((Syed K Ahmed),

Excavation, FND install, backfilling Fence Nasir

4 HRDH RH-CK Site Foreman CPP (Hashem Al Nasser),

remove & install 0599163350

(Oliver)

((Syed K Ahmed),

Excavation, FND install, backfilling Fence Nasir

5 HRDH RH-CK Site Foreman CPP (Hashem Al Nasser),

remove & install 0599163350

(Oliver)

CENTER.HARDH GGM AREA

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 21 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

((Syed K Ahmed),

CP, Coating Holiday Inspection Lowering HAO HONG TAO

1 HRDH RH-K2 Site Foreman CPP (Hashem Al Nasser),

8"-HRDH-1142-HRDH-938 0536227716

(Oliver)

((Syed K Ahmed),

CP, Coating Holiday Inspection HAO HONG TAO

2 HRDH RH-EK Site Foreman CPP (Hashem Al Nasser),

8"-HRDH-1197-HRDH-1026 0536227716

(Oliver)

CP, Coating Holiday Inspection, Lowering ((Syed K Ahmed),

HAO HONG TAO

3 Backfilling, Excavation HRDH RH-K1 Site Foreman CPP (Hashem Al Nasser),

0536227716

8"-HRDH-1078-HRDH-1037 (Oliver)

((Syed K Ahmed),

CP, Coating, Backfilling HAO HONG TAO

4 HRDH RH-IK Site Foreman CPP (Hashem Al Nasser),

8"-HRDH-1163-IK-RH 0536227716

(Oliver)

((Syed K Ahmed),

Poles hole excavation and rebar installation & HD GCP-1 To OSB / Glen

5 Site Engineer Al-Awadh (Hashem Al Nasser),

Pole Erection and pole accessories Installation HRDH K1 0557123807

(Oliver)

MV cable installation laying, red tiles ((Syed K Ahmed),

NORTH HRDH GGM / Glen

6 installation and backfilling, ACSR stringing, Site Engineer Al-Awadh (Hashem Al Nasser),

HARDH HK 0557123807

Shutdown Preparation / TIE with existing line (Oliver)

CENTER.HARDH GGM AREA INSIDE FACILITY

Skid Installation XIE CHUNQING ((Syed K Ahmed),

HRDH RH-GK

1 HRDH-1075 0580699843 Site Foreman CPP (Hashem Al Nasser),

(Oliver)

Skid Installation XIE CHUNQING ((Syed K Ahmed),

HRDH RH-EK

2 HRDH-1026 0580699843 Site Foreman CPP (Hashem Al Nasser),

(Oliver)

Skid Installation XIE CHUNQING ((Syed K Ahmed),

HRDH RH-EK

3 HRDH-1139 0580699843 Site Foreman CPP (Hashem Al Nasser),

(Oliver)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 22 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

((Syed K Ahmed),

Excavation, FND install, backfilling, Fence Nasir

4 HRDH RH-GK Site Foreman CPP (Hashem Al Nasser),

remove & install 0599163350

(Oliver)

((Syed K Ahmed),

Excavation, FND install, backfilling, Fence Nasir

5 HRDH RH-GK Site Foreman CPP (Hashem Al Nasser),

remove & install 0599163350

(Oliver)

((Syed K Ahmed),

Nasir

6 Excavation HRDH RH-K4 Site Foreman CPP (Hashem Al Nasser),

0599163350

(Oliver)

((Syed K Ahmed),

Nasir

7 Excavation HRDH RH-K3 Site Foreman CPP (Hashem Al Nasser),

0599163350

(Oliver)

((Syed K Ahmed),

Nasir

8 Excavation HRDH RH-K1 Site Foreman CPP (Hashem Al Nasser),

0599163350

(Oliver)

((Syed K Ahmed),

Nasir

9 Excavation HRDH RH-K4 Site Foreman CPP (Hashem Al Nasser),

0599163350

(Oliver)

((Syed K Ahmed),

Nasir

10 Excavation HRDH RH-K3 Site Foreman CPP (Hashem Al Nasser),

0599163350

(Oliver)

((Syed K Ahmed),

HRDH RH-DK Central XIE CHUNQING

11 Skid Installation Site Foreman CPP (Hashem Al Nasser),

HRDH 0580699843

(Oliver)

TCF-1 Fabrication Yard

((Syed K Ahmed),

1 Cutting, Grinding, Welding Fabrication Shop-2 (Hashem Al Nasser),

(Majed Al Qahtani)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 23 of 45

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

Ding ((Syed K Ahmed),

Cutting, polishing, Fit-up, Welding Fabrication shop-1 Supervisor

2 0581291442 CPP (Hashem Al Nasser),

(Majed Al Qahtani)

Blasting and painting, preservation, Waqar ((Syed K Ahmed),

TCF-1 Shop NO.4 Supervisor

3 maintenance 0558846920 CPP (Hashem Al Nasser),

(Majed Al Qahtani)

Adel ((Syed K Ahmed),

Loading & Unloading Pipes TCF-1 Yard Supervisor

4 0597510462 CPP (Hashem Al Nasser),

(Majed Al Qahtani)

TCF-1 Fabrication Yard XIA TONGCHUN ((Syed K Ahmed),

Piping Fabrication Site Foreman (Hashem Al Nasser),

5 shop2 0584712366 CPP

(Majed Al Qahtani)

Shang Pu ((Syed K Ahmed),

Piping, Cutting, welding TCF1 fabrication shop 1 Supervisor Sinopec (Hashem Al Nasser),

6 0590432391

(Majed Al Qahtani)

Mechanical ((Syed K Ahmed),

Pressure Testing for Seat and Body of Valves In Test Yard TCF-1 Waris Syed (Hashem Al Nasser),

7 Supervisor CPP

(Majed Al Qahtani)

In Test Yard & Mechanical ((Syed K Ahmed),

All types of Valves required for NGCP Project Waris Syed (Hashem Al Nasser),

8 Warehouse TCF-1 Supervisor CPP

(Majed Al Qahtani)

TCF-1 Lay-Down Yard

((Syed K Ahmed),

DUAN WEIBIN (Hashem Al Nasser),

1 Bend pipe, lifting Pipe transportation TCF-1 Lay-Down Yard Site Foreman CPP

0580647701

(Majed Al Qahtani)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 24 of 45

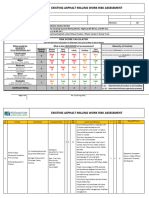

Pre-Mitigated Risk Controls / Barriers / Safeguards Post-Mitigated Risk

No. Discipline Activity Potential Hazards List all required Responsible Party

Probability Consequence Rating Probability Consequence Rating

1. Manual Excavation, 1. Struck by hand tools 4 4 16 1.1. PTW, approved JSA, MOS, IFC drawings and other required relevant documents will be 2 2 4 Cont:

Survey, Manual 2. Damage to Existing provided. PM (Zhang Wenjiang)

Facilities (U/G, A/G 1.2. Pre-job meeting will be conducted by site foreman/ supervisors in language understood by CM (Rick Lumanlan),

Excavation for Utilities)

workers before the actual activity proceeds. HSE Manager

pipe/cable exposing 3. Electrocution

1.3. Mechanical excavator/ equipment’s will not be used within 3meter to existing U/G facilities (Shahzad Khawaja),

4. Toxic Gas Leakage Site

5. Dust 1.4. Underground utilities will be identified by cable / metal detector, clearly marked on the

Foreman/Supervisor,

drawings and isolated by providing warning tapes at the actual locations.

WPR, Safety Officer,

1.5. Any underground cable that is exposed during excavation work must be assumed to be excavation

energized and verified to be de-energized by an authorized/certified electrician. competent

1.6. Involved working crew including (Site supervisor, operator & flagman) will be trained in Person/Workers

excavation safety and excavation hazards awareness.

1.7. Exposed lines will be barricaded and provided with relevant information and warning Client:

signage’s. SAPMT SPE

1.8. Gas test will be done by using celebrated MX4 gas detector by a Certified gas tester and ((Syed K Ahmed),

record will be made. HWYH PE

1.9. Each crew will be provided with personal H2S Monitor (T40).

(Haitham Alshammari)

1.10. Functional test for MX4 and H2S Monitor will be conducted by Certified Gas Test personnel

and records shall be maintained HRDH PE

1.11. Hand tools will be inspected, color coded and maintained in good condition. (Hashem Al Nasser)

1.12. Excavation competent person will fill the pre-excavation & U/G verification checklist on daily

basis.

1.13. Water sprinkling will be done to prevent dust accumulation at job site.

Civil

1.14. ANSI approved mandatory personal protective equipment (FRC, Gloves, Helmet, glasses,

1 Face Mask) will be worn.

1.15. Ample supplies of approved respiration protection (/N95/ 3M dust mask) will be provided at

the job site and will be worn while operating power tools/ exposing to dusty environment.

1.16. At least one trained first aider should be available during duty hours.

1.17. Emergency dedicated vehicle must be provided and Emergency Contact # will be posted at

all visible places.

1.18. Emergency communicate devices (like Mobile phone/ Satellite Phone) will be provided with

each crew.

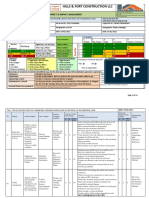

1. Mechanical 1. Mechanical Failure 3 4 12 1.1. Adequate support by providing (bracing and shoring) will be installed to support the existing 2 2 4 Cont:

Excavation, Rock 2. Struck by Heavy facilities if vibration cause damage during rock breaking activity. PM (Zhang Wenjiang)

Equipment 1.2. Suitable shoring will be installed, or the sides benched or sloped back to a safe angle, for all CM (Rick Lumanlan),

Breaking, Leveling, 3. Vibration

excavations 1.2 m (4 ft) deep. HSE Manager

Cleaning, Grading, 4. Flying Particles/objects

1.3. All hoses and connection will be fixed firmly and secured with Whip check and free from (Shahzad Khawaja),

Compaction, 5. Cave-ins/Collapse Site

6. Water Accumulation leakage.

Backfilling and Foreman/Supervisor,

7. Personnel / Equipment / 1.4. All the Heavy Equipment will be 3rd party inspected and ensure have valid 3rd party inspection

Berming WPR, Safety Officer,

Vehicle falling into sticker posted. Heavy Equipment

excavation 1.5. Periodic maintenance for the heavy equipment’s and the equipment inspection will be Operator and

8. Fire / Explosion conducted by CPP equipment inspector, valid CPP inspection sticker will be issued. excavation

1.6. All operators must have a valid certification from SA / SA approved 3rd party companies (i.e competent

SPSP/IPAF) relevant to the equipment they will use and activity they will perform. person

1.7. All Operators must have valid heavy/ Public SAG Driving licenses.

1.8. Spotter with reflective vest will be provided with all equipment maneuvering and to STOP the

unauthorized entrants.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 25 of 45

1.9. Earth moving equipment will be equipped with PWAS system and Reverse alarm should be Client:

operational and audible up to 30-meter distance. SAPMT SPE

1.10. Soil pile will be kept at least 0.6M (2ft) away from the edge of an excavation

((Syed K Ahmed),

1.11. All heavy equipment will be kept away 2M / equal to the depth of excavation (whichever is

HWYH PE

greater) from the edge of the excavation.

1.12. Excavation plan will be developed by degreed engineer as per soil type for excavation (Haitham Alshammari)

deeper than 2.4m in Type B or C Soil or for all excavations deeper than 6m regardless of soil HRDH PE

type. (Hashem Al Nasser)

1.13.Workers will not be allowed to enter in excavation where water is accumulated.

1.14.Entry of workers will not be permitted into excavation unless the excavation is inspected by

excavation competent person.

1.15.Proper means of access will be provided and should be used at all times.

1.16.All open excavation will be protected with hard barricades, blinking lights and signage’s

indicating ‘’DEEP EXCAVATION’’ STAY AWAY’’.

1.17.Hearing protection (ear Plugs/ Ear Muff) will be worn by workers exposing to high noise

areas.

1.18.Atmosphere test will be conducted by certified gas tester with calibrated MX4 gas testing

device.

1.19.Trained fire watcher with fire extinguishing (FM/UL Listed fire extinguishers will be provided

within 3 m.(10ft) in the working area.

1.20.Fully equipment Spill kit with trained spill response team will be provided with each crew.

1.21.Involved working crew including (Site supervisor, operator & flagman) will be trained in

excavation safety and excavation hazards awareness.

Civil

2. Formwork, 1. Sharp / Rough edges and 3 4 12 2.1. All protruded rebar will be provided with caps. 2 2 4 Cont:

1 Concrete Pouring, Protruded rebar 2.2. All protruding nails on woods and timber will be bended or uprooted immediately. PM (Zhang Wenjiang)

2. Defective Cutting/bending 2.3. De-nailing to be performed in designated areas only. CM (Rick Lumanlan),

Surface

machine 2.4. Ensure rebar cutting / bending machine will be free from any potential damage. HSE Manager

Preparation, 3. Manual Handling 2.5. Ample supplies of approved hearing protection (e.g., earplugs) will be provided at the job site (Shahzad Khawaja),

Painting, 4. Noise Site

and will be worn in high noise areas (i.e., 85 decibels [dBA] or higher.

5. Formwork dismantling / Foreman/Supervisor,

2.6. Formwork dismantling will be carried out step by step.

residual material Formwork erector,

6. Falling hazards / Falling 2.7. The ready-mix truck will have an operational back-up alarm and PWAS. WPR, Safety Officer,

Objects 2.8. Concrete Pump will be installed in compacted and leveled ground to prevent turn over or

7. Collapse of formwork. collapse.

Client:

8. Exposure to concrete 2.9. Adequate means of access with handrails (If required) will be provided to reach point /

concrete pouring location. SAPMT SPE

9. Environmental Hazards

2.10. Gas test will be done by using celebrated MX4 gas detector by a Certified gas tester and ((Syed K Ahmed),

record will be made. HWYH PE

2.11. Each crew will be provided with personal H2S Monitor (T40). (Haitham Alshammari)

2.12. Functional test for MX4 and H2S Monitor will be conducted by Certified Gas Test HRDH PE

personnel and records shall be maintained

(Hashem Al Nasser)

2.13. Involved working crew including (Site supervisor, Formwork erector, concrete pouring

crew and Painters) will be trained in Formwork safety and formwork hazards awareness.

2.14. Concrete Pouring personnel will stand on stable floor while standing on formwork.

2.15. Ensure all rotating parts of the concrete mixer are covered adequately

2.16. ANSI approved PPEs (FRC, Safety Glasses, Rubber Shoes and face shield will be used

at all time to protect eyes from paint splash.

2.17. Wash skin or hands with paint thinner or lacquer thinner is strictly prohibited, hand cleaner

will be used to clean the hand.

2.18. Disposable cover will be provided to protect body parts contact with concrete.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 26 of 45

3. Confined Space 1. Miscommunication / 3 4 12 3.1. SA work permit(s) as per GI 2.100 (Confined space entry work permit), (CONFINED SPACE 2 3 6 Cont:

Entry (When Misunderstanding ENTRY ACTIVITY SPECIFIC PLAN) and approved Pre-excavation checklist and Confined PM (Zhang Wenjiang)

2. Asphyxiation when entering Space entry checklist will be obtained prior to enter. CM (Rick Lumanlan),

Excavation Depth in Flammable or Toxic

3.2. Gas test will be done by using celebrated MX4 gas detector by a Certified gas tester and HSE Manager

Is More Than 1.2m) Atmosphere

record will be made. (Shahzad Khawaja),

3. Poor access/egress Site

4. Unauthorized Entry 3.3. Each crew will be provided with personal H2S Monitor (T40).

Foreman/Supervisor,

5. Slip and trip 3.4. Functional test for MX4 and H2S Monitor will be conducted by Certified Gas Test personnel

WPR, Safety Officer,

and records shall be maintained Person, CSE

3.5. Breathing apparatus will be used when the oxygen readings less than 20%, combustible supervisor and

gases 5%-10%LEL, CO is 35ppm - 1000ppm and H2S is 10ppm - 100ppm. entrants

3.6. CSE entry will not be allowed at oxygen concentration above 23.5%, combustible gases at

10% LEL or above, CO 1000ppm or above and H2S 100ppm or above. Client:

3.7. Adequate proper step access or secured ladders will be provided at all excavations. SAPMT SPE

3.8. Instructions listed in CPP (CONFINED SPACE ENTRY ACTIVITY SPECIFIC PLAN) ((Syed K Ahmed),

regarding rescue procedure must be followed in case of emergency. HWYH PE

3.9. Crew (CSE Supervisor, CSE Standby man, WPR, HSEO and Workers) involved in confined

(Haitham Alshammari)

space activities will obtained training related confined space entry procedures.

3.10. Trained standby man equipped with communication device will be assigned at entry points HRDH PE

to monitor and maintain contact with the entrants and prevent unauthorized entry. (Hashem Al Nasser)

3.11. Ladders or step access will be provided for entry and exit at every 7.5M on excavation.

3.12. Confined space entry will be monitor by using ‘’confined space entry log sheet’’ and it

should be available at designated entry points.

3.13. Excavation / confined space will be barricaded and appropriate relevant signage’s

Civil

‘’CONFINED SPACE ENTRY PERMIT REQUIRED’’ NO UNAUTHORIZED ENTRY’’ etc will

1 be posted in multi language’s.

3.14. Walk way will not be obstructed by any types of materials.

4. Installation 1. Noise. 3 4 12 4.1. Portable workshop will be constructed over the shaving area to contain the hazardous dust. 2 3 6 Cont:

/Assembly Of 2. Hazardous Dust 4.2. Hazardous dust will be collected carefully and disposed-off accordingly PM (Zhang Wenjiang)

3. Inadequate support 4.3. Shaving / Grinding activity will be done at ground level to minimize the fall / collapse of

RTR/RTP Pipes structure.

CM (Rick Lumanlan),

4. Sharp edges / scissor HSE Manager

/ blade 4.4. Adequate support and restrain system will be installed to support pipe and structure during

shaving / grinding (Shahzad Khawaja),

5. Environmental

4.5. Make sure the blade is sharp. Dull blades require more force, increasing the chance of Site

Hazards injury. Foreman/Supervisor,

4.6. Worker engaged in shaving will be provided with complete PPEs. Like FRC, respiratory WPR, Safety Officer,

protection and face shield together with safety glasses, ear plugs and disposable coverall.

4.7. Use protective clothing such as cut resistant or mesh gloves, especially for the holding Client:

hand. SAPMT SPE

4.8. Do not eat, drink or smoke when using these products

((Syed K Ahmed),

4.9. In case of eye exposure, rinse cautiously with water for several minutes until medical aid

arrived. HWYH PE

4.10. Containers will be labelled with the proper hazard communication (HAZCOM) label. Provide (Haitham Alshammari)

relevant MSDS /CHBs) at with chemicals and share MSDS with crew especially with

HRDH PE

Chemical handers

4.11. Eye wash Station/Facility” will be provided near the work location. (Hashem Al Nasser)

4.12. Workers will be provided with chemical handling training.

4.13. Waste and Empty containers will be treated at class I waste and disposed of in approved

landfill / by approved waste transporter and keep disposal manifest in record.

4.14. “Disposable PPEs like disposable cover-all, ear plugs, gloves etc. will not be used again and

will be treated as waste class III and disposed of in approved landfill / by approved waste

transporter and keep disposal manifest in record.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 27 of 45

5. Fence 1. Improper manual 3 4 12 5.1. Personnel will be trained on proper manual material handling techniques. Demonstrate how 2 3 6 Cont:

Installation/ 2. Handling to do safe manual lifting, 1. Plan the route to be taken while handling, 2. Legs apart, 3. back PM (Zhang Wenjiang)

3. Sharp edges straight, 4.hold the load close to body with firm grip, 5. Plan the route to be taken while CM (Rick Lumanlan),

Demolition handling, 6. Avoid twisting, awkward positioning

4. Struck by tools HSE Manager

5.2. If the load is unable to lift alone get assistance from co-workers (Shahzad Khawaja),

Slips, Trips & Fall

5.3. Correct PPE (FRC, Gloves, Face Shield, safety shoes) will be worn by workers at all times. Site

5. Pointed Ends 5.4. The ends of exposed wires will be bent to avoid any hazardous situation to the human body. Foreman/Supervisor,

5.5. Access will be kept free from any kind of obstruction to ensure safe evacuation in the case WPR, Safety Officer,

of any Emergency Workers

5.6. All the unwanted materials will be removed from the site Client:

5.7. Proper and safe positioning of personnel will be emphases. All body parts will be kept away

from the line of fire. SAPMT SPE

5.8. Hand tools will be inspected & maintained in good condition ((Syed K Ahmed),

5.9. Personnel shall not operate any tools unless they are appropriately trained in their selection, HWYH PE

use, inspection and storage.

5.10. Tools constructed of good quality materials shall be used. Use of “homemade” tools are (Haitham Alshammari)

prohibited HRDH PE

(Hashem Al Nasser)

Civil

6. Rock Blasting 2. Incompetent operator 3 4 12 1.1. Operator shall possess the Saudi Aramco competency Certified relevant 2 3 6 Cont:

1 1. Drilling 3. Defective equipment equipment and competent for operation. PM (Zhang Wenjiang)

4. Rotating parts 1.2. CPP inspector should conduct initial inspection of the equipment and only passed CM (Rick Lumanlan),

5. Damaged to existing equipment should be allowed to start operation. HSE Manager

lines 1.3. Operator shall check the equipment on a daily basis and fill-up the Daily Operator (Shahzad Khawaja),

6. Dust and Noise Checklist. Site

1.4. Keep all loose clothing away from turning tools. Foreman/Supervisor,

1.5. Keep all guards in place while operating. WPR, Safety Officer,

Workers

1.6. Rings, Neck less and long cloths etc. are not allowed to wear during job.

Client:

1.7. Only authorized, skilled and experienced workers to be deployed for carrying out

this task. SAPMT SPE

1.8. Updated copy of IFC drawings and crossing lines shall be available at site. ((Syed K Ahmed),

1.9. Determine & highlight the crossings on the IFC drawings. HWYH PE

1.10.Use cable detector with calibration certificate to find out underground utilities and (Haitham Alshammari)

all underground utilities shall be marked, isolated and highlighted by providing

barricades. HRDH PE

1.11.Make sure that the cutting tools are running straight before starting the operation. (Hashem Al Nasser)

1.12.Use water spray to control dust.

1.13.Use approved 3M / N95 dust mask to prevent inhalation of dust.

1.14. Ample supplies of approved hearing protection (e.g., earplugs) shall be provided at

the job site and shall be worn in high noise areas (i.e., 85 decibels [dBA] or higher.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 28 of 45

2. Blasting. 1. Incompetent Shot firer 4 4 12 2.1. The Shot-firer must possess a valid Saudi Shot-firer License to ensure that he 2 3 6 Cont:

Loading of Explosive 2. Miss Fire and explosion does not suffer from any physical disability or mental disorder that may affect the PM (Zhang Wenjiang)

Materials to the Hole 3. Damage to existing facility safe execution of his duties. CM (Rick Lumanlan),

and Connections 4. Dust 2.2. After all holes have been charged, everyone has to leave the site to a secure HSE Manager

Laying Fly Rock Cover 5. Unaware passersby and place except the Shot-firer and his assistant to check and finalize all work to start (Shahzad Khawaja),

Traffic the blast. Site

Firing the Shot Foreman/Supervisor,

6. Fly rocks and ground 2.3. No smoking during loading of explosive materials.

Checking of Un- WPR, Safety Officer,

Vibration. 2.4. Keep away all Ignition sources.

detonated Explosive Workers

7. Un detonated Explosive 2.5. Double check and cross check connections.

Martials (Post Blast material 2.6. Adequate and right kind of fire extinguisher is needed.

inspection) 2.7. Clean sand shall be used to cover the explosive materials.

2.8. Depth of sand cover shall be 1 meter.

2.9. Competent supervision shall inspect the sand cover to ensure exact covering of

trench.

2.10. The blasting sub-contractor must be prepared to provide a suitable covering

materials for protecting the facilities around the blasting area from any fly rocks, “if

that required”.

2.11. Use water spray to control dust. Wear 3M / N95 dust mask to prevent dust Client:

inhalation. SAPMT SPE SPE

2.12. Competent supervisor should be available to watch and strict the PPE usage. ((Syed K Ahmed),

2.13. Barricade and signage shall be a minimum of 500 meters of blast area. HWYH PE (Haitham

2.14. Standard warning signage e,g. “Danger; Blasting in Progress”, “No Entry”, “Keep Alshammari)

Away” signage shall be posted at all entry points.

HRDH PE (Hashem Al

Civil

2.15. Ensure blasting warning board with timing detail at entry points is kept.

1 2.16. Depute flagmen at all accessible points to prohibit entry into blasting area. Nasser)

2.17. Before blasting all the persons and machinery to be shifted from the blasting zone

to a safe place at least 500 meters away from the location.

2.18. Left some holes uncharged as per plan drilling plan to reduced vibration impact.

2.19. Vibration to be measured in nearby structures & to be reported /recorded.

2.20. After the initiation of the blast, the area will be inspected for any signs of a misfire

or undetonated explosives by a Shot-firer and the RBSG representative who will

jointly complete and sign the a Daily After Blast Report (Form RBSG 002).

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-026 PAGE# 29 of 45

7. Horizontal 1. Mechanical failure of 4 4 12 CPP inspector should conduct initial inspection of the equipment and only passed 2 3 6 Client:

Directional Drilling drilling machine. equipment should be allowed to start operation. SAPMT SPE

(HDD) 2. Rotating parts. a. Operator shall check the equipment on a daily basis and fill-up the daily

((Syed K Ahmed),

3. Damaged to existing operator checklist.

HWYH PE

lines. b. Loose clothing shall not be allowed for the operator and workers working near

4. Toxics/Noxious gases. drilling machine/rotating sleeve rod. (Haitham Alshammari)

5. Exposure to high Noise c. Keep all guards in place while operating. HRDH PE

and Dust. d. Rings, neck less and long cloths etc. are not allowed to wear during job. (Hashem Al Nasser)

e. Only authorized, skilled and experience workers to be deployed for carrying

out this task.

f. Updated copy of IFC drawings and crossing lines shall be available at site.

g. Determine & highlighted the crossings lines shall be available at site.

h. Use cable detector with calibrated certificate to find out underground utilities

and all underground utilities shall be marked, isolated and highlighted by

providing barricades.

i. Use safe and appropriate potholing techniques to the planned drill path’s

depth to expose any hidden underground utilities.

j. Ensure trackers check the tracking device readings frequently during HDD

operations and compare them with the pre-operational walkthrough reading.

k. Gas test before entry, continuous gas test shall be done by using calibrated

MX4/ MX6 gas test device based on atmospheric condition.

l. Ample supplies of approved respiration protection (3M dust mask) shall be

provided at the job site and shall be work while operating power

tools/exposing to dusty environment.

1. Shut Down (Gas Gas Release/leakage from 3 4 12 1.1. Identify isolation locations and ensure isolation is done properly by putting required isolation 2 2 4 Cont:

Release) hydrocarbon lines/well- spectacles/blind flange prior to beginning work. PM (Zhang Wenjiang)

heads/presence of H2S. 1.2. Confirm the exact isolated facility and obtain valid work permit for LOTO (lockout / tag out) permit CM (Rick Lumanlan),

from the concerned department. HSE Manager