Professional Documents

Culture Documents

HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024

HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024

Uploaded by

Sajjad AfzalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024

HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024

Uploaded by

Sajjad AfzalCopyright:

Available Formats

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS

REV 00 STATUS IFI

LOOK AHEAD

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 2 of 12

1.0 INTRODUCTION

This Hazard Identification Plan is not intended to replace and or repeat the

content of the Project Hazard Identification Plan but only to focus on main

hazards and controls to focus on for the coming month.

These hazards, controls, barriers and safeguards are triggered by the

construction activities to be undertaken, environmental factors, current

issues, recent incidents or assessments.

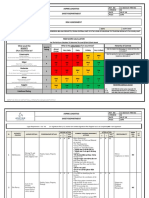

2.0 HAZARD CLASSIFICATION

When identifying hazards associated with the listed activity first determine

what the realistic consequence is, then identify what the probability of that

consequence occurring is. By plotting these two in the A3 worksheet you will

come up with Higher and Medium risk activities.

DEFINITION Severity Consequence

SAFETY / ENVIRONMENTAL DEFINITION

HEALTH IMPACT IMPACT 1 2 3 4 5

1 No injury or No or slight effect 1 Very Low - Never heard of in the industry 5 25

damage to health 5 10 15 20

CONSEQUENCE CATEGORY

PROBABILITY CATEGORY

2 Treatment beyond Minor contamination 2 Low - Some instances in the industry 4 20

First Aid 4 8 12 16

Probability

3 Lost time or Localized event 3 Medium - Incident has happened in the 3 15

restricted work company 3 6 9 12

4 Single fatality or No significant lasting 4 High - Happens several times a year in 2 10

permanent consequence the company 2 4 6 8

disability

5 Multiple fatalities Lasting 5 Very High - Happens several times a 1 5

consequence year in the facility 1 2 3 4

3.0 AUDIENCE

This Hazard Identification Plan is developed by the contractor and the

intended audience are the Contractor Leads/Supervisors. SAPMT should

also be made aware of the hazards involved and the controls that should

be put in place to ensure an incident free work place, SAPMT will use this

Hazard Identification Plan as reference for Safety Walks and Site Visits.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 3 of 12

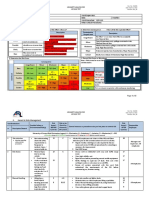

4.0 ROLES & RESPONSIBILITES

The Roles & Responsibilities involved in executing this Hazard Identification Plan are detailed in the RACI Chart

below:

Contractor

Contractor Contractor Discipline Contractor Contractor SAPMT SAPMT

Const Mgr WHO?? Lead HSE DC SPE Engineer

Develop Hazard Identification Plan

based on the Three Week A R - - -

Lookahead Schedule

Determine activities for each craft

A R - - -

Identify potential hazards

A R C

Assess the level of risk

R C

(consequence x probability)

Identify controls barriers &

safeguards to eliminate/reduce

R C

consequence/severity of an

incident

Disseminate to Craft Supervisors

R

Transmit to SAPMT

A R I

Assign to SAPMT Engineer to

verify that controls barriers &

R I

safeguards listed have been

implemented

SAPMT Engineer to verify that

controls barriers & safeguards A R

listed have been implemented

Communicate any gaps to the

I A R

Contractor WHO???

R = Responsible, A = Accountable, C = Consult, I = Informed

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 4 of 12

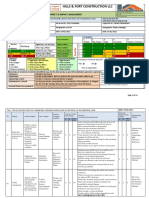

Responsible Person

S. Responsible Person SAPMT SPE/ Site Supt. /

Activity Area Designation Company

No (Contractor) Engr.

North HAWIYAH

HWYH-RH-HK, EK, CJ, (Sami al Harbi, Syed Z

1 Survey activity Zubair 0591219018 Civil Foreman CPP

BK, CK, GK Rizvi)

HWYH-RH-HK, BK, CK, (Sami al Harbi, Syed Z

2 Punch items closing (E&I) TALLAH 0556010286 E&I SUPERVISOR CPP

GK, EK, DJ, EJ Rizvi)

ABDUL ALIM (Sami al Harbi, Syed Z

3 Punch items closing (E&I) HWYH-DK E&I SUPERVISOR CPP

0594391445 Rizvi)

(Sami al Harbi, Syed Z

4 Punch items closing (E&I) HWYH-GGM SAJJAD 0581670522 Foreman CPP

Rizvi)

N. HARDH GGM AREA

(Sami al Harbi, Abdul

1 Road Marking, House keeping North Haradh GGM Umar.0537140985 Site supervisor CPP

Kareem)

HWYH-DK, HRDH, GK, (Sami al Harbi, Abdul

2 Survey work Umar.0537140985 Site supervisor CPP

CK Kareem)

ABDUL ALIM (Sami al Harbi, Abdul

3 Punch items closing (E&I) HRDH-GCP-1 E&I SUPERVISOR CPP

0594391445 Kareem)

ABDUL ALIM (Sami al Harbi, Abdul

4 Punch items closing (E&I) HRDH-GCP-2 E&I SUPERVISOR CPP

0594391445 Kareem)

ABDUL ALIM (Sami al Harbi, Abdul

5 Punch items closing (E&I) HRDH-GGM E&I SUPERVISOR CPP

0594391445 Kareem)

TCF-1 Laydown and Fabrication Yard

1 Equipment repairing housekeeping Fabrication shop-1 WANG Supervisor CPP (Sami al Harbi)

Farmwork, steel fixing, concrete pouring, TCF-1 Laydown and

2 Mudassar 0597543878 Supervisor CPP (Sami al Harbi)

Lifting precast yard

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 5 of 12

Pre-Mitigated Risk Controls / Barriers / Safeguards Post-Mitigated Risk

No. Discipline Activity Potential Hazards List all required Responsible Party

Probability Consequence Rating Probability Consequence Rating

1. Surveying work 1. Struck with hand tools 3 4 12 1.1. Pre-use inspection of hand tools by user 2 2 4 Cont:

2. Protruding Rebar (stacking) 1.2. Only competent persons are permitted to use hand tools. PM (Hou Hao)

Ends. 1.3. Homemade tools shall be strictly prohibited “Right tool for Right job” CM (RICK

3. Natural Inhabitants

1.4. Correct P.P.E. (Safety glass, Leather hand gloves, steel toe safety shoes, helmet) to be LUMANLAN), HSE

(Snakes and Scorpions)

worn at all times. Manager (Sirajul

1.5. All protruding rebar shall be protected with rebar caps. Islam), Site

1.6. Protruding rebars shall be identified by provided warning tapes or rad cloth. Foreman/Supervisor,

1.7. Wear gloves and look before approaching accumulated materials in project sites, snakes WPR, Safety Officer

mostly are hiding there. Client:

1.8. Don't sit down without first looking around.

SAPMT SPE

1.9. Never handle a snake/scorpion even if it looks dead or seems harmless.

1.10. Never left any footwear outside of the offices or temporary facility to avoid the creatures from (Abuzayed, Safouh),

sheltering inside especially safety shoes. HWYH PE

1.11. If bitten by any snake/scorpion, seek medical attention at the CPP Clinic immediately (Sami al Harbi)

HRDH PE

(Alharbi, Sami F)

2. Site Restoration/ 1. Site Waste 3 4 12 1.1. Ensure that trash and debris is properly collected and disposed of daily. 2 2 4 Cont:

General

Housekeeping 2. Slip., Trip and Fall 1.2. Once the work is completed ensure that all the unwanted materials has been removed PM (Hou Hao)

3. Dust 1.3. Trash containers shall be covered, clearly marked and emptied daily. CM (RICK

1 1.4. Access should be kept free from any kind of obstruction to ensure safe evacuation in the LUMANLAN), HSE

case of any emergency. Manager (Sirajul

1.5. Install barricades and warning sign boards at a reasonable distance. Islam), Site

1.6. Use mechanical air movers to reduced dust accumulation. Foreman/Supervisor,

1.7. Use M3 rating dust mask as a protection against dust inhalation WPR, Safety Officer

Client:

SAPMT SPE

(Abuzayed, Safouh),

HWYH PE

(Sami al Harbi)

HRDH PE

(Alharbi, Sami F)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 6 of 12

1. Asphalt Marking by 1. Hot surfaces/Burn 3 4 12 1.1. Do not touch any part of the preheater which may be hot 2 2 4 Cont:

using Mechanical 2. Chemical Exposure 1.2. Ensure clear marking and signage on machine parts exposed to high temperatures to warn PM (Hou Hao)

Preheater and Painting 3. Fire and explosion workers of potential heat-related hazards. CM (RICK

Machine 4. Dust Exposure while loading 1.3. Put “Asphalt marking” sign board and restrict unauthorized person entry by barricade. LUMANLAN), HSE

thermoplastic powder to 1.4. Heat-resistant gloves shall be worn to protect hands during handling. Manager (Sirajul

boiler 1.5. High-visibility clothing shall be worn by workers for visibility. Islam), Site

1.6. Containers shall be labeled with the proper hazard communication (HAZCOM) label. Foreman/Supervisor,

Copies of the SA chemical hazard bulletin (CHB) and/or manufacturer’s material safety data WPR, Safety Officer

sheet (MSDS) shall be readily available on-site for all coatings, solvents and cleaning fluids Client:

being used.

SAPMT SPE

1.7. Make sure an “Eye wash Station/Facility” is available nearby.

1.8. First aid kit with trained first aider shall be available on site (Abuzayed, Safouh),

1.9. Chemical shall be stored in designated area with proper labeling. HWYH PE

1.10. Ensure Dust mask, eye protection and disposable coverall must be worn by workers. (Sami al Harbi)

1.11. Respiratory Protection, eye protection shall be used. HRDH PE

1.12. Ensure that before opening an open flame to heat the thermoplastic material, the area is

(Alharbi, Sami F)

free from the presence of any flammable materials and/or flammable gas

1.13. Gas test shall be conducted prior to start the activity to eliminate the risk of fire caused by

flammable gas in the surrounding area

1.14. Fire watchman equipped with fire extinguisher shall be assigned and remained at site at

Civil

least up to 30 minutes.

2 1.15. Prohibit the use of spark lighters in areas where flammable materials or substances are

present

1.16. Enforce a strict no-smoking policy in areas where LPG cylinders are stored or used with

spark lighters.

1.17. Ensure that only trained and competent individuals use spark lighters.

1.18. Fire Blanket shall be provided.

1.19. LPG cylinder shall be kept away from ignition sources, open flames, and direct sun heat.

1.20. Ensure cylinders are stored in an upright position and secured to prevent falling/tipping

1.21. Regularly inspect the LPG cylinder and associated fittings for leaks.

1.22. Implement a tagging system to track cylinder inspection and maintenance history

1.23. Cylinder trolleys and cage shall be used for transportation of cylinders.

1.24. Ensure operators are familiar with emergency procedures, including shutdown and

evacuation.

1.25. All personnel involved in the activity shall undergo Control of Substance Hazardous to

Health (COSHH) training prior to start of activities.

1.26. Do not wash skin or hands with paint thinner or lacquer thinner, use hand cleaner.

1.27. MSDS shall always be available within the location of the work area.

1.28. Eye wash station shall be provided within the location of the work area.

1.29. Ensure mandatory PPE is provided (Coverall, Gloves, Eve Protection, NIOSH, respiratory

protection, and Hearing Protection) must be strictly worn.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 7 of 12

1. Commissioning 1. Gas Release/leakage 3 4 12 2.1. Identify isolation locations and ensure isolation is done properly by putting required isolation 2 2 4 Cont:

Assistance & from hydrocarbon spectacles/blind flange prior to beginning work. PM (Hou Hao) CM

mothballing (Shut lines/well- 2.2. Confirm the exact isolated facility and obtain valid work permit for LOTO (lockout / tag out) (RICK LUMANLAN),

heads/presence of H2S. HSE Manager (Sirajul

Down/ Line Break) permit from the concerned department.

(Gas Release) 2.3. Ensure SAPMT & SAGPD are communicated and acknowledged prior to start tie in activity. Islam), Site

2.4. Match/ confirm and ensure that the correct blind flange/ spectacle valve tag is placed. Foreman/Supervisor,

WPR, Safety Officer,

2.5. Execution team must ensure blind valve is closed, chain locked and tagged with LOTO on

Client:

the isolation valve to ensure that the valve will not accidentally open.

2.6. Comply with SA G.I 2.709 for atmospheric gas testing, gas testing shall be conducted by a SAPMT SPE

trained gas tester using MX-4 calibrated gas testing device prior to start the job. (Abuzayed, Safouh),

2.7. Use breathing apparatus when the oxygen readings less than 20%, combustible gases 5%- HWYH PE

10%LEL, CO is 35ppm - 1000ppm and H2S is 10ppm - 100ppm. (Sami al Harbi)

2.8. CSE should not be allowed at oxygen concentration above 23.5%, combustible gases at 10% HRDH PE

LEL or above, CO 1000ppm or above and H2S 100ppm or above.

(Alharbi, Sami F)

2.9. Gas test shall be done frequently at least every 2 hours otherwise in change of site conditions.

2.10. Only the personnel trained in H2S Awareness training shall engage in the particular activity.

2.11. T40 H2S detector shall be provided at least site foreman, WPR and Safety officer in each

Mechanical

crew.

2.12. A crew of maximum 20 persons working on ground / elevated area within the radius of 10

meters shall be provided with at least one T40 H2S detector at all time.

2.13. A crew of maximum 10 persons working inside confined Space within the radius of 10 meters

2 shall be provided with at least one T40 H2S detector at all time.

2.14. No person shall be allowed to work at all unless some he/ someone with T40 H2S detector is

available near him

2.15. H2S Hazards awareness/ warning signages shall be displayed on work site.

2.16. In case of Gas Leakage; Evacuate the area immediately, check wind direction and source of

toxic gas, move cross wind then upwind to safest assembly area, Report leakage to

emergency numbers and ask for help if required, Do Not Return to the Job Site until all clear

sound by Authorized Person

2. Bolting (installation of 1. Fall of Material. 3 4 12 2.1. Hand tools should be properly secured / protected by making firm grip and by using tools belt 2 2 4

valves & flanges) 2. Struck by. to prevent from falling.

3. Ergonomics Hazards. 2.2. All work areas shall be fully barricaded to restrict unauthorized person form coming in and out

and Warning signage’s shall be in place “WORK AT HEIGHT ON GOING, KEEP AWAY.”

2.3. Materials, equipment and tools not in use while working at heights shall be secured against

displacement.

2.4. Proper and safe positioning of personnel shall be emphases. All body parts shall be away from

the line of fire.

2.5. Workers shall be reminded on how to properly and safely position his extremities to avoid

being hit to the structure parts.

2.6. Establish job rotation and provide interval for the workers.

2.7. Always operate the tool at a slight angle with it leaning back towards you.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 8 of 12

3. Lay-up 1. Loose Hose connections/ 4 4 16 3.1. Use personal protective and personal monitoring equipment while handling ionizing radiation 2 2 4 Cont:

(Internal Cleaning, Nitrogen fittings equipment. PM (Hou Hao) CM

2. Cold Burn 3.2. Hoses connections shall be made using Chicago clamps.

Purging) (RICK LUMANLAN),

3. Fire

3.3. The N2 supply hoses and couplings are rated for the required service and pressure. HSE Manager (Sirajul

4. Toxic Atmosphere

5. High Noise 3.4. All pneumatic couplings are properly secure with whiplash arrestors. Islam), Site

6. Spillage 3.5. Pre-use inspection of all hoses and fitting should be conducted by user. Foreman/Supervisor,

7. Defective Drying Machine 3.6. Pre-job meeting will be conducted by site foreman/ supervisors in language understood by WPR, Safety Officer,

and Air-Compressor workers before the actual activity proceeds. Environmental

8. Pressurized air 3.7. Ensure that there are no kinks present on the hoses. Coordinator, QC and

9. Environmental Hazards 3.8. Stay away from the pressurized N2 hose & coupling to Avoid cold burn in case of leak.

10. Falling Hazards (Max Work equipment user

3.9. Deploy trained Fire Watch to look after the area to avoid fire incident or to respond in case of

at height 2m) Client:

1. Falling Objects fire

3.10. Ensure all the grating are properly fixed and grating opening / Whole are properly isolated/ SAPMT SPE

barricaded prior to start activity. (Abuzayed, Safouh),

3.11. Scaffold (2m height) will be erected by certified scaffold craftsmen under the supervision of HWYH PE (Sami al

Certified scaffold Supervisor. Harbi)

3.12. Scaffold will be inspected and tagged as per G.I 8.001 by Certified scaffold supervisor. HRDH PE (Alharbi,

3.13. All the workers performing work at height 1.8m or above will use approved ANSI (Z359.1) full Sami F)

body harness and Compliance of 100% tie off.

3.14. Lifeline will be installed at the highest possible point, preferably above shoulder height.

3.15. Elevated work platform will be provided with complete guard rail system.

3.16. Standing, Working, crawling on top of pipe will be strictly prohibited.

3.17. Have a suitable fire extinguishing (FM/UL Listed) equipment within 3 m. (10ft)

3.18. Keep a close watch on the N2 supply flow meter.

3.19. Do not enter a pipeline which is purged with N2.

3.20. Respiratory protection (3M/ N95 dust mask will be worn by the all workers fire watchman,

flagman and all other personnel exposing to dust.

3.21. Final positive pressure applied during dry and nitrogen purging should never exceed the

design pressure of the system.

3.22. Plan the work involving personnel responsible for preparation (such as isolation,

depressurization, draining, venting, flushing) of the equipment / system to be purged.

3.23. Arrange the adequate Nitrogen Cylinders / Unit Considering the volume to be purged.

3.24. Deployment of Nitrogen unit in the intended area of work does not create any hazard for the

facility.

3.25. The disposal of purged volume to a safe location such as flare or vent.

3.26. Disposable PPEs like disposable cover-all, ear plugs, gloves etc. should not be used again

and should be treated as waste class III for disposal

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 9 of 12

1. E&I Works 1.Sharp edges (knife/ cutter) 4 3 12 1.1. Worn or blunt knife and saw blades must be replaced before use. 2 2 4 Cont:

(Duct Bank Installation, 2.Cable drum Falling 1.2. Only knives with which the blade can be reversed into the knife casing will be permitted to be PM (Hou Hao) CM

Cable Pulling and 3.Improper Manual Handling used. (RICK LUMANLAN),

4.Fire 1.3. During cable peeling knife shall be used outward to prevent accident hit to body parts.

Termination, IO MAPPING, HSE Manager (Sirajul

5.Broken End / pointed end of 1.4. Only competent persons are permitted to use hacksaws and knives for the purpose of

IMMIGRATION, PI Islam), Site

cable stripping cable.

INSTALLTION, Loop Foreman/Supervisor,

11. Tripping Hazards 1.5. Pre-job meeting will be conducted by site foreman/ supervisors in language understood by

Testing, AIT Testing) WPR, Safety Officer,

Instrumentation

workers before the actual activity proceeds. electrician and

1.6. Keep hands behind the cutting edges. workers

1.7. Correct P.P.E. to be worn at all times, safety Gloves.

Client:

1.8. Assessment of cable drum weight will be ensured prior to start work

1.9. Use stand to roll the cable drum do not try it manually. SAPMT SPE

(Abuzayed, Safouh),

3 1.10. Cable drum stand should be placed on a level ground

1.11. Use mechanical equipment when cable drum unable to put on the stand manually HWYH PE (Sami al

1.12. Get assistance from co-workers if the load is unable to lift by alone. Harbi)

1.13. Follow proper manual handling techniques. HRDH PE (Alharbi,

1.14. Do not put yourself in between of two moving parts or object Sami F)

1.15. Plan the route to be taken while handling.

1.16. Fire extinguisher / fire equipment will be provided near to the work area at all times. Work

location should be free from combustible materials.

1.17. Daily inspection of fire equipment should be performed regularly and documented.

1.18. Trained and competent fire watch will be assigned.

1.19. Conduct gas test.

1.20. Keep the cable away from the access to prevent tripping hazard.

3.27. Proper arrangement of material will be followed and maintained

1. Adverse weather 4 4 16 1.1. In Extreme weather such as and not limited High Winds, Fog / Sand storms, Lightening & 2 2 4 Cont:

conditions thunderstorm operation will be stopped. PM (Hou Hao) CM

High Winds, 1.2. Leave site in-case of escalation in adversity of environment (RICK LUMANLAN),

Fog 1.3. Amply supply of dust mask (surgical/N95) will be provided and wore during sand storm. HSE Manager (Sirajul

Dust storms, 1.4. Sufficient supply of drinking water with Ice will be available at site and drinking water station Islam), Site

Lightening, should be available with 100 meter of work area. Supervisor, WPR,

Thunderstorm, 1.5. Rest shelters with green mash will be provided within 100m of work location, Safety Officer,

2. Heat/ cold stress. 1.6. Ensure Emergency vehicle and shaded rest areas are provided. Environmental

Environment

1.7. Emergency contact number will be posted at the site especially inside the rest shelter or Coordinator

emergency vehicles and call for help if struck in adverse

Client:

weather.

9. Environmental coordinator shall conduct the environment assessment. SAPMT SPE

4 1.8. Weekly Weather Condition updates will be monitored and shared with all departments to plan (Abuzayed, Safouh),

HWYH PE (Sami al

their operations.

1.9. All workers shall wear FRC rated hot clothes during cold weather seasons. Harbi)

HRDH PE (Alharbi,

Sami F)

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 10 of 12

Laydown Yard

1. Material Shifting / 1. Mechanical failure of 3 4 12 1.1. Crane/boom truck shall have a valid third-party inspection sticker and certificate by SA 2 2 4 Cont:

Material arrangement, Crane/boom truck approved 3rd party company. PM (Hou Hao)

Loading/ unloading 2. Failure of Rigging 1.2. Crane must be inspected by CPP personnel heavy equipment inspector and posted valid CM (RICK

at laydown and pre- Gears/ hardware inspection sticker on it. LUMANLAN), HSE

cast yard 3. Fall of suspended load 1.3. Crane operator will complete the daily inspection /pre-operation checklist. Manager (Sirajul

4. Struck by equipment / 1.4. Safety officer and work permit receiver must validate the inspection of all heavy equipment Islam), Site

person / material and ensure the completion of checklists. Foreman/Supervisor,

5. Overturning of

1.5. Welding or modifying the load hooks or other lifting equipment is strictly forbidden. WPR, Safety Officer

Crane/boom truck

1.6. 3rd party inspection / proof test certificates of all lifting gears shall be available at site. Client:

6. Adverse weather

1.7. Damaged slings shall be reported & removed from service, especially those with visible

conditions such as High SAPMT SPE

Winds, Fog / Sand chemical & damaged tags/rated capacity.

1.8. All rigging equipment shall be pre-inspected by certified rigger prior to its use. (Abuzayed, Safouh),

storms

1.9. Ensure that all rigging equipment & hardware are rated for the load being hoisted. HWYH PE

1.10. Protect slings from sharp edges and abrasions; avoid sharp bends. (Sami al Harbi)

1.11. Ensure all shackles and other connecting devices are completely closed or bolted.

Mechanical

HRDH PE

1.12. Comply with SA G.I. 7.029 (Rigging Hardware Requirements) All lifting tackles must be

(Alharbi, Sami F)

inspected by Rigger and color coded and valid 3rd party certificate for lifting gears shall be

available at site.

1 1.13. Damaged slings shall be reported & removed from service, especially those with visible

chemical & damaged tags/rated capacity.

1.14. Use of slings that have been repaired shall be prohibited.

1.15. The rigging hardware manufacturer's rated SWL capacity shall not be exceeded.

1.16. Hooks with self-closing safety latches, or their equivalent, shall be used to prevent

components from slipping out of the hook.

1.17. Area shall be barricades relevant warning signages shall be posted.

1.18. Tagline shall be used to control the load movement.

1.19. No one will be allowed to stay or walk under the suspended load.

1.20. Deploy spotter to warn the worker to keep them away while lifting.

1.21. Ground condition shall be leveled and compacted.

1.22. The actual lifting load shall not exceed the 85% of Crane lifting capacity.

1.23. Outrigger shall be fully extended & out rigger pad/board of suitable size shall be used.

1.24. Activity will not be performed in wind speeds exceeding 32 km/h

1.25. In Extreme weather such as and not limited dense fog or sandstorms, high speed wind and

rain lifting operation shall be stopped.

1.26. Emergency contact number must be posted at the site especially inside the rest shelter or

emergency vehicles and call for help if struck in adverse weather.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 11 of 12

2. Welding, Cutting, 1. Defective power tools 3 4 12 2.1. Valid Hot Work permit will be obtained/ issued for welding/ Cutting and Grinding activities. 2 2 4 Cont:

Grinding at CPP 2. Electrocution 2.2. All SA hot work permits will be reviewed by SAPMT Construction and safety team and CPP PM (Hou Hao) CM

laydown 3. Flying sparks /Fire Hot Work Permit will be reviewed by CPP Construction and safety teams. (RICK LUMANLAN),

4. Dust 2.3. Hot surfaces will be protected by insulation or other suitable means to prevent personnel from HSE Manager (Sirajul

5. Noise being burned or making contact with the hot surface. Islam), Site

6. Electrocution 2.4. Direct current (DC) will be used for welding/cutting operations in any situation when the effect Foreman/Supervisor,

7. Welding fumes of electric shock is likely to be extreme.

8. Arc flash WPR, Safety Officer,

2.5. Sufficient means of ventilation will be provided to avoid accumulation of welding fumes. Coating applicator,

9. Flying objects /particles

Mandatory PPE’s for the employees and welder will be provided (FRC and Welding apron Environmental

10. Welding Glare

N95, 3M respirator). Coordinator, Power

2.6. Combination of face shield, safety glasses and welding helmet with proper filter lens (shade tool user and Fire

number) for eye protection against arc flash and radiation will be used. watcher

2.7. Flying object and particles hazards awareness training will be provided to the welder, and fire

Client:

watchman.

2.8. Crimp Clamps will be used to fix / tight the hoses. SAPMT SPE

2.9. Cylinders will not be placed in confined spaces or adjacent to excavations. (Abuzayed, Safouh),

HWYH PE (Sami al

Mechanical

2.10. Oil, grease or other hydrocarbons will not be used as a lubricant on valves, fittings or threaded

attachments. Harbi)

HRDH PE (Alharbi,

3. Equipment repairing 1. Exposure to hazardous paint 4 4 12 3.1. Respiratory Protection, eye protection and spray hoods to be used. 2 2 4 Sami F)

1 painting at CPP 2.

3.

Fire

Slip, trip and fall

3.2. Check painting gun, hoses and connection prior to start up

Laydown yard 3.3. Ensure medical checkup for painters

4. Overexertion

3.4. Ensure Dust mask, eye protection and disposable coverall must be worn by painters

3.5. Containers shall be labeled with the proper hazard communication

3.6. (HAZCOM) label. Copies of the SA chemical hazard bulletin (CHB) and/or manufacturer’s

material safety data sheet (MSDS) shall be readily available on-site for all coatings, solvents

and cleaning fluids being used.

3.7. Make sure an “Eye wash Station/Facility” is available nearby.

3.8. Job rotation to be established

3.9. Switch off compressor engine before every refueling

3.10. Warning Signs “NO SMOKING” or “NO OPEN FLAMES” shall be conspicuously posted at all

paint spray operation areas and paint storage rooms.

3.11. Ensure good housekeeping at all times.

3.12. UL Listed Fire extinguisher to be available inspected and color coded

3.13. Personnel to be advised to use the right tools for right job.

3.14. Ensure all pneumatic couplings are properly secure with whiplash arrestors.

3.15. Follow proper manual handling techniques.

3.16. Plan the route to be taken while handling and avoid twisting & awkward positioning

3.17. Sufficient work space to be ensure.

3.18. Avoid overexertion to reach inspection spot.

Saudi Aramco: Company General Use

NORTH GAS COMPRESSION PLANTS (NGCP) PIPELINE

Contract # 6600042306 BI-10-02029-0003

HAZARD IDENTIFICATION PLAN (HIP) BASED ON TWO WEEKS LOOK AHEAD REV 00 STATUS IFI

DOCUMENT NO: CPP-NGCP-TWLA-HIP-HSE-083 PAGE# 12 of 12

1. Housekeeping 1. Site Waste 3 4 12 1.1. Ensure that trash and debris is properly collected and disposed of daily. 2 2 4 Cont:

2. Slip., Trip and Fall 1.2. Once the work is completed ensure that all the unwanted materials has been removed PM (Hou Hao) CM

3. Dust 1.3. Trash containers shall be covered, clearly marked and emptied daily. (RICK LUMANLAN),

1.4. Access should be kept free from any kind of obstruction to ensure safe evacuation in the HSE Manager (Sirajul

case of any emergency. Islam), Site

1.5. Install barricades and warning sign boards at a reasonable distance. Supervisor, WPR,

1.6. Use mechanical air movers to reduced dust accumulation

General

Safety Officer,

1.7. Use M3 rating dust mask as a protection against dust inhalation Environmental

Coordinator

2 Client:

SAPMT SPE

(Abuzayed, Safouh),

HWYH PE (Sami al

Harbi)

HRDH PE (Alharbi,

Sami F)

1. Adverse weather 4 4 16 1.1. In Extreme weather such as and not limited High Winds, Fog / Sand storms, Lightening & 2 2 4 Cont:

conditions thunderstorm operation will be stopped. PM (Hou Hao) CM

High Winds, Fog 1.2. Leave site in-case of escalation in adversity of environment (RICK LUMANLAN),

Dust storms, 1.3. Amply supply of dust mask (surgical/N95) will be provided and wore during sand storm. HSE Manager (Sirajul

Lightening, 1.4. Sufficient supply of drinking water with Ice will be available at site and drinking water station Islam), Site

Environment

Thunderstorm, should be available with 100 meter of work area. Supervisor, WPR,

Heat/ cold stress. 1.5. Rest shelters with green mash will be provided within 100m of work location, Safety Officer,

1.6. Ensure Emergency vehicle and shaded rest areas are provided. Environmental

1.7. Emergency contact number will be posted at the site especially inside the rest shelter or

3 emergency vehicles and call for help if struck in adverse

Coordinator

Client:

weather.

9. Environmental coordinator shall conduct the environment assessment. SAPMT SPE

1.8. Weekly Weather Condition updates will be monitored and shared with all departments to plan (Abuzayed, Safouh),

their operations. HWYH PE (Sami al

1.9. All workers shall wear FRC rated hot clothes during cold weather seasons. Harbi)

HRDH PE (Alharbi,

Sami F)

The reason for determining uncontrolled risk is to highlight the importance of the Control Measures being applied to reduce the risk

Saudi Aramco: Company General Use

You might also like

- Risk Assessment For Sheet PilingDocument33 pagesRisk Assessment For Sheet Pilingsajin75% (24)

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- RA For Sump PumpsDocument9 pagesRA For Sump PumpsAnonymous ubta67y6eNo ratings yet

- Employee Engagement As An Effort To Improve Work PerformanceDocument10 pagesEmployee Engagement As An Effort To Improve Work Performanceanfernee eboraNo ratings yet

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- RA - Demolition of Reinforced Concrete Slab - Column - Beams - PlinthsDocument12 pagesRA - Demolition of Reinforced Concrete Slab - Column - Beams - PlinthsFrancis Enriquez Tan50% (6)

- HIP CPP for NGCP PipelinesDocument15 pagesHIP CPP for NGCP PipelinesSajjad AfzalNo ratings yet

- HIP-TWLA (October 1st October 15th ,2021)Document46 pagesHIP-TWLA (October 1st October 15th ,2021)Sajjad AfzalNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- 4.1.2 Covid-19 Risk AssessmentDocument41 pages4.1.2 Covid-19 Risk AssessmentaceNo ratings yet

- RA Bored Cast in Situ PileDocument38 pagesRA Bored Cast in Situ PileAnonymous zsBCtskz100% (1)

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- Site Risk RADocument14 pagesSite Risk RAJohn GeddesNo ratings yet

- Risk Assessment FormDocument4 pagesRisk Assessment Formbeshoy100% (2)

- Example Industry Hazard Register 2022Document5 pagesExample Industry Hazard Register 2022She-Ra Sha-Ju LaNo ratings yet

- Form HIRADC K3Document1 pageForm HIRADC K3Airlangga AirlanggaNo ratings yet

- Electrical WorksDocument3 pagesElectrical WorksSaleem Basha50% (2)

- Covid-19 Risk AssessmentDocument40 pagesCovid-19 Risk AssessmentaceNo ratings yet

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- Hazard Assessment and Risk ControlDocument15 pagesHazard Assessment and Risk ControlAnisNo ratings yet

- RA-GL-HAL-PPS-445 (Working at Height)Document5 pagesRA-GL-HAL-PPS-445 (Working at Height)BalasubramanianNo ratings yet

- Hazard and Risk Register Template: The South Australian Mining and Quarrying Occupational Health and Safety CommitteeDocument14 pagesHazard and Risk Register Template: The South Australian Mining and Quarrying Occupational Health and Safety Committeearunshan1984100% (1)

- Case Study: Hazard Identification, Risk Assesment and Risk Control (HIRARC)Document8 pagesCase Study: Hazard Identification, Risk Assesment and Risk Control (HIRARC)F2013 NorfadzilahNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Risk Assessment Format For SampleDocument3 pagesRisk Assessment Format For SampleSaqib RasoolNo ratings yet

- RA GL HAL PPS 404 (Dewatering)Document6 pagesRA GL HAL PPS 404 (Dewatering)BalasubramanianNo ratings yet

- Aspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Document6 pagesAspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Kevin ColmoNo ratings yet

- RA-IM-12A - Launching Girder - Marine-Rev-02Document52 pagesRA-IM-12A - Launching Girder - Marine-Rev-02Planning C7No ratings yet

- RISKMATRIXDocument2 pagesRISKMATRIXjohnjovetNo ratings yet

- JSA006 - Vacuum Box TestingDocument5 pagesJSA006 - Vacuum Box TestingLaohan LiuNo ratings yet

- 16 HAZOP Basics3Document24 pages16 HAZOP Basics3BharatNo ratings yet

- RA-GL-HAL-PPS-442 (Air Pigging)Document5 pagesRA-GL-HAL-PPS-442 (Air Pigging)BalasubramanianNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- RA 002forklift OperationsDocument9 pagesRA 002forklift Operationsamrismail2012No ratings yet

- Job Hazard AssessmentDocument2 pagesJob Hazard AssessmentAli JawadNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- Risk Assessment For COVID-19Document3 pagesRisk Assessment For COVID-19Ali KaziNo ratings yet

- Construction COVID-19 Risk Assessment: Siemens - Co.ukDocument17 pagesConstruction COVID-19 Risk Assessment: Siemens - Co.ukMd Jawed AnsariNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- Epl258 Hse Risk AssessmentDocument43 pagesEpl258 Hse Risk Assessmentprofessional accountantsNo ratings yet

- Hazard Identification Risk Assessment and Risk Control Register HIRARC Review / Revision Control SheetDocument38 pagesHazard Identification Risk Assessment and Risk Control Register HIRARC Review / Revision Control Sheetusman4428No ratings yet

- RA For HV and MV Installation Rev0Document18 pagesRA For HV and MV Installation Rev0salaitaosama1995No ratings yet

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- Intelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2Document221 pagesIntelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2raymundwat11No ratings yet

- Painting WorksDocument3 pagesPainting WorksSaleem Basha100% (1)

- Fire Risk Assessment - 2Document6 pagesFire Risk Assessment - 2PMSIL 2018100% (3)

- SWMS Safe-Wrk-Mthd-Statement-Sample-Pump MaintenanceDocument3 pagesSWMS Safe-Wrk-Mthd-Statement-Sample-Pump Maintenancetilet26128No ratings yet

- Developing A Facility Hazard and Vulnerability Analysis (HVA)Document27 pagesDeveloping A Facility Hazard and Vulnerability Analysis (HVA)Jair Acasiete LozaNo ratings yet

- Hirarc SlideDocument19 pagesHirarc SlideKrishnan Mudaliar Bopalan100% (1)

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- A Guide To Risk Assessment in Ship OperationsDocument6 pagesA Guide To Risk Assessment in Ship OperationsDmytro OparivskyNo ratings yet

- OSHP-CH03 Risk RegisterDocument31 pagesOSHP-CH03 Risk Registerabubakrelsaid90No ratings yet

- Critical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents, Accidents and DisastersFrom EverandCritical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents, Accidents and DisastersNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- The Simple Rules of Risk: Revisiting the Art of Financial Risk ManagementFrom EverandThe Simple Rules of Risk: Revisiting the Art of Financial Risk ManagementNo ratings yet

- Ch#_40,_41,_42 (1)Document5 pagesCh#_40,_41,_42 (1)Sajjad AfzalNo ratings yet

- 4. HAZARD IDENTIFICATION PLAN (HIP) REV-06 (1)Document116 pages4. HAZARD IDENTIFICATION PLAN (HIP) REV-06 (1)Sajjad AfzalNo ratings yet

- HIP CPP for NGCP PipelinesDocument15 pagesHIP CPP for NGCP PipelinesSajjad AfzalNo ratings yet

- CSM IV-4 AviationDocument4 pagesCSM IV-4 AviationSajjad AfzalNo ratings yet

- Email Letter of Enquiry - Oct2019Document2 pagesEmail Letter of Enquiry - Oct2019Mon Luffy100% (1)

- Psych Abnormal Child Psychology - 6th Edition (2015) - 501-550Document50 pagesPsych Abnormal Child Psychology - 6th Edition (2015) - 501-550tin_ally9059No ratings yet

- Textbook Family Engagement With Schools Strategies For School Social Workers and Educators 1St Edition Chavkin Ebook All Chapter PDFDocument53 pagesTextbook Family Engagement With Schools Strategies For School Social Workers and Educators 1St Edition Chavkin Ebook All Chapter PDFjacob.henry689100% (14)

- The Impact of Modular Distance Learning On The Mental Health of Grade 10 Students of Castillejos National High SchoolDocument8 pagesThe Impact of Modular Distance Learning On The Mental Health of Grade 10 Students of Castillejos National High SchoolSanneNo ratings yet

- CBT WorkbookDocument5 pagesCBT WorkbookninoNo ratings yet

- Professional Will TemplateDocument9 pagesProfessional Will TemplateHPS_orgNo ratings yet

- Funda RleDocument4 pagesFunda RleXerxes DejitoNo ratings yet

- Antech and VETgirl Preventive Medicine Certificate ProgramDocument2 pagesAntech and VETgirl Preventive Medicine Certificate ProgramdrteresagattNo ratings yet

- NGOs in Rajasthan & Tamilnadu - SwatiDocument447 pagesNGOs in Rajasthan & Tamilnadu - SwatiSwati YadavNo ratings yet

- Ca Linear Brochure 0598 Rev-CDocument6 pagesCa Linear Brochure 0598 Rev-CMuhammad Mahbøøb SadiqNo ratings yet

- Organization Development ChangeDocument150 pagesOrganization Development ChangeKaloma PeapeNo ratings yet

- 9 Group A MeasurementDocument15 pages9 Group A MeasurementMetha SusantiNo ratings yet

- Body Composition Physical Fitness PhysicDocument8 pagesBody Composition Physical Fitness PhysicsunnybeaNo ratings yet

- Ricketts Cephalometric Syntesis PDFDocument27 pagesRicketts Cephalometric Syntesis PDFAleeJanyArroNo ratings yet

- Yoga 2Document33 pagesYoga 2sujeet232No ratings yet

- Multidimensional Emotional Intelligence AssessmentDocument13 pagesMultidimensional Emotional Intelligence AssessmentClaudio PidotoNo ratings yet

- Ls10 Reaching The Age of Adolescence WSDocument2 pagesLs10 Reaching The Age of Adolescence WSAshwika AgarwalNo ratings yet

- Tseninyuy Ronald FinaluptodateDocument6 pagesTseninyuy Ronald Finaluptodategoogle playNo ratings yet

- Journal Critiquing Article Reviewed:: Submitted To: Prof. Cynthia A. Umila, RN, MAN Submitted By: Yvette Claire L. BorresDocument6 pagesJournal Critiquing Article Reviewed:: Submitted To: Prof. Cynthia A. Umila, RN, MAN Submitted By: Yvette Claire L. BorresYVETTE CLAIRE BORRESNo ratings yet

- Beloved: The Physical Embodiment of Psychological TraumaDocument16 pagesBeloved: The Physical Embodiment of Psychological TraumaShilpa English0060No ratings yet

- Adapting To Stress Understanding The Neurobiology of ResilienceDocument17 pagesAdapting To Stress Understanding The Neurobiology of ResiliencePietro De SantisNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresFaisal RazaNo ratings yet

- U3 - The Book of PlayDocument24 pagesU3 - The Book of PlayTommy FletcherNo ratings yet

- Confident Diagnosis, Confident Decisions: We Are Ultrasound ProfessionalsDocument10 pagesConfident Diagnosis, Confident Decisions: We Are Ultrasound ProfessionalsKaran JejurkarNo ratings yet

- Agrahara Claim Form (English)Document14 pagesAgrahara Claim Form (English)hema160% (1)

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- Hba1c (Ifcc - New Method) - 2023-08-29T00 - 00 - 00Document1 pageHba1c (Ifcc - New Method) - 2023-08-29T00 - 00 - 00Michamiel SerratoNo ratings yet

- Notes On CommunicationDocument8 pagesNotes On CommunicationSWAPNIL MISHRANo ratings yet

- Early and Late Side-Effects in Radiation TherapyDocument6 pagesEarly and Late Side-Effects in Radiation Therapyungthu39No ratings yet