Professional Documents

Culture Documents

Cu Ni 70-30

Cu Ni 70-30

Uploaded by

nalin dhariaCopyright:

Available Formats

You might also like

- Forces Acting On A PropellerDocument21 pagesForces Acting On A Propellercasandra joaquin100% (2)

- COMPASS TrainingDocument383 pagesCOMPASS TrainingNikhil Barshettiwar100% (3)

- Manual de Partes Crown We - WS2300Document240 pagesManual de Partes Crown We - WS2300Andrey Fernando Luque Segura100% (1)

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Document5 pagesDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- Brosur NYRGbY SNI IECDocument5 pagesBrosur NYRGbY SNI IECMuhammad YusufNo ratings yet

- 1.pipeline Risk Assessment Definitive Approach and Its Role in Risk ManagementDocument17 pages1.pipeline Risk Assessment Definitive Approach and Its Role in Risk Managementhendry_hdw100% (1)

- QuantEconlectures Python3Document1,362 pagesQuantEconlectures Python3Cristian F. SanabriaNo ratings yet

- Copper Nickel 9010Document2 pagesCopper Nickel 9010anirudhbhokarikarNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- NTE303A Silicone Thermal Compound 1 Oz. Plunger Tube: DescriptionDocument2 pagesNTE303A Silicone Thermal Compound 1 Oz. Plunger Tube: DescriptionDavid Antonio Bonilla ChaónNo ratings yet

- Medium Carbon Steel: Nearest StandardDocument2 pagesMedium Carbon Steel: Nearest StandardMouna KallelNo ratings yet

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481No ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Silicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodDocument2 pagesSilicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodJay PNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- Wire Spec 44 PDFDocument5 pagesWire Spec 44 PDFAdnan khanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Rayyan - Brochure Final v2Document4 pagesRayyan - Brochure Final v2Ivica PrvanovićNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperPradeep KumarNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- T Work9000Document2 pagesT Work9000Maike SongNo ratings yet

- CRDocument8 pagesCRErfan EffendyNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Inbound 3471962770666101779Document4 pagesInbound 3471962770666101779mildew747No ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- UNS S32205: Duplex Stainless 2205 (UNS S32205) Is A Chromium-Nickel-Molybdenum-Nitrogen Stainless SteelDocument3 pagesUNS S32205: Duplex Stainless 2205 (UNS S32205) Is A Chromium-Nickel-Molybdenum-Nitrogen Stainless SteelCemerlang StudiNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- Technical Aluminium Alloys LM20 09 05 22Document3 pagesTechnical Aluminium Alloys LM20 09 05 22baskaran.marieNo ratings yet

- Alloy Pipe DetailsDocument4 pagesAlloy Pipe Detailsprashant.kumarNo ratings yet

- GELA CABLE SOLAR PV1-F Ficha TecnicaDocument1 pageGELA CABLE SOLAR PV1-F Ficha TecnicaPlacido León ValleNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- Data 9018 B3 LDocument2 pagesData 9018 B3 LAntonio Torres (Volcomtony)No ratings yet

- Alloy 825 - 2.4858Document4 pagesAlloy 825 - 2.4858M RNo ratings yet

- 708M40 Alloy Steel: Form of SupplyDocument3 pages708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNo ratings yet

- 9Cr - 1mo Modified With V, NB, and N.: OdificationDocument1 page9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- FS DatasheetDocument1 pageFS Datasheetazeem bilalNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- FRF Slabs: Rigid BoartdDocument16 pagesFRF Slabs: Rigid BoartdAmal RajNo ratings yet

- BS1400 AB2: Technical DatasheetDocument1 pageBS1400 AB2: Technical DatasheetBhargav PatelNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Data Sheet Schott® Borofloat: Chemical PropertiesDocument2 pagesData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNo ratings yet

- Uns s32760Document3 pagesUns s32760NitinNo ratings yet

- Description: Standard Density and ThicknessDocument2 pagesDescription: Standard Density and Thicknessarash khajeimNo ratings yet

- 7010 GB PDFDocument2 pages7010 GB PDFsanathcgrNo ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- Nitronic® 32 Austenitic Stainless Steel Alloy: Chemical CompositionDocument2 pagesNitronic® 32 Austenitic Stainless Steel Alloy: Chemical CompositionBagus WicaksanaNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- Duplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument3 pagesDuplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. Websudish mishraNo ratings yet

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberDocument4 pages3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Vector Network AnalyzerDocument2 pagesVector Network Analyzerkpgs12No ratings yet

- Chapter 9 (Cleaning and Fettling of Castings), 2003Document32 pagesChapter 9 (Cleaning and Fettling of Castings), 2003Desalegn DgaNo ratings yet

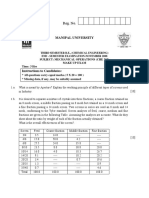

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- Genesis 30uvDocument42 pagesGenesis 30uvCARLOSNo ratings yet

- Grid Station PresentationDocument40 pagesGrid Station Presentationranafaizan773750% (2)

- Flight Management and NavigationDocument18 pagesFlight Management and NavigationmohamedNo ratings yet

- Lexmark C91x C912 5505 Service ManualDocument492 pagesLexmark C91x C912 5505 Service ManualMichael HanniganNo ratings yet

- CL 6 NSTSE-2021-Paper 464Document18 pagesCL 6 NSTSE-2021-Paper 464PrajNo ratings yet

- Rolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexDocument70 pagesRolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexAnubhuti GhaiNo ratings yet

- Bearing Capacity & Mobilisasi Unit PC3400 & HD1500 JB FixsDocument51 pagesBearing Capacity & Mobilisasi Unit PC3400 & HD1500 JB FixsLaundry ShicleanNo ratings yet

- Ironmaking and Steelmaking Theory and PracticeDocument494 pagesIronmaking and Steelmaking Theory and PracticeDrKinnor Chattopadhyay100% (12)

- 3.steel Members (Unit III)Document31 pages3.steel Members (Unit III)tauseefNo ratings yet

- Formal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurDocument23 pagesFormal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurManad MishraNo ratings yet

- Service Lift: - M. Kashif Jameel - Gaurav Khatwani - Donesh Raut - Isha Dhote - Gulnanda GahaneDocument17 pagesService Lift: - M. Kashif Jameel - Gaurav Khatwani - Donesh Raut - Isha Dhote - Gulnanda Gahanerahul sulakheNo ratings yet

- Research Article: Solution of Turbine Blade Cascade Flow Using An Improved Panel MethodDocument7 pagesResearch Article: Solution of Turbine Blade Cascade Flow Using An Improved Panel MethodAndre RochaNo ratings yet

- Earth Bulge and Path ProfileDocument3 pagesEarth Bulge and Path ProfileTim LazaroNo ratings yet

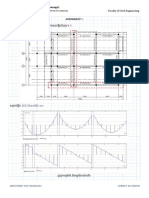

- RC Beam Design Using MCDXDocument20 pagesRC Beam Design Using MCDXChanthy RathedNo ratings yet

- Face GroovingDocument1 pageFace GroovingWilson DantasNo ratings yet

- Doka System PDFDocument116 pagesDoka System PDFAhmed MandorNo ratings yet

- Corrosion Magazine Issue117 LowresDocument36 pagesCorrosion Magazine Issue117 Lowressaminasritn100% (2)

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- FHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction GuidelinesDocument418 pagesFHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction Guidelinestenkken1504100% (2)

- Perencanaan Pelat LantaiDocument16 pagesPerencanaan Pelat LantaiNelson AugustoneNo ratings yet

- Artificial Intelligence Question Bank-RICHDocument10 pagesArtificial Intelligence Question Bank-RICHsriNo ratings yet

- Ship Power PlantDocument141 pagesShip Power Plantnguyentrunghieu51dltt100% (2)

Cu Ni 70-30

Cu Ni 70-30

Uploaded by

nalin dhariaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cu Ni 70-30

Cu Ni 70-30

Uploaded by

nalin dhariaCopyright:

Available Formats

70/30 cupronickel

70/30 cupronickel

www.columbiametals.com

CN107 / C71500 / CW354H / DEF STAN 02-780

sales@columbiametals.co.uk

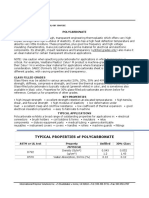

70/30 is a copper nickel alloy noted for its excellent resistance to corrosion, erosion and pitting combined

with a good strength, workability and weldability. It has enjoyed a long and successful history in the marine

sector that has since extended to industries including offshore oil and gas, power generation, desalination

and cooling plants.

The most popular specifications covering this alloy are the CN107

and C71500 designations, although the Naval Engineering

specifications DEF STAN 02-780 or NES 780 offer tighter controls

on impurities and mechanical properties together with a mandatory

impact value.

70/30 is best renowned for its excellent corrosion and erosion

resistance, especially in marine environments. Its corrosion

resistance is improved in higher velocity waters (up to 4.5m/s) and

polluted seawater. It is also highly resistant to stress corrosion

cracking and corrosion fatigue and has a high retention of

mechanical properties from sub-zero temperatures to ~300oC.

In the annealed condition, 70/30 offers moderate strength levels

which enable it to be used in more demanding applications. In

addition, it displays inherent resistance to biofouling. A protective

oxide film forms naturally over the material during the initial period

of use, creating an inhospitable surface that deters marine growth.

70/30 responds well to most fabrication processes and is readily hot

and cold worked. It is also easily joined by soldering, brazing and a

variety of welding methods. With good hot and cold formability and

a malleability approaching that of copper, 70/30 does not harden

rapidly, lending the material to drawing and spinning.

The alloy is mainly used for seawater service as forged and machined valve and pump components, fittings,

flanges and hardware thanks to its inherent corrosion resistance. It is also used in submarine and sea water

pipework, offshore fire water systems, heat exchangers, condensers, sheathing of legs and risers on

offshore platforms and boat hulls, hydraulic lines, desalination units and areas where high corrosion

resistance is required and concern over chloride stress-corrosion cracking prevents the use of stainless

steels.

Fabrication properties of 70/30 cupronickel

Hot & cold workability Good

Machinability rating (free-cutting brass=100) 20

Hot working temperature 925 - 1025oC

Annealing temperature 650 - 850oC

Soldering & brazing Good

Oxyacetylene welding Good

Gas shielded arc welding Excellent

PLEASE CONTACT US FOR AN IMMEDIATE QUOTATION OR TECHNICAL ADVICE

North, Scotland & International South, Midlands & Wales

Tel: 01422 343026 Tel: 01234 608888

Fax: 01422 346587 Fax: 01234 608800

halifaxsales@columbiametals.co.uk sales@columbiametals.co.uk

export@columbiametals.co.uk

70/30 cupronickel 70/30 cupronickel

Technical Data

Nominal Composition (%)

Cu Ni Mn

Rem 30 1

Mechanical Properties (specification minima)

12 - 25mm dia

Ultimate Tensile Strength (N/mm2) 330

2

0.2% Proof Strength (N/mm ) 125

Elongation (%) 30

Typical Physical Properties

Density (g/cm3) 8.95

Specific Heat (J/kgoC) 377

Thermal Conductivity (W/m°C) 29

Coeff. Thermal Exp. (per °C) 0.000016

2

Modulus of Elasticity (N/mm ) 152,000

Modulus of Rigidity (N/mm2) 56,000

Electrical Conductivity (% IACS) 5

Electrical Resistivity (microohm m) 0.34

Round Bar Weight and Stock Sizes

Diameter Weight Diameter Weight Diameter Weight

ins kg/ft kg/m ins kg/ft kg/m ins kg/ft kg/m

0.250 0.08 0.27 1.500 3.02 9.92 3.500 16.46 54.01

0.375 0.19 0.62 1.625 3.55 11.64 3.750 18.90 62.00

0.500 0.34 1.10 1.750 4.12 13.50 4.000 21.50 70.54

0.625 0.53 1.72 2.000 5.38 17.64 4.250 24.27 79.64

0.750 0.76 2.48 2.250 6.80 22.32 4.500 27.21 89.28

0.875 1.03 3.38 2.375 7.58 24.87 5.000 33.60 110.22

1.000 1.34 4.41 2.500 8.40 27.56 5.500 40.65 133.37

1.125 1.70 5.58 2.750 10.16 33.34 6.000 48.38 158.72

1.250 2.10 6.89 3.000 12.10 39.68 7.000 65.78 215.83

1.375 2.54 8.34 3.250 14.19 46.57 8.000 86.01 282.17

NB Weight data for guidance only

REV3/04/18

You might also like

- Forces Acting On A PropellerDocument21 pagesForces Acting On A Propellercasandra joaquin100% (2)

- COMPASS TrainingDocument383 pagesCOMPASS TrainingNikhil Barshettiwar100% (3)

- Manual de Partes Crown We - WS2300Document240 pagesManual de Partes Crown We - WS2300Andrey Fernando Luque Segura100% (1)

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Document5 pagesDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- Brosur NYRGbY SNI IECDocument5 pagesBrosur NYRGbY SNI IECMuhammad YusufNo ratings yet

- 1.pipeline Risk Assessment Definitive Approach and Its Role in Risk ManagementDocument17 pages1.pipeline Risk Assessment Definitive Approach and Its Role in Risk Managementhendry_hdw100% (1)

- QuantEconlectures Python3Document1,362 pagesQuantEconlectures Python3Cristian F. SanabriaNo ratings yet

- Copper Nickel 9010Document2 pagesCopper Nickel 9010anirudhbhokarikarNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- NTE303A Silicone Thermal Compound 1 Oz. Plunger Tube: DescriptionDocument2 pagesNTE303A Silicone Thermal Compound 1 Oz. Plunger Tube: DescriptionDavid Antonio Bonilla ChaónNo ratings yet

- Medium Carbon Steel: Nearest StandardDocument2 pagesMedium Carbon Steel: Nearest StandardMouna KallelNo ratings yet

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481No ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Silicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodDocument2 pagesSilicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodJay PNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- Wire Spec 44 PDFDocument5 pagesWire Spec 44 PDFAdnan khanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Rayyan - Brochure Final v2Document4 pagesRayyan - Brochure Final v2Ivica PrvanovićNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperPradeep KumarNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- T Work9000Document2 pagesT Work9000Maike SongNo ratings yet

- CRDocument8 pagesCRErfan EffendyNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Inbound 3471962770666101779Document4 pagesInbound 3471962770666101779mildew747No ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- UNS S32205: Duplex Stainless 2205 (UNS S32205) Is A Chromium-Nickel-Molybdenum-Nitrogen Stainless SteelDocument3 pagesUNS S32205: Duplex Stainless 2205 (UNS S32205) Is A Chromium-Nickel-Molybdenum-Nitrogen Stainless SteelCemerlang StudiNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- Technical Aluminium Alloys LM20 09 05 22Document3 pagesTechnical Aluminium Alloys LM20 09 05 22baskaran.marieNo ratings yet

- Alloy Pipe DetailsDocument4 pagesAlloy Pipe Detailsprashant.kumarNo ratings yet

- GELA CABLE SOLAR PV1-F Ficha TecnicaDocument1 pageGELA CABLE SOLAR PV1-F Ficha TecnicaPlacido León ValleNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- Data 9018 B3 LDocument2 pagesData 9018 B3 LAntonio Torres (Volcomtony)No ratings yet

- Alloy 825 - 2.4858Document4 pagesAlloy 825 - 2.4858M RNo ratings yet

- 708M40 Alloy Steel: Form of SupplyDocument3 pages708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNo ratings yet

- 9Cr - 1mo Modified With V, NB, and N.: OdificationDocument1 page9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- FS DatasheetDocument1 pageFS Datasheetazeem bilalNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- FRF Slabs: Rigid BoartdDocument16 pagesFRF Slabs: Rigid BoartdAmal RajNo ratings yet

- BS1400 AB2: Technical DatasheetDocument1 pageBS1400 AB2: Technical DatasheetBhargav PatelNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Data Sheet Schott® Borofloat: Chemical PropertiesDocument2 pagesData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNo ratings yet

- Uns s32760Document3 pagesUns s32760NitinNo ratings yet

- Description: Standard Density and ThicknessDocument2 pagesDescription: Standard Density and Thicknessarash khajeimNo ratings yet

- 7010 GB PDFDocument2 pages7010 GB PDFsanathcgrNo ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- Nitronic® 32 Austenitic Stainless Steel Alloy: Chemical CompositionDocument2 pagesNitronic® 32 Austenitic Stainless Steel Alloy: Chemical CompositionBagus WicaksanaNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- Duplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument3 pagesDuplex Stainless Steel 2507 (UNS S32750) : Heanjia Super-Metals Co., LTD, Call-12068907337. Websudish mishraNo ratings yet

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberDocument4 pages3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Vector Network AnalyzerDocument2 pagesVector Network Analyzerkpgs12No ratings yet

- Chapter 9 (Cleaning and Fettling of Castings), 2003Document32 pagesChapter 9 (Cleaning and Fettling of Castings), 2003Desalegn DgaNo ratings yet

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- Genesis 30uvDocument42 pagesGenesis 30uvCARLOSNo ratings yet

- Grid Station PresentationDocument40 pagesGrid Station Presentationranafaizan773750% (2)

- Flight Management and NavigationDocument18 pagesFlight Management and NavigationmohamedNo ratings yet

- Lexmark C91x C912 5505 Service ManualDocument492 pagesLexmark C91x C912 5505 Service ManualMichael HanniganNo ratings yet

- CL 6 NSTSE-2021-Paper 464Document18 pagesCL 6 NSTSE-2021-Paper 464PrajNo ratings yet

- Rolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexDocument70 pagesRolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexAnubhuti GhaiNo ratings yet

- Bearing Capacity & Mobilisasi Unit PC3400 & HD1500 JB FixsDocument51 pagesBearing Capacity & Mobilisasi Unit PC3400 & HD1500 JB FixsLaundry ShicleanNo ratings yet

- Ironmaking and Steelmaking Theory and PracticeDocument494 pagesIronmaking and Steelmaking Theory and PracticeDrKinnor Chattopadhyay100% (12)

- 3.steel Members (Unit III)Document31 pages3.steel Members (Unit III)tauseefNo ratings yet

- Formal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurDocument23 pagesFormal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurManad MishraNo ratings yet

- Service Lift: - M. Kashif Jameel - Gaurav Khatwani - Donesh Raut - Isha Dhote - Gulnanda GahaneDocument17 pagesService Lift: - M. Kashif Jameel - Gaurav Khatwani - Donesh Raut - Isha Dhote - Gulnanda Gahanerahul sulakheNo ratings yet

- Research Article: Solution of Turbine Blade Cascade Flow Using An Improved Panel MethodDocument7 pagesResearch Article: Solution of Turbine Blade Cascade Flow Using An Improved Panel MethodAndre RochaNo ratings yet

- Earth Bulge and Path ProfileDocument3 pagesEarth Bulge and Path ProfileTim LazaroNo ratings yet

- RC Beam Design Using MCDXDocument20 pagesRC Beam Design Using MCDXChanthy RathedNo ratings yet

- Face GroovingDocument1 pageFace GroovingWilson DantasNo ratings yet

- Doka System PDFDocument116 pagesDoka System PDFAhmed MandorNo ratings yet

- Corrosion Magazine Issue117 LowresDocument36 pagesCorrosion Magazine Issue117 Lowressaminasritn100% (2)

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- FHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction GuidelinesDocument418 pagesFHWA-NHI-00-043 - Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction Guidelinestenkken1504100% (2)

- Perencanaan Pelat LantaiDocument16 pagesPerencanaan Pelat LantaiNelson AugustoneNo ratings yet

- Artificial Intelligence Question Bank-RICHDocument10 pagesArtificial Intelligence Question Bank-RICHsriNo ratings yet

- Ship Power PlantDocument141 pagesShip Power Plantnguyentrunghieu51dltt100% (2)