Professional Documents

Culture Documents

mb_sqr2_05_14_en (1)

mb_sqr2_05_14_en (1)

Uploaded by

syarip hidayatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

mb_sqr2_05_14_en (1)

mb_sqr2_05_14_en (1)

Uploaded by

syarip hidayatCopyright:

Available Formats

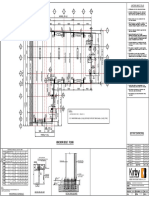

SQ 05.2 – SQ 14.2/SQR 05.2 – SQR 14.

Dimensions Part-turn actuators

With AUMA plug/socket connector and 3-phase AC motor

E

Space required for

HH

removal

P1 P2

P3

4)

H2

4)

4)

A3

A2

Version 4):

Ø D 1)

Ø D1

F

double sealed

H4

H1

X Ø d5

3)

Indicator glass for mechanical d4 x h1

h

J position indicator

Ø d2

1) Ø d3

C1 C2 C3

Ø d1

A1 B2

Detail X

A4

Ø D4

B1

L max.

h 3)

Space required for

BB

Output drives according to EN ISO 5211

removal

For dimensions see overleaf

1) Exact dimension depending on motor used

2) Standard, other threads on request

3) Allowance for spigot is not available as standard. The spigot ring is a separate component, available as option.

4) Option: Enclosure protection IPxx-DS, cover for electrical connection with additional frame

5) Combined flange F05/F07 without spigot (standard). As an alternative an individual flange F07 can be ordered with spigot

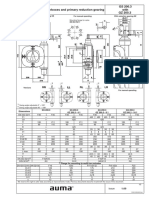

Dimensions SQ 05.2 SQ 07.2 SQ 10.2 SQ 12.2 SQ 14.2

EN ISO 5211 F05 5)

F07 5)

F05 5)

F07 5)

F10 F10 F12 F12 F14 F14 F16

A1 40 50 50 50

A2 4) 174 (201 4)) 174 (201 4)) 174 (201 4)) 174 (201 4))

A3 4) 134 (161 4)) 134 (161 4)) 134 (161 4)) 134 (161 4))

A4 103 103 103 103

B1 238 248 248 248

B2 50 65 65 65

C1 1) 265 265 265 265

C2 186 191 191 191

C3 63 63 63 63

Ø D 1) 101 101 101 101

Ø D1 160 200 200 200

Ø D4 20 20 20 20

E 115 115 115 115

F 115 115 115 115

H1 134 134 160 151 183 175 215 210 260

H2 4) 210 (237 4)) 210 (237 4)) 210 (237 4)) 210 (237 4))

H4 193 193 217 214 246 238 278 273 323

J 69 86 109 128

L max. 40 40 66 50 82 61 101 75 125

P1 2) M20 x 1.5 M20 x 1.5 M20 x 1.5 M20 x 1.5

P2 2) M32 x 1.5 M32 x 1.5 M32 x 1.5 M32 x 1.5

P3 2) M25 x 1.5 M25 x 1.5 M25 x 1.5 M25 x 1.5

BB min. 180 180 180 180

HH min. 30 30 30 30

Ø d1 90 90

125 125 150 150 175 175 210

Ø d2 – 70– 70 85 85 100 100 130

Ø d3 50 70 50 70 102 102 125 125 140 140 165

d4 4 x M6 4 x M8 4 x M6 4 x M8 4 x M10 4 x M10 4 x M12 4 x M12 4 x M16 4 x M16 4 x M20

Ø d5 125 160 210 225

h 3) – – 2.5 2.5 2.5 3.5 3.5 4.5

h1 12 15 12 15 16 18 19 22 25 29 32

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y005.557/003/en Issue 1.20 Page 1/2

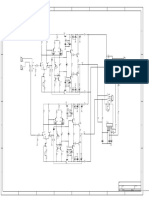

SQ 05.2 – SQ 14.2/SQR 05.2 – SQR 14.2

Dimensions Couplings according to EN ISO 5211

Bore according to EN ISO SQ../SQR.. 05.2 07.2 10.2 12.2 14.2

5211 with

keyway according to DIN EN ISO 5211 F05 F07 F07 F10 F10 F12 F12 F14 F14 F16

6885-1 ØD 41.75 41.75 51.75 67.6 81.6

L5

b JS9 1) 6 6 8 10 14

"X" Ø d7 H8 2) 18 22 28 36 48

Ø d7 max. 25.4 25.4 38 50 60

Detail X

d9 3) M5 M5 M6 M6 M6

L4 35 35 60 45 75 55 95 65 115

1,5 x d9 L5 3) 8 8 10 10 10

M 20 20 30 40 47 40

t 1) 20.8 24.8 31.3 39.3 51.8

Square bore SQ../SQR.. 05.2 07.2 10.2 12.2 14.2

according to

EN ISO 5211 EN ISO 5211 F05 F07 F07 F10 F10 F12 F12 F14 F14 F16

ØD 41.75 41.75 51.75 67.6 81.6

Ø d8 min. 2) 18.1 22.2 28.2 36.2 48.2

Ø d8 max. 28.2 28.2 40.2 4) 48.2 60.2

L4 35 35 60 45 75 55 95 65 115

L6 min. 30 30 30 30 40

M 20 20 30 40 47 40

s H11 2) 14 17 22 27 36

s H11 max. 22 22 30 4) 36 46

Two-flat SQ../SQR.. 05.2 07.2 10.2 12.2 14.2

according to EN ISO 5211

EN ISO 5211 F05 F07 F07 F10 F10 F12 F12 F14 F14 F16

ØD 41.75 41.75 51.75 67.6 81.6

Ø d8 min. 2) 18.1 22.2 28.2 36.2 48.2

Ø d8 max. 28.2 28.2 36.2 48.2 (48 5)) 60.2

L4 35 35 60 45 75 55 95 65 115

L6 min. 25 25 25 30 40

M 20 20 30 40 47 40

s H11 2) 14 17 22 27 36

s H11 max. 22 22 27 36 (41 5)) 46

Mounting position of the coupling within fitting dimensions X max. 3 4 5 8

according to AUMA definition Y max. 2 5 10 10

X

Y

1) Dimensions depend on Ø d7, refer to DIN 6885-1

2) Recommended size according to EN ISO 5211

3) Thread with grub screw

4) According to DIN 79

5) According to DIN 475

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y005.557/003/en Issue 1.20 Page 2/2

You might also like

- Hyundai Excavator Pattern Change DiagramsDocument6 pagesHyundai Excavator Pattern Change DiagramsVidi EfendiNo ratings yet

- Studio 5000 Logix Designer Advanced Lab ManualDocument280 pagesStudio 5000 Logix Designer Advanced Lab ManualOtávio Martins100% (1)

- Analytic Geometry 2Document3 pagesAnalytic Geometry 2Wayne VillarozaNo ratings yet

- MB sqr2 05 14 Am enDocument2 pagesMB sqr2 05 14 Am entrossiNo ratings yet

- mb_sar2_07_16_enDocument2 pagesmb_sar2_07_16_enwawan setiawanNo ratings yet

- MB Sarv2 07 16 Acv2 Bus enDocument2 pagesMB Sarv2 07 16 Acv2 Bus enPravin KohaleNo ratings yet

- MB Sarv2 07 16 Acv2 enDocument2 pagesMB Sarv2 07 16 Acv2 enIsnan ArsyadNo ratings yet

- MB Sar2 07 16 Ac2 Bus enDocument2 pagesMB Sar2 07 16 Ac2 Bus enGOPIKRISHNAHPTNo ratings yet

- MB Sarex2!07!16 KT enDocument2 pagesMB Sarex2!07!16 KT enAli AlashryNo ratings yet

- MB Sar2!10!16 Bremseinheit enDocument2 pagesMB Sar2!10!16 Bremseinheit enPiyapak KhunintonNo ratings yet

- MB Sar1 07 16 Am1 enDocument2 pagesMB Sar1 07 16 Am1 enKahl YeongNo ratings yet

- CUTTING PLAN J 609 DN 300 DUCT #2-Layout1Document1 pageCUTTING PLAN J 609 DN 300 DUCT #2-Layout1anastasya juniNo ratings yet

- Actuator AUMA For ValvesDocument2 pagesActuator AUMA For ValvesLassadNo ratings yet

- EQ 40 - EQ 150: Dimensions Part-Turn ActuatorsDocument2 pagesEQ 40 - EQ 150: Dimensions Part-Turn ActuatorsDennis RangwetsiNo ratings yet

- H Anchor Bolt Plan: C B B B B A ADocument1 pageH Anchor Bolt Plan: C B B B B A AArsene LupinNo ratings yet

- Auma 3Document2 pagesAuma 3Sonny LuuNo ratings yet

- Delivery TableDocument3 pagesDelivery Tableregnaidu12No ratings yet

- SA 07.1 - SA16.1 SAR 07.1 - SAR 16.1 Dimensions Multi-Turn Actuators AUMA NORMDocument2 pagesSA 07.1 - SA16.1 SAR 07.1 - SAR 16.1 Dimensions Multi-Turn Actuators AUMA NORMyzNo ratings yet

- Vehicle Stopping Distance and Time UpennDocument4 pagesVehicle Stopping Distance and Time UpennYurikoNo ratings yet

- Carvin Legacy 3 (VL300)Document1 pageCarvin Legacy 3 (VL300)Bruno MarianoNo ratings yet

- FSDR .. K Grinding Mill HousingsDocument1 pageFSDR .. K Grinding Mill Housingsdeni jakaNo ratings yet

- MB Sar1 07 16 Ac1 enDocument2 pagesMB Sar1 07 16 Ac1 enyzNo ratings yet

- Sing Sing Sing Alto 1Document4 pagesSing Sing Sing Alto 1Tom MartinNo ratings yet

- Tabel Honeycomb IWF BajaDocument2 pagesTabel Honeycomb IWF BajaIlham Eka putraNo ratings yet

- Sofn Bearing HousingsDocument4 pagesSofn Bearing HousingsLakshmisetty RamyaNo ratings yet

- Bulkhead Seal-340Document1 pageBulkhead Seal-340Dhamodaran RNo ratings yet

- 7sj641 ConnectionDocument1 page7sj641 Connectionfreyde alvarez vasquezNo ratings yet

- Terminator ThemeDocument1 pageTerminator ThemePierreCNo ratings yet

- GS 200.3 With GZ 200.3 Dimensions Worm Gearboxes and Primary Reduction GearingDocument2 pagesGS 200.3 With GZ 200.3 Dimensions Worm Gearboxes and Primary Reduction GearingDinesh ChouguleNo ratings yet

- Khối Hiển Thị Khối Nguồn: báo nhiệt độ dùng LM35Document1 pageKhối Hiển Thị Khối Nguồn: báo nhiệt độ dùng LM35Phạm Mạnh ĐứcNo ratings yet

- Wiring Diagram Transmission & Transfer Case Oil Cooling2Document2 pagesWiring Diagram Transmission & Transfer Case Oil Cooling2Muhammad AlwiNo ratings yet

- Crate GTX 212 SCHDocument4 pagesCrate GTX 212 SCHMario CabreraNo ratings yet

- Crate Flexwave Guitar Amp PDFDocument2 pagesCrate Flexwave Guitar Amp PDFManuel SilveiraNo ratings yet

- 224 - Op8502Document5 pages224 - Op8502Sas Pro EletronicaNo ratings yet

- Pump CatalogueDocument42 pagesPump CatalogueSiu KiNo ratings yet

- Peverse Polarity Timer CSG: CHANGES POLARITY EVERY 130 Seconds (2,10 Min.) For Longer Time Period, Increase Both R1, R2Document1 pagePeverse Polarity Timer CSG: CHANGES POLARITY EVERY 130 Seconds (2,10 Min.) For Longer Time Period, Increase Both R1, R2Carlos ChaflaNo ratings yet

- Electrical Notes: SymbolsDocument1 pageElectrical Notes: SymbolsCarlo M. FloresNo ratings yet

- Abarcones de RB-RUK Acero RedondoDocument1 pageAbarcones de RB-RUK Acero Redondoodps007No ratings yet

- KUDOSWORLD-Flexible Pin coupling-BOKU-N KWN22014Document8 pagesKUDOSWORLD-Flexible Pin coupling-BOKU-N KWN22014alyamaryani64No ratings yet

- Multistage Pumps: Kirloskar Brothers LimitedDocument11 pagesMultistage Pumps: Kirloskar Brothers LimitedAnilNo ratings yet

- 219 - Op8500Document5 pages219 - Op8500Sas Pro EletronicaNo ratings yet

- R Series Ex D: Stainless SteelDocument6 pagesR Series Ex D: Stainless SteelTran DucNo ratings yet

- THK Rolled Ball ScrewDocument7 pagesTHK Rolled Ball ScrewMadhuri RasalNo ratings yet

- Ax 063Document1 pageAx 063Al Fakhamah LiftsNo ratings yet

- SF 10.2 - SF 16.2: Dimensions Floor PedestalsDocument1 pageSF 10.2 - SF 16.2: Dimensions Floor PedestalsjampukNo ratings yet

- Oneal Op7502Document5 pagesOneal Op7502LUIZ COELHO PWTNo ratings yet

- 2021 07 25 Bungalow 1 1 A 2Document1 page2021 07 25 Bungalow 1 1 A 2Fred PrzNo ratings yet

- SfuDocument1 pageSfuNaza PalomoNo ratings yet

- HWU 340K EHR-03: Issued For ConstructionDocument1 pageHWU 340K EHR-03: Issued For ConstructionRedy K PutraNo ratings yet

- 9 - Sheet1Document1 page9 - Sheet1BroJokerNo ratings yet

- Feather MillDocument4 pagesFeather MillalphatoolsNo ratings yet

- Florist Fleuriste: Colour Guide / Diagramme en CouleurDocument5 pagesFlorist Fleuriste: Colour Guide / Diagramme en CouleurEricka FerrazNo ratings yet

- Skyworth 168p-p42ttf-00 Fan7530 Fsfr1700 Str-A6159m SCHDocument1 pageSkyworth 168p-p42ttf-00 Fan7530 Fsfr1700 Str-A6159m SCH62eugenNo ratings yet

- Polea Vertical DireccionalDocument1 pagePolea Vertical DireccionaldelgadinoemilianoNo ratings yet

- HP Amp SchematicDocument1 pageHP Amp SchematicComputer World sbyNo ratings yet

- 300KV Sub Station Cladding DrawingDocument7 pages300KV Sub Station Cladding DrawingSenthilkumar KNo ratings yet

- 3303 011 Stainless Steel Clevis PinsDocument2 pages3303 011 Stainless Steel Clevis PinsSangtian PhopomNo ratings yet

- Tapcon 230 Expert 6787385 ESDocument2 pagesTapcon 230 Expert 6787385 ESCristhian SaízNo ratings yet

- Part DrawingDocument1 pagePart DrawingAbhishek PatilNo ratings yet

- Tapcon 230 Basic 6787368 ESDocument1 pageTapcon 230 Basic 6787368 ESMaximiliano SanchezNo ratings yet

- mb_sqr2_05_14_en (1)Document2 pagesmb_sqr2_05_14_en (1)syarip hidayatNo ratings yet

- valve-solutions-guide-for-the-pulp--paper-industry-97.01-01Document28 pagesvalve-solutions-guide-for-the-pulp--paper-industry-97.01-01syarip hidayatNo ratings yet

- Valve-Material-ResistanceDocument4 pagesValve-Material-Resistancesyarip hidayatNo ratings yet

- Series 19L Segmented Ball Valve 1682464391Document4 pagesSeries 19L Segmented Ball Valve 1682464391syarip hidayatNo ratings yet

- Coordination Compounds Teaching PDFDocument6 pagesCoordination Compounds Teaching PDFNeel PatelNo ratings yet

- Fibonacci Numbers and The Golden SectionDocument3 pagesFibonacci Numbers and The Golden Sectionjai bachaniNo ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- Healicom Medical Equipment Co.,Ltd: Item No. Picture Product Name & Size NoteDocument7 pagesHealicom Medical Equipment Co.,Ltd: Item No. Picture Product Name & Size NoteMed ProviderNo ratings yet

- Designing and Analysis of Pumping Solar PV System Using Pvsyst SoftwareDocument5 pagesDesigning and Analysis of Pumping Solar PV System Using Pvsyst SoftwareabfstbmsodNo ratings yet

- Jet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesDocument8 pagesJet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesErinc CelikNo ratings yet

- Safety-Overall MEO Class 4 Part BDocument21 pagesSafety-Overall MEO Class 4 Part Blazyreaderr100% (1)

- Mal Positions and Mal PresentationsDocument229 pagesMal Positions and Mal PresentationsPriscilla Sarah PayneNo ratings yet

- Certificate of Calibration: Customer InformationDocument2 pagesCertificate of Calibration: Customer InformationSazzath HossainNo ratings yet

- A Place You Want To Stay at On Your Next TripDocument4 pagesA Place You Want To Stay at On Your Next TripĐoàn Thanh Chúc (FGW HN)No ratings yet

- Agar Content of Estuarine Seaweed Gracilaria Using Diffe - 2022 - Applied Food RDocument7 pagesAgar Content of Estuarine Seaweed Gracilaria Using Diffe - 2022 - Applied Food RLê Quốc Đăng KhoaNo ratings yet

- Kinematic Wave Routing - ExampleDocument33 pagesKinematic Wave Routing - ExamplethewodrosNo ratings yet

- Our Best-Selling Platform Lift: Aritco 7000Document2 pagesOur Best-Selling Platform Lift: Aritco 7000Lê Văn HoạtNo ratings yet

- Damodar Leela Kath ADocument35 pagesDamodar Leela Kath Aanshumanbiswal2319No ratings yet

- Brondizio Et Al 2009 Connectivity and The Governance of Multilevel Social Ecological Systems The Role of Social CapitalDocument29 pagesBrondizio Et Al 2009 Connectivity and The Governance of Multilevel Social Ecological Systems The Role of Social CapitalCHrisNo ratings yet

- Activity 7 Classifying of Sugars: Biochemistry LaboratoryDocument27 pagesActivity 7 Classifying of Sugars: Biochemistry LaboratoryWappy WepwepNo ratings yet

- Zgo-04!05!007 Mute Saic Detection Feature Guide Zxg10-Ibsc (v12.2.0) 20130425Document20 pagesZgo-04!05!007 Mute Saic Detection Feature Guide Zxg10-Ibsc (v12.2.0) 20130425Praveen DubeyNo ratings yet

- Flight Vehicle LoadsDocument15 pagesFlight Vehicle LoadsSantosh G Pattanad100% (1)

- Ex No: 1 DateDocument4 pagesEx No: 1 DateVignesh AadhiNo ratings yet

- SketchUp Tutorial 1 - TableDocument19 pagesSketchUp Tutorial 1 - TablenphilippNo ratings yet

- Catalogue of Fittings - Orient ChinaDocument83 pagesCatalogue of Fittings - Orient Chinapham thangNo ratings yet

- Melsec Iq-F FX5 User's Manual (CC-Link IE)Document150 pagesMelsec Iq-F FX5 User's Manual (CC-Link IE)Dedek HariyadiNo ratings yet

- Black Body RadiationDocument14 pagesBlack Body RadiationSaif KhanNo ratings yet

- Calbayog City Athletic Association (CCAA)Document14 pagesCalbayog City Athletic Association (CCAA)LindsayNo ratings yet

- Nanotechnology and Its Applications in Medicine: Medicinal Chemistry March 2015Document10 pagesNanotechnology and Its Applications in Medicine: Medicinal Chemistry March 2015Jane FrankNo ratings yet

- Tania Gabrielle - 2016 Astro-Numerology Pocket E-Guide GIFT NumDocument27 pagesTania Gabrielle - 2016 Astro-Numerology Pocket E-Guide GIFT NumEddyGren67% (3)

- Btech 1 Sem Programming For Problem Solving kcs101 2021Document1 pageBtech 1 Sem Programming For Problem Solving kcs101 2021rishabhchauhan2266No ratings yet

- Samri MSc. Thesis FinalDocument125 pagesSamri MSc. Thesis FinalMinilik Tikur SewNo ratings yet

- Lesson Plan Preparing For Parenthood Pregnancy and Labor - 0Document15 pagesLesson Plan Preparing For Parenthood Pregnancy and Labor - 0Sweta ManandharNo ratings yet