Professional Documents

Culture Documents

1

1

Uploaded by

Dan CocaliaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1

1

Uploaded by

Dan CocaliaCopyright:

Available Formats

SHOO

Screw Ejecting The SHOOTOUT multi-purpose

frame repair tool is a precision

Screw Riveting instrument. Please follow these

Screw Flaring instructions for years of trouble

free service.

Screw Slotting

Screw Ejecting

lnstructions: To assure the best performance from The SHOOTOUT avoid excessive

pressure and always check for proper alignment of the punch point, screw end, screw

head and anvil. lf too much pressure is used or the components are not lined up

properly, the point or anvil will break. ln addition if the anvil is too large for the

,

particular frame's barrel, the temple will twist and a point or anvil will snap.

lf you feel the temple twisting, stop applying pressure immediately, realign components,

and check that the anvil diameter is not too small for the screw head. The screw head

must fit inside the anvil or the screw will not move through the barrel.

Hinge Riveting

Replace the screw in a stripped barrel with a semi-permanent rivet!!!

Whenever you punch out a screw from a barrel the threads inside the barrel are destroyed.

I l

ln repairing the barrel you usually use a self-tapping screw or re-tap the barrel and use an

oversize screw. These methods are both time consuming and require a variety of taps,

screw sizes and patience. Western Optica! Supply has come up with a quick and easy

solution that will facilitate repairs on stripped barrels.

•

lnstructions: Set up The Shootout using the cupped point and the solid anvil. Insert the

rivet into the as-sembled hinge from the top. Using an end cutter plier, snip off the excess

rivet stern leaving only 2mm protruding below the barrel. Using The SHOOTOUT place the

head of the rivet against the solid anvil and the clipped rivet end into the cupped point.

GENTLY squeeze. The clipped end of the rivet will mushroom while being compressed and

expand within the barrel. �

#2042 Rivet Gold Silver or Gun Metal

,

..... #2042 Anvil Solid

This is a temporary repair. lt will, however, � #2042 Point Cupped

repair the temple until a replacement pair of

glasses is dispensed to the patient.

Screw Flaring

Stops screws from backing out of hinges.

#2042 Point Cupped lnstructions: lnstall the cupped or flaring point and solid anvil into The SHOOTOUT.

#2042 Anvil Solid Finger tighten only.

;.

#2042 Point Fiare Position the head of the screw on the solid anvil. Center the apex of the flaring point or

the cupped point on the end of the screw.

Apply SLIGHT pressure when bringing the point down on the end of the screw. Using

easy pressure the point will spread the screw outward {flaring point) or mushroom the

end (cupped point). Stop applying pressure once you see the screw distortjust slightly.

Too much pressure may damage the screw and hinge.

You might also like

- BST Basic Technology JSS 3Document142 pagesBST Basic Technology JSS 3Alvan Mmaduwuba92% (13)

- HK 630 770 and 940 ManualDocument12 pagesHK 630 770 and 940 Manualjustin_j_gaudetNo ratings yet

- Nbs Ps 15 69Document9 pagesNbs Ps 15 69شركة الطيبى100% (1)

- Mossberg 151k PDFDocument6 pagesMossberg 151k PDFmikey_tipswordNo ratings yet

- Holding ToolsDocument60 pagesHolding Toolsariel canonoy100% (1)

- Shock Repair Repair Guide GuideDocument11 pagesShock Repair Repair Guide Guidebigblock3142No ratings yet

- Internal Cutter PDFDocument20 pagesInternal Cutter PDFnasr yassinNo ratings yet

- ITCO Type Releasing SpearDocument20 pagesITCO Type Releasing SpearRazvan Radu80% (5)

- RWS Diana Model 34-36 DisassemblyDocument14 pagesRWS Diana Model 34-36 DisassemblyBrooke Price0% (1)

- 1911 Auto Schuemann Barrels InstructionsDocument2 pages1911 Auto Schuemann Barrels InstructionsDale WadeNo ratings yet

- MK4 Saw Instructions-WebDocument4 pagesMK4 Saw Instructions-WebCristian RamosNo ratings yet

- 2Document1 page2Dan CocaliaNo ratings yet

- Transmission Tower RestorationDocument21 pagesTransmission Tower Restorationjorge Angel LopeNo ratings yet

- ScrewdriverSafetyRulesDocument1 pageScrewdriverSafetyRulesSakhawat HossainNo ratings yet

- EICH Montage Anleitung E RZDocument2 pagesEICH Montage Anleitung E RZLuis TestaNo ratings yet

- Fin FanDocument4 pagesFin FanPuchit SpkNo ratings yet

- Fork Gold Valve Installation: DisassemblyDocument4 pagesFork Gold Valve Installation: DisassemblyTiyok HidrolikNo ratings yet

- Pieza de Mano NSK PANA AIRDocument12 pagesPieza de Mano NSK PANA AIRAna Teresa Manjarres MonteroNo ratings yet

- Spanners and Wrenches PDFDocument4 pagesSpanners and Wrenches PDFLoren ViejayNo ratings yet

- Spanners and WrenchesDocument4 pagesSpanners and WrenchesYounes BarakaNo ratings yet

- XT Fork ManualDocument18 pagesXT Fork Manualrusroald50% (2)

- Wrenches ProtoDocument41 pagesWrenches ProtoMauricio GarciaNo ratings yet

- Information Sheet 2.1-2docxDocument8 pagesInformation Sheet 2.1-2docxErnesto CabuyadaoNo ratings yet

- RH 200Document7 pagesRH 200NGC 7619No ratings yet

- The Highest Level of Reloading PrecisionDocument3 pagesThe Highest Level of Reloading PrecisionToxophilus TheLuckyNo ratings yet

- Assembly and Operation Manual: Information 5Document34 pagesAssembly and Operation Manual: Information 5Kayo BuenoNo ratings yet

- Federal-Mogul Document #1517 Sparkplug Twist OffDocument2 pagesFederal-Mogul Document #1517 Sparkplug Twist OffjdhickoryNo ratings yet

- Lathe SherlineDocument2 pagesLathe SherlineDaron SchullerNo ratings yet

- Kreddle ManualDocument16 pagesKreddle Manualmatt.lee3491No ratings yet

- Corbin - LTFB 4 S PDFDocument2 pagesCorbin - LTFB 4 S PDFHank EfremsNo ratings yet

- 1334-100 10 - 5 Speed Bench Drill PressDocument22 pages1334-100 10 - 5 Speed Bench Drill PressSiamakNo ratings yet

- Toolzone WhitworthDocument5 pagesToolzone WhitworthJanice WilliamsNo ratings yet

- Aircraft Stud 3Document12 pagesAircraft Stud 3Raihan AkbarNo ratings yet

- A2018rivetingtool-4976Document1 pageA2018rivetingtool-4976ranganamanojNo ratings yet

- Akses Manual Mesin BarudanDocument45 pagesAkses Manual Mesin BarudanSektor VNo ratings yet

- Shock Repair Guide 401 402 SeriesDocument11 pagesShock Repair Guide 401 402 Serieshcj920213No ratings yet

- Sear Trigger TuningDocument4 pagesSear Trigger TuningDustin Gray100% (1)

- Universal Auto Feed Reel Easy String Head: WarningDocument6 pagesUniversal Auto Feed Reel Easy String Head: WarningElena CMNo ratings yet

- Jig FixtureDocument59 pagesJig FixtureHrishikeshNo ratings yet

- 2531Document5 pages2531sangkil05No ratings yet

- RSE - Daisy 1000 Trigger GuideDocument13 pagesRSE - Daisy 1000 Trigger Guidemirizabal64No ratings yet

- Docsity Manual Divisor UniversalDocument5 pagesDocsity Manual Divisor UniversalOBRUNERANo ratings yet

- Fishing Bumper SubsDocument15 pagesFishing Bumper SubsJuancho100% (1)

- Turbuckle InstallationDocument10 pagesTurbuckle Installationmoch ganafiaNo ratings yet

- TL 02006 Z Q Head ManualDocument9 pagesTL 02006 Z Q Head ManualMagno AguiarNo ratings yet

- Clutch Damper ChangeDocument6 pagesClutch Damper ChangeAaron StaubNo ratings yet

- External Cutter PDFDocument16 pagesExternal Cutter PDFnasr yassinNo ratings yet

- Archery MaintenanceDocument15 pagesArchery Maintenanceslaiyfershin100% (1)

- Riveting Basics: Rivet Gun and Flaring RivetsDocument17 pagesRiveting Basics: Rivet Gun and Flaring RivetsTanu RdNo ratings yet

- I & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDocument11 pagesI & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDanel GonzalezNo ratings yet

- Wedge Adjustment and Short Arbor RepairDocument8 pagesWedge Adjustment and Short Arbor RepairSadBoiH0urs 1No ratings yet

- Stock "QD" Bushings: RemovalDocument2 pagesStock "QD" Bushings: RemovalmecanicoNo ratings yet

- ST 2000Document12 pagesST 2000Jorge ArbelaezNo ratings yet

- U3l1s FastenersDocument46 pagesU3l1s FastenerspmcisissengueNo ratings yet

- Threaded Fasteners: This Configuration Is Called "Cap Screw"Document23 pagesThreaded Fasteners: This Configuration Is Called "Cap Screw"Marco RicardNo ratings yet

- Dead Drop DeviceDocument7 pagesDead Drop DeviceAgino MottoNo ratings yet

- Impact-Cutting-Instructions PARTIDA 86Document3 pagesImpact-Cutting-Instructions PARTIDA 86Ale PalomoNo ratings yet

- Kick Start Pawl Replacement - A4Document3 pagesKick Start Pawl Replacement - A4barun1977No ratings yet

- Hegner Quick Clamp Vs Standard Blade ClampsDocument2 pagesHegner Quick Clamp Vs Standard Blade ClampsChester GasperNo ratings yet

- MAKITA - Llave Impacto 6905H - ManualDocument64 pagesMAKITA - Llave Impacto 6905H - Manualmarco antonio talavera salazarNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- Repair and Rehabilitation NotesDocument7 pagesRepair and Rehabilitation NotesJuan Pablo Lopez CarrascoNo ratings yet

- New 03 NBCC GREEN VIEWDocument3 pagesNew 03 NBCC GREEN VIEWsushil kumarNo ratings yet

- 279 Ultrabondp9901k GBDocument4 pages279 Ultrabondp9901k GBMarko GagroNo ratings yet

- Brosur Wika Beton Edisi 2022Document44 pagesBrosur Wika Beton Edisi 2022Dinda Hani SyarifahNo ratings yet

- WSP Usor 2018Document36 pagesWSP Usor 2018Sonu VishwakarmaNo ratings yet

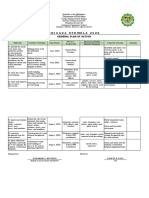

- Brigada Eskwela Action PlanDocument2 pagesBrigada Eskwela Action PlanRosemarie BestudioNo ratings yet

- Engr Micheal STRDocument12 pagesEngr Micheal STRUmar SaiduNo ratings yet

- Demo QuotDocument5 pagesDemo QuotSurendra BaislaNo ratings yet

- Case Study HotelDocument21 pagesCase Study Hotelmanu guptaNo ratings yet

- Take Off Quantities and BillsDocument26 pagesTake Off Quantities and Billskandy saidNo ratings yet

- Total Building Cost CalculationsDocument6 pagesTotal Building Cost CalculationshadeeqaNo ratings yet

- Falcon Tool Box To-20-008 ListDocument5 pagesFalcon Tool Box To-20-008 ListAbhishekprasad royNo ratings yet

- Price ScheduleDocument25 pagesPrice ScheduleGokul NathNo ratings yet

- RLS Orms 5 0Document2 pagesRLS Orms 5 0airy orzagaNo ratings yet

- Hot Work PermitDocument2 pagesHot Work Permitkumar kannanNo ratings yet

- Infill WallDocument2 pagesInfill Wallsalman arafatNo ratings yet

- Schedule Pekerjaan Pengecoran Cab. Pekan BaruDocument1 pageSchedule Pekerjaan Pengecoran Cab. Pekan BaruardiansyahNo ratings yet

- Revit MEPDocument6 pagesRevit MEPMohammed Hussam ShaikhNo ratings yet

- Sample Test On Philippine ArchitectureDocument10 pagesSample Test On Philippine ArchitecturesNo ratings yet

- Prelim - EpbuhayanDocument20 pagesPrelim - EpbuhayanQueenie Janine T. DacumosNo ratings yet

- PortofolioDocument12 pagesPortofolioursula devinaNo ratings yet

- MCQDocument12 pagesMCQmyint phyoNo ratings yet

- Philippine National Standard: Code of Practice (COP) For Packaging and Transport of Fresh Fruits and VegetablesDocument16 pagesPhilippine National Standard: Code of Practice (COP) For Packaging and Transport of Fresh Fruits and Vegetablesjeffrey sarolNo ratings yet

- Tile Care & MaintenanceDocument6 pagesTile Care & MaintenanceGD BERDINNo ratings yet

- Adendorf Drive Train Workshop ToolingDocument2 pagesAdendorf Drive Train Workshop ToolingDrum City WorkshopNo ratings yet

- Exam Preparation Associate Member Solutions 20140425Document8 pagesExam Preparation Associate Member Solutions 20140425sunaifctmNo ratings yet

- Et - 1 Detail (Overhang Steel Rafter) : A B C D A B C DDocument1 pageEt - 1 Detail (Overhang Steel Rafter) : A B C D A B C DfelixNo ratings yet

- Cupboard: Submitted To: Submitted byDocument31 pagesCupboard: Submitted To: Submitted byPiyush mauryaNo ratings yet