Professional Documents

Culture Documents

General Notes

General Notes

Uploaded by

Mohamed DarwishCopyright:

Available Formats

You might also like

- Plumbing Plans 2-StoreyDocument4 pagesPlumbing Plans 2-StoreySteel Caballero100% (1)

- Business PlanDocument11 pagesBusiness PlanRoadwell ZuluNo ratings yet

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- KBF (E5.2) : Service ManualDocument140 pagesKBF (E5.2) : Service ManualgeorgevarsasNo ratings yet

- API 650-Annex PDocument8 pagesAPI 650-Annex PSachinNo ratings yet

- You'Re On Consulting For Peak Performance-ManteshDocument272 pagesYou'Re On Consulting For Peak Performance-ManteshtaeBoNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- Veran Structural Model2Document1 pageVeran Structural Model2mr. oneNo ratings yet

- General Construction Notes: FC Engineering ServicesDocument1 pageGeneral Construction Notes: FC Engineering ServicesMac KYNo ratings yet

- Construction Notes: ElevationDocument1 pageConstruction Notes: ElevationJohn PaderangaNo ratings yet

- Typical Detail of Pre-Cast Boundary Wall Section A-A Section A-ADocument1 pageTypical Detail of Pre-Cast Boundary Wall Section A-A Section A-AManupriya KapleshNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Annex 02Document12 pagesAnnex 02rukshan jayasingheNo ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- Structural Notes: General: Reinforcing SteelDocument1 pageStructural Notes: General: Reinforcing SteelMark Allan RojoNo ratings yet

- Chauraghat Road Structural GAD R1Document18 pagesChauraghat Road Structural GAD R1Aicons Engineering Pvt. Ltd.No ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- Bridge Drawings 2019-09-02Document13 pagesBridge Drawings 2019-09-02yasirjurabaNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Saudi Arabian Oil Company: Co2 Fire Suppression System Piping LayoutDocument1 pageSaudi Arabian Oil Company: Co2 Fire Suppression System Piping Layoutsaleem shahidNo ratings yet

- Storm Water ManagementDocument1 pageStorm Water ManagementmmceplNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- 2024 - Powerhouse-Roadway Detailed DesignDocument1 page2024 - Powerhouse-Roadway Detailed Designadonis bibatNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- General NotesDocument1 pageGeneral NotesJohn Paul IldefonsoNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- Single 1Document1 pageSingle 1Altab ChNo ratings yet

- Slab Layout: DWG No 190811 DDocument14 pagesSlab Layout: DWG No 190811 DSaiful IslamNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- Roxas PWD BuildingDocument32 pagesRoxas PWD BuildingDennis SariegoNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- Wall Footing Details: Typical Connection Detail of Masonry WallDocument1 pageWall Footing Details: Typical Connection Detail of Masonry WallCarlo M. FloresNo ratings yet

- Design Example Reinforced Strip FoundationDocument6 pagesDesign Example Reinforced Strip FoundationFrans-Shixova ShipopyeniNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- GF, FF, SFDocument1 pageGF, FF, SFamit_saxena_10No ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- Temporary Staging (Marudi) - 1Document1 pageTemporary Staging (Marudi) - 1Kelvin LauNo ratings yet

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- Madhavaram radiance-GA-REV-1Document1 pageMadhavaram radiance-GA-REV-1suhailNo ratings yet

- Slab CulvertDocument3 pagesSlab CulvertSHIVANK SINGH PARIHARNo ratings yet

- Shuttering Arrangement For Box GirderDocument1 pageShuttering Arrangement For Box GirdershakeelNo ratings yet

- Uecp SD Cul 11.1 R00Document3 pagesUecp SD Cul 11.1 R00Anuradha KoswaththaNo ratings yet

- ORISSA SCHOOL (STR-ARCH) - Model - pdf73Document1 pageORISSA SCHOOL (STR-ARCH) - Model - pdf73NISHIKANTA MONDALNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- Construction Notes: Table of Lap Splice & Anchorage LengthDocument1 pageConstruction Notes: Table of Lap Splice & Anchorage LengthReyvel Sapaden CorcueraNo ratings yet

- Existing Culvert C401 - Temporary Supports DetailsDocument1 pageExisting Culvert C401 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Flooring Details DrawingDocument1 pageFlooring Details DrawingNilesh WaghNo ratings yet

- Final Sheet-Model - PDF 4Document1 pageFinal Sheet-Model - PDF 4Prateek SharmaNo ratings yet

- General Notes and Specifications: Roof Line Roof LineDocument1 pageGeneral Notes and Specifications: Roof Line Roof LineCyril AleaNo ratings yet

- Earthing BasementDocument1 pageEarthing BasementNad EemNo ratings yet

- 1 Dg-MahilaDocument1 page1 Dg-MahilaRohit JangidNo ratings yet

- Site Visit - Inspection of foundation Bottom The road and TrackDocument6 pagesSite Visit - Inspection of foundation Bottom The road and TrackMohamed DarwishNo ratings yet

- Recommendation for Manholes & Rigid DuctsDocument3 pagesRecommendation for Manholes & Rigid DuctsMohamed DarwishNo ratings yet

- Site Visit - Manholes-letterDocument9 pagesSite Visit - Manholes-letterMohamed DarwishNo ratings yet

- Site Visit Building SC3 B16 3Document3 pagesSite Visit Building SC3 B16 3Mohamed DarwishNo ratings yet

- Site Visit - Main Workshop- B13-1Document4 pagesSite Visit - Main Workshop- B13-1Mohamed DarwishNo ratings yet

- RCS - WF-006274 - B13.1-WSB-Main Workshop-Steel Structure Preliminary Design - CopyDocument6 pagesRCS - WF-006274 - B13.1-WSB-Main Workshop-Steel Structure Preliminary Design - CopyMohamed DarwishNo ratings yet

- RCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-GEN-550-0012ADocument4 pagesRCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-GEN-550-0012AMohamed DarwishNo ratings yet

- Rcs Hsr or Sub Plm Ddd Gl s01 d1 Gen 210 0033Document6 pagesRcs Hsr or Sub Plm Ddd Gl s01 d1 Gen 210 0033Mohamed DarwishNo ratings yet

- RCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-BMS-550-0013A (002)Document6 pagesRCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-BMS-550-0013A (002)Mohamed DarwishNo ratings yet

- RCS - Submission Review AndComment Sheet (002)Document4 pagesRCS - Submission Review AndComment Sheet (002)Mohamed DarwishNo ratings yet

- Navisworks CourseDocument45 pagesNavisworks CourseMohamed DarwishNo ratings yet

- RFT- Zone 4-01Document1 pageRFT- Zone 4-01Mohamed DarwishNo ratings yet

- Question Text Question Type Option 1: Multiple ChoiceDocument4 pagesQuestion Text Question Type Option 1: Multiple Choicemohamed elgammlNo ratings yet

- Full Final Drawing For ProjectDocument13 pagesFull Final Drawing For ProjectSabbir hossain100% (1)

- Fs 1-Episode 1Document9 pagesFs 1-Episode 1Louween Mendoza50% (2)

- Nyquist Stability CriterionDocument4 pagesNyquist Stability CriterionRajeev KumarNo ratings yet

- Philips Problem Solving - PRIDE - Poster Deck v02Document11 pagesPhilips Problem Solving - PRIDE - Poster Deck v02Vanita GanthadeNo ratings yet

- HP-19C & 29C Solutions Mathematics 1977 B&WDocument40 pagesHP-19C & 29C Solutions Mathematics 1977 B&WjjirwinNo ratings yet

- Demag ZKKE ManualDocument5 pagesDemag ZKKE ManualAlan MaciasNo ratings yet

- Captivity of Marine AnimalsDocument22 pagesCaptivity of Marine AnimalsJulia OrdonaNo ratings yet

- Assignment Ict (Display Qualities)Document3 pagesAssignment Ict (Display Qualities)Laiba SajjadNo ratings yet

- A Report On Self Defence Workshop For Women and GirlsDocument7 pagesA Report On Self Defence Workshop For Women and GirlsANJALI GHANSHANINo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- The English Paragraph: What Is A Paragraph?Document6 pagesThe English Paragraph: What Is A Paragraph?Khin Maung HtweNo ratings yet

- Stepan Formulation 1110Document2 pagesStepan Formulation 1110Jan Velasco100% (1)

- Ucsp Module 12Document17 pagesUcsp Module 12Aida SabadoNo ratings yet

- Class 1Document15 pagesClass 1eisha123No ratings yet

- EE420 SyllabusDocument1 pageEE420 Syllabussal1980No ratings yet

- Lecture7 PressureVessel Combined LoadingDocument22 pagesLecture7 PressureVessel Combined LoadingHarold Valle ReyesNo ratings yet

- Montessori Nomenclature Solar SystemDocument13 pagesMontessori Nomenclature Solar SystemJulieta NavoneNo ratings yet

- TAE40116 - RPL Application Kit V1Document11 pagesTAE40116 - RPL Application Kit V1Susan JackmanNo ratings yet

- Click Here For Download: (PDF) Fundamentals of EcologyDocument2 pagesClick Here For Download: (PDF) Fundamentals of EcologySujeet KumarNo ratings yet

- Mechanical Testing of CompositesDocument18 pagesMechanical Testing of CompositesSPARSH KUMAR AGARWALNo ratings yet

- Yto ZL50F CatalogoDocument97 pagesYto ZL50F CatalogoGerson Miotto50% (2)

- 12 ApspDocument6 pages12 ApspseemasuranaNo ratings yet

- BLF Q8 Narsil v1-3Document4 pagesBLF Q8 Narsil v1-3Guy Fawkes0% (1)

- 04.0 APA Style Citations and References August 2015Document28 pages04.0 APA Style Citations and References August 2015Rain BiNo ratings yet

General Notes

General Notes

Uploaded by

Mohamed DarwishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes

General Notes

Uploaded by

Mohamed DarwishCopyright:

Available Formats

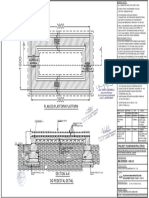

STRUCTURAL NOTES

PROJECT 3. WIND LOAD

DEEP FOUNDATION

MIDDLE RING-ROAD '' HELWAN BRIDGE '' WIND PRESSURE T/m2 PRESTRESSING DESIGN STRESSES:

1. FOUNDATIONS ARE DESIGNED UTILIZING CAST-IN-PLACE PILED FOOTINGS, THE BORED PILES

GENERAL HEIGHT ABOVE GROUND WITHOUT LIVE LOAD 1. ALLOWABLE PRESTRESSING STEEL AND CONCRETE STRESSES ARE IN ACCORDANCE TO AASHTO-LRFD. 2012.

WITH LIVE IS OF 1.5 m DIAMETER WITH 750 TONS WORKING CAPACITY AND OF 2.0 m WITH 1200 TONS WORKING CAPACITY

LEVEL OR TOP WATER

1. REFER TO THE RESPECTIVE CONTRACT DRAWING FOR STRUCTURAL NOTES WHICH WITHOUT SOUND WITH SOUND BARRIER LOAD AND, OF 1.5 m WITH 700 TONS WORKING CAPACITY. 2. SUPER STRUCTURES IS DESIGNED AS NO TENSILE STRESS PERMITTED FOR SERVICE LOAD

LEVEL

APPLY TO HELWAN BRIDGE STRUCTURES, PILES, FOUNDATIONS AND WALLS. BARRIER COMBINATIONS 1 WITH LIVE LOADING CONSIST OF 0.5 TIMES LOAD MODEL 1. FOR ALL OTHER SERVICE

2. PILE LENGTH SHOULD BE DEFINED BASED ON ACTUAL SUBSURFACE STRATIFICATION AND SCOUR DEPTH.

2. DO NOT SCALE FROM DRAWINGS, FOLLOW SHOWN DIMENSIONS AND ELEVATIONS. 0-20 0.2 0.15 0.1 COMBINATIONS, SUPER STRUCTURES SHALL NOT BE DESIGNED AS PARTIALLY PRESTRESSED UNLESS

3. THE CONTRACTOR SHALL BE RESPONSIBLE FOR OBTAINING THE REQUIRED DATA AND CONDUCTING

3. THE CONTRACTOR SHALL VERIFY ALL STATIONS, LEVELS, COORDINATES AND DIMENSIONS 0.225 0.175 0.125 OTHERWISE NOTED ON THE DRAWINGS.

20-50

AGAINST THE CIVIL DRAWINGS BEFORE COMMENCEMENT OF THE WORKS. NECESSARY PILE LOAD TESTS TO VERIFY THAT THE PILE CAPACITY AND INTEGRITY ARE MET

50-100 0.25 0.2 0.15

4. PILE CAPS AND ABUTMENTS IN CONTACT WITH SOIL FILL SHALL BE WATERPROOFED WITH 2 COATS IN ACCORDANCE TO STANDARDS OR AS DIRECTED BY THE ENGINEER.

OF BITUMINOUS COATING SPECIFIED IN OF THE CONSTRUCTION SPECIFICATION >100 0.275 0.225 0.175

TYPE OF REINFORCEMENT GROUTING

5. NO FORM WORK OR OTHER TEMPORARY WORKS SHALL BE LEFT INSIDE BOX GIRDER CELLS .

1. ALL REINFORCEMENT BARS ARE TO BE DEFORMED ROUND STEEL BARS OF GRADE 40 / 60 GROUT USED SHALL BE NON-SHRINKAGE STRUCTURAL GROUT WITH A MINIMUM

Design Life 4. TEMPERATURE LOADS COMPLYING WITH THE REQUIREMENT OF BS 4449:1988 SPECIFICATION .

CYLINDER COMPRESSIVE STRENGTH OF 21MPa AT 7 DAYS AND 55MPa AT 28 DAYS.

1. THE BRIDGE DESIGN LIFE IS 120 YEARS.

1. CONCRETE DECKS : 2. SPIRAL REINFORCEMENT PLAIN ROUND STEEL BARS GRADE 250 COMPLYING WITH

2. ADEQUATE WORKING SPACE FOR INSPECTION AND MAINTENANCE SHALL BE PROVIDED AROUND

TEMPERATURE RANGE THE REQUIREMENT OF BS 4449:1988.

PARTS SUCH AS BEARINGS, EXPANSION JOINTS AND, PRESTRESSING ANCHORAGES.

UNIFORM TEMPERATURE RISE CONCRETE COVER

3. WIRE MESH TO BE WELDED WIRE FABRIC REINFORCEMENT SMOOTH ROUND BARS COMPLYING

UNIFORM TEMPERATURE FALL

WITH THE REQUIREMENT OF BS 4483 SPECIFICATION. MINIMUM COVER TO ENDS AND SIDES OF REINFORCEMENT UNLESS OTHERWISE

DESIGN SPECIFICATIONS AND REFERENCE TEMPERATURE GRADIENT

INDICATED ON DRAWINGS SHALL BE AS FOLLOWS:

1. THE DESIGN OF THE BRIDGEWORKS IS IN ACCORDANCE TO AASHTO - LFRD BRIDGE DESIGN 4. WHERE REINFORCING BARS ARE TO BE SPLICED-ALL BAR LAP LENGTH SHALL CONFORM TO THE

SPECIFICATIONS, 2010. 2. COLUMNS AND ABUTMENTS: REQUIREMENT OF THE DESIGN SPECIFICATION SPLICE SHALL BE STAGGERED AT POINTS

TEMPERATURE GRADIENT OF MAXIMUM STRESS AND SPLICED BARS SHALL BE STAGGERED.

2. BRITISH STANDARD 5400 IS APPLIED WHEN NECESSARY FOR RELEVANT CONFORMANCE.

SUPERSTRUCTURE

3. THE LOADS ON THE BRIDGES IS IN ACCORDANCE WITH THE EGYPTIAN CODE FOR LOADS, 2012. 3. BEARINGS AND EXPANSION JOINTS DESIGN:

REINFORCEMENT DETAILS = 40 mm

CONCRETE DECKS : CAST IN PLACE OR PRECAST (ONSITE) CONCRETE EXPOSED TO WEATHER

DESIGN LOADS REINFORCING STEEL CALLOUTS SHALL BE READ AS SHOWN BELOW:

UNIFORM TEMPERATURE RISE EX FACTORY PRECAST ELEMENT = 30 mm

T - TOP

1. DEAD LOAD AND MATERIAL OWN WEIGHT UNIFORM TEMPERATURE FALL

NUMBER OF BARS SLAB & BEAM FACES DIRECTLY EXPOSED TO LANDSCAPING EARTH FILL = 60 mm

B - BOTTOM

3

EF - EXTERNAL FACE SURFACES NOT EXPOSED TO EARTH OR WATER = 30 mm

CONCRETE OWN WEIGHT (REINFORCED AND PRESTRESSED) 25 kN/m

WEARING SURFACE 23 kN/m3 NF - NEAR FACE UNPROTECTED COLUMN LOCATES WITHIN TRAFFIC WAY = 100 mm

BLINDING AND MASS CONCRETE 24 kN/m 3 5. DIFFERENTIAL SETTLEMENT BAR DIAMETER(MM) FF - FAR FACE

STRUCTURAL STEEL WORK AND STAY CABLES 78.5 kN/m

3 COLUMN LOCATES OUT OF TRAFFIC WAY = 50 mm

A DIFFERENTIAL SETTLEMENT OF 10mm IS ASSUMED BETWEEN TWO ADJACENT ALT - ALTERNATE

SOIL ABOVE GROUND WATER TABLE 19 kN/m3 BAR CENTER SPACING (MM)

SUPPORTS OF DECK. STAG - STAGGERED

SOIL BELOW GROUND WATER TABLE 9 kN/m 3

LAYOUT/LOCATION B.F - BOTH FACE

WEIGHT OF BARRIER 10.5 kN/m

UTILITIES AND SERVICES I.F - INNER FACE SUBSTRUCTURE AND FOUNDATION

0.75 kN/m 3 6. EARTHQUAKE LOADING

THE BRIDGE LOCATION SHALL BE CLASSIFIED ACCORDING TO SEISMIC HAZARD FOUNDATIONS AND PILECAPS = 75 mm

2. LIVE LOAD

MAP SHOWN IN EGYPTIAN CODE OF LOADS. ZONE 3 WAS SELECTED FOR BRIDGE

THE DESIGN VEHICULAR LIVE LOAD ARE AS FOLLOW: CONCRETE BAR DIA(MM) 12 16 18 22 25 32 ABUTMENTS, WALLS AND PIERS UP TO 300mm ABOVE GROUND = 75 mm

LOCATION WITH DESIGN GROUND ACCELERATION 0.15 g-IMPORTANCE FACTOR 1.3.

1. LOAD MODEL 1 (LM1): (MAIN TRAFFIC LOAD): GRADE

113 201 254 380 491 804 ABUTMENTS, WALLS AND PIERS AFTER 300mm ABOVE GROUND = 50 mm

(N/mm2) BAR AREA(mm2)

1.1: TRAFFIC LANE NUMBER 1: A TRUCK WEIGHTED 60 TON DISTRIBUTED ON FOUR POINTS (15 TON EACH) PILES = 80 mm

IN ADDITION TO UNIFORMLY DISTRIBUTED LOAD 0.9 T/M2 APPLIED OVER THE LANE AREA. 7. SHRINKAGE Fcu BAR WEIGHT(KGM) 0.89 1.58 2.00 2.99 3.85 6.31

AS PER AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS, SHRINKAGE COEFFICIENT CONCRETE EXPOSED TO SALT WATER AND SPLASH ZONE = 100 mm

1.2: TRAFFIC LANE NUMBER 2: A TRUCK WEIGHTED 40 TON DISTRIBUTED ON FOUR POINTS (10 TON EACH) 50 600 800 900 1100 1250 1600

TO BE 0.0002 AFTER 28 DAYS AND 0.0005 AFTER ONE YEAR OF DRYING.

IN ADDITION TO UNIFORMLY DISTRIBUTED LOAD 0.25 T/M2 APPLIED OVER THE LANE AREA.

45 TENSION LAP * 650 850 950 1200 1350 1700

1.3: TRAFFIC LANE NUMBER 3: A TRUCK WEIGHTED 20 TON DISTRIBUTED ON FOUR POINTS (5 EACH) 8. BRAKING FORCE COVER TO PRESTRESSING DUCTS:

IN ADDITION TO UNIFORMLY DISTRIBUTED LOAD 0.25 T/M2 APPLIED OVER THE LANE AREA. SPLICES(MM) 700 900 1050 1250 1400 1800

BRAKING FORCE CALCULATED BY THE FOLLOWING EQUATION : 40

MINIMUM COVER TO PRESTRESSING DUCTS SHALL BE IN ACCORDANCE TO BS-5400-4-1990, APPENDIX "D".

1.4: UNIFORMLY DISTRIBUTED LOAD 0.25 T/M2 APPLIED OVER THE REMINDER TRAFFIC BRIDGE AREA.

Q = 360 + 2.7 x ( L ) KN

30 800 1050 1200 1450 1650 2100

1.5: UNIFORMLY DISTRIBUTED LOAD 0.5T/M2 APPLIED OVER THE PEDESTRIAN AREA. WHERE ( L) IS THE SPAN , ( Q ) NOT MORE THAN 900 KN .

*LAP SIZE IS FOR CLASS B SPLICE,IF SPLICE DOES NOT MEET CLASS B REQUIREMENT,SPLICE

2. LOAD MODEL 2 (LM2): (FOR DESIGN OF FOR DESIGN DECK SLAB): GRADE OF CONCRETE CHAMFERS:

LENGTH SHALL BE RECOMPUTED BASED ON AASHTO -LRFD CLAUSE 5.11.5.3

40 TON TRUCK IN ONE AXLE CONSISTS OF TWO CONCENTRATED LOADS, EACH OF 20 TONS, ALL EXPOSED CONCRETE CORNERS SHALL BE CHAMFERED 20 MILLIMETERS UNLESS

AND ADJACENT DISTANCE IS 2.0 METERS. THE GRADE OF CONCRETE FOR THIS WORK ARE BASED ON 28 DAYS OTHERWISE NOTED ON THE DRAWINGS

COMPRESSIVE CUBIC STRENGTH AND AS PER ASTM C31/39 ARE AS FOLLOWS:

3. LOAD MODEL 3 (LM3): (FOR DESIGN OF PEDESTRIAN AREAS):

UNIFORMLY DISTRIBUTED LOAD OF TO 0.5 T/M2. ( COMPRESSIVE CUBE STRENGTH IS ASSUMED TO BE 1.25 TIMES THE

COMPRESSIVE STRENGTH OF 150 MM X 300 MM CYLINDERS.) PRE STRESSING REINFORCEMENT

CONSTRUCTION AND EXPANSION JOINT:

(MAX. SIZE AGGREGATE SHALL BE 20mm). 1. UNCOATED SEVEN WIRE HIGH TENSILE COLD DRAWN LOW RELAXATION STRAND,COMPLYING WITH

2 ALL CONSTRUCTION AND EXPANSION JOINTS SHALL BE PLACED AS SHOWN IN THE DRAWINGS

the rest part to shoulder 0.25 t/m

REINFORCED AND/OR PRESTRESSED CONCRETE DECK (PRECAST) 55 MPa THE REQUIREMENT OF ( ASTM A416 GRADE 270) SPECIFICATION WITH ULTIMATE STRENGTH OF 1770 MPa. AND AS PROVIDED IN THE SPECIFICATIONS AND AS DIRECTED BY THE ENGINEER.

(15t)

(15t) SUBSTRUCTURE (COLUMNS & FRAMES) 45 MPa

1.2 m

2

2.0 m

0.9 t/m ABUTMENTS 40 MPa

WL

Truck 60 t ROAD DECK SURFACING

35 MPa POST-TENSIONING SYSTEM

(15t) (15t) 1. THE TOP CONCRETE DECK SURFACE SHALL BE WATERPROOFED WITH AN APPROVED WATER

PILECAP 40 MPa 1. THE POST-TENSIONING SYSTEM TO BE UTILIZED SHALL BE AS PROPOSED BY THE CONTRACTOR

(10t) PROOFING SYSTEM.

(10t) APPROACH SLAB 40 MPa AND APPROVED BY THE ENGINEER.

1.2 m 2 BLINDING AND MASS CONCRETE 30 MPa 2. THE PRESTRESSING DESIGN JACKING FORCE AND ELONGATION ARE BASED ON THE FOLLOWING PARAMETERS:

2.0 m

0.25 t/m

WL

Truck 40 t AREA OF STRAND 0.6`` 150mm2 BEARING REPLACEMENT

(10t) (10t) NILE BRIDGE

PRESTRESSING STEEL ULTIMATE STRENGTH 1770 MPa.

REINFORCED AND/OR PRESTRESSED CONCRETE DECK (CAST-IN-SITU) 55 MPa 1. TRAFFIC LOAD SHALL BE LIMITED TO 50% DURING BEARINGS AND/OR EXPANSION JOINTS REPLACEMENT.

(5t) (5t) WOBBLE COEFFICIENT K=0.0017/M

SUBSTRUCTURE ( PIERS, PIER CAPS, COLUMNS & FRAMES ) 50 MPa 2. UPWARD DECK MOVEMENT DURING BEARING REPLACEMENTS SHALL NOT EXCEED 10 MM PLUS VERTICAL

1.2 m FRICTION CURVATURE COEFFICIENT U=0.20

2.0 m

2 50 MPa

WL

Truck 20 t 0.25 t/m DRAW-IN WEDGE,(ANCHORAGE SET) 6MM DEFORMATION OF BEARING.

PILECAP AT NILE PART 50 MPa

(5t) MODULES OF ELASTICITY 195000MPA 3. ALL JACKS IN THE SAME BENT SHALL BE SIMULTANEOUSLY JACKED .

(5t)

2 ALL STRUCTURAL COMPONENTS SHALL BE CONSTRUCTED OF ORDINARY PORTLAND

the rest part to shoulder 0.25 t/m CEMENT (OPC) WITH THE APPROPRIATE PROPORTIONS OF CEMENT REPLACEMENTS.

PRELIMINARY DESIGN

key plan Scale Drawing Size PROJET NO. Sheet No. Drawing Name

Draw By: Eng. A.E PROJECT

AS SHOWN A1 17049 - P STR. - 0A

El-Mansouriya Int.

Ring Road Int.

Shoubra Int.

Design By: Eng. A.E

MIDDLE RING ROAD

Abo Rawasha Int.

El-Maryotia Int.

DATE Review By: Eng. H.M Document Discipline Site Locateur Revision GENERAL NOTES

HELWAN NILE BRIDGE

Desert Road Int.

Date Modification Eng. No.

MAY - 2017 Approved By: Eng. A.B DWG CAIRO A

You might also like

- Plumbing Plans 2-StoreyDocument4 pagesPlumbing Plans 2-StoreySteel Caballero100% (1)

- Business PlanDocument11 pagesBusiness PlanRoadwell ZuluNo ratings yet

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- KBF (E5.2) : Service ManualDocument140 pagesKBF (E5.2) : Service ManualgeorgevarsasNo ratings yet

- API 650-Annex PDocument8 pagesAPI 650-Annex PSachinNo ratings yet

- You'Re On Consulting For Peak Performance-ManteshDocument272 pagesYou'Re On Consulting For Peak Performance-ManteshtaeBoNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- Veran Structural Model2Document1 pageVeran Structural Model2mr. oneNo ratings yet

- General Construction Notes: FC Engineering ServicesDocument1 pageGeneral Construction Notes: FC Engineering ServicesMac KYNo ratings yet

- Construction Notes: ElevationDocument1 pageConstruction Notes: ElevationJohn PaderangaNo ratings yet

- Typical Detail of Pre-Cast Boundary Wall Section A-A Section A-ADocument1 pageTypical Detail of Pre-Cast Boundary Wall Section A-A Section A-AManupriya KapleshNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Annex 02Document12 pagesAnnex 02rukshan jayasingheNo ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- Structural Notes: General: Reinforcing SteelDocument1 pageStructural Notes: General: Reinforcing SteelMark Allan RojoNo ratings yet

- Chauraghat Road Structural GAD R1Document18 pagesChauraghat Road Structural GAD R1Aicons Engineering Pvt. Ltd.No ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- Bridge Drawings 2019-09-02Document13 pagesBridge Drawings 2019-09-02yasirjurabaNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Saudi Arabian Oil Company: Co2 Fire Suppression System Piping LayoutDocument1 pageSaudi Arabian Oil Company: Co2 Fire Suppression System Piping Layoutsaleem shahidNo ratings yet

- Storm Water ManagementDocument1 pageStorm Water ManagementmmceplNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- 2024 - Powerhouse-Roadway Detailed DesignDocument1 page2024 - Powerhouse-Roadway Detailed Designadonis bibatNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- General NotesDocument1 pageGeneral NotesJohn Paul IldefonsoNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- Single 1Document1 pageSingle 1Altab ChNo ratings yet

- Slab Layout: DWG No 190811 DDocument14 pagesSlab Layout: DWG No 190811 DSaiful IslamNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- Roxas PWD BuildingDocument32 pagesRoxas PWD BuildingDennis SariegoNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- Wall Footing Details: Typical Connection Detail of Masonry WallDocument1 pageWall Footing Details: Typical Connection Detail of Masonry WallCarlo M. FloresNo ratings yet

- Design Example Reinforced Strip FoundationDocument6 pagesDesign Example Reinforced Strip FoundationFrans-Shixova ShipopyeniNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- GF, FF, SFDocument1 pageGF, FF, SFamit_saxena_10No ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- Temporary Staging (Marudi) - 1Document1 pageTemporary Staging (Marudi) - 1Kelvin LauNo ratings yet

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- Madhavaram radiance-GA-REV-1Document1 pageMadhavaram radiance-GA-REV-1suhailNo ratings yet

- Slab CulvertDocument3 pagesSlab CulvertSHIVANK SINGH PARIHARNo ratings yet

- Shuttering Arrangement For Box GirderDocument1 pageShuttering Arrangement For Box GirdershakeelNo ratings yet

- Uecp SD Cul 11.1 R00Document3 pagesUecp SD Cul 11.1 R00Anuradha KoswaththaNo ratings yet

- ORISSA SCHOOL (STR-ARCH) - Model - pdf73Document1 pageORISSA SCHOOL (STR-ARCH) - Model - pdf73NISHIKANTA MONDALNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- Construction Notes: Table of Lap Splice & Anchorage LengthDocument1 pageConstruction Notes: Table of Lap Splice & Anchorage LengthReyvel Sapaden CorcueraNo ratings yet

- Existing Culvert C401 - Temporary Supports DetailsDocument1 pageExisting Culvert C401 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Flooring Details DrawingDocument1 pageFlooring Details DrawingNilesh WaghNo ratings yet

- Final Sheet-Model - PDF 4Document1 pageFinal Sheet-Model - PDF 4Prateek SharmaNo ratings yet

- General Notes and Specifications: Roof Line Roof LineDocument1 pageGeneral Notes and Specifications: Roof Line Roof LineCyril AleaNo ratings yet

- Earthing BasementDocument1 pageEarthing BasementNad EemNo ratings yet

- 1 Dg-MahilaDocument1 page1 Dg-MahilaRohit JangidNo ratings yet

- Site Visit - Inspection of foundation Bottom The road and TrackDocument6 pagesSite Visit - Inspection of foundation Bottom The road and TrackMohamed DarwishNo ratings yet

- Recommendation for Manholes & Rigid DuctsDocument3 pagesRecommendation for Manholes & Rigid DuctsMohamed DarwishNo ratings yet

- Site Visit - Manholes-letterDocument9 pagesSite Visit - Manholes-letterMohamed DarwishNo ratings yet

- Site Visit Building SC3 B16 3Document3 pagesSite Visit Building SC3 B16 3Mohamed DarwishNo ratings yet

- Site Visit - Main Workshop- B13-1Document4 pagesSite Visit - Main Workshop- B13-1Mohamed DarwishNo ratings yet

- RCS - WF-006274 - B13.1-WSB-Main Workshop-Steel Structure Preliminary Design - CopyDocument6 pagesRCS - WF-006274 - B13.1-WSB-Main Workshop-Steel Structure Preliminary Design - CopyMohamed DarwishNo ratings yet

- RCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-GEN-550-0012ADocument4 pagesRCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-GEN-550-0012AMohamed DarwishNo ratings yet

- Rcs Hsr or Sub Plm Ddd Gl s01 d1 Gen 210 0033Document6 pagesRcs Hsr or Sub Plm Ddd Gl s01 d1 Gen 210 0033Mohamed DarwishNo ratings yet

- RCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-BMS-550-0013A (002)Document6 pagesRCS - HSR-OR-RPT-ELE-SPC-GL-S01-D1-BMS-550-0013A (002)Mohamed DarwishNo ratings yet

- RCS - Submission Review AndComment Sheet (002)Document4 pagesRCS - Submission Review AndComment Sheet (002)Mohamed DarwishNo ratings yet

- Navisworks CourseDocument45 pagesNavisworks CourseMohamed DarwishNo ratings yet

- RFT- Zone 4-01Document1 pageRFT- Zone 4-01Mohamed DarwishNo ratings yet

- Question Text Question Type Option 1: Multiple ChoiceDocument4 pagesQuestion Text Question Type Option 1: Multiple Choicemohamed elgammlNo ratings yet

- Full Final Drawing For ProjectDocument13 pagesFull Final Drawing For ProjectSabbir hossain100% (1)

- Fs 1-Episode 1Document9 pagesFs 1-Episode 1Louween Mendoza50% (2)

- Nyquist Stability CriterionDocument4 pagesNyquist Stability CriterionRajeev KumarNo ratings yet

- Philips Problem Solving - PRIDE - Poster Deck v02Document11 pagesPhilips Problem Solving - PRIDE - Poster Deck v02Vanita GanthadeNo ratings yet

- HP-19C & 29C Solutions Mathematics 1977 B&WDocument40 pagesHP-19C & 29C Solutions Mathematics 1977 B&WjjirwinNo ratings yet

- Demag ZKKE ManualDocument5 pagesDemag ZKKE ManualAlan MaciasNo ratings yet

- Captivity of Marine AnimalsDocument22 pagesCaptivity of Marine AnimalsJulia OrdonaNo ratings yet

- Assignment Ict (Display Qualities)Document3 pagesAssignment Ict (Display Qualities)Laiba SajjadNo ratings yet

- A Report On Self Defence Workshop For Women and GirlsDocument7 pagesA Report On Self Defence Workshop For Women and GirlsANJALI GHANSHANINo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- The English Paragraph: What Is A Paragraph?Document6 pagesThe English Paragraph: What Is A Paragraph?Khin Maung HtweNo ratings yet

- Stepan Formulation 1110Document2 pagesStepan Formulation 1110Jan Velasco100% (1)

- Ucsp Module 12Document17 pagesUcsp Module 12Aida SabadoNo ratings yet

- Class 1Document15 pagesClass 1eisha123No ratings yet

- EE420 SyllabusDocument1 pageEE420 Syllabussal1980No ratings yet

- Lecture7 PressureVessel Combined LoadingDocument22 pagesLecture7 PressureVessel Combined LoadingHarold Valle ReyesNo ratings yet

- Montessori Nomenclature Solar SystemDocument13 pagesMontessori Nomenclature Solar SystemJulieta NavoneNo ratings yet

- TAE40116 - RPL Application Kit V1Document11 pagesTAE40116 - RPL Application Kit V1Susan JackmanNo ratings yet

- Click Here For Download: (PDF) Fundamentals of EcologyDocument2 pagesClick Here For Download: (PDF) Fundamentals of EcologySujeet KumarNo ratings yet

- Mechanical Testing of CompositesDocument18 pagesMechanical Testing of CompositesSPARSH KUMAR AGARWALNo ratings yet

- Yto ZL50F CatalogoDocument97 pagesYto ZL50F CatalogoGerson Miotto50% (2)

- 12 ApspDocument6 pages12 ApspseemasuranaNo ratings yet

- BLF Q8 Narsil v1-3Document4 pagesBLF Q8 Narsil v1-3Guy Fawkes0% (1)

- 04.0 APA Style Citations and References August 2015Document28 pages04.0 APA Style Citations and References August 2015Rain BiNo ratings yet