Professional Documents

Culture Documents

DYWIDAG_GEWI_Plus_Threadbar_Data_Sheet

DYWIDAG_GEWI_Plus_Threadbar_Data_Sheet

Uploaded by

Simon BeaudoinCopyright:

Available Formats

You might also like

- Engineering Management Principles and Economics PDFDocument406 pagesEngineering Management Principles and Economics PDFkjsNo ratings yet

- TerpDocument5 pagesTerpAnas DarifNo ratings yet

- Chain DesignDocument5 pagesChain Designomid1302No ratings yet

- MK4 High Tensile Bars brochureDocument17 pagesMK4 High Tensile Bars brochuremoezartNo ratings yet

- Inersia Balok: (Bersadarkan SNI)Document4 pagesInersia Balok: (Bersadarkan SNI)Siti Mariam AnakpakijanNo ratings yet

- EcoFIT PolyethyleneDocument66 pagesEcoFIT PolyethyleneKadiri OlanrewajuNo ratings yet

- G-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration NonwovensDocument1 pageG-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration Nonwovensfer17165No ratings yet

- XC Flanged CouplingsDocument6 pagesXC Flanged Couplingstexwan_No ratings yet

- Icp Electric Tooth Clutch M Series Etcm: DesignDocument4 pagesIcp Electric Tooth Clutch M Series Etcm: DesignsandraNo ratings yet

- Jet Diffusers Single PagesDocument13 pagesJet Diffusers Single PagesFareethAbdullahNo ratings yet

- BS HWC4 PN25 2Document4 pagesBS HWC4 PN25 2Norman MendozaNo ratings yet

- Steel Fe 415 M20 Concrete: Lateral TiesDocument12 pagesSteel Fe 415 M20 Concrete: Lateral TiesSurekha DeshpandeNo ratings yet

- Cu 325Document4 pagesCu 325Pedja BekicNo ratings yet

- WP SDCDocument3 pagesWP SDCTaklimKamaludinNo ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Data Sheet: Valid From: 4/15/21Document2 pagesData Sheet: Valid From: 4/15/21Omar GuillenNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Disc Pack Coupling LP2Document4 pagesDisc Pack Coupling LP2Rakesh B BalehosurNo ratings yet

- Rubber DuckbillDocument3 pagesRubber DuckbillKumar NawneetNo ratings yet

- Tables, Notes and Design MethodsDocument3 pagesTables, Notes and Design MethodsSwaminathanNo ratings yet

- MNB 2Document1 pageMNB 2Phan Thanh BảoNo ratings yet

- Barrel Coupling PDFDocument1 pageBarrel Coupling PDFRajendra PagarNo ratings yet

- WP SDC HDocument3 pagesWP SDC HTaklimKamaludinNo ratings yet

- Detail Dimensi Material GRPDocument5 pagesDetail Dimensi Material GRPdwi noviana nugrohoNo ratings yet

- Gfps-Datasheet-Ball Valve Type 546 Pro PVC-U-800056529Document2 pagesGfps-Datasheet-Ball Valve Type 546 Pro PVC-U-800056529Amanda OliveiraNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Benny 37No ratings yet

- DYWIDAG_WR-E__F__GEWI__GEWI__Threadbar_Properties (1)Document1 pageDYWIDAG_WR-E__F__GEWI__GEWI__Threadbar_Properties (1)Simon BeaudoinNo ratings yet

- 220 Fi3 (Grade) : Deltas1 (MM)Document18 pages220 Fi3 (Grade) : Deltas1 (MM)Alin DiaconuNo ratings yet

- Datasheetuc 16 F 876 A 3Document10 pagesDatasheetuc 16 F 876 A 3Saurabh MishraNo ratings yet

- Brosur DIP - 2022Document2 pagesBrosur DIP - 2022agus hakimNo ratings yet

- K', Comp R/F Required 0.95dDocument6 pagesK', Comp R/F Required 0.95drifkasmnmNo ratings yet

- Toyo Rubber CouplingDocument14 pagesToyo Rubber CouplingGreg SanjayaNo ratings yet

- 2622-2x-0317 (DN65 To DN400)Document1 page2622-2x-0317 (DN65 To DN400)SHINOS 3SNo ratings yet

- RBL Spherical Plain BearingsDocument8 pagesRBL Spherical Plain BearingsRingball_GusNo ratings yet

- With Continuous Threaded Anchor Bolts On Both Sides, Welded Steel - EpoxyDocument3 pagesWith Continuous Threaded Anchor Bolts On Both Sides, Welded Steel - EpoxyeljammalNo ratings yet

- BKL - R+W CouplingsDocument4 pagesBKL - R+W Couplingsgökhan tanrıseverNo ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- DSI UK DYWI Drill Hollow Bar ENG PDFDocument16 pagesDSI UK DYWI Drill Hollow Bar ENG PDFFrans van der MerweNo ratings yet

- Calcul SelfsDocument45 pagesCalcul SelfsGUINo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- Spur Gears 9: Series 101Document52 pagesSpur Gears 9: Series 101Aiam PandianNo ratings yet

- Super-T Girders OpenPropertiesDocument1 pageSuper-T Girders OpenPropertiesRajeev SharanNo ratings yet

- Main Relief Valve and Waste Cone - : Submittal DrawingDocument2 pagesMain Relief Valve and Waste Cone - : Submittal Drawingumair186No ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- Redbook r5 C03a JawDocument8 pagesRedbook r5 C03a Jawaxel.correaNo ratings yet

- T Beam PDFDocument2 pagesT Beam PDFjabri kotaNo ratings yet

- HSG 01series of Hydraulic Cylinders: Performance ParametersDocument4 pagesHSG 01series of Hydraulic Cylinders: Performance ParametersHao VănNo ratings yet

- HSG 01series of Hydraulic Cylinders: Performance ParametersDocument4 pagesHSG 01series of Hydraulic Cylinders: Performance ParametersHao VănNo ratings yet

- Beam CalculationDocument9 pagesBeam CalculationPandiyan StrNo ratings yet

- RVNL Bridges Bar Bending ScheduleDocument12 pagesRVNL Bridges Bar Bending ScheduleSaraswati ChandraNo ratings yet

- Brochure SEU-20201010Document5 pagesBrochure SEU-20201010Sendy PratamaNo ratings yet

- BOM of EPC UttarakhandDocument8 pagesBOM of EPC UttarakhandAnonymous b9fkTYfEoRNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- Drop in Anchor PDFDocument1 pageDrop in Anchor PDFKABIR CHOPRANo ratings yet

- LFTC Flanged Bearing Dimensions.Document60 pagesLFTC Flanged Bearing Dimensions.stuart3962No ratings yet

- Filterpress - ENG - Rev 3 - MailDocument12 pagesFilterpress - ENG - Rev 3 - MailDaniele BacchiNo ratings yet

- Air Cylinder: Series A12, A13 AIR CYLINDERS Double Acting (Ø32 - 100) MMDocument7 pagesAir Cylinder: Series A12, A13 AIR CYLINDERS Double Acting (Ø32 - 100) MMgopi_krishnan_29No ratings yet

- Design No. F817: BXUVC.F817 Fire-Resistance RatingsDocument4 pagesDesign No. F817: BXUVC.F817 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Design No. F818: BXUVC.F818 Fire-Resistance RatingsDocument2 pagesDesign No. F818: BXUVC.F818 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Design No. Z810: BXUVC.Z810 Fire-Resistance RatingsDocument2 pagesDesign No. Z810: BXUVC.Z810 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Vulcraft Grating Manual Aug 23Document48 pagesVulcraft Grating Manual Aug 23Simon BeaudoinNo ratings yet

- PCA - Circular Concrete Tanks-1993Document59 pagesPCA - Circular Concrete Tanks-1993Simon BeaudoinNo ratings yet

- Evolution of Design Standards and Recorded Failures of Guyed TowersDocument8 pagesEvolution of Design Standards and Recorded Failures of Guyed TowersSimon BeaudoinNo ratings yet

- APA Performance Rated Rim Boards: D A T A F I L EDocument7 pagesAPA Performance Rated Rim Boards: D A T A F I L ESimon BeaudoinNo ratings yet

- Gt-7071-A&b - 081023 - eDocument16 pagesGt-7071-A&b - 081023 - eCarlos Andres GuzmanNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- Job Hazard Analysis TemplateDocument2 pagesJob Hazard Analysis TemplateIzmeer JaslanNo ratings yet

- Cicol NT SlurryDocument3 pagesCicol NT SlurryTori SmallNo ratings yet

- ACC Annual Report 2017Document360 pagesACC Annual Report 2017Anonymous wXV066fANo ratings yet

- Recurrent & Refresher Question Bank For Cabin CrewDocument31 pagesRecurrent & Refresher Question Bank For Cabin CrewMarkXI MarkXINo ratings yet

- 2017 Dec Intermediate 2 Exam ME IDocument2 pages2017 Dec Intermediate 2 Exam ME IshanthakumargcNo ratings yet

- Mis Practice QuizDocument3 pagesMis Practice QuizkmuthukaruppanNo ratings yet

- 1103 GBDocument28 pages1103 GBTien Hong DoNo ratings yet

- Jurnal 4Document84 pagesJurnal 4okesNo ratings yet

- Management Reporter 2012 For Microsoft Dynamics ERP: Installation and Configuration GuidesDocument27 pagesManagement Reporter 2012 For Microsoft Dynamics ERP: Installation and Configuration Guidesobad2011100% (1)

- Inventory Master Items Attributes Oracle EBS R12Document42 pagesInventory Master Items Attributes Oracle EBS R12arsal6323No ratings yet

- 2016 Commercial Transportation Trends PDFDocument12 pages2016 Commercial Transportation Trends PDFJose BarajasNo ratings yet

- Vendor Management TipsDocument12 pagesVendor Management Tipssushant_jhawerNo ratings yet

- Blanking or Stamping or Punching of Sheet Metal Project Report (Punch and Die)Document44 pagesBlanking or Stamping or Punching of Sheet Metal Project Report (Punch and Die)gopi_krishnan_2986% (22)

- Vendor Attendees: Supplier Name Date: AuditorsDocument5 pagesVendor Attendees: Supplier Name Date: AuditorsRahul kumarNo ratings yet

- Iso 15012-1-2013Document20 pagesIso 15012-1-2013Sorin SorinNo ratings yet

- MGT 214 - Module 2Document25 pagesMGT 214 - Module 2Muhammad FaisalNo ratings yet

- Kokeb Marble & Paint Factory June 2022Document9 pagesKokeb Marble & Paint Factory June 2022Kiya KinfeNo ratings yet

- Iso 26262tutorial 2010 FinalDocument160 pagesIso 26262tutorial 2010 FinalFurkan Aydoğan100% (2)

- 004 Aircraft General Information JUNE 12Document137 pages004 Aircraft General Information JUNE 12AraNo ratings yet

- Measuring Tapered Journals With An Fag TaperDocument7 pagesMeasuring Tapered Journals With An Fag TaperJuan Carlos CárdenasNo ratings yet

- C & G Graduate Level QS Past Papers 2014 - JuneDocument4 pagesC & G Graduate Level QS Past Papers 2014 - JuneDushan SenarathneNo ratings yet

- Compoud Water CycloneDocument16 pagesCompoud Water CycloneMarcos SoldadoNo ratings yet

- OMC Routes Aerodrome Instructions InformationDocument10 pagesOMC Routes Aerodrome Instructions InformationPero PericNo ratings yet

- Fluor Maintenance Assessment MethodologyDocument163 pagesFluor Maintenance Assessment MethodologyAndres Felipe Garcia Reina100% (2)

- 1.okay DieselDocument34 pages1.okay DieselUliAlejandroRodriguezCorianga100% (2)

- Explain Facility at Teradata For A QueryDocument13 pagesExplain Facility at Teradata For A QueryArvind VishwakarmaNo ratings yet

DYWIDAG_GEWI_Plus_Threadbar_Data_Sheet

DYWIDAG_GEWI_Plus_Threadbar_Data_Sheet

Uploaded by

Simon BeaudoinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DYWIDAG_GEWI_Plus_Threadbar_Data_Sheet

DYWIDAG_GEWI_Plus_Threadbar_Data_Sheet

Uploaded by

Simon BeaudoinCopyright:

Available Formats

DYWIDAG-Systems International Pty Ltd

Bennetts Green, NSW, Australia

Tel.: 02 4081 5500

Email: sales.au@dywidag.com

The DYWIDAG THREADBAR is a steel bar with continuous coarse threads hot rolled on two opposite

sides. The continuous threads allow for anchorage and coupler installation anyhere along the bar. The

coarse threads provide excellent bond to grout and are insensitive to dirt and damage. In addition,

there is no loss of strength due to thread cutting.

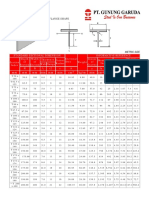

High Strength GEWI Plus Reinforcing Threadbar: TR Grade

Minimum Ultimate Grade (MPa) 800 800 800 800 800 800 800 800 800 800 800

Minimum Yield Grade (MPa) 670 670 670 670 670 670 670 670 670 670 670

Nominal Diameter (mm) 18 22 25 28 30 35 43 50 57.5 63.5 75

Minimum Breaking Load (kN) 204 304 393 493 565 770 1162 1571 2077 2534 3534

Minimum Yield Load (kN) 170 255 329 413 474 645 973 1316 1740 2122 2960

2

Cross-section Area (mm ) 254 380 491 616 707 962 1452 1964 2597 3167 4418

Maximum Thread Diameter (mm) 21.0 25.0 28.0 32.0 34.0 40.0 48.0 55.0 63.0 69.0 82.0

Unit Weight (kg/m) 2.00 2.98 3.85 4.83 5.55 7.55 11.40 15.41 20.38 24.86 34.68

Minimum Bar Protrusion: P1) (mm) 50 55 60 70 75 85 100 105 125 150 130

Dome Nut L (mm) 35 45 50 55 60 70 85 115 115 125 150

p/n: TR 2001 A/F2) (mm) 32 36 41 46 50 60 70 90 90 100 120

Hex Nut L (mm) 45 50 55 60 65 70 90 100 120 145 130

p/n: TR 2002 A/F2) (mm) 36 41 46 50 53 65 80 80 90 100 100

Coupler C (mm) 100 110 120 140 150 170 200 210 250 300 260

p/n: TR 3003 D (mm) 36 40 45 50 55 65 80 90 102 114 108

Typical Domed Plate for W (mm) 150 150 200 200 200 250 275 280 300 330 370

Soil Nails and T (mm) 10 12 12 16 16 16 50 55 65 70 75

Rock Bolts H (mm) 25 25 25 25 30 30 0 0 0 0 0

D or F D D D D D D F F F F F

Typical applications: Passive soil and rock anchors, soil nails, mini-piles, tie rods and reinforcement.

Specifications: Threads are right hand. High ductility and elasticity.

Notes

1) Minimum Threadbar protrusion to accommodate tensioning or coupling; P=½C (mm).

2) Width measured across flats of nut.

3) Bendable up to 35mm with 6D

4) Weldable with DSI weldinstuctions

5) Other hardware available not shown.

6) Corrosion protection available: pre-grouting in sheathing, hot dipped galvanising and epoxy coating.

7) ACRS approved according to AS 4671

P L P L H C

W W D

P

T T

You might also like

- Engineering Management Principles and Economics PDFDocument406 pagesEngineering Management Principles and Economics PDFkjsNo ratings yet

- TerpDocument5 pagesTerpAnas DarifNo ratings yet

- Chain DesignDocument5 pagesChain Designomid1302No ratings yet

- MK4 High Tensile Bars brochureDocument17 pagesMK4 High Tensile Bars brochuremoezartNo ratings yet

- Inersia Balok: (Bersadarkan SNI)Document4 pagesInersia Balok: (Bersadarkan SNI)Siti Mariam AnakpakijanNo ratings yet

- EcoFIT PolyethyleneDocument66 pagesEcoFIT PolyethyleneKadiri OlanrewajuNo ratings yet

- G-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration NonwovensDocument1 pageG-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration Nonwovensfer17165No ratings yet

- XC Flanged CouplingsDocument6 pagesXC Flanged Couplingstexwan_No ratings yet

- Icp Electric Tooth Clutch M Series Etcm: DesignDocument4 pagesIcp Electric Tooth Clutch M Series Etcm: DesignsandraNo ratings yet

- Jet Diffusers Single PagesDocument13 pagesJet Diffusers Single PagesFareethAbdullahNo ratings yet

- BS HWC4 PN25 2Document4 pagesBS HWC4 PN25 2Norman MendozaNo ratings yet

- Steel Fe 415 M20 Concrete: Lateral TiesDocument12 pagesSteel Fe 415 M20 Concrete: Lateral TiesSurekha DeshpandeNo ratings yet

- Cu 325Document4 pagesCu 325Pedja BekicNo ratings yet

- WP SDCDocument3 pagesWP SDCTaklimKamaludinNo ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Data Sheet: Valid From: 4/15/21Document2 pagesData Sheet: Valid From: 4/15/21Omar GuillenNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Disc Pack Coupling LP2Document4 pagesDisc Pack Coupling LP2Rakesh B BalehosurNo ratings yet

- Rubber DuckbillDocument3 pagesRubber DuckbillKumar NawneetNo ratings yet

- Tables, Notes and Design MethodsDocument3 pagesTables, Notes and Design MethodsSwaminathanNo ratings yet

- MNB 2Document1 pageMNB 2Phan Thanh BảoNo ratings yet

- Barrel Coupling PDFDocument1 pageBarrel Coupling PDFRajendra PagarNo ratings yet

- WP SDC HDocument3 pagesWP SDC HTaklimKamaludinNo ratings yet

- Detail Dimensi Material GRPDocument5 pagesDetail Dimensi Material GRPdwi noviana nugrohoNo ratings yet

- Gfps-Datasheet-Ball Valve Type 546 Pro PVC-U-800056529Document2 pagesGfps-Datasheet-Ball Valve Type 546 Pro PVC-U-800056529Amanda OliveiraNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Benny 37No ratings yet

- DYWIDAG_WR-E__F__GEWI__GEWI__Threadbar_Properties (1)Document1 pageDYWIDAG_WR-E__F__GEWI__GEWI__Threadbar_Properties (1)Simon BeaudoinNo ratings yet

- 220 Fi3 (Grade) : Deltas1 (MM)Document18 pages220 Fi3 (Grade) : Deltas1 (MM)Alin DiaconuNo ratings yet

- Datasheetuc 16 F 876 A 3Document10 pagesDatasheetuc 16 F 876 A 3Saurabh MishraNo ratings yet

- Brosur DIP - 2022Document2 pagesBrosur DIP - 2022agus hakimNo ratings yet

- K', Comp R/F Required 0.95dDocument6 pagesK', Comp R/F Required 0.95drifkasmnmNo ratings yet

- Toyo Rubber CouplingDocument14 pagesToyo Rubber CouplingGreg SanjayaNo ratings yet

- 2622-2x-0317 (DN65 To DN400)Document1 page2622-2x-0317 (DN65 To DN400)SHINOS 3SNo ratings yet

- RBL Spherical Plain BearingsDocument8 pagesRBL Spherical Plain BearingsRingball_GusNo ratings yet

- With Continuous Threaded Anchor Bolts On Both Sides, Welded Steel - EpoxyDocument3 pagesWith Continuous Threaded Anchor Bolts On Both Sides, Welded Steel - EpoxyeljammalNo ratings yet

- BKL - R+W CouplingsDocument4 pagesBKL - R+W Couplingsgökhan tanrıseverNo ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- DSI UK DYWI Drill Hollow Bar ENG PDFDocument16 pagesDSI UK DYWI Drill Hollow Bar ENG PDFFrans van der MerweNo ratings yet

- Calcul SelfsDocument45 pagesCalcul SelfsGUINo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- Spur Gears 9: Series 101Document52 pagesSpur Gears 9: Series 101Aiam PandianNo ratings yet

- Super-T Girders OpenPropertiesDocument1 pageSuper-T Girders OpenPropertiesRajeev SharanNo ratings yet

- Main Relief Valve and Waste Cone - : Submittal DrawingDocument2 pagesMain Relief Valve and Waste Cone - : Submittal Drawingumair186No ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- Redbook r5 C03a JawDocument8 pagesRedbook r5 C03a Jawaxel.correaNo ratings yet

- T Beam PDFDocument2 pagesT Beam PDFjabri kotaNo ratings yet

- HSG 01series of Hydraulic Cylinders: Performance ParametersDocument4 pagesHSG 01series of Hydraulic Cylinders: Performance ParametersHao VănNo ratings yet

- HSG 01series of Hydraulic Cylinders: Performance ParametersDocument4 pagesHSG 01series of Hydraulic Cylinders: Performance ParametersHao VănNo ratings yet

- Beam CalculationDocument9 pagesBeam CalculationPandiyan StrNo ratings yet

- RVNL Bridges Bar Bending ScheduleDocument12 pagesRVNL Bridges Bar Bending ScheduleSaraswati ChandraNo ratings yet

- Brochure SEU-20201010Document5 pagesBrochure SEU-20201010Sendy PratamaNo ratings yet

- BOM of EPC UttarakhandDocument8 pagesBOM of EPC UttarakhandAnonymous b9fkTYfEoRNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- Drop in Anchor PDFDocument1 pageDrop in Anchor PDFKABIR CHOPRANo ratings yet

- LFTC Flanged Bearing Dimensions.Document60 pagesLFTC Flanged Bearing Dimensions.stuart3962No ratings yet

- Filterpress - ENG - Rev 3 - MailDocument12 pagesFilterpress - ENG - Rev 3 - MailDaniele BacchiNo ratings yet

- Air Cylinder: Series A12, A13 AIR CYLINDERS Double Acting (Ø32 - 100) MMDocument7 pagesAir Cylinder: Series A12, A13 AIR CYLINDERS Double Acting (Ø32 - 100) MMgopi_krishnan_29No ratings yet

- Design No. F817: BXUVC.F817 Fire-Resistance RatingsDocument4 pagesDesign No. F817: BXUVC.F817 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Design No. F818: BXUVC.F818 Fire-Resistance RatingsDocument2 pagesDesign No. F818: BXUVC.F818 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Design No. Z810: BXUVC.Z810 Fire-Resistance RatingsDocument2 pagesDesign No. Z810: BXUVC.Z810 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- Vulcraft Grating Manual Aug 23Document48 pagesVulcraft Grating Manual Aug 23Simon BeaudoinNo ratings yet

- PCA - Circular Concrete Tanks-1993Document59 pagesPCA - Circular Concrete Tanks-1993Simon BeaudoinNo ratings yet

- Evolution of Design Standards and Recorded Failures of Guyed TowersDocument8 pagesEvolution of Design Standards and Recorded Failures of Guyed TowersSimon BeaudoinNo ratings yet

- APA Performance Rated Rim Boards: D A T A F I L EDocument7 pagesAPA Performance Rated Rim Boards: D A T A F I L ESimon BeaudoinNo ratings yet

- Gt-7071-A&b - 081023 - eDocument16 pagesGt-7071-A&b - 081023 - eCarlos Andres GuzmanNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- Job Hazard Analysis TemplateDocument2 pagesJob Hazard Analysis TemplateIzmeer JaslanNo ratings yet

- Cicol NT SlurryDocument3 pagesCicol NT SlurryTori SmallNo ratings yet

- ACC Annual Report 2017Document360 pagesACC Annual Report 2017Anonymous wXV066fANo ratings yet

- Recurrent & Refresher Question Bank For Cabin CrewDocument31 pagesRecurrent & Refresher Question Bank For Cabin CrewMarkXI MarkXINo ratings yet

- 2017 Dec Intermediate 2 Exam ME IDocument2 pages2017 Dec Intermediate 2 Exam ME IshanthakumargcNo ratings yet

- Mis Practice QuizDocument3 pagesMis Practice QuizkmuthukaruppanNo ratings yet

- 1103 GBDocument28 pages1103 GBTien Hong DoNo ratings yet

- Jurnal 4Document84 pagesJurnal 4okesNo ratings yet

- Management Reporter 2012 For Microsoft Dynamics ERP: Installation and Configuration GuidesDocument27 pagesManagement Reporter 2012 For Microsoft Dynamics ERP: Installation and Configuration Guidesobad2011100% (1)

- Inventory Master Items Attributes Oracle EBS R12Document42 pagesInventory Master Items Attributes Oracle EBS R12arsal6323No ratings yet

- 2016 Commercial Transportation Trends PDFDocument12 pages2016 Commercial Transportation Trends PDFJose BarajasNo ratings yet

- Vendor Management TipsDocument12 pagesVendor Management Tipssushant_jhawerNo ratings yet

- Blanking or Stamping or Punching of Sheet Metal Project Report (Punch and Die)Document44 pagesBlanking or Stamping or Punching of Sheet Metal Project Report (Punch and Die)gopi_krishnan_2986% (22)

- Vendor Attendees: Supplier Name Date: AuditorsDocument5 pagesVendor Attendees: Supplier Name Date: AuditorsRahul kumarNo ratings yet

- Iso 15012-1-2013Document20 pagesIso 15012-1-2013Sorin SorinNo ratings yet

- MGT 214 - Module 2Document25 pagesMGT 214 - Module 2Muhammad FaisalNo ratings yet

- Kokeb Marble & Paint Factory June 2022Document9 pagesKokeb Marble & Paint Factory June 2022Kiya KinfeNo ratings yet

- Iso 26262tutorial 2010 FinalDocument160 pagesIso 26262tutorial 2010 FinalFurkan Aydoğan100% (2)

- 004 Aircraft General Information JUNE 12Document137 pages004 Aircraft General Information JUNE 12AraNo ratings yet

- Measuring Tapered Journals With An Fag TaperDocument7 pagesMeasuring Tapered Journals With An Fag TaperJuan Carlos CárdenasNo ratings yet

- C & G Graduate Level QS Past Papers 2014 - JuneDocument4 pagesC & G Graduate Level QS Past Papers 2014 - JuneDushan SenarathneNo ratings yet

- Compoud Water CycloneDocument16 pagesCompoud Water CycloneMarcos SoldadoNo ratings yet

- OMC Routes Aerodrome Instructions InformationDocument10 pagesOMC Routes Aerodrome Instructions InformationPero PericNo ratings yet

- Fluor Maintenance Assessment MethodologyDocument163 pagesFluor Maintenance Assessment MethodologyAndres Felipe Garcia Reina100% (2)

- 1.okay DieselDocument34 pages1.okay DieselUliAlejandroRodriguezCorianga100% (2)

- Explain Facility at Teradata For A QueryDocument13 pagesExplain Facility at Teradata For A QueryArvind VishwakarmaNo ratings yet