Professional Documents

Culture Documents

201702020

201702020

Uploaded by

pkvssraoCopyright:

Available Formats

You might also like

- Meteorology Today An Introduction To Weather Climate and The Environment 2nd Edition Ahrens Solutions ManualDocument26 pagesMeteorology Today An Introduction To Weather Climate and The Environment 2nd Edition Ahrens Solutions ManualElizabethRuizrxka100% (45)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Dr. Nikolai KozyrevDocument12 pagesDr. Nikolai Kozyrevivica100% (2)

- English: Giving Expanded Definitions of WordsDocument24 pagesEnglish: Giving Expanded Definitions of WordsHellen Dea60% (5)

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringDocument23 pagesMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarNo ratings yet

- Refrigration Saving HeatDocument39 pagesRefrigration Saving HeatTanviNo ratings yet

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringDocument23 pagesMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarNo ratings yet

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Document47 pagesLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueNo ratings yet

- Solar-Driven Refrigeration SystemDocument7 pagesSolar-Driven Refrigeration SystemIJAMTESNo ratings yet

- Design Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeDocument6 pagesDesign Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeNeeraj SamadhiyaNo ratings yet

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 pagesRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimNo ratings yet

- JETIR1501025Document9 pagesJETIR1501025MARIVEL BASANo ratings yet

- Industrial Visit To Centralized Air Conditioning SystemDocument9 pagesIndustrial Visit To Centralized Air Conditioning SystemsoumikNo ratings yet

- Presentation of Engineering Design (HVAC)Document159 pagesPresentation of Engineering Design (HVAC)vamotir290No ratings yet

- Industrial Refrigeration TrainerDocument6 pagesIndustrial Refrigeration TrainerEugine BalomagaNo ratings yet

- Ice Plant ModelDocument12 pagesIce Plant ModelAtul Sartape100% (2)

- Solar Powered Air Conditioner For Car in Parking Condition Under The SunDocument12 pagesSolar Powered Air Conditioner For Car in Parking Condition Under The SunPRANAV PATILNo ratings yet

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Document8 pagesDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainNo ratings yet

- A Review of Literature On Air Cooled Heat ExchangerDocument7 pagesA Review of Literature On Air Cooled Heat ExchangerKent Jastin PiitNo ratings yet

- Improving Boiler Efficiency by Using Air PreheaterDocument14 pagesImproving Boiler Efficiency by Using Air PreheaterBudiharyatno Arif PangestuNo ratings yet

- The Effect of Capillary Tube Length On The Performance of Vapour Compression Refrigeration SystemDocument7 pagesThe Effect of Capillary Tube Length On The Performance of Vapour Compression Refrigeration SystemmahmudNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- GES's R.H.Sapat College of Engineering and Research Center, NashikDocument55 pagesGES's R.H.Sapat College of Engineering and Research Center, Nashikmrunali jadhavNo ratings yet

- An Analysis of The Performance of An Ejector RefriDocument6 pagesAn Analysis of The Performance of An Ejector RefriHalvor JohnsenNo ratings yet

- R&AC - Unit-3 LecturesDocument50 pagesR&AC - Unit-3 Lecturesganeshkumar4424kNo ratings yet

- Design of Chiller For Air Conditioning of Residential BuildingDocument7 pagesDesign of Chiller For Air Conditioning of Residential BuildingEditor IJTSRDNo ratings yet

- Presentation 1Document47 pagesPresentation 1Abhishek KumarNo ratings yet

- Study, Analysis and Design of Automobile Radiator PDFDocument10 pagesStudy, Analysis and Design of Automobile Radiator PDFRamón G. PachecoNo ratings yet

- Design and Heat Transfer Analysis of AC Condenser For Different MaterialsDocument7 pagesDesign and Heat Transfer Analysis of AC Condenser For Different MaterialsFawaz IqbalNo ratings yet

- Study of Refrigeration SystemsDocument28 pagesStudy of Refrigeration SystemsAkhil ShettyNo ratings yet

- Air Conditioning Systems Experiment: ProposalDocument16 pagesAir Conditioning Systems Experiment: ProposalShaktivell Letchumanan100% (1)

- Rac Lab ManualDocument69 pagesRac Lab ManualHrshita SinghNo ratings yet

- Analysis of Multiple Evaporator Refrigeration SystemDocument3 pagesAnalysis of Multiple Evaporator Refrigeration SystemInternational Jpurnal Of Technical Research And Applications0% (1)

- Ice Plant Test RigDocument58 pagesIce Plant Test Rigjuned shaikhNo ratings yet

- Air Cycle RefrigerationDocument2 pagesAir Cycle RefrigerationLuis Miguel Vargas CruzNo ratings yet

- Improving Boiler Efficiency by Using Air Preheater: V. Mallikarjuna N. Jashuva B. Rama Bhupal ReddyDocument14 pagesImproving Boiler Efficiency by Using Air Preheater: V. Mallikarjuna N. Jashuva B. Rama Bhupal ReddyHitesh PatelNo ratings yet

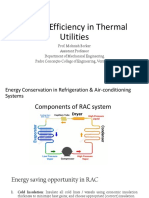

- Energy Efficiency in Thermal UtilitiesDocument14 pagesEnergy Efficiency in Thermal UtilitiesJoeb DsouzaNo ratings yet

- Hvac 3Document4 pagesHvac 3emumerr69No ratings yet

- 3 Theoretical Basis of Cold ProductionDocument6 pages3 Theoretical Basis of Cold ProductionAnastasia FlamehostNo ratings yet

- Proposal Lab Thermo Topic 2 COMPLETEDocument10 pagesProposal Lab Thermo Topic 2 COMPLETEsaperuddinNo ratings yet

- Irjet V5i1236 180319101623 PDFDocument6 pagesIrjet V5i1236 180319101623 PDFsuchismita swainNo ratings yet

- Design of Waste Heat Driven Vapour AdsorDocument5 pagesDesign of Waste Heat Driven Vapour AdsorsisayNo ratings yet

- Chiller SelectionDocument17 pagesChiller SelectionMiggy Pascual100% (1)

- The Design and Performance Analysis of Refrigeration System Using R12 & R134a RefrigerantsDocument6 pagesThe Design and Performance Analysis of Refrigeration System Using R12 & R134a RefrigerantsEugine BalomagaNo ratings yet

- Vol-1, Issue-5Document7 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- Refrigerator Air ConditionerDocument61 pagesRefrigerator Air ConditionerVijay GanapathyNo ratings yet

- Performance of Airpreheater PDFDocument32 pagesPerformance of Airpreheater PDFAMIT PRAJAPATINo ratings yet

- Color Coding and Other Info For ProjectDocument11 pagesColor Coding and Other Info For ProjectTanya Nataniel NoahNo ratings yet

- Industrial Refrigeration Projects: Challenges and Opportunities For Energy EfficiencyDocument12 pagesIndustrial Refrigeration Projects: Challenges and Opportunities For Energy Efficiencycefa84No ratings yet

- Osintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Document5 pagesOsintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Pooja ChughNo ratings yet

- Vapor Compression Cycle (History) : (Schmidt Et Al., 2002)Document8 pagesVapor Compression Cycle (History) : (Schmidt Et Al., 2002)jess calderonNo ratings yet

- Refrigeration and Air ConditioningDocument21 pagesRefrigeration and Air ConditioningShiva Kumar H MNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyFrom EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyNo ratings yet

- aberoumand2017Document8 pagesaberoumand2017pkvssraoNo ratings yet

- ANSYSWB Pages 3Document2 pagesANSYSWB Pages 3pkvssraoNo ratings yet

- Ansyswb Pages 8Document2 pagesAnsyswb Pages 8pkvssraoNo ratings yet

- ANSYSWB Pages 4Document2 pagesANSYSWB Pages 4pkvssraoNo ratings yet

- Ansyswb Pages 6Document2 pagesAnsyswb Pages 6pkvssraoNo ratings yet

- ANSYSWB Pages 2Document2 pagesANSYSWB Pages 2pkvssraoNo ratings yet

- ANSYSWB Page1Document2 pagesANSYSWB Page1pkvssraoNo ratings yet

- ANSYSWB Pages 1Document2 pagesANSYSWB Pages 1pkvssraoNo ratings yet

- ANSYSWB Pages2Document2 pagesANSYSWB Pages2pkvssraoNo ratings yet

- Fluid Mechanics and Hydraulic Machines Lab ManualDocument55 pagesFluid Mechanics and Hydraulic Machines Lab ManualpkvssraoNo ratings yet

- C10M01U02L01 National Board of Accreditation RKDDocument2 pagesC10M01U02L01 National Board of Accreditation RKDpkvssraoNo ratings yet

- Weather - Grade 6Document33 pagesWeather - Grade 6Teacher MaedelNo ratings yet

- How To Avoid A Climate DisasterDocument2 pagesHow To Avoid A Climate DisasterRaghdi HaneneNo ratings yet

- CAPF Study Plan and Book ListDocument20 pagesCAPF Study Plan and Book ListDinesh KumarNo ratings yet

- Air Conditioner-600527Document5 pagesAir Conditioner-600527samir addidasNo ratings yet

- Steam Blowing BASICSDocument14 pagesSteam Blowing BASICSadarsh_gangradeNo ratings yet

- BAUTISTA Gas StoichiometryDocument13 pagesBAUTISTA Gas StoichiometryTito V. Bautista Jr.No ratings yet

- ABF Pilot Training Manual: Meteorology (MET)Document22 pagesABF Pilot Training Manual: Meteorology (MET)Sanjay JayaratneNo ratings yet

- Installation Manual: Branch JointsDocument2 pagesInstallation Manual: Branch JointsFabianoGoesNo ratings yet

- Chemical Technology Production of Ammonia: Dr. Abhi Mukherjee Department of Chemical Engineering Contai PolytechnicDocument3 pagesChemical Technology Production of Ammonia: Dr. Abhi Mukherjee Department of Chemical Engineering Contai PolytechnicSk jahidul IslamNo ratings yet

- Factores de Conversion Gas NaturalDocument10 pagesFactores de Conversion Gas NaturalIvan SarmientoNo ratings yet

- Plants Help in Reducing Global WarmingDocument7 pagesPlants Help in Reducing Global Warmingshakshi panchalNo ratings yet

- Nitrogen N-5030 FillingDocument2 pagesNitrogen N-5030 FillingAnil KumarNo ratings yet

- Earths Climate Past and Future 3rd Edition Ruddiman Test BankDocument8 pagesEarths Climate Past and Future 3rd Edition Ruddiman Test BankThomasClinewpsix100% (21)

- Environmental Science (Module 7 Part 2)Document21 pagesEnvironmental Science (Module 7 Part 2)Rosemarie R. ReyesNo ratings yet

- 9.2 Carbon Dioxide & Methane As Greenhouse Gases MSDocument8 pages9.2 Carbon Dioxide & Methane As Greenhouse Gases MSRNo ratings yet

- The Planets of The Solar System With All Their DescriptionsDocument1 pageThe Planets of The Solar System With All Their DescriptionsMiranda SosaNo ratings yet

- Đề Ôn Thi Số 21: the following questionsDocument6 pagesĐề Ôn Thi Số 21: the following questionsHa Van AnhNo ratings yet

- Q8 - Atmospheric Pressure & Winds - IVDocument10 pagesQ8 - Atmospheric Pressure & Winds - IVprash_hingeNo ratings yet

- RT 5 3wewet N: Exam TaskDocument2 pagesRT 5 3wewet N: Exam TaskPataki-Peter HannaNo ratings yet

- Geography NotesDocument4 pagesGeography NotesPassw0rdNo ratings yet

- Rpactice ExamDocument6 pagesRpactice Examnaloma.juliacamilleNo ratings yet

- Effect of The Atmosphere On The PerformancesDocument4 pagesEffect of The Atmosphere On The PerformancesjuanNo ratings yet

- TEG Regeneration in Natural Gas Dehydration ProcessDocument54 pagesTEG Regeneration in Natural Gas Dehydration ProcessHira MahmoodNo ratings yet

- Micro Climate: Average High and Low TemperatureDocument9 pagesMicro Climate: Average High and Low Temperatureedward kenwayNo ratings yet

- APC Module 2 APCDocument14 pagesAPC Module 2 APCVadiraj HathwarNo ratings yet

- Tutorial 1Document2 pagesTutorial 1kaeshav manivannanNo ratings yet

- O Level Geography Notes Physical NotesDocument157 pagesO Level Geography Notes Physical NotesBrendon T100% (3)

201702020

201702020

Uploaded by

pkvssraoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

201702020

201702020

Uploaded by

pkvssraoCopyright:

Available Formats

INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD ISSN – 2455-0620 Volume - 3, Issue - 2, Feb - 2017

DESIGN OF HYBRID AIR COOLER USING VAPOUR COMPRESSION

REFRIGERATION SYSTEM

Vimalkirti Shende1, Sushil Borkar2, Touseef Iqbal Qureshi3

Asst. Prof. Nikhil Bhende1

1,2,3

U.G. Student, Department of Mechanical Engineering, J D Engineering College, Nagpur, Maharashtra, India

1

Associate Professor, Department Mechanical of Engineering, J D Engineering College, Nagpur, Maharashtra, India

Email –vimalkirti2012@gmail.com

Abstract: Now a days, global warming is one of the serious concern for environment to get protected from it

every one is taking help of technology by the means of different types of refrigeration system for comfort food

process, medicines, blood storage, humidity control, etc. use of refrigeration system is not only ineffective

environment but also give total comfort. In India middle class and poor families cannot afford all types of

Refrigeration system like an AC, Refrigerator, etc. Generally they purchase only Air cooler. To solve this we can

integrate Refrigeration system of AC, refrigerator and Air cooler in one product. In this type of system consist of

various components such as compressor, condenser, capillary tube, evaporator, motor, fan, etc. Our project is to

use technology of vapour compression refrigeration system.

Key words: compressor, condenser, evaporator, expansion valve, electric fan.

1. INTRODUCTION:

Refrigeration is the process of maintaining low temperature in comparison to surrounding temperature.

Refrigeration is the process of removing heat from an enclosed space or from a substance and rejecting it elsewhere

for the primary purpose of lowering the temperature of the enclose space or substance and then maintaining that lower

temperature .Basic concept of the project is to design an appliance that can work like AC as well as fan but will not

consume that much amount of electricity, cost, size and water. In this method of cooling system we are going to use

copper pipes, fan, compressor, cooling gas, compact body, condenser, Evaporator, etc.Cooling systems or air

conditioning systems are going to be in detail description in the following report; these systems also have huge

impacts on the surrounding environment. New method of cooling with concept of AC could solve the problems

generated by the existing air-conditioning installations. It not only reduces the power consumption but also increases

cooling effects and having less cost than air-conditioning system. It works in the absence of water and having less

maintenance as compare to domestic cooler. And its cost is cheaper than the AC, so it will beneficial for middle class

people.

2. WORKING CONCEPT:

The vapor-compression uses a circulating liquid refrigerant (R134a is also known as Tetrafluoroethane) as the

medium which absorbs and removes heat from the space to be cooled and subsequently rejects that heat

elsewhere. All such systems have four components: a compressor, a condenser, a thermal expansion valve (also

called a throttle valve or metering device) and an Evaporator.

That hot vapor is routed through a condenser where it is cooled and condensed into a liquid by flowing through a

coil or tubes with cool water or cool air flowing across the coil or tubes.

This is where the circulating refrigerant rejects heat from the system and the rejected heat is carried away.

3. DESIGN OF HYBRID COOLER:

Available online on – WWW.IJIRMF.COM Page 77

INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD ISSN – 2455-0620 Volume - 3, Issue - 2, Feb - 2017

4. COMPONENTS:

COMPRESSOR:- The primary advantage of a hermetic and semi-hermetic is that there is no route for the gas to

leak out of the system and less maintenance and it is widely used in household refrigerator. Compressor

compresses the refrigerant. We are use hermetically sealed compressor. In hermetically sealed compressor, the

compressor and motor are welded in steel casing and the two are connected by a common shaft. This makes whole

compressor and the motor a single compact and portable unit that can be handled easily. The hermetically sealed

compressor is very different from the traditional open type of compressor.

Compressor selection:- Compressor = 96 watt, btu-365, 92Kcal/hr

Capacity 1 TR, 50 Hz, 1PH

Condenser temp. range =-23.3°c to 54.4°c

Temp. Range = -5°c to 15°c

Specification:- Inlet pipe 6 mm, 220/50Hz, 1 PH, thermally protected, capacity 1 TR.

Fig1:-Compressor

CONDENSER: - The initial part of the cooling process de-superheats the gas before it is then turned back into

liquid. The condenser is a heat exchanger that rejects all the heat from the refrigeration system. This includes not

only the heat absorbed by the evaporator but also the heat energy to the compressor. The condenser accept hot,

high pressure refrigerant, usually superheated gas from the compressor and reject heat from the gas to some

cooler substance, usually air and water.

Specification: - Height 240 mm, Length 255 mm, No coil present in condenser with

IP/OP is 8, condenser pipe 10 mm, width 40 mm

Fig 2:- Condenser

EXPANSION VALVE: The capillary tube substituted for the convectional liquid line from the condenser

and soldered to the suction line to form a single heat exchanger. The function of expansion valve to allow the

low temperature and high pressure liquid enters with the restricted area, and they can be leave from the

expansion valve with low pressure and temperature in form of mixture of vapour and liquid, and then keep the

evaporator active. Expansion process one of the main factors responsible for energy loss in VCR cycle.

Specification: - Length of capillary tube 1300 mm. No of turns 11, Diameter is 2mm.

Available online on – WWW.IJIRMF.COM Page 78

INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD ISSN – 2455-0620 Volume - 3, Issue - 2, Feb - 2017

Fig3:- Expansion Valve

EVAPORATOR: - During this process it changes its state from a liquid to a gas. For the purpose of

compression, evaporator part also suggested. The evaporator has number of circular tube inside it as shown in

figure bellow, and is manufactured to yield same pressure drop as the original one. The number and diameter of

the tubes are selected iteratively to obtain the same design requirements, such as, heat load, pressure drop, at

the inlet and exit condition.

Fig4:- Evaporator

FAN:-An apparatus rotating blades that create a current of air for cooling or ventilation.

Specification:- Blade diameter is 234 mm , Angle is 230 .

Fig 5:- Fan

MOTOR:

1. Electric motor is used to convert electrical energy into mechanical energy.

2. In particular, the squirrel-cage design is the most widely used electric motor in industrial Applications.

3. Electric motors are used to produce linear and rotary forces (torque).

4. This motor runs at 1500 rpm & 1.5 HP.

5. We used copper winding motor.

Fig6:- Motor

Available online on – WWW.IJIRMF.COM Page 79

INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD ISSN – 2455-0620 Volume - 3, Issue - 2, Feb - 2017

REFRIGERANT:-

1. In this project we are use a refrigerant is R-134a. It is also known as tetrafluroethane (CH3CH2F) from the

family of HFC refrigerant.

2. Currently it is also being widely used in the air conditioning system in newer automotive vehicles. It exists

in gas form when

3. Expose to the environment as the boiling temperature is -14.9°F or -26.1°C.

4. The CFCs and HCFCs refrigerants produce more defects to ozone layer.

5. Hence we are used to R134a and concluded that energetic defect occurred in compressor was highest as

compare to the other refrigerant through their analysis it has been found that instead of 145g of R134a if

60g of R600a is use in consider system gave same performance which ultimately result in economical

advantages.

V. Analysis of standard vapour compression refrigeration system:-

Fig 7:- Standard vapour compression refrigeration cycle on p-h chart

Evaporator:

Heat transfer rate at evaporator or refrigeration capacity Qe=m(h1-h4)

The evaporator pressure P=Psat(Te)

Where,

m-mass flow rate in kg/s

h1, h4 – are specific enthalpies kj/kg

Psat- saturation temperature

Te-evaporator temperature

Compressor :

Power input to the compressor Wc=m(h2-h1)

h1, h2-specific enthalpies

Condenser :

Heat transfer rate of condenser Qc=m(h2-h3)

h1, h2-specific enthalpies

Expansion device: h3=h4

The COP of the system is given by

COP= (Qe/We) = (m (h1-h4)/m (h2-h1)) = (h1-h4)/ (h2-h1)

At any point in the cycle , the mass floe rate of refrigerant m can be written in terms of volumetric flow rate and

specific volume at that point i.e.,

M=V/v

Applying this equation to the inlet condition of the compressor

M=V1/v

Where, V1-volumetric flow rate at compressor inlet, v1-indication of the size if the compressor.

The refrigeration capacity in terms of volumetric flow rate

Qe=m (h1-h4) =V1 ((h1-h4)/v1)

(h1-h4)/v1-volumetric effect (kj/m3)

Available online on – WWW.IJIRMF.COM Page 80

INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD ISSN – 2455-0620 Volume - 3, Issue - 2, Feb - 2017

5. CONCLUSION:

R134a refrigerant is non-toxic and does not flare up within the whole range of operational temperatures. This

project is very cheap and effective as compared with the conventional cooler and air conditioner system as it based on

VCRs system. It has very low power consumption which ultimately increases the COP of the system which increases

the cooling effect (refrigeration effect) of the system. It has very low effect on environment as it saves electricity and

water. The concept is very cost effective as compared to AC and Very Energy Effective system.

6. LITERATURE REVIEW:

Taliv Hussain , Arjun Sharma, “Effect Of Sub-cooling in VCRS Cycle and Compared to simple VCRS

System” , ELK Asia Pacific Journal ,Punjab 978-81-930411-4-7.

According to this paper, Decreasing the consumption of power in a vapors compression air conditioning

system with increase in refrigeration effect and reduction of compressor work is a major concern and

challenging problem especially in the area where extreme weather conditions of about 50°C

exists.Experimental results show that the use of sub-cooling by heat exchanger will improve the COP.

G Venkatarathnam , S Srinivasa Murthy,” Refrigerants for Vapour Compression Refrigeration Systems”,

General Article on Feb 2012.

In this article, various issues related to this changeover of refrigerants being used in vapor compression

refrigeration systems are discussed. This paper Discuss the mandate of Montreal Protocol banning ozone

depleting substances, and Kyoto Protocol later on curtailing the use of substances which contribute to global

warming, conventional refrigerants are to be replaced by environment friendly working fluids.

R. T. Saudagar, U. S. Wankhede, “Experimental Analysis of Vapor Compression Refrigeration System with

Diffuser at Condenser Inlet”, International Journal of Engineering and Advanced Technology (IJEAT) on

April 2013.

This concept reduces size of condenser to achieve the same system efficiency. This paper discusses design and

testing of diffuser at condenser inlet in vapors compression refrigeration system.

K. Nagalakshmi , G. Marurhiprasad Yadav, “The Design and Performance Analysis of Refrigeration System

Using R12 & R134a Refrigerants”, Int. Journal of Engineering Research and Applications Feb on 2014.

In this report, the design and performance analysis of refrigeration system using R12 & R134a refrigerants are

presented. The design calculations of the suitable and necessary refrigerator equipment and their results are

also reported here.

REFERENCES:

1. Taliv Hussain, Arjun Sharma, “Effect of Sub-cooling in VCRS Cycle and Compared to simple VCRS

System”, ELK Asia Pacific Journal Punjab 978-81-930411-4-7.

2. G Venkatarathnam, S Srinivasa Murthy,” Refrigerants for Vapor Compression Refrigeration Systems”,

General Article Feb 2012.

3. R. T. Saudagar, U. S. Wankhede, “Experimental Analysis of Vapor Compression Refrigeration System

with Diffuser at Condenser Inlet”, International Journal of Engineering and Advanced Technology

(IJEAT) April 2013.

4. K. Nagalakshmi, G. Marurhiprasad Yadav, “The Design and Performance Analysis of Refrigeration

System Using R12 & R134a Refrigerants”, Int. Journal of Engineering Research and Applications Feb on

2014.

5. Shireesha Mary Ch, Nandini Ch, Divya Samala, Siva Kumar B, Parthasarathy Garrr, “A review: Increase

in Performance of vapor compression refrigeration system using fan“, International Journal of

Engineering and Applied Sciences.

Available online on – WWW.IJIRMF.COM Page 81

You might also like

- Meteorology Today An Introduction To Weather Climate and The Environment 2nd Edition Ahrens Solutions ManualDocument26 pagesMeteorology Today An Introduction To Weather Climate and The Environment 2nd Edition Ahrens Solutions ManualElizabethRuizrxka100% (45)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Dr. Nikolai KozyrevDocument12 pagesDr. Nikolai Kozyrevivica100% (2)

- English: Giving Expanded Definitions of WordsDocument24 pagesEnglish: Giving Expanded Definitions of WordsHellen Dea60% (5)

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringDocument23 pagesMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarNo ratings yet

- Refrigration Saving HeatDocument39 pagesRefrigration Saving HeatTanviNo ratings yet

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringDocument23 pagesMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarNo ratings yet

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Document47 pagesLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueNo ratings yet

- Solar-Driven Refrigeration SystemDocument7 pagesSolar-Driven Refrigeration SystemIJAMTESNo ratings yet

- Design Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeDocument6 pagesDesign Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeNeeraj SamadhiyaNo ratings yet

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 pagesRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimNo ratings yet

- JETIR1501025Document9 pagesJETIR1501025MARIVEL BASANo ratings yet

- Industrial Visit To Centralized Air Conditioning SystemDocument9 pagesIndustrial Visit To Centralized Air Conditioning SystemsoumikNo ratings yet

- Presentation of Engineering Design (HVAC)Document159 pagesPresentation of Engineering Design (HVAC)vamotir290No ratings yet

- Industrial Refrigeration TrainerDocument6 pagesIndustrial Refrigeration TrainerEugine BalomagaNo ratings yet

- Ice Plant ModelDocument12 pagesIce Plant ModelAtul Sartape100% (2)

- Solar Powered Air Conditioner For Car in Parking Condition Under The SunDocument12 pagesSolar Powered Air Conditioner For Car in Parking Condition Under The SunPRANAV PATILNo ratings yet

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Document8 pagesDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainNo ratings yet

- A Review of Literature On Air Cooled Heat ExchangerDocument7 pagesA Review of Literature On Air Cooled Heat ExchangerKent Jastin PiitNo ratings yet

- Improving Boiler Efficiency by Using Air PreheaterDocument14 pagesImproving Boiler Efficiency by Using Air PreheaterBudiharyatno Arif PangestuNo ratings yet

- The Effect of Capillary Tube Length On The Performance of Vapour Compression Refrigeration SystemDocument7 pagesThe Effect of Capillary Tube Length On The Performance of Vapour Compression Refrigeration SystemmahmudNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- GES's R.H.Sapat College of Engineering and Research Center, NashikDocument55 pagesGES's R.H.Sapat College of Engineering and Research Center, Nashikmrunali jadhavNo ratings yet

- An Analysis of The Performance of An Ejector RefriDocument6 pagesAn Analysis of The Performance of An Ejector RefriHalvor JohnsenNo ratings yet

- R&AC - Unit-3 LecturesDocument50 pagesR&AC - Unit-3 Lecturesganeshkumar4424kNo ratings yet

- Design of Chiller For Air Conditioning of Residential BuildingDocument7 pagesDesign of Chiller For Air Conditioning of Residential BuildingEditor IJTSRDNo ratings yet

- Presentation 1Document47 pagesPresentation 1Abhishek KumarNo ratings yet

- Study, Analysis and Design of Automobile Radiator PDFDocument10 pagesStudy, Analysis and Design of Automobile Radiator PDFRamón G. PachecoNo ratings yet

- Design and Heat Transfer Analysis of AC Condenser For Different MaterialsDocument7 pagesDesign and Heat Transfer Analysis of AC Condenser For Different MaterialsFawaz IqbalNo ratings yet

- Study of Refrigeration SystemsDocument28 pagesStudy of Refrigeration SystemsAkhil ShettyNo ratings yet

- Air Conditioning Systems Experiment: ProposalDocument16 pagesAir Conditioning Systems Experiment: ProposalShaktivell Letchumanan100% (1)

- Rac Lab ManualDocument69 pagesRac Lab ManualHrshita SinghNo ratings yet

- Analysis of Multiple Evaporator Refrigeration SystemDocument3 pagesAnalysis of Multiple Evaporator Refrigeration SystemInternational Jpurnal Of Technical Research And Applications0% (1)

- Ice Plant Test RigDocument58 pagesIce Plant Test Rigjuned shaikhNo ratings yet

- Air Cycle RefrigerationDocument2 pagesAir Cycle RefrigerationLuis Miguel Vargas CruzNo ratings yet

- Improving Boiler Efficiency by Using Air Preheater: V. Mallikarjuna N. Jashuva B. Rama Bhupal ReddyDocument14 pagesImproving Boiler Efficiency by Using Air Preheater: V. Mallikarjuna N. Jashuva B. Rama Bhupal ReddyHitesh PatelNo ratings yet

- Energy Efficiency in Thermal UtilitiesDocument14 pagesEnergy Efficiency in Thermal UtilitiesJoeb DsouzaNo ratings yet

- Hvac 3Document4 pagesHvac 3emumerr69No ratings yet

- 3 Theoretical Basis of Cold ProductionDocument6 pages3 Theoretical Basis of Cold ProductionAnastasia FlamehostNo ratings yet

- Proposal Lab Thermo Topic 2 COMPLETEDocument10 pagesProposal Lab Thermo Topic 2 COMPLETEsaperuddinNo ratings yet

- Irjet V5i1236 180319101623 PDFDocument6 pagesIrjet V5i1236 180319101623 PDFsuchismita swainNo ratings yet

- Design of Waste Heat Driven Vapour AdsorDocument5 pagesDesign of Waste Heat Driven Vapour AdsorsisayNo ratings yet

- Chiller SelectionDocument17 pagesChiller SelectionMiggy Pascual100% (1)

- The Design and Performance Analysis of Refrigeration System Using R12 & R134a RefrigerantsDocument6 pagesThe Design and Performance Analysis of Refrigeration System Using R12 & R134a RefrigerantsEugine BalomagaNo ratings yet

- Vol-1, Issue-5Document7 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- Refrigerator Air ConditionerDocument61 pagesRefrigerator Air ConditionerVijay GanapathyNo ratings yet

- Performance of Airpreheater PDFDocument32 pagesPerformance of Airpreheater PDFAMIT PRAJAPATINo ratings yet

- Color Coding and Other Info For ProjectDocument11 pagesColor Coding and Other Info For ProjectTanya Nataniel NoahNo ratings yet

- Industrial Refrigeration Projects: Challenges and Opportunities For Energy EfficiencyDocument12 pagesIndustrial Refrigeration Projects: Challenges and Opportunities For Energy Efficiencycefa84No ratings yet

- Osintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Document5 pagesOsintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Pooja ChughNo ratings yet

- Vapor Compression Cycle (History) : (Schmidt Et Al., 2002)Document8 pagesVapor Compression Cycle (History) : (Schmidt Et Al., 2002)jess calderonNo ratings yet

- Refrigeration and Air ConditioningDocument21 pagesRefrigeration and Air ConditioningShiva Kumar H MNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyFrom EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyNo ratings yet

- aberoumand2017Document8 pagesaberoumand2017pkvssraoNo ratings yet

- ANSYSWB Pages 3Document2 pagesANSYSWB Pages 3pkvssraoNo ratings yet

- Ansyswb Pages 8Document2 pagesAnsyswb Pages 8pkvssraoNo ratings yet

- ANSYSWB Pages 4Document2 pagesANSYSWB Pages 4pkvssraoNo ratings yet

- Ansyswb Pages 6Document2 pagesAnsyswb Pages 6pkvssraoNo ratings yet

- ANSYSWB Pages 2Document2 pagesANSYSWB Pages 2pkvssraoNo ratings yet

- ANSYSWB Page1Document2 pagesANSYSWB Page1pkvssraoNo ratings yet

- ANSYSWB Pages 1Document2 pagesANSYSWB Pages 1pkvssraoNo ratings yet

- ANSYSWB Pages2Document2 pagesANSYSWB Pages2pkvssraoNo ratings yet

- Fluid Mechanics and Hydraulic Machines Lab ManualDocument55 pagesFluid Mechanics and Hydraulic Machines Lab ManualpkvssraoNo ratings yet

- C10M01U02L01 National Board of Accreditation RKDDocument2 pagesC10M01U02L01 National Board of Accreditation RKDpkvssraoNo ratings yet

- Weather - Grade 6Document33 pagesWeather - Grade 6Teacher MaedelNo ratings yet

- How To Avoid A Climate DisasterDocument2 pagesHow To Avoid A Climate DisasterRaghdi HaneneNo ratings yet

- CAPF Study Plan and Book ListDocument20 pagesCAPF Study Plan and Book ListDinesh KumarNo ratings yet

- Air Conditioner-600527Document5 pagesAir Conditioner-600527samir addidasNo ratings yet

- Steam Blowing BASICSDocument14 pagesSteam Blowing BASICSadarsh_gangradeNo ratings yet

- BAUTISTA Gas StoichiometryDocument13 pagesBAUTISTA Gas StoichiometryTito V. Bautista Jr.No ratings yet

- ABF Pilot Training Manual: Meteorology (MET)Document22 pagesABF Pilot Training Manual: Meteorology (MET)Sanjay JayaratneNo ratings yet

- Installation Manual: Branch JointsDocument2 pagesInstallation Manual: Branch JointsFabianoGoesNo ratings yet

- Chemical Technology Production of Ammonia: Dr. Abhi Mukherjee Department of Chemical Engineering Contai PolytechnicDocument3 pagesChemical Technology Production of Ammonia: Dr. Abhi Mukherjee Department of Chemical Engineering Contai PolytechnicSk jahidul IslamNo ratings yet

- Factores de Conversion Gas NaturalDocument10 pagesFactores de Conversion Gas NaturalIvan SarmientoNo ratings yet

- Plants Help in Reducing Global WarmingDocument7 pagesPlants Help in Reducing Global Warmingshakshi panchalNo ratings yet

- Nitrogen N-5030 FillingDocument2 pagesNitrogen N-5030 FillingAnil KumarNo ratings yet

- Earths Climate Past and Future 3rd Edition Ruddiman Test BankDocument8 pagesEarths Climate Past and Future 3rd Edition Ruddiman Test BankThomasClinewpsix100% (21)

- Environmental Science (Module 7 Part 2)Document21 pagesEnvironmental Science (Module 7 Part 2)Rosemarie R. ReyesNo ratings yet

- 9.2 Carbon Dioxide & Methane As Greenhouse Gases MSDocument8 pages9.2 Carbon Dioxide & Methane As Greenhouse Gases MSRNo ratings yet

- The Planets of The Solar System With All Their DescriptionsDocument1 pageThe Planets of The Solar System With All Their DescriptionsMiranda SosaNo ratings yet

- Đề Ôn Thi Số 21: the following questionsDocument6 pagesĐề Ôn Thi Số 21: the following questionsHa Van AnhNo ratings yet

- Q8 - Atmospheric Pressure & Winds - IVDocument10 pagesQ8 - Atmospheric Pressure & Winds - IVprash_hingeNo ratings yet

- RT 5 3wewet N: Exam TaskDocument2 pagesRT 5 3wewet N: Exam TaskPataki-Peter HannaNo ratings yet

- Geography NotesDocument4 pagesGeography NotesPassw0rdNo ratings yet

- Rpactice ExamDocument6 pagesRpactice Examnaloma.juliacamilleNo ratings yet

- Effect of The Atmosphere On The PerformancesDocument4 pagesEffect of The Atmosphere On The PerformancesjuanNo ratings yet

- TEG Regeneration in Natural Gas Dehydration ProcessDocument54 pagesTEG Regeneration in Natural Gas Dehydration ProcessHira MahmoodNo ratings yet

- Micro Climate: Average High and Low TemperatureDocument9 pagesMicro Climate: Average High and Low Temperatureedward kenwayNo ratings yet

- APC Module 2 APCDocument14 pagesAPC Module 2 APCVadiraj HathwarNo ratings yet

- Tutorial 1Document2 pagesTutorial 1kaeshav manivannanNo ratings yet

- O Level Geography Notes Physical NotesDocument157 pagesO Level Geography Notes Physical NotesBrendon T100% (3)