Professional Documents

Culture Documents

Guardman Datasheet 2022 P Compressed

Guardman Datasheet 2022 P Compressed

Uploaded by

JEAN FELLIPE BARROSCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guardman Datasheet 2022 P Compressed

Guardman Datasheet 2022 P Compressed

Uploaded by

JEAN FELLIPE BARROSCopyright:

Available Formats

Guardman

Datasheet

Industry Mandals Guardman has been developed, manufactured and continuously

Fire Fighting updated since 1960’s.

It’s a World Class Lay-Flat hose made of a special rubber blend extruded

through the circular woven polyester jacket, ensuring an exceptional good

bonding and no delamination.

Our red fire hose has been chosen by the most demanding customers

for decades.

Key Features

• Developed and manufactured since 1960’s.

• Can withstand great physical strain and temperature fluctuation.

• Light weight design.

• Operating temperature from -30°C to +75°C ( -22°F to +167°F). Intermittent use up to +80°C (+176°F).

• Fully extruded hose where the rubber blend has been extruded through the circular woven

polyester jacket, ensuring exceptionally good bonding and no delimitation.

Design

• The hose is designed to absorb the pressure increase by swelling rather than stretching. This means

increased diameter under pressure and reduced friction loss.

• The rubber blend has added UV barrier to prevent damage to the rubber from UV radiation. It can stand

most of the commonly used chemicals and low aromatic oil products.

Advantages

• Specifically designed for marine use providing the user a long life product suitable for extreme climatic

and fire fighting conditions.

Guardman (Technical data) ISSUE 3.0 - 13.08.21

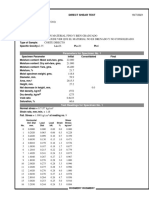

Internal Diameter Wall Thickness Weight Burst Pressure Tensile Strength

Inch mm Inch mm Lbs / ft Kg / m Psi Bar X1000 lbs Tons

1 1/2 38.0 + 1.6 0.09 2.2 0.23 0.34 940 65 6.9 3.1

1 2/3 42.0 + 1.6 0.09 2.2 0.23 0.32 940 65 6.9 3.1

1 3/4 45.0 + 1.6 0.09 2.2 0.23 0.35 725 50 7.6 3.4

2 51.0 + 2.0 0.09 2.2 0.29 0.44 700 48 8.7 3.9

2 1/2 65.0 + 2.0 0.09 2.2 0.38 0.57 700 48 11.1 5.0

3 76.0 + 2.0 0.09 2.4 0.49 0.73 680 47 15.6 7.0

3 1/2 90.0 + 2.0 0.11 2.7 0.67 1.00 640 44 21.3 9.6

4 102.0 + 2.5 0.11 2.8 0.77 1.15 610 42 20.4 9.2

6 150.0 + 3.0 0.13 3.3 1.27 1.90 610 42 35.8 16.1

NOTE: Safety factor (BP/WP) is 3:1, meaning actual Working pressure should not exceed 1/3 of the listed Burst pressure

Contact: sales@mandals.com. +47 3827 2400. Nordre Banegate 26, 4515. Mandals, Norway Org. No. NO 998 281 636 MVA

www.mandals.com

Legacy Through Innovation

Made in Norway

You might also like

- A Requiem To Mother EarthDocument5 pagesA Requiem To Mother EarthSandra SabuNo ratings yet

- Unconfined Compression Test 33Document12 pagesUnconfined Compression Test 33Helio García50% (2)

- Brochure-Ultraman-18 03 20Document1 pageBrochure-Ultraman-18 03 20Tubos FiltrosNo ratings yet

- Mandals - AntistaticaDocument1 pageMandals - Antistaticaplain xiaNo ratings yet

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- 12.1031 - Balflex Vacuum Light & HeavyDocument2 pages12.1031 - Balflex Vacuum Light & HeavyJuan Alberto Mendoza VegaNo ratings yet

- FODRX06YDocument3 pagesFODRX06YChristian Camilo Suarez RodriguezNo ratings yet

- PP-R Pipes & Fittings: Technical CatalogueDocument24 pagesPP-R Pipes & Fittings: Technical CataloguevictorNo ratings yet

- Mandals - AquamanDocument1 pageMandals - Aquamanplain xiaNo ratings yet

- TR 60Document3 pagesTR 60Narayanan MoorthyNo ratings yet

- Amc Bentonite Pellets R30 PDSDocument1 pageAmc Bentonite Pellets R30 PDSYusufi GushavNo ratings yet

- Technical Data For Pipes Conforming To Astm A-53.gr A&b SCHDocument1 pageTechnical Data For Pipes Conforming To Astm A-53.gr A&b SCHAltaf ur RehmanNo ratings yet

- iWASH Civil Works and Sanitation and Hygiene Programming: D R Watsan HubDocument40 pagesiWASH Civil Works and Sanitation and Hygiene Programming: D R Watsan Hubsheil.cogayNo ratings yet

- Catalog of Henan Central Plain CableDocument12 pagesCatalog of Henan Central Plain CableAgnes CastilloNo ratings yet

- Technical Submittal For Pipes (Interpipe)Document18 pagesTechnical Submittal For Pipes (Interpipe)ahsan100% (1)

- FT Vidrio Plomado MEDX-GAMMADocument2 pagesFT Vidrio Plomado MEDX-GAMMACarlos Manuel Alban RuizNo ratings yet

- TMG PC Strands, Wire & BarDocument10 pagesTMG PC Strands, Wire & BarHenrique Braglia PachecoNo ratings yet

- Technical Factor HWDocument14 pagesTechnical Factor HWKhoa Lê TrườngNo ratings yet

- Mandals Brochure SUPERMAN HVTDocument1 pageMandals Brochure SUPERMAN HVTTubos FiltrosNo ratings yet

- Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsDocument2 pagesStrux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsneilNo ratings yet

- 2.2.16 KaMOS® Test Seal RingDocument3 pages2.2.16 KaMOS® Test Seal RingAmmar KmkNo ratings yet

- Brosur TAL JEC 3406 - Rev27Document1 pageBrosur TAL JEC 3406 - Rev27Muhammad Yusuf100% (2)

- TEW/AWM 1015/ 1019/1020/1230 MTW: ApplicationsDocument2 pagesTEW/AWM 1015/ 1019/1020/1230 MTW: ApplicationsJesús SánchezNo ratings yet

- Schedule 80 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 PVC Pipe Dimensions & Pressure RatingsprathapNo ratings yet

- SSBP Company ProfileDocument10 pagesSSBP Company ProfileRian HeriawanNo ratings yet

- Dripnet PC HWD Technical Product SheetDocument16 pagesDripnet PC HWD Technical Product SheetMartín BrunelloNo ratings yet

- Tubing, Casing and Drill Pipe Stretch DataDocument34 pagesTubing, Casing and Drill Pipe Stretch DataNicasio AlonzoNo ratings yet

- SMDJSW Sta 1003 v5 Tr60Document3 pagesSMDJSW Sta 1003 v5 Tr60syedaliabl2023No ratings yet

- DN Pipe PDFDocument6 pagesDN Pipe PDFnassimNo ratings yet

- Schedule 80 Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 Pipe Dimensions & Pressure RatingsDGWNo ratings yet

- KEI Productcatalogue - RemovePdfPagesDocument7 pagesKEI Productcatalogue - RemovePdfPagesammu pallaviNo ratings yet

- Veriflex Intercon 1.8-3kV Cable - 1Document2 pagesVeriflex Intercon 1.8-3kV Cable - 1anastasia abengoaNo ratings yet

- PLT - Din 18134Document4 pagesPLT - Din 18134Mohamed BarakatNo ratings yet

- Dripnet PC Thick Walled Dripperlines Product SheetDocument2 pagesDripnet PC Thick Walled Dripperlines Product SheetIgnacio RinaldiNo ratings yet

- SUPA75 Slickline Rev 29 May 18Document1 pageSUPA75 Slickline Rev 29 May 18hoss mosafaNo ratings yet

- Solco Training Solar Collectors enDocument28 pagesSolco Training Solar Collectors enMohammad MohammadNo ratings yet

- Major Civil Engineering: A3 Hindhead Determination of Particle Size Distribution: BS EN 933-1: 1997Document2 pagesMajor Civil Engineering: A3 Hindhead Determination of Particle Size Distribution: BS EN 933-1: 1997Andrew TorranceNo ratings yet

- Garnet Opta MineralsDocument2 pagesGarnet Opta MineralsMaison Braúl ManriqueNo ratings yet

- 01 Al Munaif Dranage Sewerage Fittings OrangeDocument28 pages01 Al Munaif Dranage Sewerage Fittings OrangemohammedNo ratings yet

- Sr. No. Result Test IS Code: Zone-I Zone-II Zone-III Zone-IVDocument1 pageSr. No. Result Test IS Code: Zone-I Zone-II Zone-III Zone-IVsachin sNo ratings yet

- Whatman Filtration Catalog PDFDocument68 pagesWhatman Filtration Catalog PDFJohn E. BeNo ratings yet

- Thermal Aluminium Conductor: Technical PropertiesDocument1 pageThermal Aluminium Conductor: Technical Propertiesabd salam100% (1)

- 高强度输送带用钢丝绳 High strength steel wire ropes for conveyor beltsDocument4 pages高强度输送带用钢丝绳 High strength steel wire ropes for conveyor beltsNorberto A. GhiggiNo ratings yet

- 1.19 Corrosive Environments: T Able 1.1Document1 page1.19 Corrosive Environments: T Able 1.1SardarNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Karkim Sodium Formate enDocument2 pagesKarkim Sodium Formate enIqbal batchaNo ratings yet

- M30Easycrete, Trial SheetDocument1 pageM30Easycrete, Trial Sheetabir senguptaNo ratings yet

- Spears - PIPE SCH80Document1 pageSpears - PIPE SCH80F. AhmadNo ratings yet

- Tabla Cutata SMD - DAT - .119.V11-SMD-Technical-Data-Sheet-TR80+ PDFDocument3 pagesTabla Cutata SMD - DAT - .119.V11-SMD-Technical-Data-Sheet-TR80+ PDFMonica Adriana PopescuNo ratings yet

- Schedule 40 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 40 PVC Pipe Dimensions & Pressure RatingsprathapNo ratings yet

- Schedule 40 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 40 PVC Pipe Dimensions & Pressure RatingspicottNo ratings yet

- Dripnet PC AS Thick Walled Dripperlines Product SheetDocument2 pagesDripnet PC AS Thick Walled Dripperlines Product SheetIgnacio RinaldiNo ratings yet

- Floor Decking:: Technical Data SheetDocument4 pagesFloor Decking:: Technical Data SheetImran MulaniNo ratings yet

- Hi - Span DeckDocument2 pagesHi - Span DeckJubin MathewNo ratings yet

- FT Sifer 950iDocument2 pagesFT Sifer 950iAshik M RasheedNo ratings yet

- BCC - 1 2 H Astm B2Document2 pagesBCC - 1 2 H Astm B2Bagus Arief WibowoNo ratings yet

- Parameters For Specimen No. 1: Direct Shear TestDocument5 pagesParameters For Specimen No. 1: Direct Shear TestRosmery Roman UñojaNo ratings yet

- National Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)Document2 pagesNational Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)DeepakNo ratings yet

- Solar Cable 2023Document5 pagesSolar Cable 2023H. NurzeinNo ratings yet

- برنامج حساب وزن الدكت كونستكDocument9 pagesبرنامج حساب وزن الدكت كونستكSameh Salama MohamedNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Uccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversDocument38 pagesUccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversTeles SilvaNo ratings yet

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- Jewellery Shop Design 3dDocument5 pagesJewellery Shop Design 3dTrường Thọ NguyễnNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Ehaccp - Allergen Control StatementDocument1 pageEhaccp - Allergen Control StatementAlfred RangelNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocument23 pagesSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- Electronics Cooling: Mechanical Power Engineering DeptDocument22 pagesElectronics Cooling: Mechanical Power Engineering DeptneilNo ratings yet

- Exercise # 1: Statistics and ProbabilityDocument6 pagesExercise # 1: Statistics and ProbabilityAszyla ArzaNo ratings yet

- 4 Poisonous & Venomous AnimalsDocument47 pages4 Poisonous & Venomous AnimalsAnyi Yulieth AMPUDIA MURILLONo ratings yet

- Amina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionDocument1 pageAmina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionFïzã PäthäñNo ratings yet

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Technical Data: Digital Color Progressive Scan Camera DÜRR TXG06c-K22 - Gigabit EthernetDocument20 pagesTechnical Data: Digital Color Progressive Scan Camera DÜRR TXG06c-K22 - Gigabit EthernetDiogo FiaesNo ratings yet

- Valve Body 55Document3 pagesValve Body 55Davidoff RedNo ratings yet

- Toro Homelite 3354-726Document8 pagesToro Homelite 3354-726Cameron ScottNo ratings yet

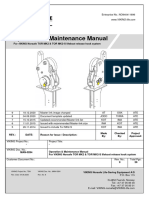

- SOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.Document20 pagesSOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.arfaoui salimNo ratings yet

- 400PNR CDocument3 pages400PNR CmdisicNo ratings yet

- Vacon Nxs Robust Drive For Heavy UseDocument11 pagesVacon Nxs Robust Drive For Heavy UseLuis PinedaNo ratings yet

- HP Deskjet D1600 Printer SeriesDocument13 pagesHP Deskjet D1600 Printer SeriesRizki JuliadiNo ratings yet

- CESCCommunityProjectPlan Brgy - MacarioDaconDocument6 pagesCESCCommunityProjectPlan Brgy - MacarioDaconKennedy BalmoriNo ratings yet

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- Op-Amp ExperimentDocument34 pagesOp-Amp ExperimentArooj Mukarram100% (1)

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- Ag4q-212s KBDocument2 pagesAg4q-212s KBhtek.thunderainNo ratings yet

- Low Noise Amplifier Basics: by V. M. García-ChocanoDocument4 pagesLow Noise Amplifier Basics: by V. M. García-ChocanoPranjal Jalan100% (1)

- 5 - Introduction Q-Series Vs2 Customer Version2Document49 pages5 - Introduction Q-Series Vs2 Customer Version2mahreza189100% (1)