Professional Documents

Culture Documents

21 LSI SPECS (5)

21 LSI SPECS (5)

Uploaded by

Javier ArdilesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21 LSI SPECS (5)

21 LSI SPECS (5)

Uploaded by

Javier ArdilesCopyright:

Available Formats

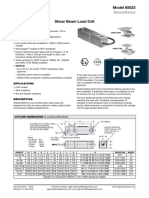

Load Cell

GC005 thru GC600

Wireless Load Cell

Features

Standard single part line pull sizes ranging from 5,000

to 600,000 lb.

All stainless frame and hardware

Heavy duty construction from 17-4PH1150 stainless

steel (17-4PH1025 on models 250,000lb and up)

Accuracy of +/-1% on a single part of line

Option available with ATEX zone 0 and CSA Class 1

division 1 certification.

Ships calibrated

Stock and custom bushings for most applications

Radio range with line of sight: 4000 ft. (1300 m)

Operates with one 'D' cell battery lithium 3.6V or

Wireless Load Cells Family

alkaline 1.5V.

2 years battery life for typical applications

ISM license free radio; wavelength and modulation

optimized for radio communication in industrial

environments.

Temperature range: -40°C to 85°C (-40°F to 185°F)

Temperature compensated

Potted electronics for increased water protection

Rugged field-replaceable antenna (TA011)

Custom sizes on request

2 year warranty

Designed with a safety factor of 5:1 on the safe

working load.

All load bearing bodies have been tested by

ultrasounds, die-penetrant and proof loaded to 150% of

capacity.

Applications

Designed for all applications in the lifting industry,

including offshore, that do not require the load cell to be

submerged (due to radio communications). Installation

above a ball, odd parted on the block, or even parted on the

boom tip.

General Description

The load cell is installed in-line with the wire-rope. This

load creates minute deformations of the load cell and

electronics convert it into a load value, which is transmitted

to the receiving unit.

Figure: Typical installation on a crane

The transmitter box mounted to the load cell houses the

battery, radio transmitter, and load converter.

LSI Rev.1.7 Page 1 of 9

Load Cell

GC005 thru GC600

Table of Contents

Features ................................................................................................................................................ 1

Applications ......................................................................................................................................... 1

General Description ............................................................................................................................. 1

Table of Contents ................................................................................................................................. 2

Ordering Information ........................................................................................................................... 2

Specifications ....................................................................................................................................... 3

Absolute Maximum Ratings ................................................................................................................ 3

Certifications ........................................................................................................................................ 3

Specifications by Model and Options .................................................................................................. 4

Materials............................................................................................................................................... 4

Dimensions (Not to Scale) .................................................................................................................. 5

Standard Bushings................................................................................................................................ 6

Adapter Plate Kits ................................................................................................................................ 7

Adapter Plate Geometry ....................................................................................................................... 8

Adapter Plate Kits ................................................................................................................................ 9

Ordering Information

Model Description

GCxxx Load Cell. The three ‘X’ digits are working load limit (WLL) in thousands of

pounds. For example, GC060 is for a 60,000-lb WLL or 27215-kg WLL. Load cell

is FCC approved.

GCxxx-CSA Load cell certified Class 1 Division 1, suitable for Div 1 and Div 2

GCxxx-ATEX Load cell certified ATEX zone 0, suitable for zone 0, zone 1 and zone 2

GCxxx-xx-CE Load cell CE certified, with radio frequency suitable for Europe, most of Asia and

Middle East

LC6XX-XX Appropriate adapter plate kit for load cell (see table page 6).

LC6XX-5X Appropriate 90° adapter plate kit for load cell (see table page 8).

Examples:

GC012-ATEX-CE: is a 12,000 lbs load cell with ATEX certification for Europe

GC170: is a 170,000 lbs load cell with FCC certification

LSI Rev.1.7 Page 2 of 9

Load Cell

GC005 thru GC600

Specifications

Parameter Test Condition Min Typ Max Unit

Load Tension Measurement

Resolution +/- 0.025 0.075 0.2 % of SWL

Accuracy +/- 0.5 1 2 % of SWL

Radio Power

GCXXX 0.013 0.016 0.020 W

11 12 13 dBm

Radio Frequency

North American version GCXXX 902 928 MHz

European version GCXXX-CE 868 870 MHz

Battery life

‘D’ cell lithium 12 24 28 Month

‘D’ cell alkaline 8 12 16 Month

Absolute Maximum Ratings

Parameter Test Condition Min Typ Max Unit

Ambient temperature range Operating -40 +60 ºC

-40 +140 ºF

Storage -40 +85 ºC

-40 +185 ºF

Certifications

FCC/IC/CE certification

ETSI 300-220-1, 300-220-3, EN 301 489-3

EN61000-3-2, EN61000-3-3, EN61000-4-3, EN61000-4-6

In option : Class 1 division 1

In option : ATEX zone 0

CSA C22.2 No.0.4.M2004, No.0-M1991, No.0142,M1987, No0.157-M1992, No.213-M1987

UL508, UL913, UL1604

EN61000-4, EN60079-0, EN60079-11, EN60079-26

LSI Rev.1.7 Page 3 of 9

Load Cell

GC005 thru GC600

Specifications by Model and Options

Load Cell model Max load Weight

(lb) (kg) (lb) (kg)

GC005 5000 2270 5 2.3

GC012 12000 5440 9.00 4.08

GC018 18000 8160 10.00 4.54

GC035 35000 15880 16.00 7.26

GC060 60000 27215 29.00 13.15

GC100 100000 45360 46.00 20.87

GC170 170000 77000 94.00 42.64

GC250 250000 113400 106.00 48.08

GC300 300000 136100 122.00 55.34

GC400 400000 181000 199.00 90.26

GC600 600000 227000 288.00 130.63

Materials

The load cell and hardware are made of stainless steel, AISI 304 and 17-4PH1150 (up to GC170) or 17-4PH1025 (GC250 and

over). The bushings are made from 1045 steel.

LSI Rev.1.7 Page 4 of 9

Load Cell

GC005 thru GC600

Dimensions (Not to Scale)

GC005-GC018 GC035-GC100 GC170-GC600

Load DIMENSIONS

Cell

φJ for φK for

A B C D E F G H Pin Pin

(in) 3.93 6.20 8.30 1.14 2.95 0.65 3.00 6.12 7/8 7/8

GC005

(mm) 99.8 157.5 210.8 28.9 74.9 16.5 76.2 155.4 22 22

(in) 3.93 7.50 10.40 1.79 2.95 0.95 3.17 6.28 1-1/4 1-1/4

GC012

(mm) 99.8 190.5 264.2 45.4 74.9 24.1 80.4 159.6 32 32

(in) 3.93 7.50 10.40 1.79 2.95 1.20 3.44 6.55 1-3/8 1-3/8

GC018

(mm) 99.8 190.5 264.2 45.4 74.9 30.5 87.2 166.4 35 32

(in) 2.86 8.75 13.15 2.79 3.95 1.20 3.42 6.54 2-1/4 1-5/8

GC035

(mm) 72.5 222.3 334.0 70.9 100.3 30.5 86.7 166.0 57 41

(in) 2.86 9.00 14.58 3.32 4.95 1.65 3.92 7.04 2-1/2 2-1/2

GC060

(mm) 72.5 228.6 370.33 84.3 125.7 41.9 99.5 178.7 63 63

(in) 2.86 11.60 18.90 4.37 6.00 2.00 4.22 7.34 3 3

GC100

(mm) 72.5 294.6 480.1 111.0 152.4 50.8 107.1 186.3 76 76

(in) 2.86 13.00 21.20 5.07 7.00 3.00 4.98 8.10 3-1/8 3-1/8

GC170

(mm) 72.5 330.2 538.5 128.8 177.8 76.2 126.5 205.7 80 80

(in) 2.86 14.50 23.56 5.82 7.10 2.88 4.76 7.87 3-3/4 3-3/4

GC250

(mm) 72.5 368.3 598.4 147.9 180.3 73.2 120.8 200.0 95 95

(in) 2.86 14.00 23.688 5.57 7.44 3.38 5.04 8.15 4-1/4 4-1/4

GC300

(mm) 72.5 355.6 601.5 141.5 189.0 85.7 127.9 207.1 108 108

(in) 2.86 17.50 28.78 7.32 8.67 3.88 5.32 8.44 5 5

GC400

(mm) 72.5 444.5 731.0 186.0 220.2 98.4 135.1 214.3 127 127

(in) 2.86 19.00 32.08 8.07 10.70 3.88 5.44 8.55 5-1/4 5-1/4

GC600

(mm) 72.5 482.6 814.8 205.0 271.8 98.4 138.0 217.2 133 133

LSI Rev.1.7 Page 5 of 9

Load Cell

GC005 thru GC600

Standard Bushings

ADAPTS

TO PIN

Load Cell Bushing (in) (mm)

GC012 PC401 1 25

GC018 PC118 1-1/4 32

GC035 PC424 1-1/2 38

PC425 1-5/8 41

PC426 1-3/4 44

PC427 1-7/8 48

PC428 2 50

PC429* 1-1/4 32

GC060 PC114 2-1/4 57

PC115 2 8

GC100 PC416 2-1/2 64

PC419 2-3/4 70

PC431 2 51

GC170 PC448 2-1/4 57

PC449 2-1/2 64

GC250 PC443 2-1/4 57

PC444 2-3/4 70

PC445 3-1/4 83

GC300 PC446 3-3/4 96

PC447 4-1/8 105

GC400 PC453 4-1/8 105

PC454 4-1/4 108

PC455 4-3/4 121

GC600 PC456 5 127

Standard included bushings are in bold and depends on adapter

plate kit when load cell and adapter plate kit are ordered together.

*Fits in the 1-5/8 hole, the other bushings for the GC035 fit in the 2-1/4 hole.

LSI Rev.1.7 Page 6 of 9

Load Cell

GC005 thru GC600

Adapter Plate Kits (designed with a 5:1 safety factor

Pin Nut Cotter WLL

Load Kit # Plate Number Pin Washer Nut Pin Washer Bushing* lb

Cell ITM 1 ITM 2 ITM 3 ITM 4 ITM 5 ITM 6 Qty ITM 7 (kg)

GC012 LC612-01 PC612-01 1 PC501 QW912 QV930 QP003S QW901 6 PC401 12,000

2 PC502 QW912 QV930 QP003S QW902 6 (5454)

GC018 LC618-01 PC618-01 1 PC502 QW912 QV930 QP003S QW902 4 PC118 18,000

2 PC503 QW912 QV930 QP003S QW906 4 (8181)

GC035 LC635-01 PC635-01 1 PC502 QW912 QV930 QP003S QW902 2 PC429 35,000

2 PC502 QW912 QV930 QP003S QW902 2 PC423 (15909)

LC635-02 PC635-02 1 PC506 QW902 QV950 QP003S QW903 6 35,000

2 PC504 QW907 QV951 QP004S QW904 6 PC428 (15909)

LC635-03 PC635-03 1 PC506 QW902 QV950 QP003S QW903 6 35,000

2 PC505 QW902 QV950 QP003S QW903 6 PC424 (15909)

LC635-04 PC635-04 1 PC506 QW902 QV950 QP003S QW903 6 PC424 35,000

2 PC505 QW902 QV950 QP003S QW903 6 PC424 (15909)

LC635-06 PC635-02 1 PC524 QW902 QV951 QP003S QW908 6 PC427 35,000

(w/ PC432) 2 PC506 QW903 QV950 QP003S QW903 6 (15909)

LC635-07 PC635-02 1 PC519 QW902 QV951 QP004S QW908 6 PC426 35,000

(w/ PC417) 2 PC506 QW903 QV950 QP003S QW903 6 (15909)

LC635-09 PC635-05 1 PC522 QW903 QV951 QP004S QW904B 4 35,000

2 PC506 QW903 QV950 QP003S QW903 4 (15909)

GC060 LC660-01 PC660-01 1 PC506 QW902 QV950 QP003S QW903 2 PC108 60,000

2 PC506 QW902 QV950 QP003S QW903 2 PC108 (27272)

LC660-02 PC660-02 1 PC508 QW903 QV951 QP004S QW904B 4 PC114 60,000

2 PC507 QW903 QV951 QP004S QW904 4 PC115 (27272)

LC660-03 PC660-03 1 PC508 QW903 QV951 QP004S QW904B 4 PC114 60,000

2 PC507 QW903 QV951 QP004S QW904 4 PC115 (27272)

LC660-04 PC660-04 1 PC508 QW903 QV951 QP004S QW904B 4 PC114 60,000

2 PC507 QW903 QV951 QP004S QW904 4 PC115 (27272)

LC660-05 PC660-05 1 PC509 QW904 QV952 QP004S QW904C 10 60,000

2 PC509 QW904 QV952 QP004S QW904C 10 (27272)

LC660-06 PC660-06 1 PC509 QW904 QV952 QP004S QW904C 10 60,000

2 PC509 QW904 QV952 QP004S QW904C 10 (27272)

* Bushings not included. Required bushings included with load when load cell and adapter plate are ordered together.

LSI Rev.1.7 Page 7 of 9

Load Cell

GC005 thru GC600

Adapter Plate Geometry

Pin 1 Pin 2

Load Cell Kit # Diameter Diameter C D L X Y Z

GC012 LC612-01 (in) 1.00 1.25 4.23 2.00 3.75 0.50 3.00 6.75

(cm) 25.4 31.8 107.4 50.8 95.3 12.7 76.2 171.5

GC018 LC618-01 (in) 1.25 1.38 4.23 1.75 4.25 0.63 3.00 7.35

(cm) 31.8 34.9 107.4 44.5 108.0 15.9 76.2 186.7

GC035 LC635-01 (in) 1.25 1.25 4.23 1.50 4.25 0.75 4.00 8.25

(cm) 31.8 31.8 107.4 38.1 108.0 19.1 101.6 209.6

LC635-02 (in) 1.63 2.00 5.84 2.50 7.25 0.75 4.00 11.50

(cm) 41.3 50.8 148.3 63.5 184.2 19.1 101.6 292.1

LC635-03 (in) 1.63 1.50 5.53 2.50 10.25 0.75 4.00 14.50

(cm) 41.3 38.1 140.5 63.5 260.4 19.1 101.6 368.3

LC635-04 (in) 1.63 1.50 5.53 2.50 36.00 0.75 4.00 40.25

(cm) 41.3 38.1 140.5 63.5 914.4 19.1 101.6 1022.4

LC635-06 (in) 1.88 1.63 5.84 2.50 7.25 0.75 4.00 8.25

(cm) 47.6 41.3 148.3 63.5 184.2 19.1 101.6 209.6

LC635-07 (in) 1.75 1.63 5.84 2.50 7.25 0.75 4.00 8.25

(cm) 44.5 41.3 148.3 63.5 184.2 19.1 101.6 209.6

LC635-09 (in) 2.25 1.63 5.84 2.50 6.00 0.75 4.00 10.10

(cm) 57.2 41.3 148.3 63.5 152.4 19.1 101.6 256.5

GC060 LC660-01 (in) 1.63 1.63 5.53 2.00 5.25 1.00 5.00 10.25

(cm) 41.3 41.3 140.5 50.8 133.4 25.4 127.0 260.4

LC660-02 (in) 2.25 2.00 6.34 2.50 5.25 1.00 5.00 10.50

(cm) 57.2 50.8 161.0 63.5 133.4 25.4 127.0 266.7

LC660-03 (in) 2.25 2.00 6.34 2.50 11.25 1.00 5.00 16.50

(cm) 57.2 50.8 161.0 63.5 285.8 25.4 127.0 419.1

LC660-04 (in) 2.25 2.00 6.34 2.50 24.00 1.00 5.00 29.25

(cm) 57.2 50.8 161.0 63.5 609.6 25.4 127.0 743.0

LC660-05 (in) 2.50 2.50 8.09 3.00 7.25 1.00 5.00 12.50

(cm) 63.5 63.5 205.5 76.2 184.2 25.4 127.0 317.5

LC660-06 (in) 2.50 2.50 8.09 3.00 11.25 1.00 5.00 16.50

(cm) 63.5 63.5 205.5 76.2 285.8 25.4 127.0 419.1

LSI Rev.1.7 Page 8 of 9

Load Cell

GC005 thru GC600

Adapter Plate Kits

Adapter Pin Nut Cotter WLL

Load Cell Kit # Bar Number Pin Washer Nut Pin Washer Bushing lb

ITM 1 ITM 2 ITM 3 ITM 4 ITM 5 ITM 6 Qty ITM 7 (kg)

GC035 LC635-51 PC635-51 1 PC531 --- QV954 QP003 --- --- --- 35,000

2 PC530 --- QV954 QP003 --- --- PC405 (15909)

GC060 LC660-51 PC660-51 1 PC507 QW903 QV951 QP004S QW904 4 PC108 60,000

--- --- --- --- --- --- --- --- (27272)

Pin 1 Pin 2

Load Cell Kit # Diameter Diameter C D L X Z

GC035 LC635-51 (in) 1.63 1.50 3.93 1.50 24.00 0.75 28.00

(cm) 41.3 38.1 99.8 38.1 609.6 19.1 711.2

GC060 LC660-51 (in) 2.00 3.00* 6.34 2.50 45.00 1.00 50.50

(cm) 50.8 76.2* 161.0 63.5 1143.0 25.4 1282.7

*Pin not included with Adapter kit

LSI Rev.1.7 Page 9 of 9

You might also like

- Statement of Account: Customer Name Start DateDocument6 pagesStatement of Account: Customer Name Start DateAGBESE GODWIN OCHEPANo ratings yet

- GC005 Thru GC600: Wireless Load CellDocument9 pagesGC005 Thru GC600: Wireless Load Cellsamsularief03No ratings yet

- Lsi GCXXX Load Cells DatasheetDocument8 pagesLsi GCXXX Load Cells Datasheetdeathh6584No ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsCarlos CatañoNo ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsPaMe ParraNo ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsReinaldo Castillo RivasNo ratings yet

- Lsi Gs550-Csa Multi Sensor Display DatasheetDocument5 pagesLsi Gs550-Csa Multi Sensor Display DatasheetMauricio Bulla ValenciaNo ratings yet

- K2Series DS 1015370 5 20141104Document4 pagesK2Series DS 1015370 5 20141104曾乙申No ratings yet

- Data Sheet Rollmax RettangolariDocument3 pagesData Sheet Rollmax RettangolariRanjita DashNo ratings yet

- Ultrasonic Flow Meter'sDocument4 pagesUltrasonic Flow Meter'sFer TiscoNo ratings yet

- Célula de Carga Balança IkeaDocument3 pagesCélula de Carga Balança IkeatrutleptNo ratings yet

- 65023Document3 pages65023Eong Huat Corporation Sdn BhdNo ratings yet

- U1620RGDocument5 pagesU1620RGLeonardo OuverneyNo ratings yet

- 0ZRS0050FF1E BelDocument4 pages0ZRS0050FF1E BelVictor GomesNo ratings yet

- Model 3410: Shear Beam Load CellsDocument4 pagesModel 3410: Shear Beam Load CellsIvanMilovanovicNo ratings yet

- Zelio Relay Rxm4ab1mdDocument7 pagesZelio Relay Rxm4ab1mdroko241No ratings yet

- Lg255s1c g2 Spec SheetDocument2 pagesLg255s1c g2 Spec SheettzorrroNo ratings yet

- Metal-Oxide Varistors (Movs) Radial Leaded - Medium Surge V SeriesDocument25 pagesMetal-Oxide Varistors (Movs) Radial Leaded - Medium Surge V SeriesBadshah SalamatNo ratings yet

- Specifications Sheet Ez1000 8mm Eddy Current Sensor Ams en 1723544Document9 pagesSpecifications Sheet Ez1000 8mm Eddy Current Sensor Ams en 1723544heartsseven36No ratings yet

- DataSheet SLS510 LC en 091201Document4 pagesDataSheet SLS510 LC en 091201Nguyễn Văn SơnNo ratings yet

- Safe, Accurate, Service Friendly: Right The First TimeDocument10 pagesSafe, Accurate, Service Friendly: Right The First TimeSiewkuan LeeNo ratings yet

- Model 1022 Model 1022: Tedea-HuntleighDocument2 pagesModel 1022 Model 1022: Tedea-HuntleighMartin GandaraNo ratings yet

- We en Web in Ar Sic Mosfet 1638931895460Document29 pagesWe en Web in Ar Sic Mosfet 1638931895460Алексей ЯмаNo ratings yet

- 011 - 2008 - Medium Voltage (36 Ka) Surge ArrestersDocument10 pages011 - 2008 - Medium Voltage (36 Ka) Surge Arresterse09341No ratings yet

- Sverker650 enDocument2 pagesSverker650 enbig_lebowskiNo ratings yet

- IMC-101G Series: Industrial Gigabit Ethernet-To-Fiber Media ConvertersDocument4 pagesIMC-101G Series: Industrial Gigabit Ethernet-To-Fiber Media ConvertersAdnan Naeem MalikNo ratings yet

- Dados - Placa SolarDocument4 pagesDados - Placa SolarCamila OliveiraNo ratings yet

- 3410 3411Document3 pages3410 3411Eong Huat Corporation Sdn BhdNo ratings yet

- Service Manuals LG TV PLASMA 42PB4D 42PB4D Service ManualDocument59 pagesService Manuals LG TV PLASMA 42PB4D 42PB4D Service Manual邱政鋒100% (1)

- Acelerometro ADXL103-ADXL203Document12 pagesAcelerometro ADXL103-ADXL203cukey13No ratings yet

- IXblue-DS-Oceano HD15 Cable LayDocument2 pagesIXblue-DS-Oceano HD15 Cable LayYoucef BoukhnazerNo ratings yet

- Appendix IDocument6 pagesAppendix I大漠飞鱼No ratings yet

- DataSheet SWC515 Pinmount WM en 111001Document6 pagesDataSheet SWC515 Pinmount WM en 111001GOW_23No ratings yet

- Megger DELTA Accessories BrochureDocument10 pagesMegger DELTA Accessories BrochureAgustina Montoya GamarraNo ratings yet

- LG Solar Monoxci (Mc4) - lg250s1c-g2Document2 pagesLG Solar Monoxci (Mc4) - lg250s1c-g2Ashraf CardiffNo ratings yet

- PVS 10 ManualDocument4 pagesPVS 10 Manualdiegorodriguez1988No ratings yet

- Zelio Relay(s) - RXM4AB1P7Document7 pagesZelio Relay(s) - RXM4AB1P7HitachiNo ratings yet

- Material Specifications Cell: Technical Specification OFDocument8 pagesMaterial Specifications Cell: Technical Specification OFkajale.shrikantNo ratings yet

- Trafo Huawei DatasheetDocument17 pagesTrafo Huawei DatasheetWachito VarelaNo ratings yet

- Features: EconolineDocument2 pagesFeatures: EconolineCristian BandilaNo ratings yet

- Specification of Product: For Lithium-Ion Rechargeable Cell ModelDocument18 pagesSpecification of Product: For Lithium-Ion Rechargeable Cell ModelFrancisco Daniel ColimbaNo ratings yet

- Operations Manual-Ktps, Version02Document110 pagesOperations Manual-Ktps, Version02Ganesh DasaraNo ratings yet

- Operations Manual-Ktps, Version02Document110 pagesOperations Manual-Ktps, Version02Ganesh DasaraNo ratings yet

- Schneider Electric - Zelio-Electromechanical-Relay - RXM3AB2BDDocument9 pagesSchneider Electric - Zelio-Electromechanical-Relay - RXM3AB2BDshaik shafiNo ratings yet

- RC4558 Dual General-Purpose Operational Amplifier: 1 Features 3 DescriptionDocument31 pagesRC4558 Dual General-Purpose Operational Amplifier: 1 Features 3 DescriptionCarloz FriazNo ratings yet

- Photovoltaic Solar h1z2z2 K CableDocument2 pagesPhotovoltaic Solar h1z2z2 K CableShubhambaderiyaNo ratings yet

- Data SheetDocument2 pagesData SheetLuke Mayta ParedesNo ratings yet

- The 85000 Series ProvidesDocument2 pagesThe 85000 Series ProvidesMauricio AndresNo ratings yet

- Field Service Report ACS1k - SN 5607 BB 8Document14 pagesField Service Report ACS1k - SN 5607 BB 8Achmad Ardiansyah JayaNo ratings yet

- Mode Demploi 2104307 Sauter CB 1000 3q2 Cellule de Pesage CB q1cb q2Document6 pagesMode Demploi 2104307 Sauter CB 1000 3q2 Cellule de Pesage CB q1cb q2CAlou PsoNo ratings yet

- Industrial Ethernet Switch - FL SWITCH SFNB 5TX - 2891001: Key Commercial DataDocument7 pagesIndustrial Ethernet Switch - FL SWITCH SFNB 5TX - 2891001: Key Commercial DataRoger Andres OrdoñezNo ratings yet

- Surge Arrest Test ProceduresDocument11 pagesSurge Arrest Test Proceduresmarevey100% (3)

- Q50 Pancake Load Cell BrosurDocument2 pagesQ50 Pancake Load Cell BrosurHermantoro W. PradanaNo ratings yet

- Harmony Timer Relays - REXL4TMJDDocument7 pagesHarmony Timer Relays - REXL4TMJDSifoo SifooNo ratings yet

- Technnical Schedule of BR10-PS-25 - Reply - 20170814Document5 pagesTechnnical Schedule of BR10-PS-25 - Reply - 20170814HopNo ratings yet

- Photovoltaic Solar H1Z2Z2-K Cable: Application StandardsDocument2 pagesPhotovoltaic Solar H1Z2Z2-K Cable: Application StandardsMOHAMED RAAISNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Adventures in Cybersound: Trevor BlakeDocument4 pagesAdventures in Cybersound: Trevor BlakeMaciej JüngstNo ratings yet

- Power Source: 78 HIACE (EWD622E)Document4 pagesPower Source: 78 HIACE (EWD622E)Egoro KapitoNo ratings yet

- Instruction Manual - Alfa Laval Agitator - Alt - Altb Ese03504en PDFDocument108 pagesInstruction Manual - Alfa Laval Agitator - Alt - Altb Ese03504en PDFMuhammad SyawalNo ratings yet

- Robot History 03 PDFDocument16 pagesRobot History 03 PDFBien LeNo ratings yet

- DSP CEP Part3&4Document7 pagesDSP CEP Part3&4Huzaifa YasirNo ratings yet

- Selco-India: Lighting The Base of The PyramidDocument4 pagesSelco-India: Lighting The Base of The Pyramidankit baidNo ratings yet

- Weekly CryptoDocument13 pagesWeekly CryptoForkLogNo ratings yet

- Quectel Rm502Q-Ae: Iot/Embb-Optimized 5G Sub-6 GHZ M.2 ModuleDocument3 pagesQuectel Rm502Q-Ae: Iot/Embb-Optimized 5G Sub-6 GHZ M.2 ModuleRosarioNo ratings yet

- Dist 03 4 PDFDocument28 pagesDist 03 4 PDFTazar phyo waiNo ratings yet

- VRV Condensing UnitDocument24 pagesVRV Condensing UnitLeo NgNo ratings yet

- MememerenemefeegeDocument2 pagesMememerenemefeegeSoRRYC3LNo ratings yet

- Computer System Servicing 10 w1 2Document43 pagesComputer System Servicing 10 w1 2Catherine IlaganNo ratings yet

- Teaching Scheme (In Hours) Total Credits (L+T+P) Examination Scheme Theory Marks Practical Marks Total MarksDocument6 pagesTeaching Scheme (In Hours) Total Credits (L+T+P) Examination Scheme Theory Marks Practical Marks Total Marksritikmachhi7No ratings yet

- Kea 091 NSTRDocument7 pagesKea 091 NSTRamin shirkhaniNo ratings yet

- Course Code: M105 DESCRIPTIVE TITLE: Calculus With Analytic Geometry Prerequisite (S) : Credit Units: 3 Course DescriptionDocument23 pagesCourse Code: M105 DESCRIPTIVE TITLE: Calculus With Analytic Geometry Prerequisite (S) : Credit Units: 3 Course DescriptionMarjorie MalvedaNo ratings yet

- Pejsa BallisticsDocument6 pagesPejsa BallisticsPhil StaudingerNo ratings yet

- Objective:: Study Single Phase Cycloconverter Point Configuration)Document4 pagesObjective:: Study Single Phase Cycloconverter Point Configuration)Mukesh Kumar BeheraNo ratings yet

- M3a Report Writing Process (Student Version) (Updated Aug 2020)Document23 pagesM3a Report Writing Process (Student Version) (Updated Aug 2020)You RanNo ratings yet

- Turbocharger Maint, Cleaning & SurgingDocument5 pagesTurbocharger Maint, Cleaning & SurgingSayem kaif100% (1)

- 425-06 - Duo Sas 360 - UkDocument1 page425-06 - Duo Sas 360 - UkchiralicNo ratings yet

- Accelerating Digital Transformations: A Playbook For UtilitiesDocument11 pagesAccelerating Digital Transformations: A Playbook For UtilitiesPaola Andrea Mejia MejiaNo ratings yet

- Preparation For The Second Written Work 8th GradeDocument3 pagesPreparation For The Second Written Work 8th GradeJelena DajevićNo ratings yet

- ILX69 PBM DatasheetDocument2 pagesILX69 PBM DatasheetSantinNo ratings yet

- H13 511 - v4.0 DemoDocument5 pagesH13 511 - v4.0 Demomy pcNo ratings yet

- Pressure Vessels: Choice of The Vessels Depending OnDocument45 pagesPressure Vessels: Choice of The Vessels Depending OnAmol RastogiNo ratings yet

- Nukeproof Headset Technical ManualDocument5 pagesNukeproof Headset Technical ManualNicky KiloNo ratings yet

- Final PPT SIH2023 CollegeDocument4 pagesFinal PPT SIH2023 CollegeNipunNo ratings yet

- Datasheet Phoenix Battery Charger ENDocument2 pagesDatasheet Phoenix Battery Charger ENcueNo ratings yet

- Software EngineeringDocument79 pagesSoftware EngineeringKartik sharmaNo ratings yet