Professional Documents

Culture Documents

scan0004

scan0004

Uploaded by

MTPS OperationCopyright:

Available Formats

You might also like

- HVAC SymbolsDocument1 pageHVAC SymbolsDuxToyNo ratings yet

- Boiler Cooling MethodDocument7 pagesBoiler Cooling Methodjp mishra100% (2)

- Steam Power Plant Standard Operating ProceduresDocument4 pagesSteam Power Plant Standard Operating Proceduresarvidkumar8706050% (4)

- HP-LP Bypass SystemDocument28 pagesHP-LP Bypass SystemMadhav Pande100% (6)

- Problem Sheet No 3Document3 pagesProblem Sheet No 3Waqas Ud-dinNo ratings yet

- Control Flownex SimulinkDocument8 pagesControl Flownex SimulinkSrashmiNo ratings yet

- Important Things To Be Done Just After Tripping: ExplanationsDocument2 pagesImportant Things To Be Done Just After Tripping: Explanationsu yadavNo ratings yet

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (2)

- Write Up On Turbine OperationDocument5 pagesWrite Up On Turbine OperationSarah Frazier100% (2)

- To Carry Out Cleanup ActivityDocument4 pagesTo Carry Out Cleanup Activitysarojdubey0107No ratings yet

- Turbine SopDocument8 pagesTurbine SopDominic Daniel100% (1)

- Procedure For Shutting Down of Turbine & EquipmentsDocument4 pagesProcedure For Shutting Down of Turbine & EquipmentsPrakash Choudhary100% (2)

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiNo ratings yet

- Stopping of One Pa FanDocument1 pageStopping of One Pa FanShift Incharge BrbclNo ratings yet

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Boiler Sop RevDocument17 pagesBoiler Sop RevDhilip AnNo ratings yet

- EmergencyDocument24 pagesEmergencySanjeevImprove100% (1)

- Maintenance Manual SDR-1500Document47 pagesMaintenance Manual SDR-1500Jaipal S. Nagi100% (4)

- Shutdown ProcedureDocument4 pagesShutdown ProcedureRahul KurmiNo ratings yet

- Preparation and RequirementDocument2 pagesPreparation and RequirementAdy FardyNo ratings yet

- Power Plant OperationDocument199 pagesPower Plant OperationVijay Bhargav Badam86% (7)

- Unit Start UpDocument8 pagesUnit Start UpDebabrata TantubaiNo ratings yet

- Steam Power Plant Standard Operating ProceduresDocument3 pagesSteam Power Plant Standard Operating ProceduresganimechNo ratings yet

- Precautions To Avoid Barring Gear StallingDocument2 pagesPrecautions To Avoid Barring Gear StallingSrinivas Budati100% (1)

- Starting of ZCU 20Document5 pagesStarting of ZCU 20Usman GhaniNo ratings yet

- Turbine OperationDocument30 pagesTurbine OperationAjay Chauhan100% (9)

- Boiler Start UpDocument15 pagesBoiler Start UpMt. Sasongko100% (1)

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- Auxiliary Boiler Training Manual RADocument89 pagesAuxiliary Boiler Training Manual RAbmw316100% (1)

- Unit Normal Shutdown To ColdDocument100 pagesUnit Normal Shutdown To Coldishak100% (2)

- Boiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsDocument56 pagesBoiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsPranav Sai100% (1)

- IOM - Operating Procedure For Ball and Tube MillDocument5 pagesIOM - Operating Procedure For Ball and Tube MillAnoop Kumar AllankiNo ratings yet

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- Power Plant OperationDocument0 pagesPower Plant OperationSHIVAJI CHOUDHURY100% (1)

- 300 MW ThermalPower Plant Cold Start UpDocument4 pages300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Plant Shut Down Procedure - BHELCOMMDocument27 pagesPlant Shut Down Procedure - BHELCOMMNishali SamNo ratings yet

- Power Plant Emergency InsructionDocument14 pagesPower Plant Emergency Insructionbatpora100% (1)

- Turbine OperationDocument30 pagesTurbine OperationGanesh Dasara100% (3)

- Cold Start Up ProcedureDocument18 pagesCold Start Up ProcedurerahulNo ratings yet

- Code: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionDocument5 pagesCode: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionPrakash Choudhary100% (1)

- Miscellaneous Procedures & Other StuffDocument34 pagesMiscellaneous Procedures & Other StuffpepeNo ratings yet

- Turbine RollingDocument3 pagesTurbine RollingAnudeep Chittluri100% (3)

- Basf Bm018 Slow Firing AlkaliDocument4 pagesBasf Bm018 Slow Firing AlkaliRamu NallathambiNo ratings yet

- Triveni SOP NathDocument3 pagesTriveni SOP NathDhaval GohilNo ratings yet

- Burner Management SystemDocument11 pagesBurner Management SystemS Bharadwaj ReddyNo ratings yet

- Gas Turbine StartupDocument9 pagesGas Turbine Startuppawangwl100% (4)

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Turbine Start Up Procedure-2Document2 pagesTurbine Start Up Procedure-2kumarmm1234100% (2)

- Welcome: Presentation ON Boilers & AuxiliariesDocument58 pagesWelcome: Presentation ON Boilers & Auxiliariestanuja singhNo ratings yet

- Procedure of Turbine Cold Startup?Document3 pagesProcedure of Turbine Cold Startup?sunil601100% (1)

- Mjis Operation Order For - # Turbine Hot Status StartingDocument4 pagesMjis Operation Order For - # Turbine Hot Status StartingEduardo GarridoNo ratings yet

- Boiler in Parallel Operation BariDocument6 pagesBoiler in Parallel Operation BariJOSEPH DIAS100% (1)

- Bromyard Pierburg Fitting InstructionsDocument4 pagesBromyard Pierburg Fitting InstructionsGeorgi GeorgievNo ratings yet

- Sop TurbineDocument4 pagesSop Turbineshailendra183No ratings yet

- Warm StartupDocument3 pagesWarm StartupRahul KurmiNo ratings yet

- 500 MW Unit Startup ProcedureDocument39 pages500 MW Unit Startup ProcedureMohammad Asif50% (2)

- Turbine Start Up ProcedureDocument3 pagesTurbine Start Up ProcedureShameer Majeed100% (1)

- IR CFBC Cold Start Up ProcedureDocument15 pagesIR CFBC Cold Start Up ProcedureJose Angie CabreraNo ratings yet

- Cooling PDFDocument38 pagesCooling PDFred eagle winsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- An Experimental Comparison Study Between Single-Axis Tracking and Fixed Photovoltaic Solar Panel Efficiency and Power Output: Case Study in East Coast MalaysiaDocument11 pagesAn Experimental Comparison Study Between Single-Axis Tracking and Fixed Photovoltaic Solar Panel Efficiency and Power Output: Case Study in East Coast MalaysiaReparrNo ratings yet

- Browse Placement Papers Company Code Snippets Certifications Visa Questions Post Question Post Answer My Panel Search Articles TopicsDocument4 pagesBrowse Placement Papers Company Code Snippets Certifications Visa Questions Post Question Post Answer My Panel Search Articles TopicsShankar JhaNo ratings yet

- 6 MBDocument2 pages6 MBpatel gauravNo ratings yet

- Lect-20 Power Plant Rating, Relative CostDocument10 pagesLect-20 Power Plant Rating, Relative CostAwesh KumarNo ratings yet

- Second Generation Solar CellsDocument2 pagesSecond Generation Solar CellsManish ChoudharyNo ratings yet

- SOLAR PUMP Technical Specification WPS JNNSMDocument8 pagesSOLAR PUMP Technical Specification WPS JNNSMJP GuptaNo ratings yet

- Batangas Solar Farm PDS DraftDocument15 pagesBatangas Solar Farm PDS Draftjeicg21No ratings yet

- Steam SystemsDocument20 pagesSteam Systemschristian vergaray gonzalesNo ratings yet

- Distributed Generation and Combined Heat & Power System Characteristics and Costs in The Buildings SectorDocument146 pagesDistributed Generation and Combined Heat & Power System Characteristics and Costs in The Buildings SectorppourmoghaddamNo ratings yet

- Technical English Course For Students in Renewable EnergiesDocument16 pagesTechnical English Course For Students in Renewable Energiesdjoudi mouradNo ratings yet

- OCH752-Energy Technology - by WWW - LearnEngineering.inDocument11 pagesOCH752-Energy Technology - by WWW - LearnEngineering.inGOWTHAM BNo ratings yet

- Condenser & BoilerDocument33 pagesCondenser & BoilerShaun Patrick Albao100% (2)

- Boiler Light Up ProcedureDocument14 pagesBoiler Light Up ProcedureGary Luna CuaquiraNo ratings yet

- Automatic Level Control Systems - Spirax SarcoDocument13 pagesAutomatic Level Control Systems - Spirax SarcokaustavNo ratings yet

- Pliant Cazan Abur Electric, Stirmatic - CA24Document1 pagePliant Cazan Abur Electric, Stirmatic - CA24Marius StanNo ratings yet

- 2 Stroke VS 4 StrokeDocument5 pages2 Stroke VS 4 StrokeMichael YeapNo ratings yet

- Unit 1 - Introduction of Energy Sources and Its Conversion: Strength of Mechanical Engineering Multiple Choice QuestionsDocument12 pagesUnit 1 - Introduction of Energy Sources and Its Conversion: Strength of Mechanical Engineering Multiple Choice QuestionsMahesh DhopeNo ratings yet

- Numerical On Engine DesignDocument3 pagesNumerical On Engine DesignKiran Jot SinghNo ratings yet

- Gas Turbine: Principle of OperationDocument20 pagesGas Turbine: Principle of Operationwaleed paliNo ratings yet

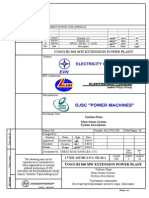

- Uong Bi 300 MW Extension Power Plant: OwnerDocument21 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnProNo ratings yet

- CPL Cross Reference - Overhaul KitsDocument13 pagesCPL Cross Reference - Overhaul KitsAugusto NuñezNo ratings yet

- FIMER PVS800-57B-from1645to1732 EN RevB 0Document6 pagesFIMER PVS800-57B-from1645to1732 EN RevB 0JayapavidranNo ratings yet

- 12837Document7 pages12837massera.p2540No ratings yet

- Approved List of Models and Manufacturers ALMM 1633167831Document21 pagesApproved List of Models and Manufacturers ALMM 1633167831srsinghal223No ratings yet

- 005 Osaka BoilerDocument2 pages005 Osaka BoilerPreeth jayasingheNo ratings yet

- Techlink Article HF Engine TimingDocument1 pageTechlink Article HF Engine TimingRey FloresNo ratings yet

- k21-k25 Parts CatalogDocument69 pagesk21-k25 Parts CatalogKoczyNo ratings yet

scan0004

scan0004

Uploaded by

MTPS OperationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

scan0004

scan0004

Uploaded by

MTPS OperationCopyright:

Available Formats

IMPORTANT THINGS TO BE DONE JUST AFTER TRIPPING~

1.) Do not ~ panic & stay in control room.

2.)* Immediately take the boiler feed pump's scoop in manual mode & bring it to zero

position Irrespective of drum level.

3.) Open the deareator & hotwel page & check the status of CEP,If third CEPhave taken

start stop it. Maintain the deaerator & hot-we I level, manage the CEPthrust brg temp by

opening the recirculation valve CD-22(Pneumaticcontrol) & CD-24(motorized).

4.) Maintain the PRDSpressure & temp bv, op.e.rcfti.ng'-,the.motorizedvalveAS #21 &

~-.-. p~eu'~aticcontrol valveAS#21,&'~-orre;p()nding spray valves(FD~22). .:

5.**) Maintain the gland steam pressure, temp & condenser vacuum.

6.) Checkthe AOP has taken start on auto at the turbine speed just below the 2800 rpm, if

not start the AOP. Observe turbine speed till machine comes on BIG on cutting in JOP

on auto and opening Gate valve gearing valve.

7. Reduce the air flow < 400TPH and bring the drum level in normal position for the purge

ready condition. Do not start purging without seeing the first cause of boiler trip.

8.) Analyze the cause of unit tripping, (Seethe Turbine & Generator FST& also the first cause

of trip page.)Note down the first cause of boiler trip & first cause of turbine trip &

mention it in the log book.

~ - - ~ ~ -..- "--..- - ~-- - -

After seeing the first cause of tripping Purge Boiler & wait for purge complete .If it is a

normal tripping, then proceed for boiler lit up & synchronization. But if tripping is from

generator side, lit up the boiler with one or two oil support just for holding the blr drum

pressure at around 80Kg /Cm2.Ask electrical engineer to give clearance for rolling. After

getting the clearance charge HP/LP bypass system, Cut in Coal firing through 'B' or 'C'

elevation. Raisethe MST& roll the machine after satisfying the respective curves.

10.) BD isolating valve is generally kept in closed position during unit running condition so it

should be opened cautiously before charging the HP bypass.

Explainations

*Point#2.-- HP bypass is not generally kept on auto owing to variety of reasons. Due to this the steam

flow suddenly reduces to minimum as soon as Unit trips. Sudden stoppage of steam flow

cause suppression of drum level but as there is no loss of steam boiler does not require

any more water in actual. If we leave the drum level control on auto seeing the very low

drum level control system will act so as huge.amount of feed water will enter inside the

boiler which will have to be drained out later causing huge losses in terms of feed water

& heat. Moreover, maximum % of dearator pegging is generally from IP extraction so

You might also like

- HVAC SymbolsDocument1 pageHVAC SymbolsDuxToyNo ratings yet

- Boiler Cooling MethodDocument7 pagesBoiler Cooling Methodjp mishra100% (2)

- Steam Power Plant Standard Operating ProceduresDocument4 pagesSteam Power Plant Standard Operating Proceduresarvidkumar8706050% (4)

- HP-LP Bypass SystemDocument28 pagesHP-LP Bypass SystemMadhav Pande100% (6)

- Problem Sheet No 3Document3 pagesProblem Sheet No 3Waqas Ud-dinNo ratings yet

- Control Flownex SimulinkDocument8 pagesControl Flownex SimulinkSrashmiNo ratings yet

- Important Things To Be Done Just After Tripping: ExplanationsDocument2 pagesImportant Things To Be Done Just After Tripping: Explanationsu yadavNo ratings yet

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (2)

- Write Up On Turbine OperationDocument5 pagesWrite Up On Turbine OperationSarah Frazier100% (2)

- To Carry Out Cleanup ActivityDocument4 pagesTo Carry Out Cleanup Activitysarojdubey0107No ratings yet

- Turbine SopDocument8 pagesTurbine SopDominic Daniel100% (1)

- Procedure For Shutting Down of Turbine & EquipmentsDocument4 pagesProcedure For Shutting Down of Turbine & EquipmentsPrakash Choudhary100% (2)

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiNo ratings yet

- Stopping of One Pa FanDocument1 pageStopping of One Pa FanShift Incharge BrbclNo ratings yet

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Boiler Sop RevDocument17 pagesBoiler Sop RevDhilip AnNo ratings yet

- EmergencyDocument24 pagesEmergencySanjeevImprove100% (1)

- Maintenance Manual SDR-1500Document47 pagesMaintenance Manual SDR-1500Jaipal S. Nagi100% (4)

- Shutdown ProcedureDocument4 pagesShutdown ProcedureRahul KurmiNo ratings yet

- Preparation and RequirementDocument2 pagesPreparation and RequirementAdy FardyNo ratings yet

- Power Plant OperationDocument199 pagesPower Plant OperationVijay Bhargav Badam86% (7)

- Unit Start UpDocument8 pagesUnit Start UpDebabrata TantubaiNo ratings yet

- Steam Power Plant Standard Operating ProceduresDocument3 pagesSteam Power Plant Standard Operating ProceduresganimechNo ratings yet

- Precautions To Avoid Barring Gear StallingDocument2 pagesPrecautions To Avoid Barring Gear StallingSrinivas Budati100% (1)

- Starting of ZCU 20Document5 pagesStarting of ZCU 20Usman GhaniNo ratings yet

- Turbine OperationDocument30 pagesTurbine OperationAjay Chauhan100% (9)

- Boiler Start UpDocument15 pagesBoiler Start UpMt. Sasongko100% (1)

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- Auxiliary Boiler Training Manual RADocument89 pagesAuxiliary Boiler Training Manual RAbmw316100% (1)

- Unit Normal Shutdown To ColdDocument100 pagesUnit Normal Shutdown To Coldishak100% (2)

- Boiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsDocument56 pagesBoiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsPranav Sai100% (1)

- IOM - Operating Procedure For Ball and Tube MillDocument5 pagesIOM - Operating Procedure For Ball and Tube MillAnoop Kumar AllankiNo ratings yet

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- Power Plant OperationDocument0 pagesPower Plant OperationSHIVAJI CHOUDHURY100% (1)

- 300 MW ThermalPower Plant Cold Start UpDocument4 pages300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Plant Shut Down Procedure - BHELCOMMDocument27 pagesPlant Shut Down Procedure - BHELCOMMNishali SamNo ratings yet

- Power Plant Emergency InsructionDocument14 pagesPower Plant Emergency Insructionbatpora100% (1)

- Turbine OperationDocument30 pagesTurbine OperationGanesh Dasara100% (3)

- Cold Start Up ProcedureDocument18 pagesCold Start Up ProcedurerahulNo ratings yet

- Code: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionDocument5 pagesCode: Btpp/Turbine/007/Vacuum Raising Guidelines For Condenser Vacuum Raising PreconditionPrakash Choudhary100% (1)

- Miscellaneous Procedures & Other StuffDocument34 pagesMiscellaneous Procedures & Other StuffpepeNo ratings yet

- Turbine RollingDocument3 pagesTurbine RollingAnudeep Chittluri100% (3)

- Basf Bm018 Slow Firing AlkaliDocument4 pagesBasf Bm018 Slow Firing AlkaliRamu NallathambiNo ratings yet

- Triveni SOP NathDocument3 pagesTriveni SOP NathDhaval GohilNo ratings yet

- Burner Management SystemDocument11 pagesBurner Management SystemS Bharadwaj ReddyNo ratings yet

- Gas Turbine StartupDocument9 pagesGas Turbine Startuppawangwl100% (4)

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Turbine Start Up Procedure-2Document2 pagesTurbine Start Up Procedure-2kumarmm1234100% (2)

- Welcome: Presentation ON Boilers & AuxiliariesDocument58 pagesWelcome: Presentation ON Boilers & Auxiliariestanuja singhNo ratings yet

- Procedure of Turbine Cold Startup?Document3 pagesProcedure of Turbine Cold Startup?sunil601100% (1)

- Mjis Operation Order For - # Turbine Hot Status StartingDocument4 pagesMjis Operation Order For - # Turbine Hot Status StartingEduardo GarridoNo ratings yet

- Boiler in Parallel Operation BariDocument6 pagesBoiler in Parallel Operation BariJOSEPH DIAS100% (1)

- Bromyard Pierburg Fitting InstructionsDocument4 pagesBromyard Pierburg Fitting InstructionsGeorgi GeorgievNo ratings yet

- Sop TurbineDocument4 pagesSop Turbineshailendra183No ratings yet

- Warm StartupDocument3 pagesWarm StartupRahul KurmiNo ratings yet

- 500 MW Unit Startup ProcedureDocument39 pages500 MW Unit Startup ProcedureMohammad Asif50% (2)

- Turbine Start Up ProcedureDocument3 pagesTurbine Start Up ProcedureShameer Majeed100% (1)

- IR CFBC Cold Start Up ProcedureDocument15 pagesIR CFBC Cold Start Up ProcedureJose Angie CabreraNo ratings yet

- Cooling PDFDocument38 pagesCooling PDFred eagle winsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- An Experimental Comparison Study Between Single-Axis Tracking and Fixed Photovoltaic Solar Panel Efficiency and Power Output: Case Study in East Coast MalaysiaDocument11 pagesAn Experimental Comparison Study Between Single-Axis Tracking and Fixed Photovoltaic Solar Panel Efficiency and Power Output: Case Study in East Coast MalaysiaReparrNo ratings yet

- Browse Placement Papers Company Code Snippets Certifications Visa Questions Post Question Post Answer My Panel Search Articles TopicsDocument4 pagesBrowse Placement Papers Company Code Snippets Certifications Visa Questions Post Question Post Answer My Panel Search Articles TopicsShankar JhaNo ratings yet

- 6 MBDocument2 pages6 MBpatel gauravNo ratings yet

- Lect-20 Power Plant Rating, Relative CostDocument10 pagesLect-20 Power Plant Rating, Relative CostAwesh KumarNo ratings yet

- Second Generation Solar CellsDocument2 pagesSecond Generation Solar CellsManish ChoudharyNo ratings yet

- SOLAR PUMP Technical Specification WPS JNNSMDocument8 pagesSOLAR PUMP Technical Specification WPS JNNSMJP GuptaNo ratings yet

- Batangas Solar Farm PDS DraftDocument15 pagesBatangas Solar Farm PDS Draftjeicg21No ratings yet

- Steam SystemsDocument20 pagesSteam Systemschristian vergaray gonzalesNo ratings yet

- Distributed Generation and Combined Heat & Power System Characteristics and Costs in The Buildings SectorDocument146 pagesDistributed Generation and Combined Heat & Power System Characteristics and Costs in The Buildings SectorppourmoghaddamNo ratings yet

- Technical English Course For Students in Renewable EnergiesDocument16 pagesTechnical English Course For Students in Renewable Energiesdjoudi mouradNo ratings yet

- OCH752-Energy Technology - by WWW - LearnEngineering.inDocument11 pagesOCH752-Energy Technology - by WWW - LearnEngineering.inGOWTHAM BNo ratings yet

- Condenser & BoilerDocument33 pagesCondenser & BoilerShaun Patrick Albao100% (2)

- Boiler Light Up ProcedureDocument14 pagesBoiler Light Up ProcedureGary Luna CuaquiraNo ratings yet

- Automatic Level Control Systems - Spirax SarcoDocument13 pagesAutomatic Level Control Systems - Spirax SarcokaustavNo ratings yet

- Pliant Cazan Abur Electric, Stirmatic - CA24Document1 pagePliant Cazan Abur Electric, Stirmatic - CA24Marius StanNo ratings yet

- 2 Stroke VS 4 StrokeDocument5 pages2 Stroke VS 4 StrokeMichael YeapNo ratings yet

- Unit 1 - Introduction of Energy Sources and Its Conversion: Strength of Mechanical Engineering Multiple Choice QuestionsDocument12 pagesUnit 1 - Introduction of Energy Sources and Its Conversion: Strength of Mechanical Engineering Multiple Choice QuestionsMahesh DhopeNo ratings yet

- Numerical On Engine DesignDocument3 pagesNumerical On Engine DesignKiran Jot SinghNo ratings yet

- Gas Turbine: Principle of OperationDocument20 pagesGas Turbine: Principle of Operationwaleed paliNo ratings yet

- Uong Bi 300 MW Extension Power Plant: OwnerDocument21 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnProNo ratings yet

- CPL Cross Reference - Overhaul KitsDocument13 pagesCPL Cross Reference - Overhaul KitsAugusto NuñezNo ratings yet

- FIMER PVS800-57B-from1645to1732 EN RevB 0Document6 pagesFIMER PVS800-57B-from1645to1732 EN RevB 0JayapavidranNo ratings yet

- 12837Document7 pages12837massera.p2540No ratings yet

- Approved List of Models and Manufacturers ALMM 1633167831Document21 pagesApproved List of Models and Manufacturers ALMM 1633167831srsinghal223No ratings yet

- 005 Osaka BoilerDocument2 pages005 Osaka BoilerPreeth jayasingheNo ratings yet

- Techlink Article HF Engine TimingDocument1 pageTechlink Article HF Engine TimingRey FloresNo ratings yet

- k21-k25 Parts CatalogDocument69 pagesk21-k25 Parts CatalogKoczyNo ratings yet