Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsTRC Technical textile ppt-1

TRC Technical textile ppt-1

Uploaded by

natureslove2001Textile material

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Astm A385-A385m-20Document10 pagesAstm A385-A385m-20Rodrigo PizarroNo ratings yet

- Inorganic Fibers Lecture Class NoteDocument23 pagesInorganic Fibers Lecture Class NoteGemeda GebinoNo ratings yet

- M 2008 Ceet 28 Zirimwabagabo Leodomir Gs20020131Document52 pagesM 2008 Ceet 28 Zirimwabagabo Leodomir Gs20020131Katie SandersNo ratings yet

- Turbine BladeDocument27 pagesTurbine BladesrtanandNo ratings yet

- 18221a0119 Innovative Materials PDFDocument19 pages18221a0119 Innovative Materials PDFVenky RajuNo ratings yet

- Glass Reinforced Plastic PPTXDocument43 pagesGlass Reinforced Plastic PPTXTRISTAR TEKZONENo ratings yet

- Glass Fibre Reinforced ConcreteDocument19 pagesGlass Fibre Reinforced ConcreteFaizan muhammedNo ratings yet

- Glass Reinforced Plastic PPTXDocument43 pagesGlass Reinforced Plastic PPTXSatyam LakheraNo ratings yet

- EMS 223 Chapter 1Document38 pagesEMS 223 Chapter 1charles makasabiNo ratings yet

- Special - Concrete - Fahim Al-Neshawy & Esko SistonenDocument30 pagesSpecial - Concrete - Fahim Al-Neshawy & Esko SistonenCésar HuamánNo ratings yet

- Application of Textile Reinforced Concrete in PrecastDocument7 pagesApplication of Textile Reinforced Concrete in PrecastShankar NarenNo ratings yet

- Reinforcement Material For Composite SystemsDocument27 pagesReinforcement Material For Composite Systems21P410 - VARUN MNo ratings yet

- Evaluation of The Mechanical Properties of Translucent ConcreteDocument8 pagesEvaluation of The Mechanical Properties of Translucent ConcretesehunNo ratings yet

- Advanced Concrete Technology Assignment 2 D.Kavya GTE-04Document14 pagesAdvanced Concrete Technology Assignment 2 D.Kavya GTE-04kavya.dasthariNo ratings yet

- Carbon Fibre ReportDocument33 pagesCarbon Fibre ReportAyanala Bhagyasri0% (1)

- Arabinda SamalDocument11 pagesArabinda SamalJiban Nath LipunNo ratings yet

- Nanotechnology in Civil EngineeringDocument22 pagesNanotechnology in Civil EngineeringNehad AhmedNo ratings yet

- Chapter 2 - Advanced Construction MaterialsDocument43 pagesChapter 2 - Advanced Construction Materialsaddis zewdNo ratings yet

- Carbocrete: The Future of ConcreteDocument9 pagesCarbocrete: The Future of Concretesiddharth gautamNo ratings yet

- Lecture 2 Advanced Composites MEC509J2Document14 pagesLecture 2 Advanced Composites MEC509J2Ben MurrayNo ratings yet

- Chapter 2 General Introduction About Advanced Construction MaterialsDocument44 pagesChapter 2 General Introduction About Advanced Construction Materialseyob yohannesNo ratings yet

- Project 0075Document9 pagesProject 0075krishna reddyNo ratings yet

- Charan 3Document15 pagesCharan 3yakubsamadshaikNo ratings yet

- Carbon Fiber Reinforced Concrete (Carbocrete) : Seminar PresentationDocument17 pagesCarbon Fiber Reinforced Concrete (Carbocrete) : Seminar PresentationharikaNo ratings yet

- Concrete TermsDocument22 pagesConcrete TermsNadeem YousafzaiNo ratings yet

- Advanced Technologies in ConcreteDocument24 pagesAdvanced Technologies in ConcreteNaga Ashok GandiNo ratings yet

- Study of Manufacturing of Fiber Glass Reinforced CompositesDocument4 pagesStudy of Manufacturing of Fiber Glass Reinforced CompositesAbdullah SubbirNo ratings yet

- Present & Future of Lightweight ConcreteDocument7 pagesPresent & Future of Lightweight ConcreteGlobal_FriendshipNo ratings yet

- Unit 7Document21 pagesUnit 7YASHWANTH.M.KNo ratings yet

- Composite Materials in Building and Construction ApplicationsDocument52 pagesComposite Materials in Building and Construction Applicationsizzat kamil100% (1)

- Microstructure and Hardness Analysis of Silicon Emulsion & Graphene Oxide Coating Material For Helmet VisorsDocument5 pagesMicrostructure and Hardness Analysis of Silicon Emulsion & Graphene Oxide Coating Material For Helmet VisorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nano Technologies in Building and ConstructionDocument10 pagesNano Technologies in Building and ConstructionNandha KumarNo ratings yet

- Fiber Rein-Forced Concrete (Seminar) 1Document17 pagesFiber Rein-Forced Concrete (Seminar) 1GaneshNo ratings yet

- Application of Nanomaterials in Civil EngineeringDocument12 pagesApplication of Nanomaterials in Civil EngineeringChristelle AlipisNo ratings yet

- CE5604-Advanced Concrete Technology: - History and Origins - Greeks: Addition ofDocument27 pagesCE5604-Advanced Concrete Technology: - History and Origins - Greeks: Addition ofzzz_monsterNo ratings yet

- Carbon Fibre As A Recent Material Use in Construction 5889 Ysod1iuDocument28 pagesCarbon Fibre As A Recent Material Use in Construction 5889 Ysod1iuPratik RathodNo ratings yet

- 1 PBDocument7 pages1 PBKarthik SNNo ratings yet

- FRC1Document49 pagesFRC1Pavan Kalyan YadavNo ratings yet

- Module - 5 (B)Document31 pagesModule - 5 (B)Kenneth C.LinojNo ratings yet

- VijayDocument67 pagesVijayvijay kumarNo ratings yet

- Autoclaved Aerated Concrete 1Document22 pagesAutoclaved Aerated Concrete 1Abhi NandNo ratings yet

- Composite MaterialsDocument23 pagesComposite MaterialsNithin KannanNo ratings yet

- Under The Guidance of Sri K. Dileep Kumar (Assistant Professor, Mtech, Ucek)Document16 pagesUnder The Guidance of Sri K. Dileep Kumar (Assistant Professor, Mtech, Ucek)safNo ratings yet

- 7) Current Concrete TechnologyDocument93 pages7) Current Concrete TechnologynghoeNo ratings yet

- MKAE1153 SEAA4163 v5 Current Concrete TechnologyDocument93 pagesMKAE1153 SEAA4163 v5 Current Concrete TechnologyAbdullah RamziNo ratings yet

- Polymer Fiber Reinforced Concrete Pavement: by MD Mutiullah MD Faisal Mohd Abdul Quddus B. MadhuriDocument42 pagesPolymer Fiber Reinforced Concrete Pavement: by MD Mutiullah MD Faisal Mohd Abdul Quddus B. MadhuriGamer RckNo ratings yet

- Ceramic AluminaDocument44 pagesCeramic AluminasakthidhisaNo ratings yet

- Final ResearchDocument29 pagesFinal Researchshubham dhakulkarNo ratings yet

- 1.2.1 Types of Construction ConcreteDocument34 pages1.2.1 Types of Construction ConcreteYash RajNo ratings yet

- Muffakham Jah College of Engineering and TechnologyDocument19 pagesMuffakham Jah College of Engineering and TechnologyRehan QuadriNo ratings yet

- Special Concrete and Concreting TechniquesDocument47 pagesSpecial Concrete and Concreting TechniquesTesfayeNo ratings yet

- Composite Materials Uc5713-Jil Sheth Uc1813-Keshav SharmaDocument18 pagesComposite Materials Uc5713-Jil Sheth Uc1813-Keshav SharmaKristian Marlowe OleNo ratings yet

- Architectural & Constructional TextilesDocument33 pagesArchitectural & Constructional TextilesMusa EltayebNo ratings yet

- Module 1Document66 pagesModule 1mUSINo ratings yet

- Textile Composites: Shahrukh ShahbazDocument55 pagesTextile Composites: Shahrukh ShahbazShahrukh100% (1)

- Ilovepdf MergedDocument38 pagesIlovepdf Mergedalina.tlekkabylova270202No ratings yet

- Wrapping Concrete Project-RajeshDocument41 pagesWrapping Concrete Project-RajeshMEHALA SNo ratings yet

- A Study On 3D Carbon Braided CompositeDocument56 pagesA Study On 3D Carbon Braided CompositeDaryl LeeNo ratings yet

- Pneumatic Structures - Building ConstructionDocument8 pagesPneumatic Structures - Building ConstructionRajkumari PonnammalNo ratings yet

- Ceramics Science and Technology, Volume 4: ApplicationsFrom EverandCeramics Science and Technology, Volume 4: ApplicationsRalf RiedelNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Recent Advances in Turning With Textured Cutting Tools A ReviewDocument15 pagesRecent Advances in Turning With Textured Cutting Tools A ReviewAbhishek BihariNo ratings yet

- BF2 DPR - 230514 - Steel PlantDocument2 pagesBF2 DPR - 230514 - Steel PlantManas JadavNo ratings yet

- OCTOBER 2021 Surplus Record Machinery & Equipment DirectoryDocument719 pagesOCTOBER 2021 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

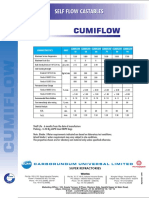

- Pro Self Flow Castables Cumiflow CumicastDocument2 pagesPro Self Flow Castables Cumiflow CumicastjulianoducaNo ratings yet

- Development of Novel Self Healing Concrete Using Carbon NanotubesDocument20 pagesDevelopment of Novel Self Healing Concrete Using Carbon NanotubesVujjini RaghuNo ratings yet

- Packaging Industry (71)Document13 pagesPackaging Industry (71)aparna aravamudhanNo ratings yet

- VIU in Index-Priced WorldDocument20 pagesVIU in Index-Priced WorldPaul VermeulenNo ratings yet

- HIMC Co., Ltd. Catalog enDocument12 pagesHIMC Co., Ltd. Catalog endenny saputraNo ratings yet

- Interspec Paint SpecificationDocument17 pagesInterspec Paint Specificationcameo.exteriorlightsNo ratings yet

- Valmont Larson Pine Tree SolutionsDocument2 pagesValmont Larson Pine Tree Solutionssalvador RiveraNo ratings yet

- MSizer Compact enDocument8 pagesMSizer Compact enMoey AhmedNo ratings yet

- Building Inspection ReportDocument8 pagesBuilding Inspection ReportA DubeyNo ratings yet

- Wood Ash 7Document4 pagesWood Ash 7r;rNo ratings yet

- Bezinal XPDocument2 pagesBezinal XPHeca WahyuniNo ratings yet

- European Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TDocument22 pagesEuropean Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TAshok Kumar BakshiNo ratings yet

- Astm A311 - 2015 - ObsoletoDocument4 pagesAstm A311 - 2015 - ObsoletoRicardo Ricardo100% (1)

- E-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1Document15 pagesE-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1vincentkNo ratings yet

- 2023 Wedo Tools CatalogDocument135 pages2023 Wedo Tools CatalogsaurabhNo ratings yet

- Portland Cement Type Cem Ii - A-L 42.5 NDocument2 pagesPortland Cement Type Cem Ii - A-L 42.5 NAllache IsmailNo ratings yet

- 8607 43745 2 PBDocument12 pages8607 43745 2 PBToni D.No ratings yet

- High Temperature Behaviour of Concrete Produced With Desert SandDocument4 pagesHigh Temperature Behaviour of Concrete Produced With Desert SandDelahan AbatyoughNo ratings yet

- Developing Welding Procedures For 4140 SteelDocument17 pagesDeveloping Welding Procedures For 4140 SteelJose Felix AcevedoNo ratings yet

- Polystick Tu Plus Pds 8Document2 pagesPolystick Tu Plus Pds 8jgarciaNo ratings yet

- ms264 (High Strength Steel)Document18 pagesms264 (High Strength Steel)Enrique Maya VisuetNo ratings yet

- Tle10 Q1 W3 Classification of Materials Tools and Equipment in Fashion AccessoriesDocument72 pagesTle10 Q1 W3 Classification of Materials Tools and Equipment in Fashion AccessorieskarttzyNo ratings yet

- Crystals 11 01196 v3Document23 pagesCrystals 11 01196 v3Dattatreya PatiNo ratings yet

- EN - Klinger Italy - LLG Transparent 2015Document25 pagesEN - Klinger Italy - LLG Transparent 2015GordinhorsNo ratings yet

- Solvay - Algoflon L203RDocument3 pagesSolvay - Algoflon L203RRenan GadioliNo ratings yet

- Study Notes - Electricity and Circuits - Science Class 6 PDF DownloadDocument5 pagesStudy Notes - Electricity and Circuits - Science Class 6 PDF DownloadruchikaNo ratings yet

TRC Technical textile ppt-1

TRC Technical textile ppt-1

Uploaded by

natureslove20010 ratings0% found this document useful (0 votes)

1 views18 pagesTextile material

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTextile material

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views18 pagesTRC Technical textile ppt-1

TRC Technical textile ppt-1

Uploaded by

natureslove2001Textile material

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 18

Presented by - Saurabh Popat Borkar

B. Tech in textile technology

Roll no. 211050915

Introduction

• Five months after ahmedabad textile

industry’s research association (atira),

along with instut fur textiltechnik-rwth

aachen (ITA), germany set up

innovative and green building laboratory

– IGB lab for testing and display of

textile reinforced concrete (TRC), top

companies like L&T and godrej have

approached atira for collaborations for

their upcoming projects

Textile reinforced concrete

• Textile Reinforced Concrete (TRC) is an innovative technology in

concrete filed in which the steel reinforcement is replaced by textile

reinforcement.

• The textile reinforcement provides enhanced tensile strength, ductility

and other features to the finished TRC composites

History

• Began in the 1980

• The first patent for textile-reinforced concrete design, granted in 1982,

• These items were specifically meant to be reinforced with materials

other than steel. In 1988.

• This reinforcement was made from concrete waste and textiles, and

the innovative arrangement and size of the reinforcing fibers inside

was notable.

• In 1996, German university students created two concrete canoes

using textile reinforcement.

Textile reinforcement materials

• The choice of fiber material based on various factors

1. Corrosion

2. Temperature Resistance

3. Bond Quality

4. Demand

5. Production Cost

6. Environmental Impact.

Types of materials

1. Alkali Resistant glas (AR-glass)

2. Carbon

3. Basalt

4. Aramid

5. Polyvinyl-alcohol (PVA) with polyvinyl chloride(PVC) coating.

1. Alkali Resistant Glass

• These are derived from organic non-

metallic raw materials.

• These raw materials go to the melting

process in 12500C to 1350 0C to form

molten glass and fabrication of molten

glass is done by wet-spinning process.

2. Carbon

• Carbon fibre is produced from

the element polyacrylonitrile an

organic polymer resin.

• Carbon has good tensile strength

and low heating expansion.

• But it is not economic and has

bad adhesion to concrete.

3. Basalt

• Basalt is extracted from

volcanic rock.

• The manufacturing process

of basalt fibre is similar to

glass fibres.

• It is cost-effective and good

tensile strength

Properties of materials

Mechanical behavior of TRC

Applications of TRC

• Textile reinforced concrete can be used for repairing of existing RC

structures or strengthening old buildings (historic buildings) etc.

• Textile materials like Kevlar or jute or glass fibres are used in the

construction of pillars, bridges, and road guards etc.

• textile reinforced concrete used for the construction of lightweight

structures and pre-cast materials.

Advantages

• Non-corrosive nature of fiber materials.

• Provide higher degree of effectiveness.

• It enhances mechanical behavior.

• It provides great flexibility in textile design.

• It is light weight of concrete as compared to conventional concrete.

Disadvantages

• Not much economical compared to Steel Reinforced concrete

• Sensitive to moisture and UV radiation

• Lack of fire resistance

• Sensitive to cross pressure

Conclusion

• Considering all these factors, Textile Reinforce concrete is essential to

implement in future construction practices.

• So the application of TRC in this purpose is very needful.

References

• J.HEGGER, S.VOSS, A.SCHOLZEN (3/1/2008): Textile Reinforced

Concrete for light structures, Vol.251,pp.97-108

• RHEMPEL, M.BUTLER, S. HEMPEL and H.SCHORN (5/1/2007):

Durabilityof Textile Reinforced Concrete, Vol.22, pp.87-108ss

• https://atira.in/

• https://timesofindia.indiatimes.com/city/ahmedabad/textile-

reinforced-concrete-gets-industry-boost/articleshow/47342388.cms

• Textile Reinforced Concrete-CIVILWALE

• Textile reinforced concrete History-WIKIPEDIA

You might also like

- Astm A385-A385m-20Document10 pagesAstm A385-A385m-20Rodrigo PizarroNo ratings yet

- Inorganic Fibers Lecture Class NoteDocument23 pagesInorganic Fibers Lecture Class NoteGemeda GebinoNo ratings yet

- M 2008 Ceet 28 Zirimwabagabo Leodomir Gs20020131Document52 pagesM 2008 Ceet 28 Zirimwabagabo Leodomir Gs20020131Katie SandersNo ratings yet

- Turbine BladeDocument27 pagesTurbine BladesrtanandNo ratings yet

- 18221a0119 Innovative Materials PDFDocument19 pages18221a0119 Innovative Materials PDFVenky RajuNo ratings yet

- Glass Reinforced Plastic PPTXDocument43 pagesGlass Reinforced Plastic PPTXTRISTAR TEKZONENo ratings yet

- Glass Fibre Reinforced ConcreteDocument19 pagesGlass Fibre Reinforced ConcreteFaizan muhammedNo ratings yet

- Glass Reinforced Plastic PPTXDocument43 pagesGlass Reinforced Plastic PPTXSatyam LakheraNo ratings yet

- EMS 223 Chapter 1Document38 pagesEMS 223 Chapter 1charles makasabiNo ratings yet

- Special - Concrete - Fahim Al-Neshawy & Esko SistonenDocument30 pagesSpecial - Concrete - Fahim Al-Neshawy & Esko SistonenCésar HuamánNo ratings yet

- Application of Textile Reinforced Concrete in PrecastDocument7 pagesApplication of Textile Reinforced Concrete in PrecastShankar NarenNo ratings yet

- Reinforcement Material For Composite SystemsDocument27 pagesReinforcement Material For Composite Systems21P410 - VARUN MNo ratings yet

- Evaluation of The Mechanical Properties of Translucent ConcreteDocument8 pagesEvaluation of The Mechanical Properties of Translucent ConcretesehunNo ratings yet

- Advanced Concrete Technology Assignment 2 D.Kavya GTE-04Document14 pagesAdvanced Concrete Technology Assignment 2 D.Kavya GTE-04kavya.dasthariNo ratings yet

- Carbon Fibre ReportDocument33 pagesCarbon Fibre ReportAyanala Bhagyasri0% (1)

- Arabinda SamalDocument11 pagesArabinda SamalJiban Nath LipunNo ratings yet

- Nanotechnology in Civil EngineeringDocument22 pagesNanotechnology in Civil EngineeringNehad AhmedNo ratings yet

- Chapter 2 - Advanced Construction MaterialsDocument43 pagesChapter 2 - Advanced Construction Materialsaddis zewdNo ratings yet

- Carbocrete: The Future of ConcreteDocument9 pagesCarbocrete: The Future of Concretesiddharth gautamNo ratings yet

- Lecture 2 Advanced Composites MEC509J2Document14 pagesLecture 2 Advanced Composites MEC509J2Ben MurrayNo ratings yet

- Chapter 2 General Introduction About Advanced Construction MaterialsDocument44 pagesChapter 2 General Introduction About Advanced Construction Materialseyob yohannesNo ratings yet

- Project 0075Document9 pagesProject 0075krishna reddyNo ratings yet

- Charan 3Document15 pagesCharan 3yakubsamadshaikNo ratings yet

- Carbon Fiber Reinforced Concrete (Carbocrete) : Seminar PresentationDocument17 pagesCarbon Fiber Reinforced Concrete (Carbocrete) : Seminar PresentationharikaNo ratings yet

- Concrete TermsDocument22 pagesConcrete TermsNadeem YousafzaiNo ratings yet

- Advanced Technologies in ConcreteDocument24 pagesAdvanced Technologies in ConcreteNaga Ashok GandiNo ratings yet

- Study of Manufacturing of Fiber Glass Reinforced CompositesDocument4 pagesStudy of Manufacturing of Fiber Glass Reinforced CompositesAbdullah SubbirNo ratings yet

- Present & Future of Lightweight ConcreteDocument7 pagesPresent & Future of Lightweight ConcreteGlobal_FriendshipNo ratings yet

- Unit 7Document21 pagesUnit 7YASHWANTH.M.KNo ratings yet

- Composite Materials in Building and Construction ApplicationsDocument52 pagesComposite Materials in Building and Construction Applicationsizzat kamil100% (1)

- Microstructure and Hardness Analysis of Silicon Emulsion & Graphene Oxide Coating Material For Helmet VisorsDocument5 pagesMicrostructure and Hardness Analysis of Silicon Emulsion & Graphene Oxide Coating Material For Helmet VisorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nano Technologies in Building and ConstructionDocument10 pagesNano Technologies in Building and ConstructionNandha KumarNo ratings yet

- Fiber Rein-Forced Concrete (Seminar) 1Document17 pagesFiber Rein-Forced Concrete (Seminar) 1GaneshNo ratings yet

- Application of Nanomaterials in Civil EngineeringDocument12 pagesApplication of Nanomaterials in Civil EngineeringChristelle AlipisNo ratings yet

- CE5604-Advanced Concrete Technology: - History and Origins - Greeks: Addition ofDocument27 pagesCE5604-Advanced Concrete Technology: - History and Origins - Greeks: Addition ofzzz_monsterNo ratings yet

- Carbon Fibre As A Recent Material Use in Construction 5889 Ysod1iuDocument28 pagesCarbon Fibre As A Recent Material Use in Construction 5889 Ysod1iuPratik RathodNo ratings yet

- 1 PBDocument7 pages1 PBKarthik SNNo ratings yet

- FRC1Document49 pagesFRC1Pavan Kalyan YadavNo ratings yet

- Module - 5 (B)Document31 pagesModule - 5 (B)Kenneth C.LinojNo ratings yet

- VijayDocument67 pagesVijayvijay kumarNo ratings yet

- Autoclaved Aerated Concrete 1Document22 pagesAutoclaved Aerated Concrete 1Abhi NandNo ratings yet

- Composite MaterialsDocument23 pagesComposite MaterialsNithin KannanNo ratings yet

- Under The Guidance of Sri K. Dileep Kumar (Assistant Professor, Mtech, Ucek)Document16 pagesUnder The Guidance of Sri K. Dileep Kumar (Assistant Professor, Mtech, Ucek)safNo ratings yet

- 7) Current Concrete TechnologyDocument93 pages7) Current Concrete TechnologynghoeNo ratings yet

- MKAE1153 SEAA4163 v5 Current Concrete TechnologyDocument93 pagesMKAE1153 SEAA4163 v5 Current Concrete TechnologyAbdullah RamziNo ratings yet

- Polymer Fiber Reinforced Concrete Pavement: by MD Mutiullah MD Faisal Mohd Abdul Quddus B. MadhuriDocument42 pagesPolymer Fiber Reinforced Concrete Pavement: by MD Mutiullah MD Faisal Mohd Abdul Quddus B. MadhuriGamer RckNo ratings yet

- Ceramic AluminaDocument44 pagesCeramic AluminasakthidhisaNo ratings yet

- Final ResearchDocument29 pagesFinal Researchshubham dhakulkarNo ratings yet

- 1.2.1 Types of Construction ConcreteDocument34 pages1.2.1 Types of Construction ConcreteYash RajNo ratings yet

- Muffakham Jah College of Engineering and TechnologyDocument19 pagesMuffakham Jah College of Engineering and TechnologyRehan QuadriNo ratings yet

- Special Concrete and Concreting TechniquesDocument47 pagesSpecial Concrete and Concreting TechniquesTesfayeNo ratings yet

- Composite Materials Uc5713-Jil Sheth Uc1813-Keshav SharmaDocument18 pagesComposite Materials Uc5713-Jil Sheth Uc1813-Keshav SharmaKristian Marlowe OleNo ratings yet

- Architectural & Constructional TextilesDocument33 pagesArchitectural & Constructional TextilesMusa EltayebNo ratings yet

- Module 1Document66 pagesModule 1mUSINo ratings yet

- Textile Composites: Shahrukh ShahbazDocument55 pagesTextile Composites: Shahrukh ShahbazShahrukh100% (1)

- Ilovepdf MergedDocument38 pagesIlovepdf Mergedalina.tlekkabylova270202No ratings yet

- Wrapping Concrete Project-RajeshDocument41 pagesWrapping Concrete Project-RajeshMEHALA SNo ratings yet

- A Study On 3D Carbon Braided CompositeDocument56 pagesA Study On 3D Carbon Braided CompositeDaryl LeeNo ratings yet

- Pneumatic Structures - Building ConstructionDocument8 pagesPneumatic Structures - Building ConstructionRajkumari PonnammalNo ratings yet

- Ceramics Science and Technology, Volume 4: ApplicationsFrom EverandCeramics Science and Technology, Volume 4: ApplicationsRalf RiedelNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Recent Advances in Turning With Textured Cutting Tools A ReviewDocument15 pagesRecent Advances in Turning With Textured Cutting Tools A ReviewAbhishek BihariNo ratings yet

- BF2 DPR - 230514 - Steel PlantDocument2 pagesBF2 DPR - 230514 - Steel PlantManas JadavNo ratings yet

- OCTOBER 2021 Surplus Record Machinery & Equipment DirectoryDocument719 pagesOCTOBER 2021 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Pro Self Flow Castables Cumiflow CumicastDocument2 pagesPro Self Flow Castables Cumiflow CumicastjulianoducaNo ratings yet

- Development of Novel Self Healing Concrete Using Carbon NanotubesDocument20 pagesDevelopment of Novel Self Healing Concrete Using Carbon NanotubesVujjini RaghuNo ratings yet

- Packaging Industry (71)Document13 pagesPackaging Industry (71)aparna aravamudhanNo ratings yet

- VIU in Index-Priced WorldDocument20 pagesVIU in Index-Priced WorldPaul VermeulenNo ratings yet

- HIMC Co., Ltd. Catalog enDocument12 pagesHIMC Co., Ltd. Catalog endenny saputraNo ratings yet

- Interspec Paint SpecificationDocument17 pagesInterspec Paint Specificationcameo.exteriorlightsNo ratings yet

- Valmont Larson Pine Tree SolutionsDocument2 pagesValmont Larson Pine Tree Solutionssalvador RiveraNo ratings yet

- MSizer Compact enDocument8 pagesMSizer Compact enMoey AhmedNo ratings yet

- Building Inspection ReportDocument8 pagesBuilding Inspection ReportA DubeyNo ratings yet

- Wood Ash 7Document4 pagesWood Ash 7r;rNo ratings yet

- Bezinal XPDocument2 pagesBezinal XPHeca WahyuniNo ratings yet

- European Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TDocument22 pagesEuropean Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TAshok Kumar BakshiNo ratings yet

- Astm A311 - 2015 - ObsoletoDocument4 pagesAstm A311 - 2015 - ObsoletoRicardo Ricardo100% (1)

- E-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1Document15 pagesE-Catalog & Company Profile PT. Total Solusindo Mesin (FEASpack) - 1vincentkNo ratings yet

- 2023 Wedo Tools CatalogDocument135 pages2023 Wedo Tools CatalogsaurabhNo ratings yet

- Portland Cement Type Cem Ii - A-L 42.5 NDocument2 pagesPortland Cement Type Cem Ii - A-L 42.5 NAllache IsmailNo ratings yet

- 8607 43745 2 PBDocument12 pages8607 43745 2 PBToni D.No ratings yet

- High Temperature Behaviour of Concrete Produced With Desert SandDocument4 pagesHigh Temperature Behaviour of Concrete Produced With Desert SandDelahan AbatyoughNo ratings yet

- Developing Welding Procedures For 4140 SteelDocument17 pagesDeveloping Welding Procedures For 4140 SteelJose Felix AcevedoNo ratings yet

- Polystick Tu Plus Pds 8Document2 pagesPolystick Tu Plus Pds 8jgarciaNo ratings yet

- ms264 (High Strength Steel)Document18 pagesms264 (High Strength Steel)Enrique Maya VisuetNo ratings yet

- Tle10 Q1 W3 Classification of Materials Tools and Equipment in Fashion AccessoriesDocument72 pagesTle10 Q1 W3 Classification of Materials Tools and Equipment in Fashion AccessorieskarttzyNo ratings yet

- Crystals 11 01196 v3Document23 pagesCrystals 11 01196 v3Dattatreya PatiNo ratings yet

- EN - Klinger Italy - LLG Transparent 2015Document25 pagesEN - Klinger Italy - LLG Transparent 2015GordinhorsNo ratings yet

- Solvay - Algoflon L203RDocument3 pagesSolvay - Algoflon L203RRenan GadioliNo ratings yet

- Study Notes - Electricity and Circuits - Science Class 6 PDF DownloadDocument5 pagesStudy Notes - Electricity and Circuits - Science Class 6 PDF DownloadruchikaNo ratings yet