Professional Documents

Culture Documents

Concrete Work Risk-Assessment in Word

Concrete Work Risk-Assessment in Word

Uploaded by

Zakaria MtepaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Work Risk-Assessment in Word

Concrete Work Risk-Assessment in Word

Uploaded by

Zakaria MtepaCopyright:

Available Formats

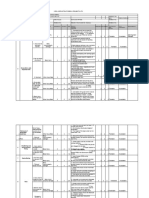

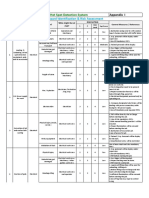

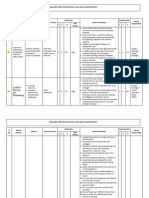

TASK BASED RISK ASSESSEMENT FORM

DATE:

REFERENCES WORK DESCRIPTION: Concrete Works

RISK ASSESSMENT DATE:

PTW No.:

OTHERS: WORK LOCATION:

No. TASK HAZARDS CONSEQUENCE INITIAL RISK

CONTROL MEASURES

RESIDUAL RISK

RESPONSIBLE

(Job Steps) EFFECT S L R S L R PERSON

1. Get a Permit to work

2. Conduct a pre-job safety meeting (TBT) before starting to work

1. Slip, trip and fall

3. Discuss all hazards & controls with workers.

1 Pre Work and Survey the area 2. Lack of Permit 1.Personnel Injury 2 1 2 1 1 1

3. Toolbox talk not held

1. Personnel Injury

2. Health illness 1. The ground surface should be even for shifting of materials

2.Identify the required manpower and evaluate the required lifting device; reduce

manual handling

1. Body posture

3.Ensure good grip, good footing and keep the load closer to the man lifting

2. Caught in between

2 Movement of materials 3 3 9 4.Enhance proper lifting technique, bend knees of joints. Back reasonably straight 2 1 2

3.Bumped and use leg muscles by providing training to the employees

4. Heat Exposure 5.Provide barrier, safety signages and secure defined locatn of activities

6.Schedule heavy objects in morning and move those light weight objects at nights

7.Ensure potable drinking water availability. Proceed to cool area once feel dizziness

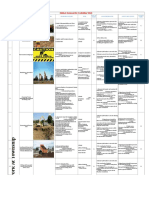

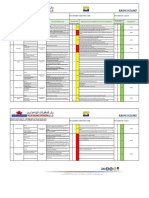

1. All power saws will have manufacturersupplied guards in place and

operational at all times

2. Inspect and test equipment and cords prior to use.

1. High pitched noise can

3. Power tools not in use shall be disconnected from their power

damage hearing

2. Saw blades cut source.

1. Personel Injury

whatever they come in contact 4. . Person using sledge hammer will makesure everyone else is clear

3 Laying out form with 3. Electrical Shock 2. Property Damage 3 3 9 before swinging 2 1 2

4. Sledge hammer can send particles 3.Health illness 5. Saw operators and adjacent workers will wear hearing and eye

of

protection when operating saws.

wood/metal flying

1. Grinder wheel throws

off sparks and hot bits of metal 1. Workers will ensure the grinder’s guard is in place and fully

operational before use

2. Accidental contact with

2. Debris should be removed from work areas on a regular basis.

grinder

1. Personel Injury 3. All protruding ends of steel rebar shall be guarded with rebar caps or

wheel

4 Installing Rebar 2. Property Damage 3 3 9 wooden troughs, or bent so that exposed ends no longer create an impalement 2 1 2

can cause bad cuts hazard

3.Health illness

3. Mill scale, 4. Rebar cutters will wear safety glasses,gloves, hearing protection,

sharp/sheared ends of tie wire safety vest, and hardhats.

can injure eyes 4.Slip,trip and fall

5. Workers tying rebar will wear appropriate PPE.

5. 5. Impalement hazard

1.While heavy equipment is operating, all ground workers will wear hardhats

1. Workers run over/backed and safety vests

1. Personel Injury 2. Pumpers and redi-mix trucks will use spotters

into by equipment

5 Concrete Pouring 2. Air in line causing high- 2. Property Damage 3 3 9 3. Equipment idling more than 3 minutes will be shut off 2 2 4

speed burst of concrete 3.Health illness

4. Only trained workers will use the whip-hose

5. Whip-hose operator and others will coordinate signals with pump operator

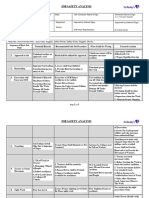

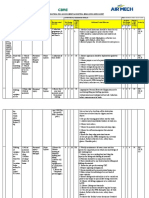

1.Make sure that load is not carried for a long distance

2.Beware of the size and shape of materials

1.Personnel Injury 3.Make sure that materila is not too hot or cold, if so use appropriate PPE

1.Slip, trip and fall

2.Ill health 4.When materials are loaded, keep feet and fingers clear of picnh point

2.Collapsed of stacked materials

3. Musculoskeletal 5.Load should not be lifted above shoulder

6 Manual Handling 3.Wrong posture, method of lifting 3 3 9 2 2 4

disorders 6.Bend knees, keep back straight, keep the load close to the body and lift the load

4.Overloading

including sprains 7.Avoid any twisted movement

5.Pinch points

and strains 8.Do not carry the load that will obscure the your vision

9.Carrying too heavy load should be avoided, use mechanical handling

10. Necessary PPE must be worn

1. Use anti-vibration models, hand-grips and gloves.

2. Issue hand protection to users so that hands can be kept warm when the

1. Vibrating tools causing 1.Personnel Injury weather is cold.

finger/hand injury. 3. Carry out a noise assessment of the activity and issue ear defenders

2. Musculoskeletal

2. Vibrating tools causing when necessary.

7 Use of vibrating power tools excessive noise. disorders 3 3 9 4. Ensure users take regular breaks from the activity - alternate the task 2 1 2

3. Vibrating tools causing including sprains between different persons.

musculoskeletal injury and strains 5. Instruct users to exercise the hands and fingers regularly between uses.

6. Carry out manual handling assessments for heavy tools.

7. Establish a regular inspection and maintenance regime and keep records.

RISK MATRIX

KEY LEGENDS: RISK CLASIFICATIONS S = SEVERITY 1-4 = (S)x(L) LIKELIHOOD SEVERITY LIKELIHOOD

LOW RISK

1

L = LIKELIHOOD 5-9 = MEDIUM RISK R = 1 2 3 4 5 1 Negligible Injury Effect 1 Unlikey - Occurance Close To Zero

RISK RATING 10-16 = HIGH RISK 1 2 3 4 5 2 Minor Injury 2 May Happen - Capable of Taking Place

20-25 = SERIOUS RISK

2 2 4 6 8 10 3 Significant Injury with Work Absence (LTI) 3 Likely - Inclined to Occur

SEVERITY

3 3 6 9 12 15 4 Major Injury -Permanent Disabilities 4 Very Likely - Highly Inclined to Occur

4 4 8 12 16

RESIDUAL RISK: No work to proceed if the Residual Risk after use of Control Measures remains High. 20 5 Fatal - Death 5 Certain - Sure Will Occur

5 5 10 15 20 25

WORK SUPERVISOR :________________________________________Sign:______________________ REVIEWED BY PROJECT MANAGER:_____________________________Sign:_______________________

REVIEWED AND APPROVED BY (HSE):___________________________________________Sign:_______________________

You might also like

- Risk Assessment For Concrete WorksDocument3 pagesRisk Assessment For Concrete WorksMario Marasigan83% (42)

- Risk Assessment - Installation of Cable Trays & DCAC CablesDocument5 pagesRisk Assessment - Installation of Cable Trays & DCAC CablesIbrahim Esmat100% (1)

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- Band Saw Machine HIRADocument4 pagesBand Saw Machine HIRAChethanNo ratings yet

- 81W173047 (P13069) PDFDocument435 pages81W173047 (P13069) PDFharounNo ratings yet

- Risk Assessment For Concrete WorksDocument3 pagesRisk Assessment For Concrete Worksprecivalcamilus19No ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Job Safety Analysis WorksheetDocument57 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- JSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- JSA - Structure Lifting PlanDocument2 pagesJSA - Structure Lifting Planmuiqbal.workNo ratings yet

- Hira BCN 22aDocument33 pagesHira BCN 22aDhaneswar SwainNo ratings yet

- JSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- RA of Manual ChippingDocument2 pagesRA of Manual ChippingMohamedSaidNo ratings yet

- Risk Assessment For PVC ConduitsDocument2 pagesRisk Assessment For PVC Conduitsمقاول تكييف كهرباء وصحي100% (1)

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Method Statement For Scaffolding WorkDocument4 pagesMethod Statement For Scaffolding WorkChayank TiwariNo ratings yet

- Jsa Welding GrindingDocument5 pagesJsa Welding GrindingWiedz PrastNo ratings yet

- Risk Assessment For Installation of Water Supply SystemDocument2 pagesRisk Assessment For Installation of Water Supply Systemمقاول تكييف كهرباء وصحيNo ratings yet

- RCC Safety Supervisor: CivilDocument7 pagesRCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- Hirarc ScaffoldDocument2 pagesHirarc ScaffoldArinaAhmad100% (1)

- Job Safety Analysis WorksheetDocument3 pagesJob Safety Analysis Worksheetmohammed a hseNo ratings yet

- Vacuum Test Risk AssessmentDocument6 pagesVacuum Test Risk AssessmentJohn Mark Macoy100% (1)

- ExcavationDocument3 pagesExcavationKoneti JanardhanaraoNo ratings yet

- JSA For Childrens RoomDocument3 pagesJSA For Childrens Roomkalai selvanNo ratings yet

- Hira Work at Height-1Document4 pagesHira Work at Height-1Optimistic anonymousNo ratings yet

- Ohs Monitoring Event Management Services NC IiiDocument5 pagesOhs Monitoring Event Management Services NC IiiIrishNo ratings yet

- HSE Risk AssessmentDocument4 pagesHSE Risk Assessmentwhtez0neNo ratings yet

- JSA For HP and LP Piping ErectionDocument1 pageJSA For HP and LP Piping ErectionAmit SinghNo ratings yet

- Fitout RaDocument14 pagesFitout RaАлёна Драчева100% (1)

- Risk Assessment - Al EthihadDocument6 pagesRisk Assessment - Al EthihadKrishnan GreeshmaNo ratings yet

- Risk Assessment For Hot Spot Detection SystemDocument2 pagesRisk Assessment For Hot Spot Detection SystemprabhumanocNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Hazard Identification & Risk AssessmentDocument8 pagesHazard Identification & Risk Assessmentanand.v4491No ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Hira Cutting of RodDocument2 pagesHira Cutting of RodDwitikrushna RoutNo ratings yet

- HIRA For Watching PlantDocument13 pagesHIRA For Watching PlantVikash Kumar RayNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- PTL JSA Maintenance of Cooling Towers - National Cycling Centre - SPORTTDocument7 pagesPTL JSA Maintenance of Cooling Towers - National Cycling Centre - SPORTTShannon MooreNo ratings yet

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- OH Crane OverhaulingDocument2 pagesOH Crane OverhaulingSharjeel AhmedNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- JSA Overhead Crane NH3, Urea, NADocument2 pagesJSA Overhead Crane NH3, Urea, NASharjeel AhmedNo ratings yet

- HIRA of FTC Erection.Document3 pagesHIRA of FTC Erection.Gyanendra SrivastavaNo ratings yet

- Risk Assessment For Above Ground Drainage SystemDocument2 pagesRisk Assessment For Above Ground Drainage Systemمقاول تكييف كهرباء وصحيNo ratings yet

- JHA Equipments Declaration FormDocument4 pagesJHA Equipments Declaration Formzuqhair sherryNo ratings yet

- Risk Assessment For Chilled Water CladdingDocument2 pagesRisk Assessment For Chilled Water CladdingHAMIDULLAH MNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- 8.1 Jha For Retaining Ground Slab Construction WorksDocument2 pages8.1 Jha For Retaining Ground Slab Construction Worksdahlanconstruction66No ratings yet

- Job Hazard Analysis: Installation of Fm200 Fire Suppression SystemDocument6 pagesJob Hazard Analysis: Installation of Fm200 Fire Suppression SystemJohn Mark MacoyNo ratings yet

- Job Activity Hazard Effect Control MeasuresDocument2 pagesJob Activity Hazard Effect Control Measuresperquino oasan100% (1)

- Jha For SMP 2Document7 pagesJha For SMP 2Rohit TharseNo ratings yet

- Jsa Roof Sheeting & Wall CladdingDocument23 pagesJsa Roof Sheeting & Wall Claddingsamir ranjan dhalNo ratings yet

- Job Safety Analysis: Gujarat RefineryDocument11 pagesJob Safety Analysis: Gujarat RefineryMICHAEL Rose100% (2)

- Risk Assessment Form: 1. Workin Gat HeightDocument3 pagesRisk Assessment Form: 1. Workin Gat HeightS.SRI KRISHNA (RA2111026020166)No ratings yet

- JSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block CDocument5 pagesJSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block Cnoahlungu96No ratings yet

- Machinery RegisterDocument84 pagesMachinery RegisterZakaria MtepaNo ratings yet

- Roof Risk Assessment Template FormDocument10 pagesRoof Risk Assessment Template FormZakaria MtepaNo ratings yet

- GPN RoofingDocument9 pagesGPN RoofingZakaria MtepaNo ratings yet

- Tanipac Hse April2023Document13 pagesTanipac Hse April2023Zakaria MtepaNo ratings yet

- NDMC PR No 11Document8 pagesNDMC PR No 11Zakaria MtepaNo ratings yet

- CCKL VacancyDocument2 pagesCCKL VacancyZakaria MtepaNo ratings yet

- How To Conduct Material Condition InspectionsDocument32 pagesHow To Conduct Material Condition InspectionsJoselito CortesNo ratings yet

- Abrasive Blasters 1.5 - 20 Cu. FT: Operation and Maintenance ManualDocument86 pagesAbrasive Blasters 1.5 - 20 Cu. FT: Operation and Maintenance Manualhainguyenbkvhv100% (1)

- MDSD FludarabinDocument10 pagesMDSD FludarabinImanda EsaNo ratings yet

- 01 HSE Induction - VisitorDocument28 pages01 HSE Induction - VisitorMusadiq HussainNo ratings yet

- Uniquat 2250M MSDSDocument11 pagesUniquat 2250M MSDSgregorypage2No ratings yet

- Msds BHT PDFDocument6 pagesMsds BHT PDFTon BlokNo ratings yet

- SOP of Conveyor Belt Re-JointingDocument9 pagesSOP of Conveyor Belt Re-JointingDwitikrushna RoutNo ratings yet

- Apexior 3 Hoja SeguridadDocument11 pagesApexior 3 Hoja SeguridadArturo SalinasNo ratings yet

- BOSH SO2 Manual GovernmentDocument138 pagesBOSH SO2 Manual Governmentjasonrey.saysonNo ratings yet

- Occupational Hygiene In: Construction WorkDocument16 pagesOccupational Hygiene In: Construction WorkPhong NgôNo ratings yet

- COVID Business Travel Approval Form 10-30-2020 PauloDocument2 pagesCOVID Business Travel Approval Form 10-30-2020 PauloMarco LamadridNo ratings yet

- Drilling Safety ManualDocument23 pagesDrilling Safety ManualAlvaro MadridNo ratings yet

- Sevoflurane UsoDocument7 pagesSevoflurane Usohasan_j688675No ratings yet

- Ensuring A Positive Practice Environment: Occupational Safety For Health Worker ProductivityDocument8 pagesEnsuring A Positive Practice Environment: Occupational Safety For Health Worker ProductivityCapacityPlusNo ratings yet

- Jsa Heat Exchanger Inspection Water Cleaning 2Document5 pagesJsa Heat Exchanger Inspection Water Cleaning 2halfy safitri100% (2)

- Health and Safety in Cement IndustryDocument7 pagesHealth and Safety in Cement Industryوائل شديوةNo ratings yet

- Anggik Prasetyo-2002411030 - SOP ChamferDocument5 pagesAnggik Prasetyo-2002411030 - SOP ChamferAnggi PrasetyoNo ratings yet

- SDS - Flobas PD-14Document3 pagesSDS - Flobas PD-14reginaulfahNo ratings yet

- INTRODUCTIONDocument54 pagesINTRODUCTIONUjwal JaiswalNo ratings yet

- TR Hairdressing NC IIDocument72 pagesTR Hairdressing NC IIRachel Grace S. VillaverNo ratings yet

- EU Declaration of Conformity Latex (UG) 2022 MDR+PPE SRNDocument2 pagesEU Declaration of Conformity Latex (UG) 2022 MDR+PPE SRNwijayagerrad75No ratings yet

- Gec 218 Module One - Safety TechnologyDocument10 pagesGec 218 Module One - Safety TechnologyOyedotun TundeNo ratings yet

- Crown Trade Red Oxide Primer SDSDocument9 pagesCrown Trade Red Oxide Primer SDSMonique BarbaraNo ratings yet

- SL No. Gate Pass No. Name of Contractor Incident Date Name of Reporting Person Incident Time (Hrs and Min)Document5 pagesSL No. Gate Pass No. Name of Contractor Incident Date Name of Reporting Person Incident Time (Hrs and Min)Dth InfraNo ratings yet

- Cp2245 Finish Paint Ea4-5991 MsdsDocument11 pagesCp2245 Finish Paint Ea4-5991 MsdsPanneer SelvamNo ratings yet

- Laf 1001Document22 pagesLaf 1001Feray Kebeli AvcıNo ratings yet

- f11 Competency Based CurriculumDocument41 pagesf11 Competency Based CurriculumVictor Rosales100% (4)

- Method Statement For Installation of Telephone ManholeDocument4 pagesMethod Statement For Installation of Telephone ManholemujtiobamaliblNo ratings yet

- MSDS 918267Document12 pagesMSDS 918267anibal_rios_rivasNo ratings yet