Professional Documents

Culture Documents

Report Paint

Report Paint

Uploaded by

rohmathidayat112Copyright:

Available Formats

You might also like

- Dye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuDocument4 pagesDye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuTWI CertificationNo ratings yet

- Daily Insp Report For SLV (Tape Coating)Document6 pagesDaily Insp Report For SLV (Tape Coating)Richart SembiringNo ratings yet

- Method Statement For Exterior Wall FinishingDocument6 pagesMethod Statement For Exterior Wall FinishingMin LuoNo ratings yet

- TK-103-FGL-16-caulking InspectionDocument1 pageTK-103-FGL-16-caulking InspectionjoseNo ratings yet

- Internal Coating ReportDocument2 pagesInternal Coating ReportHusaimNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Procedure No.: Liquid Penetrant TestDocument4 pagesProcedure No.: Liquid Penetrant Testคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Interconnecting Piping For Hook Up New Wells at Guebiba ClusterDocument1 pageInterconnecting Piping For Hook Up New Wells at Guebiba ClusterCss SfaxienNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Document4 pagesLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky FirdyanNo ratings yet

- Form Welding Summary and Material Traceability Record - Piping TuhupDocument6 pagesForm Welding Summary and Material Traceability Record - Piping TuhupYuwantoniAlNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Ibo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Document6 pagesIbo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Gokhula KannanNo ratings yet

- 0362 Ekl Pi PaintingDocument5 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- Shell Kecil Osp08Document3 pagesShell Kecil Osp08Adnan FrrNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Int-Aim-231861 MT 06-08-23Document4 pagesInt-Aim-231861 MT 06-08-23Joshua ClaytonNo ratings yet

- DP Test Tank 1Document2 pagesDP Test Tank 1sushant sanjay jadhav0% (1)

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- 0362 Ekl Pi PaintingDocument5 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- PT 001 PDFDocument1 pagePT 001 PDFDang sonNo ratings yet

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- Plumbness Inspection ReportDocument3 pagesPlumbness Inspection ReportDoris DorisNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- Sump Tank (New)Document1 pageSump Tank (New)RonniNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- 0362 Ekl Pi PaintingDocument8 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- Dye Penetrant Testing: Surface PreparationDocument2 pagesDye Penetrant Testing: Surface PreparationyuwantoniNo ratings yet

- Painting ReportDocument2 pagesPainting ReporthikmahNo ratings yet

- Liquid PenetrantDocument2 pagesLiquid PenetrantabdiNo ratings yet

- 0362 Ekl Pi PaintingDocument5 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- Painting Ins Report DakDocument45 pagesPainting Ins Report DakVinayaga MoorthiNo ratings yet

- Painting 1Document2 pagesPainting 1Kilerz 91100% (2)

- DP Format Bhel 1Document1 pageDP Format Bhel 1narayandasraikwar100% (1)

- Daily Insp Report For SLV (Polymeric Sheet Coating)Document2 pagesDaily Insp Report For SLV (Polymeric Sheet Coating)Richart SembiringNo ratings yet

- 03-09092021-DPR-003-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliDocument5 pages03-09092021-DPR-003-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliQA QCNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- 1553 SM-ST-002Document3 pages1553 SM-ST-002Massimo FumarolaNo ratings yet

- Painting Report Cd1Document77 pagesPainting Report Cd1sivaNo ratings yet

- Bao Cao PT Ba Ria-04Document4 pagesBao Cao PT Ba Ria-04Sang Nguyen QuangNo ratings yet

- Compressor Cb01Document3 pagesCompressor Cb01Adnan FrrNo ratings yet

- TK-103-FGL-32 Tissue Visual and Thickness InspectionDocument1 pageTK-103-FGL-32 Tissue Visual and Thickness InspectionjoseNo ratings yet

- BHA AD 68 NOT# 200000708382 RepDocument13 pagesBHA AD 68 NOT# 200000708382 RepArun SidharthNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- Master Format SummaryDocument5 pagesMaster Format Summaryunto gunungNo ratings yet

- TK-103-FGL-26-matt Inspection Prior To Tissue ApplicationDocument1 pageTK-103-FGL-26-matt Inspection Prior To Tissue ApplicationjoseNo ratings yet

- PT Report of Hit Ace 28-03-2022-11423Document3 pagesPT Report of Hit Ace 28-03-2022-11423HARDIK PATELNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech AnandNo ratings yet

- SSC SA-6543 Yoke CAT785C ThiessDocument4 pagesSSC SA-6543 Yoke CAT785C ThiessEngineering ProductionNo ratings yet

- Pipeline HSS Coating Inspection ReportDocument1 pagePipeline HSS Coating Inspection Reportcsc EXPERTISE100% (1)

- 3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Document1 page3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Cristobal CherigoNo ratings yet

- Daily Painting Inspection Report 08Document2 pagesDaily Painting Inspection Report 08Oussama Ben AbbesNo ratings yet

- D.P. Test ReportDocument1 pageD.P. Test Reportvirendra katkeNo ratings yet

- Inspection Certificate Leser CGA (EN)Document3 pagesInspection Certificate Leser CGA (EN)Anas BadarNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- MOM (QF-RM-001)Document2 pagesMOM (QF-RM-001)rohmathidayat112No ratings yet

- ITPDocument2 pagesITProhmathidayat112No ratings yet

- Dimension Check Sheet GT-33 Unit06Document9 pagesDimension Check Sheet GT-33 Unit06rohmathidayat112No ratings yet

- List Calibration JPAIDocument2 pagesList Calibration JPAIrohmathidayat112No ratings yet

- MMR_ Tank-PX-211Document2 pagesMMR_ Tank-PX-211rohmathidayat112No ratings yet

- ITPDocument2 pagesITProhmathidayat112No ratings yet

- QP SPC L002 Rev 2 ReferenceDocument1 pageQP SPC L002 Rev 2 ReferencekannanNo ratings yet

- Coating SpecsDocument3 pagesCoating SpecsAhmed WagihNo ratings yet

- d30 - ENERTITE MD 1602-10 - Ed04 - ENDocument6 pagesd30 - ENERTITE MD 1602-10 - Ed04 - ENMangalagiu BogdanNo ratings yet

- TDS Kan Ethyl Zinc Silicate PrimerDocument3 pagesTDS Kan Ethyl Zinc Silicate PrimeroliviaNo ratings yet

- Fosroc Nitobond AR and HAR 1209Document1 pageFosroc Nitobond AR and HAR 1209er_sanjaypatelNo ratings yet

- MasterSeal 122Document23 pagesMasterSeal 122Ah MedNo ratings yet

- Hempel WB Primer 28830Document3 pagesHempel WB Primer 28830Noman AhmedNo ratings yet

- Ceilcote 680 Primer AKZO PDFDocument4 pagesCeilcote 680 Primer AKZO PDFamitzalteNo ratings yet

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDocument8 pages3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaNo ratings yet

- Michem® Indicator 001: Technical Data SheetDocument2 pagesMichem® Indicator 001: Technical Data SheetFranco Rodriguez DelgadoNo ratings yet

- General Waterproofing Brochure 58 1Document21 pagesGeneral Waterproofing Brochure 58 1KAMAL BEHL100% (1)

- Nitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningDocument4 pagesNitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningkalidindivenkatarajuNo ratings yet

- Contoh: Jadual Pembahagian Penilaian Berterusan Tp-306-1:2012 Automotive Spray Painting Cu01: Masking ProcessDocument13 pagesContoh: Jadual Pembahagian Penilaian Berterusan Tp-306-1:2012 Automotive Spray Painting Cu01: Masking ProcessAhmad Rizduan Dyana HafizahNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Floor DeckDocument184 pagesFloor DeckAbelbelachewNo ratings yet

- Specification For Bitumen Slip Layer: 1.0 GeneralDocument4 pagesSpecification For Bitumen Slip Layer: 1.0 Generalmhamed1No ratings yet

- Boscoseal PuxDocument4 pagesBoscoseal PuxSri WatsonNo ratings yet

- Epoxy-Primer Tds Rev2Document2 pagesEpoxy-Primer Tds Rev2antecristorodriguezNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Sigma Zinc 102en-US - 7702 PDFDocument5 pagesSigma Zinc 102en-US - 7702 PDFaselabollegalaNo ratings yet

- MPL-P142 - 6316345 - Vol.2 Sec. 6 General Specs-Waterproof & RoofingDocument14 pagesMPL-P142 - 6316345 - Vol.2 Sec. 6 General Specs-Waterproof & RoofinganishNo ratings yet

- Mastercoat Chassis Black DatasheetDocument2 pagesMastercoat Chassis Black DatasheetJimDavisNo ratings yet

- Customer Al Khaleej Sugar Refinery Company, Jebel Ali, DubaiDocument6 pagesCustomer Al Khaleej Sugar Refinery Company, Jebel Ali, DubaiRoshan aravinthNo ratings yet

- Qualified Product List: Edition E03.20Document160 pagesQualified Product List: Edition E03.20David Eduardo Arteaga Faubla (LATAM)No ratings yet

- Epoxy Polyurethane PrimersDocument1 pageEpoxy Polyurethane Primersonkar pareekNo ratings yet

- GW PDFDocument24 pagesGW PDFCarlos Eduardo ZelidonNo ratings yet

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngNo ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUPageduesca RouelNo ratings yet

- Wall FinishesDocument21 pagesWall FinisheslavekushNo ratings yet

Report Paint

Report Paint

Uploaded by

rohmathidayat112Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report Paint

Report Paint

Uploaded by

rohmathidayat112Copyright:

Available Formats

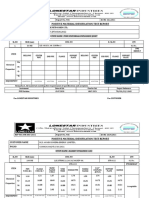

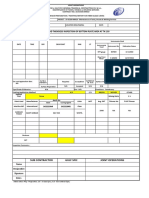

SNF: QC-012

PAINT INSPECTION REPORT

Date : Agustus, 08-2022

Report No. : 001/SBJS-EEI/PI-E1034-01/22

Customer : PT. Elsewedy Electric Indonesia Ref Drawing No. : E1034

Project Name : Tank E1034 UNIT 1 Stamp No. : SL-E1034-1

Part Name : Losse Part Unit : #01

Process : Blasting, Zinc Spray & Painting

PREPARATION PAINTING REPORT

1 AMBIENT CONDITION

Time 09:00 11:00 13:00 15:00 Remaks

Air Temperature Dry / Wet Bulb ̶ 25 ˚C 24 ˚C 25 ˚C

Relative Humidity ̶ 71% 68% 70%

Dew Point ( ˚ C ) ̶ 23 ˚C 24 ˚C 24 ˚C

Steel Surface Temperature ̶ 29 ˚C 30 ˚C 29 ˚C

2 SURFACE PREPARATION

A. Steel Surface Condition Before Surface Preparation

Rush Grade : N/A

Oil and Grease : N/A

Wellding Spatter : Cleaning

Sharp Egdes : N/A

Steel Defect : Repair

B Surface Cleaning Standart and Degree

Cleaning Degree : Brushing √ Actual Achieved SSPC-SP 10 Others

C Abrasive Blast Cleaning

Type : STEEL GRID Mesh : 24 Condition:

Specified profile 3.0 (Medium) Actual Achieved :

3 PAINTING PREPARATION

A. Strip Coat

Coating Aplication Method : √ Spray Airless spray √ Brush √ Rolled

Swipe Coat Method : N/A

Preasure At pump : N/A

4 PAINTING APLICATION

Paint Curing Agent Mixing DFT

Coating Layer Thiner Colour RAL

Name Bact No. Name Bact No. Ratio Spec

Zinc Spray 85

IN Hempadur 15600 532060919 Hempel's 95600 532050278 Hempel's White 90

Primery Coat

OUT Hempadur 15553 532050175 Hempel's 98021 531040568 Hempel's 40

IN

Second Coat

OUT H. Mastic 45881 531110418 Hempel's 95881 532070914 Hempel's Reddish grey 200

IN

Top Coat

OUT H. Polyenamel 532040353 Hempel's Hempel's 75

DATE APLICATION Strart Finish Drying Time

Zinc Spray : 04/08/2022 : 05/08/2022

Primer : 02/08/2022 : 05/08/2023 09:30 - 15:00 Prepared By. Approved By. Reviewed By.

Second : 04/08/2022 : 05/08/2024

Top Coat : 06/08/2022 : 05/08/2025

Rohmat H Rusito Cust. Inspector

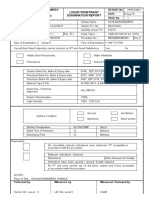

SNF: QC-012

PAINT INSPECTION REPORT

Date : Agustus, 08-2022

Report No. : 001/SBJS-EEI/PI-E1034-01/22

Customer : PT. Elsewedy Electric Indonesia Ref Drawing No. : E1034

Project Name : Tank E1034 UNIT 1 Stamp No. : SL-E1034-1

Part Name : Losse Part Unit : #01

Process : Blasting, Zinc Spray & Painting

Coating Aplication Method : √ Airless Spray Spec DFT : Zinc Spray : 85 µm

√ Air Spray Primer Coat : 40 µm

√ Roll Second Coat : 200 µm

Brush ( Touch Up) Top Coat : 75 µm

ZINC SPRAY (µm) Tank

Spot/Area AVG Visual Check Remaks

A B C D E

Outside 135 109 130 149 113 127,2 Accepted

Primery Dry Film Thickness (µm) Tank

Spot/Area AVG Visual Check Remaks

A B C D E

Inside #DIV/0! Accepted

Outside #DIV/0! Accepted

Second Coat Dry Film Thickness (µm) Tank

Spot/Area AVG Visual Check Remaks

A B C D E

Inside #DIV/0! Accepted

Outside #DIV/0! Accepted

Top Coat Dry Film Thickness (µm) Tank

Spot/Area AVG Visual Check Remaks

A B C D E

Inside #DIV/0! Accepted

Outside #DIV/0! Accepted

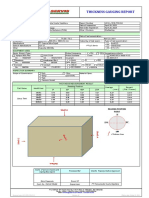

SKETCH

Note:

Prepared By. Approved By. Reviewed By.

Rohmat Hidayat Rusito Cust. Inspector

You might also like

- Dye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuDocument4 pagesDye Penetrant Report: Pembangunan Dermaga TBBM Tanjung BatuTWI CertificationNo ratings yet

- Daily Insp Report For SLV (Tape Coating)Document6 pagesDaily Insp Report For SLV (Tape Coating)Richart SembiringNo ratings yet

- Method Statement For Exterior Wall FinishingDocument6 pagesMethod Statement For Exterior Wall FinishingMin LuoNo ratings yet

- TK-103-FGL-16-caulking InspectionDocument1 pageTK-103-FGL-16-caulking InspectionjoseNo ratings yet

- Internal Coating ReportDocument2 pagesInternal Coating ReportHusaimNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Procedure No.: Liquid Penetrant TestDocument4 pagesProcedure No.: Liquid Penetrant Testคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Interconnecting Piping For Hook Up New Wells at Guebiba ClusterDocument1 pageInterconnecting Piping For Hook Up New Wells at Guebiba ClusterCss SfaxienNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Liquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Document4 pagesLiquid Penetrant Examination Report: Jasa Perbaikan Silincer & Dinding Dalam Gas Duct Mi GT 1.1 MUARA KARANG 2020Riesky FirdyanNo ratings yet

- Form Welding Summary and Material Traceability Record - Piping TuhupDocument6 pagesForm Welding Summary and Material Traceability Record - Piping TuhupYuwantoniAlNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Ibo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Document6 pagesIbo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Gokhula KannanNo ratings yet

- 0362 Ekl Pi PaintingDocument5 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- Shell Kecil Osp08Document3 pagesShell Kecil Osp08Adnan FrrNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Int-Aim-231861 MT 06-08-23Document4 pagesInt-Aim-231861 MT 06-08-23Joshua ClaytonNo ratings yet

- DP Test Tank 1Document2 pagesDP Test Tank 1sushant sanjay jadhav0% (1)

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- 0362 Ekl Pi PaintingDocument5 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- PT 001 PDFDocument1 pagePT 001 PDFDang sonNo ratings yet

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- Plumbness Inspection ReportDocument3 pagesPlumbness Inspection ReportDoris DorisNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- Sump Tank (New)Document1 pageSump Tank (New)RonniNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- 0362 Ekl Pi PaintingDocument8 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- Dye Penetrant Testing: Surface PreparationDocument2 pagesDye Penetrant Testing: Surface PreparationyuwantoniNo ratings yet

- Painting ReportDocument2 pagesPainting ReporthikmahNo ratings yet

- Liquid PenetrantDocument2 pagesLiquid PenetrantabdiNo ratings yet

- 0362 Ekl Pi PaintingDocument5 pages0362 Ekl Pi PaintingAbdul Gafoor ShaikhNo ratings yet

- Painting Ins Report DakDocument45 pagesPainting Ins Report DakVinayaga MoorthiNo ratings yet

- Painting 1Document2 pagesPainting 1Kilerz 91100% (2)

- DP Format Bhel 1Document1 pageDP Format Bhel 1narayandasraikwar100% (1)

- Daily Insp Report For SLV (Polymeric Sheet Coating)Document2 pagesDaily Insp Report For SLV (Polymeric Sheet Coating)Richart SembiringNo ratings yet

- 03-09092021-DPR-003-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliDocument5 pages03-09092021-DPR-003-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliQA QCNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- 1553 SM-ST-002Document3 pages1553 SM-ST-002Massimo FumarolaNo ratings yet

- Painting Report Cd1Document77 pagesPainting Report Cd1sivaNo ratings yet

- Bao Cao PT Ba Ria-04Document4 pagesBao Cao PT Ba Ria-04Sang Nguyen QuangNo ratings yet

- Compressor Cb01Document3 pagesCompressor Cb01Adnan FrrNo ratings yet

- TK-103-FGL-32 Tissue Visual and Thickness InspectionDocument1 pageTK-103-FGL-32 Tissue Visual and Thickness InspectionjoseNo ratings yet

- BHA AD 68 NOT# 200000708382 RepDocument13 pagesBHA AD 68 NOT# 200000708382 RepArun SidharthNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- Master Format SummaryDocument5 pagesMaster Format Summaryunto gunungNo ratings yet

- TK-103-FGL-26-matt Inspection Prior To Tissue ApplicationDocument1 pageTK-103-FGL-26-matt Inspection Prior To Tissue ApplicationjoseNo ratings yet

- PT Report of Hit Ace 28-03-2022-11423Document3 pagesPT Report of Hit Ace 28-03-2022-11423HARDIK PATELNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech AnandNo ratings yet

- SSC SA-6543 Yoke CAT785C ThiessDocument4 pagesSSC SA-6543 Yoke CAT785C ThiessEngineering ProductionNo ratings yet

- Pipeline HSS Coating Inspection ReportDocument1 pagePipeline HSS Coating Inspection Reportcsc EXPERTISE100% (1)

- 3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Document1 page3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Cristobal CherigoNo ratings yet

- Daily Painting Inspection Report 08Document2 pagesDaily Painting Inspection Report 08Oussama Ben AbbesNo ratings yet

- D.P. Test ReportDocument1 pageD.P. Test Reportvirendra katkeNo ratings yet

- Inspection Certificate Leser CGA (EN)Document3 pagesInspection Certificate Leser CGA (EN)Anas BadarNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- MOM (QF-RM-001)Document2 pagesMOM (QF-RM-001)rohmathidayat112No ratings yet

- ITPDocument2 pagesITProhmathidayat112No ratings yet

- Dimension Check Sheet GT-33 Unit06Document9 pagesDimension Check Sheet GT-33 Unit06rohmathidayat112No ratings yet

- List Calibration JPAIDocument2 pagesList Calibration JPAIrohmathidayat112No ratings yet

- MMR_ Tank-PX-211Document2 pagesMMR_ Tank-PX-211rohmathidayat112No ratings yet

- ITPDocument2 pagesITProhmathidayat112No ratings yet

- QP SPC L002 Rev 2 ReferenceDocument1 pageQP SPC L002 Rev 2 ReferencekannanNo ratings yet

- Coating SpecsDocument3 pagesCoating SpecsAhmed WagihNo ratings yet

- d30 - ENERTITE MD 1602-10 - Ed04 - ENDocument6 pagesd30 - ENERTITE MD 1602-10 - Ed04 - ENMangalagiu BogdanNo ratings yet

- TDS Kan Ethyl Zinc Silicate PrimerDocument3 pagesTDS Kan Ethyl Zinc Silicate PrimeroliviaNo ratings yet

- Fosroc Nitobond AR and HAR 1209Document1 pageFosroc Nitobond AR and HAR 1209er_sanjaypatelNo ratings yet

- MasterSeal 122Document23 pagesMasterSeal 122Ah MedNo ratings yet

- Hempel WB Primer 28830Document3 pagesHempel WB Primer 28830Noman AhmedNo ratings yet

- Ceilcote 680 Primer AKZO PDFDocument4 pagesCeilcote 680 Primer AKZO PDFamitzalteNo ratings yet

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDocument8 pages3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaNo ratings yet

- Michem® Indicator 001: Technical Data SheetDocument2 pagesMichem® Indicator 001: Technical Data SheetFranco Rodriguez DelgadoNo ratings yet

- General Waterproofing Brochure 58 1Document21 pagesGeneral Waterproofing Brochure 58 1KAMAL BEHL100% (1)

- Nitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningDocument4 pagesNitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningkalidindivenkatarajuNo ratings yet

- Contoh: Jadual Pembahagian Penilaian Berterusan Tp-306-1:2012 Automotive Spray Painting Cu01: Masking ProcessDocument13 pagesContoh: Jadual Pembahagian Penilaian Berterusan Tp-306-1:2012 Automotive Spray Painting Cu01: Masking ProcessAhmad Rizduan Dyana HafizahNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Floor DeckDocument184 pagesFloor DeckAbelbelachewNo ratings yet

- Specification For Bitumen Slip Layer: 1.0 GeneralDocument4 pagesSpecification For Bitumen Slip Layer: 1.0 Generalmhamed1No ratings yet

- Boscoseal PuxDocument4 pagesBoscoseal PuxSri WatsonNo ratings yet

- Epoxy-Primer Tds Rev2Document2 pagesEpoxy-Primer Tds Rev2antecristorodriguezNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Sigma Zinc 102en-US - 7702 PDFDocument5 pagesSigma Zinc 102en-US - 7702 PDFaselabollegalaNo ratings yet

- MPL-P142 - 6316345 - Vol.2 Sec. 6 General Specs-Waterproof & RoofingDocument14 pagesMPL-P142 - 6316345 - Vol.2 Sec. 6 General Specs-Waterproof & RoofinganishNo ratings yet

- Mastercoat Chassis Black DatasheetDocument2 pagesMastercoat Chassis Black DatasheetJimDavisNo ratings yet

- Customer Al Khaleej Sugar Refinery Company, Jebel Ali, DubaiDocument6 pagesCustomer Al Khaleej Sugar Refinery Company, Jebel Ali, DubaiRoshan aravinthNo ratings yet

- Qualified Product List: Edition E03.20Document160 pagesQualified Product List: Edition E03.20David Eduardo Arteaga Faubla (LATAM)No ratings yet

- Epoxy Polyurethane PrimersDocument1 pageEpoxy Polyurethane Primersonkar pareekNo ratings yet

- GW PDFDocument24 pagesGW PDFCarlos Eduardo ZelidonNo ratings yet

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngNo ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUPageduesca RouelNo ratings yet

- Wall FinishesDocument21 pagesWall FinisheslavekushNo ratings yet