Professional Documents

Culture Documents

Fault Tree Analysis

Fault Tree Analysis

Uploaded by

brij kishorCopyright:

Available Formats

You might also like

- BMW N57D30 Engine Specifications & ProblemsDocument3 pagesBMW N57D30 Engine Specifications & ProblemsCallum Smith60% (10)

- Fault Tree AnalysisDocument18 pagesFault Tree AnalysisAnonymous 2DZjkvGNo ratings yet

- Fault Tree AnalysisDocument19 pagesFault Tree Analysismabhisekh623No ratings yet

- Fault Tree Analysis: M. Pandey, University of WaterlooDocument18 pagesFault Tree Analysis: M. Pandey, University of WaterlooveereshascribdNo ratings yet

- 2 Tool of Analysis PDFDocument44 pages2 Tool of Analysis PDFArmanda PutraNo ratings yet

- Fault & Failure Analysis: Dr. Ir. M. SabriDocument44 pagesFault & Failure Analysis: Dr. Ir. M. Sabricalvin100% (1)

- Fault Tree Analysis FTA Methode Analisis PohonDocument44 pagesFault Tree Analysis FTA Methode Analisis PohonRahman SonowijoyoNo ratings yet

- Investigacion Accidentes GerenciaDocument8 pagesInvestigacion Accidentes GerenciaJuan David RosalesNo ratings yet

- 06 - Cristescu, CiovicaDocument13 pages06 - Cristescu, CiovicaAdriana CalinNo ratings yet

- Risk Tree GTDocument11 pagesRisk Tree GTkp pkNo ratings yet

- Fault Tree AnalysisDocument5 pagesFault Tree AnalysismarioetiagoNo ratings yet

- Module 4-1Document23 pagesModule 4-1Aditya ranjan BubunNo ratings yet

- Fault Tree Analysis For SISDocument8 pagesFault Tree Analysis For SISNabil Al-KhirdajiNo ratings yet

- SHM - Practical 12 - Risk Assessment MethodsDocument8 pagesSHM - Practical 12 - Risk Assessment MethodsBhaliya AadityaNo ratings yet

- Event Tree AnalysisDocument12 pagesEvent Tree Analysisbayu_pratama_18No ratings yet

- An Introduction To Fault Tree AnalysisDocument11 pagesAn Introduction To Fault Tree AnalysisChristian Jay UayanNo ratings yet

- Fault Tree Analysis What Is Fault Tree Analysis?Document6 pagesFault Tree Analysis What Is Fault Tree Analysis?MDR PRAPHUNo ratings yet

- Fault Tree AnalysisDocument14 pagesFault Tree AnalysisStarwin JohnsonNo ratings yet

- Fault Tree Analysis I. Concept DiscussionDocument7 pagesFault Tree Analysis I. Concept DiscussionDxtr MedinaNo ratings yet

- Fault Tree AnalysisDocument10 pagesFault Tree AnalysisLooi Kok HuaNo ratings yet

- Lecture Notes 5Document11 pagesLecture Notes 5lydiaqwerty1234No ratings yet

- A Dynamic Fault Tree PDFDocument9 pagesA Dynamic Fault Tree PDFJosé MéndezNo ratings yet

- Ericson Evidence TreeDocument9 pagesEricson Evidence Treedomingos netoNo ratings yet

- Ericson Evidence TreeDocument9 pagesEricson Evidence Treedomingos netoNo ratings yet

- Fault Tree AnalysisDocument18 pagesFault Tree AnalysisKyle Kelly100% (1)

- Week9-Pre ClassDocument27 pagesWeek9-Pre Classxxuu0120No ratings yet

- C System Reliability 3bDocument23 pagesC System Reliability 3bAndrei CiobanasuNo ratings yet

- Piston CylinderDocument13 pagesPiston CylinderJGDjsfdjsNo ratings yet

- What Is A Fault Tree AnalysisDocument5 pagesWhat Is A Fault Tree AnalysisummulkhairNo ratings yet

- BossDocument3 pagesBossKwame PeeNo ratings yet

- 18 May 20 PSHM 6 CHDocument36 pages18 May 20 PSHM 6 CHDeo Karan RamNo ratings yet

- Chapter 22Document13 pagesChapter 22faridaNo ratings yet

- Risk BARRIER EFFECTS ShahrokhiDocument6 pagesRisk BARRIER EFFECTS ShahrokhimowglitownNo ratings yet

- Fault Tree AnalysisDocument7 pagesFault Tree AnalysisthawdarNo ratings yet

- Fta 2Document24 pagesFta 2irfanyudiaNo ratings yet

- Procedure On FTADocument24 pagesProcedure On FTAKrishna Kumar AlagarNo ratings yet

- Event Tree AnalysisDocument3 pagesEvent Tree AnalysisMDR PRAPHUNo ratings yet

- Microteaching Test: Disusun Oleh: Hazen AlrasyidDocument26 pagesMicroteaching Test: Disusun Oleh: Hazen AlrasyidIhadz CleverleyNo ratings yet

- Design of A Programmable System For Failure Modes and Effect Analysis of Steam-Power Plant Based On The Fault Tree AnalysisDocument22 pagesDesign of A Programmable System For Failure Modes and Effect Analysis of Steam-Power Plant Based On The Fault Tree AnalysisVinoth KumarNo ratings yet

- 1 s2.0 S0951832021003410 MainDocument12 pages1 s2.0 S0951832021003410 MainmkNo ratings yet

- Cause ConsequenceDocument2 pagesCause Consequencecamille_faye100% (1)

- Domain 2 Safety Management SystemsDocument13 pagesDomain 2 Safety Management SystemsjyothishNo ratings yet

- Fault Tree AnalysisDocument48 pagesFault Tree AnalysisAditya BramanthaNo ratings yet

- Investigasi Pelaporan Dan Pencegahan Kecelakaan KerjaDocument27 pagesInvestigasi Pelaporan Dan Pencegahan Kecelakaan KerjaAnnisaa MawarNo ratings yet

- Fault Tree AnalysisDocument37 pagesFault Tree AnalysisIyer VasundharaNo ratings yet

- Ericson-FTA TutorialDocument232 pagesEricson-FTA Tutorialmeheboob100% (1)

- Fault Tree AnalysisDocument26 pagesFault Tree AnalysisELVIS KIPKORIRNo ratings yet

- Analyzing System Safety and Risks Under Uncertainty Using A Bow-Tie Diagram: An Innovative ApproachDocument18 pagesAnalyzing System Safety and Risks Under Uncertainty Using A Bow-Tie Diagram: An Innovative ApproachRmz ExeNo ratings yet

- How Complex Systems FailDocument5 pagesHow Complex Systems FailromulusxNo ratings yet

- Applsci 13 03843 v2Document27 pagesApplsci 13 03843 v2ugrceylnNo ratings yet

- Fault Tree AnalysisDocument38 pagesFault Tree AnalysisRonnin Roby FlormataNo ratings yet

- Application of The Cause-Consequence Diagram Method To Static SystemsDocument21 pagesApplication of The Cause-Consequence Diagram Method To Static SystemsJennica SurbaktiNo ratings yet

- BOW TIE Base Risk AnalysisDocument6 pagesBOW TIE Base Risk AnalysisMazhar KaleemNo ratings yet

- Master Logic DiagramDocument31 pagesMaster Logic DiagramitszoeyNo ratings yet

- A Quantitative Risk Analysis Framework ForDocument4 pagesA Quantitative Risk Analysis Framework ForRmz ExeNo ratings yet

- FTA in Probability Safety ManagementDocument3 pagesFTA in Probability Safety Managementlydiaqwerty1234No ratings yet

- Risk Analysis Methodology Applied To Industrial Machine DevelopmentDocument8 pagesRisk Analysis Methodology Applied To Industrial Machine DevelopmentHeliliano GuedesNo ratings yet

- Unit IA2: Loss Causation and Incident Investigation: GO GO GO GO GO GO GO GODocument20 pagesUnit IA2: Loss Causation and Incident Investigation: GO GO GO GO GO GO GO GOsamer alrawashdehNo ratings yet

- Information Technology Risk Management in Enterprise Environments: A Review of Industry Practices and a Practical Guide to Risk Management TeamsFrom EverandInformation Technology Risk Management in Enterprise Environments: A Review of Industry Practices and a Practical Guide to Risk Management TeamsRating: 5 out of 5 stars5/5 (1)

- Reliability Assessment of Safety and Production Systems: Analysis, Modelling, Calculations and Case StudiesFrom EverandReliability Assessment of Safety and Production Systems: Analysis, Modelling, Calculations and Case StudiesNo ratings yet

- 05 ShaftsDocument37 pages05 ShaftsJay Ann TondoNo ratings yet

- NS PracticeProblemsDocument13 pagesNS PracticeProblemsSuhrita MukherjeeNo ratings yet

- WHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriDocument24 pagesWHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriTĩnh Hồ TrungNo ratings yet

- The Instruction Manual For Automatic Molding Machine and Warranty CardDocument21 pagesThe Instruction Manual For Automatic Molding Machine and Warranty CardMohammad FaroukNo ratings yet

- UNO-2174 2178 Manual Ed4Document44 pagesUNO-2174 2178 Manual Ed4sonali_sadhukhan88No ratings yet

- Your Palletizing SolutionDocument8 pagesYour Palletizing SolutionKien Nguyen TrungNo ratings yet

- MH CranesDocument9 pagesMH Cranesfika nashirotul millahNo ratings yet

- Vx86: x86 Assembler Simulated in C Powered by Automated Theorem ProvingDocument15 pagesVx86: x86 Assembler Simulated in C Powered by Automated Theorem ProvingTanzeel ShakeelNo ratings yet

- Bridge Erection MethodDocument9 pagesBridge Erection MethodChi-chi Rahayu HarikeNo ratings yet

- Composite Bridge DesignDocument23 pagesComposite Bridge DesignHarold Jackson MtyanaNo ratings yet

- Obdii U Obd Trouble CodesDocument6 pagesObdii U Obd Trouble Codesdds94No ratings yet

- Chapter 10Document36 pagesChapter 10Kandan DhivyaNo ratings yet

- Ethyl Alcohol, 70%, in Water: Safety Data SheetDocument6 pagesEthyl Alcohol, 70%, in Water: Safety Data SheetAmalia Desy SaputriNo ratings yet

- Cable Testing DIN 4102-12Document10 pagesCable Testing DIN 4102-12asscracker9000No ratings yet

- DSP Assignment 3Document11 pagesDSP Assignment 3anoopk778No ratings yet

- Tabel Konversi Nilai KekerasanDocument14 pagesTabel Konversi Nilai KekerasanSeptiana NugrahaNo ratings yet

- Basic Machine Tools: Nikunj PatelDocument23 pagesBasic Machine Tools: Nikunj PatelIshan Patel100% (1)

- 1 Unified Application For BLDG PermitDocument2 pages1 Unified Application For BLDG PermitJoven MagnoNo ratings yet

- CP DDoSProtector 6.14 GuideDocument237 pagesCP DDoSProtector 6.14 GuideAnh Bui TuanNo ratings yet

- Brooke CromptonDocument24 pagesBrooke Cromptond3xterNo ratings yet

- Course2a-Energy Efficiency PDFDocument59 pagesCourse2a-Energy Efficiency PDFNazaruddin SinagaNo ratings yet

- Abrasive Jet Machining (AJM)Document31 pagesAbrasive Jet Machining (AJM)Abhishek KumarNo ratings yet

- Huawei Ale-L23c212b180 Upgrade Guideline v1.0Document7 pagesHuawei Ale-L23c212b180 Upgrade Guideline v1.0Johnatan Flores Reyes100% (1)

- ETSI ES 201 235-3: Specification of Dual Tone Multi-Frequency (DTMF) Transmitters and Receivers Part 3: ReceiversDocument12 pagesETSI ES 201 235-3: Specification of Dual Tone Multi-Frequency (DTMF) Transmitters and Receivers Part 3: Receivershadiranji4No ratings yet

- Bid Bulletin 20la0130Document2 pagesBid Bulletin 20la0130MANNY CARAJAYNo ratings yet

- Evolution V-Backed Pump Intake Screen BrochureDocument4 pagesEvolution V-Backed Pump Intake Screen BrochureEvolution Oil ToolsNo ratings yet

- Chapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinDocument8 pagesChapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinchatxxnoirNo ratings yet

- Enviromail HK012 CompostDocument2 pagesEnviromail HK012 CompostShivang SharmaNo ratings yet

- IS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Document3 pagesIS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Shivangi BhardwajNo ratings yet

Fault Tree Analysis

Fault Tree Analysis

Uploaded by

brij kishorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fault Tree Analysis

Fault Tree Analysis

Uploaded by

brij kishorCopyright:

Available Formats

M.

Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

Fault Tree Analysis

Table of Contents

Introduction ............................................................................................................... 3

Fault Tree Analysis ................................................................................................... 3

Basic Events ............................................................................................................ 4

Advantages ............................................................................................................. 4

Limitations .............................................................................................................. 4

Notation................................................................................................................... 5

General Procedure for Fault Tree Analysis........................................................ 6

Rules of Fault Tree Construction ......................................................................... 7

Considerations...................................................................................................... 11

Fault Tree Evaluation ............................................................................................. 12

Boolean Algebra ................................................................................................... 12

The OR Gate ....................................................................................................... 12

The AND Gate.................................................................................................... 12

Qualitative Analysis ............................................................................................ 14

Minimal Cut Sets ............................................................................................... 14

Criticality............................................................................................................ 14

Quantitative Analysis.......................................................................................... 16

Common-Cause Failures..................................................................................... 16

References................................................................................................................. 18

Fault Tree Analysis – Page 1

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

Fault Tree Analysis – Page 2

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

Introduction

there is a need to analyze all the possible failure mechanisms in complex

systems (e.g. nuclear power plants)

also perform probabilistic analyses for the expected rate of failures

estimate probabilities of events that are modelled as logical combinations

or logical outcomes of other random events

two main methods:

z fault tree analysis

z event tree analysis

decision trees also exist and are used in risk analysis (combines all

feasible alternatives, possible outcomes and their probabilities, monetary

consequences and utility evaluations)

other graphical methods include

z reliability block diagrams

z functional logic diagrams

z Failure Modes and Effects Analysis (FMEA)

Fault Tree Analysis

A technique by which many events that interact to produce other events can be

related using simple logical relationships.

a good reference is NRC “The Fault Tree Handbook”

(http://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr0492/sr0492.pdf)

also Chapter 8 and 10 in McCormick (1981)

one of the principal methods of probabilistic safety (or risk) analysis

(PRA)

developed by Bell Telephone Laboratories in 1962 for the U.S. Air Force

Minuteman system, later adopted and extensively used by Boeing

Company

fault tree diagrams

z are used most often as a system-level risk assessment technique

z can model the possible combinations of equipment failures, human

errors, and external conditions that can lead to a specific type of

accident

z follow a top-down structure and represent a graphical model of the

pathways within a system between basic events that can lead to a

foreseeable loss event (or a failure) referred to as the top event

the contributory events and conditions are interconnected using standard

logic symbols (AND, OR, etc.), also referred to as gates

events that must coexist to cause the top event are described using the

AND relationship

alternate events that can individually cause the top event are described

using the OR relationship

Fault Tree Analysis – Page 3

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

the occurrence of a top event may or may not lead to a serious or adverse

consequence

the relative likelihood of a number of potential consequences will depend

on the conditions or subsequent events that follow

potential consequences can be systematically identified using an event

tree

Basic Events

An event that cannot be developed any further.

all basic events are generally assumed to be statistically independent

unless they are common cause failures (i.e. failures arising from a

common cause or an initiating event)

basic events can be either

z primary fault events, i.e. subsystem failure due to a basic mode such as

a structural fault, failure to open or close, or to start or stop, or

z secondary fault events, i.e. subsystem failure due to excessive

operational or environmental stress resulting in the system element to

be out of tolerance

Advantages

allow the use of reliable information on component failure and other basic

events to estimate the overall risk associated with new system designs for

which no historical data exists

simple to understand and easy to implement

qualitative descriptions of potential problems and combinations of events

causing specific problems of interest

quantitative estimates of failure frequencies and likelihoods, and relative

importances of various failure sequences and contributing events

lists of recommendations for reducing risks

quantitative evaluations of recommendation effectiveness

Limitations

difficult to conceive all possible scenarios leading to the top event

construction of fault trees for large systems can be tedious

correlations between basic events (e.g. failure of components belonging to

the same batch) are difficult to model and exact solutions to correlated

events do not exist

subjective decisions regarding the level of detail and completeness are

often necessary

Fault Tree Analysis – Page 4

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

Notation

Symbol Name Description

Primary Event Symbols

Circle Basic Event – a basic initiating fault requiring

no further development

Oval Conditioning Event – specific conditions or

restrictions that apply to any logic gate (used

with INHIBIT gate)

Diamond Undeveloped Event – an event that is not

developed further because it is of insufficient

consequence or because information is

unavailable

House External Event – an event which is normally

expected to occur (not a fault event)

Intermediate Event Symbols

Rectangle A fault event that occurs as a result of the

logical combination of other events

Gate Symbols

OR Gate The union operation of events, i.e. the output

event occurs if (at least) one or more of the

inputs occur

AND Gate The intersection operation of events, i.e. the

output event occurs if and only if all the inputs

occur

INHIBIT The output event occurs if the (single) input

Gate event occurs in the presence of an enabling

condition (i.e. Conditioning Event (oval) drawn

to the right of the gate)

Transfer Symbols

Triangle-in Indicates that the tree is developed further

someplace else (e.g. another page)

Triangle-out Indicates that this portion of the tree is a sub-

tree connected to the corresponding Triangle-In

(appears at the top of the tree)

Fault Tree Analysis – Page 5

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

General Procedure for Fault Tree Analysis

from the U.S. Coast Guard Risk-based Decision-making Guidelines, Vol. 3

- Risk Assessment Tools Reference, Chapter 9 – Fault Tree Analysis (FTA)

(http://www.uscg.mil/hq/g-m/risk/E-Guidelines/RBDMGuide.htm)

Step 1. Define the system of interest.

Specify and clearly define the boundaries and initial conditions of

the system for which failure information is needed.

Step 2. Define the top event for the analysis.

Specify the problem of interest that the analysis will address

(e.g. a specific quality problem, shutdown, safety issue, etc.).

Step 3. Define the treetop structure.

Determine the events and conditions (i.e., intermediate events) that

most directly lead to the top event.

Step 4. Explore each branch in successive levels of detail.

Determine the events and conditions that most directly lead to each

intermediate event. Repeat the process at each successive level of

the tree until the fault tree model is complete.

Step 5. Solve the fault tree for the combinations of events contributing to

the top event.

Examine the fault tree model to identify all the possible

combinations of events and conditions that can cause the top event

of interest. A combination of events and conditions sufficient and

necessary to cause the top event is called a minimal cut set.

Step 6. Identify important dependent failure potentials and adjust the

model appropriately (qualitative common cause failure analysis).

Study the fault tree model and the list of minimal cut sets to identify

potentially important dependencies among events. Dependencies

are single occurrences that may cause multiple events or conditions

to occur at the same time.

Step 7. Perform quantitative analysis (if necessary).

Use statistical characterizations regarding the failure and repair of

specific events and conditions in the fault tree model to predict

future performance for the system.

Step 8. Use the results in decision making.

Use results of the analysis to identify the most significant

vulnerabilities in the system and to make effective recommendations

for reducing the risks associated with those vulnerabilities.

Fault Tree Analysis – Page 6

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

Rules of Fault Tree Construction

a fault tree should only be constructed once the functioning of the entire

system is fully understood

objective is to identify all the component failures, or combinations thereof

that could lead to the top event (Steps 2 - 4 above)

after McCormick (1981)

Rule 1. State the fault event as a fault, including the description and timing of

a fault condition at some particular time.

Include

(a) what the fault state of that system or component is,

(b) when that system or component is in the fault state.

Test the fault event by asking

(c) is it a fault?

(d) is the what-and-when portion included in the fault statement?

Rule 2. There are two basic types of fault statements, state-of-system and

state-of-component.

To continue the tree,

(a) if state-of-system fault statement, use Rule 3

(b) if state-of-component fault statement, use Rule 4

Rule 3. A state-of-system fault may use an AND, OR, or INHIBIT gate or no

gate at all.

To determine which gate to use, the faults must be then

(a) minimum necessary and sufficient fault events,

(b) immediate fault events.

Rule 4. A state-of-component fault always uses an OR gate.

To continue, look for the primary, secondary, and command failure

fault events. Then state those fault events.

(a) primary failure is failure of that component within the design

envelope or environment

(b) secondary failures are failures of that component due to

excessive environments exceeding the design environment

(c) command faults are inadvertent operation of the component

because of a failure of a control element

Rule 5. No gate-to-gate relationships.

Put an event statement between any two gates.

Rule 6. Expect no miracles.

Those things that would normally occur as the result of a fault will

occur, and only those things. Also, normal system operation may be

expected to occur when faults occur.

Fault Tree Analysis – Page 7

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

Rule 7. In an OR gate, the input does not cause output.

If any input exists, the output exists. Fault events under the gate may

be a restatement of the output events.

Rule 8. An AND gate defines a causal relationship.

If the input events coexist, the output is produced.

Rule 9. An INHIBIT gate describes a causal relationship between one fault

and another, but the indicated condition must be present.

The fault is the direct and sole cause of the output when that

specified condition is present. Inhibit conditions may be faults or

situations, which is why AND and INHIBIT gates differ.

Fault Tree Analysis – Page 8

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

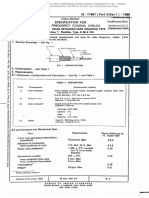

Example: (McCormick, 1981) Construct a fault tree for the simple electric

motor circuit shown below.

Switch Fuse

Power

Motor

Supply

Wire

Solution:

Step 1. Define the system of interest.

Need to identify

z Intended Functions

z Physical Boundaries (to avoid overlooking key elements of a system at

interfaces and penalizing a system by associating other equipment

with the subject of the study)

z Analytical Boundaries (to limit the level of analysis resolution, to

explicitly exclude certain types of events and conditions, such as

sabotage, from the analysis)

z Initial Conditions, (including equipment that is assumed to be out of

service initially, which affect the combinations of additional events

necessary to produce a specific system problem)

For this particular problem we have,

Intended Function – the motor is used for some (unknown)

purpose

Physical Boundaries – power supply

Analytical Boundaries – include all contributors in the above diagram

Initial Conditions – switch closed, motor on

Step 2. Define the top event.

We are interested in the event that the motor fails to operate. Therefore,

the top event is defined as

Motor fails

to operate

Step 3. Construct the fault tree, starting from the top, i.e., define the treetop

structure. Identify the main contributing events, including all events and

scenarios that may cause the top event.

Fault Tree Analysis – Page 9

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

Step 4. Explore each branch in successive levels of detail, following the rules

of fault tree construction.

Motor fails

to operate

Defect No current

in motor to motor

Switch Wire Fuse fails Power

open failure open supply

(open) failure

3 4

Fuse

Switch Switch failure under

Fuse failure

fails opened normal

due to overload

open erroneously conditions

(open)

Fuse fails

5

open

Overload

in circuit

Wire Power

failure failure

(shorted) (surge)

Fault Tree Construction

Gate 1. One primary failure event is the failure of the motor itself (for

example, due to a wiring failure within the motor or loss of lubrication

to the bearings). This event is a basic event because no details of the

motor are given, therefore, the event cannot be developed further. The

other possibility is the event that no current is supplied to the motor.

Fault Tree Analysis – Page 10

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

Gate 2. The event “No current in motor” is the result of other events and

is therefore developed further. The lack of current to the motor can

result from a broken connection in any of the other four components in

the circuit, including the failure of the wire or power supply (basic

events), the switch being open, or failure of the fuse.

Gate 3. The open switch may be due to a basic failure of the switch, or the

event that the switch was opened erroneously. The erroneous opening

of the switch is due to human error, which could be developed further

into more basic events (i.e. operator is inexperienced, under stress,

etc.). However, due to insufficient information, the event is not

explored further. This purposely undeveloped event is therefore

denoted with the diamond symbol.

Gate 4. The fuse failure event may be caused by fuse failure under normal

conditions (primary failure) or due to overload from the circuit.

Gate 5. The secondary fuse failure can occur if the fuse does not open

every time an overload is present in the circuit (because all conditions

of an overload do not necessarily result in sufficient overcurrent to

open the fuse). This is why a conditional gate, denoted by the

hexagon, is used. The condition, i.e. “Fuse fails open” is placed in the

connecting oval, and the conditional gate is treated similarly to an

AND gate in subsequent tree analysis.

Gate 6. The overload in the circuit may be caused either by a short or a

power surge, both of which are primary (i.e. basic) events.

Considerations

construction of a fault tree is subjective

need to take into account

z Level of Detail – the number of basic events should be defined such

that the size of the tree is reasonable with respect to the scope of the

analysis

z Probability Assignment – need to stop development at the level

where probability or failure data is available

z Meaningfulness – the level of detail should be such that the basic and

undeveloped events correspond to the design aspects being analyzed

Fault Tree Analysis – Page 11

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

Fault Tree Evaluation

identify critical events and event combinations that lead to the top event

calculate the probability of the top event based on the probabilities of the

basic and undeveloped events in the fault tree

two types of analysis

z qualitative

z quantitative

based on Boolean logic

Boolean Algebra

fault trees describe the relationships between events using Boolean logic

a fault tree can be translated into an equivalent set of Boolean equations

The OR Gate

Represents the union of events at the gate. For event Q with two input events

A and B attached to the OR gate, the probability is obtained as

P (Q ) = P (A) + P (B ) − P (A ∩ B ) (1)

or

P (Q ) = P (A) + P (B ) − P (A)P (B | A) (2)

If A and B are mutually exclusive events then P (A ∩ B ) = 0 and

P (Q ) = P (A) + P (B ) (3)

If A and B are independent events then P (B | A) = P (B ) and

P (Q ) = P (A) + P (B ) − P (A)P (B ) (4)

If event B is completely dependent on event A then P (B | A) = 1 and

P (Q ) = P (A) + P (B ) − P (A)(1) = P (B ) (5)

Therefore, the approximation of

P (Q ) = P (A) + P (B ) (6)

is always a conservative estimate for the probability of event Q (because

P (A ∩ B ) is small compared with P (A) + P (B ) for very low probability

events). Event Q will occur if any (at least) one of the input events to the OR

gate occur.

The AND Gate

Represents the intersection of events at the gate. For event Q with two input

events A and B attached to the AND gate, the probability is obtained as

P (Q ) = P (A)P (B | A) = P (B )P (A | B ) (7)

Fault Tree Analysis – Page 12

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

If A and B are independent events then P (B | A) = P (B ) and

P (A | B ) = P (A) therefore

P (Q ) = P (A)P (B ) (8)

If A and B are not independent, then Q may be significantly greater than

P (A)P (B ) . Event Q is caused only if every (all) input event attached to the

AND gate occur.

Rules of Boolean Algebra

Mathematical Notation Engineering Notation Designation

X ∩Y = Y ∩ X X ⋅Y = Y ⋅ X Commutative Law

X ∪Y = Y ∪ X X +Y = Y + X

X ∩ (Y ∩ Z ) = (X ∩ Y ) ∩ Z X ⋅ (Y ⋅ Z ) = (X ⋅Y ) ⋅ Z Associative Law

X (YZ ) = (XY )Z

X ∪ (Y ∪ Z ) = (X ∪ Y ) ∪ Z X + (Y + Z ) = (X +Y ) + Z

X ∩ (Y ∪ Z ) = (X ∩ Y ) ∪ (X ∩ Z ) X ⋅ (Y + Z ) = X ⋅Y + X ⋅ Z Distributive Law

X (Y + Z ) = XY + XZ

X ∪ (Y ∩ Z ) = (X ∪Y ) ∩ (X ∪ Z ) X + (Y ⋅ Z ) = (X +Y ) ⋅ (X + Z )

X ∩X = X X ⋅X = X Idempotent Law

X ∪X = X X +X = X

X ∩ (X ∪ Y ) = X X ⋅ (X + Y ) = X Law of Absorption

X ∪ (X ∩ Y ) = X X + (X ⋅Y ) = X

X ∩X = φ X ⋅X = φ Complementation

X ∪X =Ω= I X +X = Ω= I

X ∩Y = X ∪Y X ⋅Y = X + Y de Morgan’s Rule

X ∪Y = X ∩Y X + Y = X ⋅Y

φ∩X =φ φ⋅X = φ Operations with φ and Ω

φ∪X = X φ+X = X

Ω∩X = X Ω⋅X = X

Ω∪X = Ω Ω+X = Ω

φ =Ω φ =Ω

Ω=φ Ω=φ

X ∪ (X ∩ Y ) = X ∪ Y X + (X ⋅Y ) = X + Y Other relationships

X ∩ (X ∪ Y ) = X ∩ Y X ⋅ (X + Y ) = X ⋅Y

φ is the empty or null set which is equal to zero

Ω or I is the universal set which is equal to one

Fault Tree Analysis – Page 13

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

Qualitative Analysis

used for identifying

critical events

z

potential system weaknesses

z

z best ways to reduce the risk associated with the top event

conducted using minimal cut sets

Minimal Cut Sets

The smallest combination of basic events which, if they occur,

will cause the top event to occur.

can be seen as a specific scenario that leads to the top event

cut sets are combinations (intersections) of component failures sufficient

for the top event

the occurrence of all events in a minimal cut set is necessary for the

occurrence of the top event, i.e. if one of the failures in a cut set does not

occur, then the top event will not occur (by this combination)

there are a finite number of minimal cut sets for each fault tree, which are

unique for the top event

one-component minimal cut sets represent failures which will cause the

top event to occur

the minimal cut sets for a fault tree are obtained by

z translating the tree to its equivalent Boolean equations

(assume that events are independent)

z using top-down or bottom-up substitution

z using the Distributive Law and Law of Absorption to remove

redundancies

Criticality

the importance of each minimal cut set can be based on its relative

contribution to the total probability of the top event

the minimal cut sets for a fault tree can be used to identify the most critical

basic events using the following criteria

z minimal cut sets that include a small number of events represent less

redundancy and so have higher criticality

z events that appear on a large number of minimal cut sets are more

important because they can contribute to the top event in several

scenarios

must also consider the relative probabilities of each of the events

z the importance of each event can be based on the total probability of

the cut sets to which the basic event contributes (i.e. represents the

total probability of failure involving the event)

Fault Tree Analysis – Page 14

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

Example: Determine all the minimal cut sets for the small motor problem.

Solution:

Let T denote the top event

Let P denote primary events (circles)

Let G denote intermediate events (rectangles)

Let S denote undeveloped events (diamonds)

Let C denote conditioning events (ovals)

T

Therefore +

T = motor fails to operate

P1 = defect in motor G1

P1

P2 = wire failure (open)

P3 = power supply failure +

P4 = switch fails open

P5 = fuse failure under normal G2 P2 G3 P3

conditions (open) + +

P6 = wire failure (shorted)

P7 = power failure (surge) P4 S1 G4 P5

G1 = no current to motor

x C1

G2 = fuse fails open

G3 = switch open G5

G4 = fuse failure due to overload +

G5 = overload in circuit

S1 = switch opened erroneously P6 P7

C1 = fuse fails to open

Writing equations for each gate of the tree

T = P1 + G1 (9)

G1 = P2 + P3 + G2 + G3 (10)

G2 = P4 + S1 (11)

G3 = G4 + P5 (12)

G4 = C1 · G5 (13)

G5 = P6 + P7 (14)

Using the top-down approach we get by substitution

T = P1 + G1 (15)

= P1 + P2 + P3 + G2 + G3 (15.1)

= P1 + P2 + P3 + P4 + S1 + G3 (15.2)

= P1 + P2 + P3 + P4 + S1 + G4 + P5 (15.3)

= P1 + P2 + P3 + P4 + S1 + (C1 · G5) + P5 (15.4)

= P1 + P2 + P3 + P4 + S1 + P5 + C1 · (P6 + P7) (15.5)

= P1 + P2 + P3 + P4 + S1 + P5 + (C1 · P6) + (C1 · P7) (15.6)

The top event, therefore, contains 6 single component minimum cut sets and

2 double component minimum cut sets.

Fault Tree Analysis – Page 15

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

Quantitative Analysis

calculate the probability of occurrence of the top event, given the fault

tree and the probability of occurrence of the basic events

common approaches include

zassume all basic events are independent

zassume the probabilities of basic events are small (rare-event

approximation)

if each basic event on the fault tree occurs only once, then the tree

branches emanating from any given gate in the tree are independent

the probability of the top event is given by the probability of the union of

the minimum cut sets

results in a conservative estimate of the probability of failure

Common-Cause Failures

Multiple failures originating from a common cause that fails the system.

the basic events may not always be independent

failure events can be caused by a common environment or have factors in

common (e.g. an operator has miscalibrated all sensors)

common causes often arise from factors such as manufacturer,

environment, energy sources, and humans

the evaluation of probabilities will require conditional or joint

probabilities

Example: Calculate the probability of occurrence of the top event for the

simple motor example. Assume the probability of occurrence of each basic

event is equal to 0.01 and the probability of the event S1 “Switch opened

erroneously” is equal to 0.001. Also assume that the condition C1 “Fuse

fails open” has a probability of occurrence of 0.50.

Solution:

Using the same notation as before we are given

Event Description Probability

P1 Defect in motor 0.01

P2 Wire failure (open) 0.01

P3 Power supply failure 0.01

P4 Switch fails open 0.01

P5 Fuse failure under normal conditions (open) 0.01

P6 Wire failure (shorted) 0.01

P7 Power failure (surge) 0.01

S1 Switch opened erroneously 0.001

C1 Fuse fails open 0.50

Fault Tree Analysis – Page 16

M. Pandey, University of Waterloo CIVE 240 – Engineering and Sustainable Development

The probability of intermediate events can be evaluated using the fault tree.

The probability of the top event is given by the union of the minimum cut sets

determined before as

T = P1 + P2 + P3 + P4 + S1 + P5 + (C1 · P6) + (C1 · P7) (16)

= 0.01 + 0.01 + 0.01 + 0.01 + 0.001 + 0.01 + (0.50)(0.01) + (0.50)(0.01) (16.1)

= 0.061 (16.2)

0.061

0.01 0.051

0.011 0.01 0.02 0.01

+ +

0.01 0.001 0.01 0.01

x 0.50

0.02

0.01 0.01

Fault Tree Analysis – Page 17

CIVE 240 – Engineering and Sustainable Development M. Pandey, University of Waterloo

References

McCormick, N.J. 1981. Reliability and Risk Analysis: Methods and Nuclear Power

Applications. Academic Press, New York.

United States Coast Guard. 2004. Risk-based Decision-making (RBDM)

Guidelines (3rd Ed.), Vol. 3 – Risk Assessment Tools Reference, Chapter 9 –

Fault Tree Analysis.

(http://www.uscg.mil/hq/g-m/risk/E-Guidelines/RBDMGuide.htm)

United States Nuclear Regulatory Commission (NRC). 1981. Fault Tree

Handbook. NUREG-0492. Systems and Reliability Research Office of

Nuclear Regulatory Research, Washington, D.C.

(http://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr0492/sr0492.pdf)

Fault Tree Analysis – Page 18

You might also like

- BMW N57D30 Engine Specifications & ProblemsDocument3 pagesBMW N57D30 Engine Specifications & ProblemsCallum Smith60% (10)

- Fault Tree AnalysisDocument18 pagesFault Tree AnalysisAnonymous 2DZjkvGNo ratings yet

- Fault Tree AnalysisDocument19 pagesFault Tree Analysismabhisekh623No ratings yet

- Fault Tree Analysis: M. Pandey, University of WaterlooDocument18 pagesFault Tree Analysis: M. Pandey, University of WaterlooveereshascribdNo ratings yet

- 2 Tool of Analysis PDFDocument44 pages2 Tool of Analysis PDFArmanda PutraNo ratings yet

- Fault & Failure Analysis: Dr. Ir. M. SabriDocument44 pagesFault & Failure Analysis: Dr. Ir. M. Sabricalvin100% (1)

- Fault Tree Analysis FTA Methode Analisis PohonDocument44 pagesFault Tree Analysis FTA Methode Analisis PohonRahman SonowijoyoNo ratings yet

- Investigacion Accidentes GerenciaDocument8 pagesInvestigacion Accidentes GerenciaJuan David RosalesNo ratings yet

- 06 - Cristescu, CiovicaDocument13 pages06 - Cristescu, CiovicaAdriana CalinNo ratings yet

- Risk Tree GTDocument11 pagesRisk Tree GTkp pkNo ratings yet

- Fault Tree AnalysisDocument5 pagesFault Tree AnalysismarioetiagoNo ratings yet

- Module 4-1Document23 pagesModule 4-1Aditya ranjan BubunNo ratings yet

- Fault Tree Analysis For SISDocument8 pagesFault Tree Analysis For SISNabil Al-KhirdajiNo ratings yet

- SHM - Practical 12 - Risk Assessment MethodsDocument8 pagesSHM - Practical 12 - Risk Assessment MethodsBhaliya AadityaNo ratings yet

- Event Tree AnalysisDocument12 pagesEvent Tree Analysisbayu_pratama_18No ratings yet

- An Introduction To Fault Tree AnalysisDocument11 pagesAn Introduction To Fault Tree AnalysisChristian Jay UayanNo ratings yet

- Fault Tree Analysis What Is Fault Tree Analysis?Document6 pagesFault Tree Analysis What Is Fault Tree Analysis?MDR PRAPHUNo ratings yet

- Fault Tree AnalysisDocument14 pagesFault Tree AnalysisStarwin JohnsonNo ratings yet

- Fault Tree Analysis I. Concept DiscussionDocument7 pagesFault Tree Analysis I. Concept DiscussionDxtr MedinaNo ratings yet

- Fault Tree AnalysisDocument10 pagesFault Tree AnalysisLooi Kok HuaNo ratings yet

- Lecture Notes 5Document11 pagesLecture Notes 5lydiaqwerty1234No ratings yet

- A Dynamic Fault Tree PDFDocument9 pagesA Dynamic Fault Tree PDFJosé MéndezNo ratings yet

- Ericson Evidence TreeDocument9 pagesEricson Evidence Treedomingos netoNo ratings yet

- Ericson Evidence TreeDocument9 pagesEricson Evidence Treedomingos netoNo ratings yet

- Fault Tree AnalysisDocument18 pagesFault Tree AnalysisKyle Kelly100% (1)

- Week9-Pre ClassDocument27 pagesWeek9-Pre Classxxuu0120No ratings yet

- C System Reliability 3bDocument23 pagesC System Reliability 3bAndrei CiobanasuNo ratings yet

- Piston CylinderDocument13 pagesPiston CylinderJGDjsfdjsNo ratings yet

- What Is A Fault Tree AnalysisDocument5 pagesWhat Is A Fault Tree AnalysisummulkhairNo ratings yet

- BossDocument3 pagesBossKwame PeeNo ratings yet

- 18 May 20 PSHM 6 CHDocument36 pages18 May 20 PSHM 6 CHDeo Karan RamNo ratings yet

- Chapter 22Document13 pagesChapter 22faridaNo ratings yet

- Risk BARRIER EFFECTS ShahrokhiDocument6 pagesRisk BARRIER EFFECTS ShahrokhimowglitownNo ratings yet

- Fault Tree AnalysisDocument7 pagesFault Tree AnalysisthawdarNo ratings yet

- Fta 2Document24 pagesFta 2irfanyudiaNo ratings yet

- Procedure On FTADocument24 pagesProcedure On FTAKrishna Kumar AlagarNo ratings yet

- Event Tree AnalysisDocument3 pagesEvent Tree AnalysisMDR PRAPHUNo ratings yet

- Microteaching Test: Disusun Oleh: Hazen AlrasyidDocument26 pagesMicroteaching Test: Disusun Oleh: Hazen AlrasyidIhadz CleverleyNo ratings yet

- Design of A Programmable System For Failure Modes and Effect Analysis of Steam-Power Plant Based On The Fault Tree AnalysisDocument22 pagesDesign of A Programmable System For Failure Modes and Effect Analysis of Steam-Power Plant Based On The Fault Tree AnalysisVinoth KumarNo ratings yet

- 1 s2.0 S0951832021003410 MainDocument12 pages1 s2.0 S0951832021003410 MainmkNo ratings yet

- Cause ConsequenceDocument2 pagesCause Consequencecamille_faye100% (1)

- Domain 2 Safety Management SystemsDocument13 pagesDomain 2 Safety Management SystemsjyothishNo ratings yet

- Fault Tree AnalysisDocument48 pagesFault Tree AnalysisAditya BramanthaNo ratings yet

- Investigasi Pelaporan Dan Pencegahan Kecelakaan KerjaDocument27 pagesInvestigasi Pelaporan Dan Pencegahan Kecelakaan KerjaAnnisaa MawarNo ratings yet

- Fault Tree AnalysisDocument37 pagesFault Tree AnalysisIyer VasundharaNo ratings yet

- Ericson-FTA TutorialDocument232 pagesEricson-FTA Tutorialmeheboob100% (1)

- Fault Tree AnalysisDocument26 pagesFault Tree AnalysisELVIS KIPKORIRNo ratings yet

- Analyzing System Safety and Risks Under Uncertainty Using A Bow-Tie Diagram: An Innovative ApproachDocument18 pagesAnalyzing System Safety and Risks Under Uncertainty Using A Bow-Tie Diagram: An Innovative ApproachRmz ExeNo ratings yet

- How Complex Systems FailDocument5 pagesHow Complex Systems FailromulusxNo ratings yet

- Applsci 13 03843 v2Document27 pagesApplsci 13 03843 v2ugrceylnNo ratings yet

- Fault Tree AnalysisDocument38 pagesFault Tree AnalysisRonnin Roby FlormataNo ratings yet

- Application of The Cause-Consequence Diagram Method To Static SystemsDocument21 pagesApplication of The Cause-Consequence Diagram Method To Static SystemsJennica SurbaktiNo ratings yet

- BOW TIE Base Risk AnalysisDocument6 pagesBOW TIE Base Risk AnalysisMazhar KaleemNo ratings yet

- Master Logic DiagramDocument31 pagesMaster Logic DiagramitszoeyNo ratings yet

- A Quantitative Risk Analysis Framework ForDocument4 pagesA Quantitative Risk Analysis Framework ForRmz ExeNo ratings yet

- FTA in Probability Safety ManagementDocument3 pagesFTA in Probability Safety Managementlydiaqwerty1234No ratings yet

- Risk Analysis Methodology Applied To Industrial Machine DevelopmentDocument8 pagesRisk Analysis Methodology Applied To Industrial Machine DevelopmentHeliliano GuedesNo ratings yet

- Unit IA2: Loss Causation and Incident Investigation: GO GO GO GO GO GO GO GODocument20 pagesUnit IA2: Loss Causation and Incident Investigation: GO GO GO GO GO GO GO GOsamer alrawashdehNo ratings yet

- Information Technology Risk Management in Enterprise Environments: A Review of Industry Practices and a Practical Guide to Risk Management TeamsFrom EverandInformation Technology Risk Management in Enterprise Environments: A Review of Industry Practices and a Practical Guide to Risk Management TeamsRating: 5 out of 5 stars5/5 (1)

- Reliability Assessment of Safety and Production Systems: Analysis, Modelling, Calculations and Case StudiesFrom EverandReliability Assessment of Safety and Production Systems: Analysis, Modelling, Calculations and Case StudiesNo ratings yet

- 05 ShaftsDocument37 pages05 ShaftsJay Ann TondoNo ratings yet

- NS PracticeProblemsDocument13 pagesNS PracticeProblemsSuhrita MukherjeeNo ratings yet

- WHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriDocument24 pagesWHP01-PMC1-ASYYY-23-182002-0001 - Rev01 Inspection & Test Plan For Piping FabriTĩnh Hồ TrungNo ratings yet

- The Instruction Manual For Automatic Molding Machine and Warranty CardDocument21 pagesThe Instruction Manual For Automatic Molding Machine and Warranty CardMohammad FaroukNo ratings yet

- UNO-2174 2178 Manual Ed4Document44 pagesUNO-2174 2178 Manual Ed4sonali_sadhukhan88No ratings yet

- Your Palletizing SolutionDocument8 pagesYour Palletizing SolutionKien Nguyen TrungNo ratings yet

- MH CranesDocument9 pagesMH Cranesfika nashirotul millahNo ratings yet

- Vx86: x86 Assembler Simulated in C Powered by Automated Theorem ProvingDocument15 pagesVx86: x86 Assembler Simulated in C Powered by Automated Theorem ProvingTanzeel ShakeelNo ratings yet

- Bridge Erection MethodDocument9 pagesBridge Erection MethodChi-chi Rahayu HarikeNo ratings yet

- Composite Bridge DesignDocument23 pagesComposite Bridge DesignHarold Jackson MtyanaNo ratings yet

- Obdii U Obd Trouble CodesDocument6 pagesObdii U Obd Trouble Codesdds94No ratings yet

- Chapter 10Document36 pagesChapter 10Kandan DhivyaNo ratings yet

- Ethyl Alcohol, 70%, in Water: Safety Data SheetDocument6 pagesEthyl Alcohol, 70%, in Water: Safety Data SheetAmalia Desy SaputriNo ratings yet

- Cable Testing DIN 4102-12Document10 pagesCable Testing DIN 4102-12asscracker9000No ratings yet

- DSP Assignment 3Document11 pagesDSP Assignment 3anoopk778No ratings yet

- Tabel Konversi Nilai KekerasanDocument14 pagesTabel Konversi Nilai KekerasanSeptiana NugrahaNo ratings yet

- Basic Machine Tools: Nikunj PatelDocument23 pagesBasic Machine Tools: Nikunj PatelIshan Patel100% (1)

- 1 Unified Application For BLDG PermitDocument2 pages1 Unified Application For BLDG PermitJoven MagnoNo ratings yet

- CP DDoSProtector 6.14 GuideDocument237 pagesCP DDoSProtector 6.14 GuideAnh Bui TuanNo ratings yet

- Brooke CromptonDocument24 pagesBrooke Cromptond3xterNo ratings yet

- Course2a-Energy Efficiency PDFDocument59 pagesCourse2a-Energy Efficiency PDFNazaruddin SinagaNo ratings yet

- Abrasive Jet Machining (AJM)Document31 pagesAbrasive Jet Machining (AJM)Abhishek KumarNo ratings yet

- Huawei Ale-L23c212b180 Upgrade Guideline v1.0Document7 pagesHuawei Ale-L23c212b180 Upgrade Guideline v1.0Johnatan Flores Reyes100% (1)

- ETSI ES 201 235-3: Specification of Dual Tone Multi-Frequency (DTMF) Transmitters and Receivers Part 3: ReceiversDocument12 pagesETSI ES 201 235-3: Specification of Dual Tone Multi-Frequency (DTMF) Transmitters and Receivers Part 3: Receivershadiranji4No ratings yet

- Bid Bulletin 20la0130Document2 pagesBid Bulletin 20la0130MANNY CARAJAYNo ratings yet

- Evolution V-Backed Pump Intake Screen BrochureDocument4 pagesEvolution V-Backed Pump Intake Screen BrochureEvolution Oil ToolsNo ratings yet

- Chapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinDocument8 pagesChapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinchatxxnoirNo ratings yet

- Enviromail HK012 CompostDocument2 pagesEnviromail HK012 CompostShivang SharmaNo ratings yet

- IS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Document3 pagesIS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Shivangi BhardwajNo ratings yet