Professional Documents

Culture Documents

IR Valve, Tube & Fittings KKC HPCL 06.05.2024

IR Valve, Tube & Fittings KKC HPCL 06.05.2024

Uploaded by

Parampreet singhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IR Valve, Tube & Fittings KKC HPCL 06.05.2024

IR Valve, Tube & Fittings KKC HPCL 06.05.2024

Uploaded by

Parampreet singhCopyright:

Available Formats

Report No:

DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

SOURCE - INSPECTION REPORT Revision No:

01

Particulars of project

DNV project name: CNG STATION CONSTRUCTION WORKS SS TUBING & MECH-

UP CLUS For HPCL.

DNV customer name: M/s. KULDEEP KUMAR CONTRACTOR.

Supplier: M/s. KULDEEP KUMAR CONTRACTOR.

Manufacturer: PARKER, DK-LOK & TUBACEX

DNV acts on behalf of: M/s. KULDEEP KUMAR CONTRACTOR.

DNV project number: PR-054205

DNV assignment number: NA

DNV order/PO number: NA

Inspection details

Customer's PO number to Supplier: Contract No.: 5300009417Date: 18.07.2023

Supplier's reference: ITP. No. for SS Ball Valve: TEW/22-23/103 Date: 21.02.2023

ITP. No. for SS Tube: TEW/TUBACEX/SS TUBES 026/22-

23Date:25.01.2023

ITP.No. for SS Fittings: KKC/HPCL/SS Fittings & Valves/22-

23/01 Rev.01 Date: 17.01.2023

Additional references: NIL

Inspection location: G.T. Road, Ansal Town, Karnal. 132001

Inspection start date: (2024-05-06)

Inspection end date: (2024-05-06)

Report frequency: Weekly Daily

This report contains

Comments:

Rejected items ☐ NIL

Areas of concern ☐ NIL

Action items ☐ NIL

NCR ☐ NIL

HSE issues ☐ NIL

Photographs ☒ Attached

Attachments ☒ Internal reports, RMTC, Packing List & Calibration Certificate

This report shall not be used as part of a verification or certification service.

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 1 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

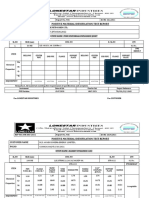

SR.No. Quantity Description & Serial No.

Ordered Offered Inspected

SS TUBING

1 1320 Meter 1320 Meter 1320 Meter 3/4” OD X 0.095” min wall thk. SS Tube and other SS

tube accessories of Grade SS 316 as per ASTM A269

2 156 Meter 156 Meter 156 Meter 1/2” OD X 0.083” min wall thk. SS Tube and other SS

tube accessories of Grade SS 316 as per ASTM A269

Equal Tee

3 89 Nos. 89 Nos. 89 Nos. Size:3/4” ODx3/4” ODx3/4” OD, Material : SS316

(Rated pressure : 5000 PSI @ 70°F Temperature :

0°F to 400°F)

Reducing Union Tee

4 60 Nos. 60 Nos. 60 Nos. Size: 3/4” OD X 1/2” OD X 3/4” OD, Material : SS316

(Rated pressure : 5000 PSI @ 70°F Temperature :

0°F to 400°F)

Nut

5 30 Nos. 30 Nos. 30 Nos. Size: 1/2” OD Material : SS316 (Rated pressure :

5000 PSI @ 70°F Temperature : 0°F to 400°F)

Front Ferrule

6 150 Nos. 150 Nos. 150 Nos. Size: 3/4” OD Material : SS316/SS316L (Rated

pressure : 5000 PSI @ 70°F Temperature : 0°F to

400°F)

7 100 Nos. 100 Nos. 100 Nos. Size: 1/2” OD Material : SS316/SS316L (Rated

pressure : 5000 PSI @ 70°F Temperature : 0°F to

400°F)

Back Ferrule

8 150 Nos. 150 Nos. 150 Nos. Size: 3/4” OD Material : SS316/SS316L (Rated

pressure : 5000 PSI @ 70°F Temperature : 0°F to

400°F)

9 100 Nos. 100 Nos. 100 Nos. Size: 1/2” OD Material : SS316/SS316L (Rated

pressure : 5000 PSI @ 70°F Temperature : 0°F to

400°F)

Reducing Union

10 40 Nos. 40 Nos. 40 Nos. Tube OD 3/4”” X Tube OD 1/2”, Material : SS316

(Rated pressure : 5000 PSI @ 70°F Temperature :

0°F to 400°F)

Ball Valves

11 60 Nos. 60 Nos. 60 Nos. Ball Valve 3/4” (Parker)

12 40 Nos. 40 Nos. 40 Nos. Ball Valve 1/2” (Parker)

Over all result

Comments

Satisfactory ☒ Inspection Carried out as per qap & found satisfactory.

Unsatisfactory ☐ NIL

HSE issues ☐ NIL

Details of visit

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 2 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

Persons present

Name Company Position Phone no. E-mail address

Mr. Sumit Kumar DNV Surveyor +91-9058209226 dnvinspector@dnv.com

Mr. Shubham Rana KKC Representative +91- 9997335855 --

Reference documentation1

Number/Reference Rev/Date Title/Approval status

5300009417 --/ 18.07.2023 Contract /HPCL

TEW/22-23/103 00/ 21.02.2023 ITP for SS Ball Valve / Tractebel

TEW/TUBACEX/SS TUBES 026/22-23 00/ 25.01.2023 ITP for SS Tube / Tractebel

KKC/HPCL/SS Fittings & Valves/22-23/01 01/17.01.2023 ITP for SS fittings/ Tractebel

Measuring/testing equipment and calibration status

Equipment description Serial no./ID No. Last cal. Date Cal. Due date

Vernier Caliper DVC-01 01.04.2024 31.03.2025

PMI Machine SPX1475 05.12.2023 04.12.2024

Measuring Tape MT-01 03.03.2023 05.04.2025

QP/Inspection and PMC Comments Resolution Sheet items covered

ITP Activity description for SS Ball Inspection Sample size–

2

Interventi Valve type for DNV extent of

on point Inspection

no. (Specify%)

1. Material Identification Reviewed As per Qap.

PMI Test Reviewed As per Qap.

2. Typical Hydrostatic Test Reports for Valve & Reviewed As per Qap.

Seat closure test

Typical Gas Pressure Test Reports for Valve Reviewed As per Qap.

Body & Seat closure test

3. Visual and Dimension Inspection Random/Witnessed As per Qap.

4. Traceability & Identification Random/Witnessed As per Qap.

5. Preparation of shipment and Packing Random/Witnessed As per Qap.

Inspection

6. Issue of Inspection Release Certificate Reviewed As per Qap.

Inspection details for SS Valves

Activities performed, results and deviations:

Following inspection activity carried out during inspection with reference of approved documents.

1. As per Qap. Sr. No. 1: Review the Raw Material Test certificate (Mechanical & Chemical Analysis) and

PMI test report of offered material & found satisfactory.

2. As per Qap. Sr. No. 2: Review the test report of Typical Hydrostatic test report for valve and seat closure

test and Gas pressure test report for valve body and seat of the offered material and found accepted.

3. As per Qap. Sr. No. 3: Witness the dimension and visually check the offered material & found

satisfactory.

4. As per Qap. Sr. No. 4: Visually check the identification and verified with the catalogs and found satisfactory.

5. As per Qap. Sr. No. 5: Witness the preparation of shipment and packing inspection of the offered

material and found accepted.

6. As per Qap. Sr. No. 6: Review of all inspection documents as per requirement & issue inspection

certificate.

1

Quality plans, drawing numbers, test procedures. Include revision.

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 3 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

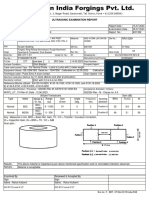

ITP Activity description for SS Tubes Inspection Sample size–

2

Intervention type forDNV extent of

point no. Inspection

(Specify%)

1. Raw Material Inspection Reviewed As per Qap.

2. Chemical Composition Reviewed As per Qap.

3. Corrosion Test (IGC Practice E) Reviewed As per Qap.

4. Destructive Testing

A. Tensile Test Reviewed As per Qap.

B. Hardness Test Reviewed As per Qap.

C. Flaring Test Reviewed As per Qap.

5. Eddy current test Reviewed As per Qap.

2

6. Hydrostatic Test at Test Pressure of 350kg/cm Reviewed As per Qap.

7. PMI Test Witness As per Qap.

8. Marking Witness As per Qap.

9. Visual & Dimension Inspection Witness As per Qap.

10. Packing Reviewed As per Qap.

Inspection details for SS Tubes

Activities performed, results and deviations:

Following inspection activity carried out during inspection with reference of approved documents.

1. As per QAP Clause no.1. Reviewed the Raw material test certificate of offered material and found

satisfactory.

2. As per QAP Clause no.2 & 3. Reviewed the chemical composition and corrosion test as per given

in inspection certificate and found satisfactory.

3. As per QAP Clause no 4A, 4B & 4C. Reviewed the tensile test, hardness test & flaring test as per

given in inspection certificate and found satisfactory.

4. As per QAP Clause no.5. Reviewed the eddy current test as per given in inspection certificate and

found satisfactory.

5. As per QAP Clause no.6. Reviewed the hydrostatic pressure tested at 350kg/cm2 for 5 sec as per

given in inspection report and found satisfactory.

6. As per QAP Clause no.7. Witnessed the PMI test of offered material and result found satisfactory.

7. As per QAP Clause no.8. Witnessed the marking of grade, standard, heat no etc over offered

material and found satisfactory.

8. As per QAP Clause no.9. Witnessed the visual & dimension of the offered material as per MTC

and found satisfactory.

9. As per QAP Clause no.10. Reviewed the packing list and certificate of the offered material and

found satisfactory.

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 4 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

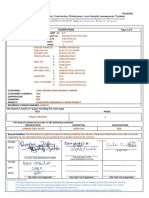

ITP Activity description for SS Fittings Inspection Sample size–

2

Intervention type forDNV extent of

point no. Inspection

(Specify%)

1. Material certificate review (Fitting: Body) Reviewed As per Qap.

2. Visual & Marking Identification Witness As per Qap.

3. Positive Material identification Reviewed As per Qap.

4. Final inspection Visual & Dimension inspection Witness As per Qap.

5. Hydraulic Burst pressure test, Impulse & vibration Reviewed As per Qap.

test

6. Helium Leak test Reviewed As per Qap.

7. Re-assembly test Reviewed As per Qap.

8. Final inspection Visual & Dimension inspection Witness As per Qap.

9. Packing Inspection with QVD check Reviewed As per Qap.

Inspection details for SS Fittings

Activities performed, results and deviations:

Following inspection activity carried out during inspection with reference of approved documents.

1. As per QAP Clause no.1. Reviewed the material test certificate of offered material and found

satisfactory.

2. As per QAP Clause no.2. Visually check & verified the marking with test certificate of the offered

material and found satisfactory.

3. As per QAP Clause no 3. Reviewed the positive material identification inspection certificate and

found satisfactory.

4. As per QAP Clause no.4. Visually check and witnessed the dimension of the offered material and

found satisfactory.

5. As per QAP Clause no.5. Reviewed the hydraulic burst pressure test, impulse & vibration and found

satisfactory.

6. As per QAP Clause no.6 & 7. Reviewed test Helium test & Re-assembly test report of offered

material and result found satisfactory.

7. As per QAP Clause no.8. Visually check and witnessed the dimension of the offered material and

found satisfactory..

8. As per QAP Clause no.9. Reviewed the packing list and certificate of the offered material and found

satisfactory.

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 5 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

Post inspection

NCRs issued during this visit2

NRC no. Description of NRC

NIL

Outstanding NCRs from previous inspection

NCR no. Reason why still outstanding and when to be completed

NIL

Action items3

Action no. Description Responsible party

NIL

Punch list

Punch list issued: ☐ Yes ☐ No ☒ N/A

Punch list number/title: N/A

Punch list attached to this report: ☐

Comments: N/A

Additional visit forecast

Further inspection required? ☐ Yes, probably on (yyyy-mm-dd) ☒ No

Additional comments: NIL

List of attachments

Attachment(s) and ID No(s) Description

RMTC, Internal Report, Packing List & Calibration Certificate

The goods/items specified have been inspected in accordance with the scope of inspection provided. The result is as

stated on the inspection report front page.

This report (and its appendices) is not related to Classification by DNV.

Report issued on (2024-05-06)

DNV Performing office: Delhi for DNV

DNV Contracting office: MUMBAI

(Sumit Kumar)

Inspector

Stamp:-

2

Any NCR shall be issued on the same day after inspection and shall be attached to the report.

3

Actions/information needed to complete or clarify the process of Inspection, by Customer, DNV, or the Equipment/Service provider.

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 6 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

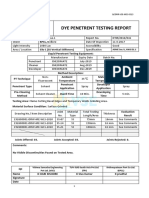

Photographs

Insert photographs to show progress of inspection, identification of parts or areas of concern.

(Make sure the pictures are numbered and add any comments to assist with conclusions.)

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 7 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 8 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 9 of 10

Report No: DNV/HPCL/KKC/

5300009417/2024/SK/

IR/01

Revision No: 01

SOURCE - INSPECTION REPORT

Form code: SRI 401 Revision: 2021-03 www.dnv.com Page 10 of 10

You might also like

- KCSE Form 3 NotesDocument265 pagesKCSE Form 3 NotesN Katana100% (1)

- IRN Valve, Tube & Fitting KKC HPCL 06.05.2024 R1Document3 pagesIRN Valve, Tube & Fitting KKC HPCL 06.05.2024 R1Parampreet singhNo ratings yet

- VMS GailDocument129 pagesVMS GailManjunatha VNo ratings yet

- IRN-Rev 01-4600575835 Dated 050809 14.05.2024Document2 pagesIRN-Rev 01-4600575835 Dated 050809 14.05.2024anilnwaychalNo ratings yet

- MSCL-SEC-ME-ISO-002 Rev.BDocument2 pagesMSCL-SEC-ME-ISO-002 Rev.BMohd Sami UddinNo ratings yet

- 01 Total No. of Drgs. / Docs. 6 2 10 32 6 02 No. of Drgs. / Docs. SubmittedDocument12 pages01 Total No. of Drgs. / Docs. 6 2 10 32 6 02 No. of Drgs. / Docs. SubmittedSai Kiran ChandrasekharuniNo ratings yet

- DRAING AND DRYING_N2 REPORTDocument1 pageDRAING AND DRYING_N2 REPORTAgni DuttaNo ratings yet

- Welding RegisterDocument1 pageWelding RegisterTouil HoussemNo ratings yet

- Bygp2 DPC DD m03 000 Mec DWG 0001 Refinal 2 PidDocument9 pagesBygp2 DPC DD m03 000 Mec DWG 0001 Refinal 2 PidRidhuan RaisNo ratings yet

- 172784-00-PR-LS-00001 - 5-Service Index ListDocument6 pages172784-00-PR-LS-00001 - 5-Service Index ListStevanNikolicNo ratings yet

- QAP-UEPL-BHOPAL-54-9550-01 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-9550-01 Rev.03udayakarnaNo ratings yet

- BSEN 10204 Test Certificate 3.2 For CT-293Document15 pagesBSEN 10204 Test Certificate 3.2 For CT-293Anonymous FHkX0ANo ratings yet

- ONGC - Pipe Stress PhilosphyDocument26 pagesONGC - Pipe Stress Philosphyraj100% (2)

- NAWPPL-BIMSVAL-NPPL-000-QC-ITP-00200 - 002 - QUALITY PLAN (Incl. Inspection and Test Plan) FOR GLOBE & CHECK VALVESDocument10 pagesNAWPPL-BIMSVAL-NPPL-000-QC-ITP-00200 - 002 - QUALITY PLAN (Incl. Inspection and Test Plan) FOR GLOBE & CHECK VALVESHoussemSoltanaNo ratings yet

- TAP0000271-revision1 240316 222031Document16 pagesTAP0000271-revision1 240316 222031ewgenykuzinNo ratings yet

- FW IRN of Surya Roshni PipesDocument4 pagesFW IRN of Surya Roshni PipesDIVYESH CHAUHANNo ratings yet

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDocument10 pagesO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- TB2-SDC.VP101-00100-I-M12-DCS-5001_Rev2_INSTRUMENT CABLE SCHEDULEDocument77 pagesTB2-SDC.VP101-00100-I-M12-DCS-5001_Rev2_INSTRUMENT CABLE SCHEDULEPhong Thế NguyễnNo ratings yet

- Format Intermediate Checks Point For Weing BalanceDocument1 pageFormat Intermediate Checks Point For Weing BalanceSrishti sNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh KumarNo ratings yet

- Client:: Project Job No.Document6 pagesClient:: Project Job No.Halliday Gerald DabokikaNo ratings yet

- Signed Survey Visit Report 13202 Accommodation ModuleDocument2 pagesSigned Survey Visit Report 13202 Accommodation ModulegeamanoudNo ratings yet

- Non Return Valve For Intake & CWR (32006-Lwss-Me-Ds-0007) Rev. ADocument3 pagesNon Return Valve For Intake & CWR (32006-Lwss-Me-Ds-0007) Rev. ASouvik DaluiNo ratings yet

- JSA For Cathodic Protection Installation For PipelineDocument15 pagesJSA For Cathodic Protection Installation For PipelineAmeerHamzaWarraich100% (1)

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- 00 PR SP 00003 - 1 General Pipe Weld Examination RequirementsDocument8 pages00 PR SP 00003 - 1 General Pipe Weld Examination RequirementsStevanNikolicNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- DNV-GL CertificateDocument3 pagesDNV-GL Certificategetfarhan786No ratings yet

- RPT 001Document6 pagesRPT 001Juan Montes de ocaNo ratings yet

- 23a02.nd30-08 Pompa Cip Uf SwroDocument7 pages23a02.nd30-08 Pompa Cip Uf SwroArsa WijayaNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Ut & Mpi ProcedureDocument23 pagesUt & Mpi ProcedurePRASHANT100% (2)

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IRDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IRDadaso Baburao JamdarNo ratings yet

- Procedure For Manual Ultrasonic Testing PDFDocument17 pagesProcedure For Manual Ultrasonic Testing PDFbaskaran ayyapparaj100% (2)

- Pipe 6'' 8'' (Base Metal)Document6 pagesPipe 6'' 8'' (Base Metal)HanifZawawiNo ratings yet

- Final Dimension ReportDocument2 pagesFinal Dimension Reportvirendra katkeNo ratings yet

- Inspection Report No.01 - NRS - 21Document4 pagesInspection Report No.01 - NRS - 21Pradhipta W NurrobbiNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- Material Receiving Inspection SENDING ULN3 TO LPGU3Document30 pagesMaterial Receiving Inspection SENDING ULN3 TO LPGU3ReduddboyNo ratings yet

- Cover PageDocument2 pagesCover PageAbubakar lawan moduNo ratings yet

- Procedure For Manual Body UtDocument8 pagesProcedure For Manual Body Utprasanna deshpandeNo ratings yet

- TR015-P LR - MazarineDocument10 pagesTR015-P LR - MazarineTouil HoussemNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- DRP001 Ouf Gal Spe B 000 001 S1Document25 pagesDRP001 Ouf Gal Spe B 000 001 S1Rafat KhanNo ratings yet

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- RPT-1000483-PL-000-00-00-010 - Rev 1Document65 pagesRPT-1000483-PL-000-00-00-010 - Rev 1process1plecoNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- 65A10184-09-0905-01-008 Rev.2 (FLow Meter Sizing Cal)Document8 pages65A10184-09-0905-01-008 Rev.2 (FLow Meter Sizing Cal)chhandak beraNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Certificate of ComplianceDocument7 pagesCertificate of ComplianceNabilah HusnaNo ratings yet

- 2020-4075 HCT6 C-Con R100 23-24Document1 page2020-4075 HCT6 C-Con R100 23-24abrar4012No ratings yet

- MOC JHA JADE MECH EQP MDS 16ST-0101 R0 DM Water Feed TankDocument4 pagesMOC JHA JADE MECH EQP MDS 16ST-0101 R0 DM Water Feed Tanksanjay wakchoureNo ratings yet

- SSG Ng01017365 Gen MP 7303 00001 - d01 - MR For Stud Bolts and NutsDocument8 pagesSSG Ng01017365 Gen MP 7303 00001 - d01 - MR For Stud Bolts and NutsDaniel DamboNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Test ReportDocument65 pagesTest ReportParampreet singhNo ratings yet

- Tc-03-Hpcl-Up&uk-4x6.40-1613 Pipes - 0001Document6 pagesTc-03-Hpcl-Up&uk-4x6.40-1613 Pipes - 0001Parampreet singhNo ratings yet

- TC & Talyy SheetDocument44 pagesTC & Talyy SheetParampreet singhNo ratings yet

- Insp Report-001Document6 pagesInsp Report-001Parampreet singhNo ratings yet

- Resume SANJEEV MANKOTIYA-1Document5 pagesResume SANJEEV MANKOTIYA-1Parampreet singhNo ratings yet

- MJ Spec NI-346-21R1-MS New Eoan AssociatesDocument1 pageMJ Spec NI-346-21R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- QAP-NI-IJ-346-21 R1-MS New Eoan AssociatesDocument2 pagesQAP-NI-IJ-346-21 R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- 12 - Evaluasi Shaly SandDocument31 pages12 - Evaluasi Shaly SandYordanNo ratings yet

- Questions and ProblemsDocument6 pagesQuestions and ProblemsRie CabigonNo ratings yet

- Gas Laws AssignmentDocument5 pagesGas Laws AssignmentShweta SharmaNo ratings yet

- Cataleg PSCDocument151 pagesCataleg PSCAntônio Cesar de OliveiraNo ratings yet

- Is The Homogeneity of Your Dry Mix Acceptable - Chemical ProcessingDocument9 pagesIs The Homogeneity of Your Dry Mix Acceptable - Chemical Processingaswar teknikNo ratings yet

- Physical Science Reviewer: A) NM + NMDocument16 pagesPhysical Science Reviewer: A) NM + NMElishaNo ratings yet

- Non Aqueous SolventsDocument24 pagesNon Aqueous SolventsRSLNo ratings yet

- Inferences. Use Equations To Aid in Your Answers, and Use A Table To Represent Your Findings.)Document2 pagesInferences. Use Equations To Aid in Your Answers, and Use A Table To Represent Your Findings.)DanelNo ratings yet

- 12th Chemistry EM Centum Special Question Paper English Medium PDF DownloadDocument4 pages12th Chemistry EM Centum Special Question Paper English Medium PDF Downloadushamuthuraja123No ratings yet

- Critical Resolved Shear StressDocument31 pagesCritical Resolved Shear StressLumamba ChiyabiNo ratings yet

- Berol 226Document15 pagesBerol 226rahul sharmaNo ratings yet

- h2s Scavenging BRDocument12 pagesh2s Scavenging BROmid LarkiNo ratings yet

- Enercare Lubricant Analysis: Rating Summary Table For British Osprey (9258882)Document11 pagesEnercare Lubricant Analysis: Rating Summary Table For British Osprey (9258882)Jagmohan SinghNo ratings yet

- HaslabDocument10 pagesHaslabPrabhakar Toravi100% (1)

- CH 8. Chemical Equilibrium (Chem +1)Document40 pagesCH 8. Chemical Equilibrium (Chem +1)Dipin Preet SinghNo ratings yet

- M.vimaladevi - Text Book of CosmeticsDocument332 pagesM.vimaladevi - Text Book of CosmeticsShivalingaiah100% (1)

- Vensil Price List 2022-2023Document210 pagesVensil Price List 2022-2023ajay1581990No ratings yet

- SampleQP UG Chemistry 23042024Document4 pagesSampleQP UG Chemistry 23042024mr.beam0popcornNo ratings yet

- Tylose For Personal CareDocument8 pagesTylose For Personal Carehenriquefxs2926No ratings yet

- BI309 Lab 3 Ryan CarrollDocument4 pagesBI309 Lab 3 Ryan CarrollRyan CarrollNo ratings yet

- LI-7200RS and SmartFlux 2 User CalibrationDocument1 pageLI-7200RS and SmartFlux 2 User CalibrationTomás Arturo Soto MurilloNo ratings yet

- Problem Set 1 (THEREZZE CARINO-BSCE-1D)Document10 pagesProblem Set 1 (THEREZZE CARINO-BSCE-1D)Therezze Jane ParanadaNo ratings yet

- LN-Guide To Leather Making PART TWODocument44 pagesLN-Guide To Leather Making PART TWOkaanozcann02No ratings yet

- Map - Inorganic Chemistry (Housecroft) - Chemistry LibreTextsDocument3 pagesMap - Inorganic Chemistry (Housecroft) - Chemistry LibreTextsreddygrNo ratings yet

- Potash Alum 12Document16 pagesPotash Alum 12Xiao ZhanNo ratings yet

- TechnicalDataSheet (TDS) BONDERITEL-FGADAGC English 07012022Document2 pagesTechnicalDataSheet (TDS) BONDERITEL-FGADAGC English 07012022carlos dominguez torresNo ratings yet

- Enzymatic Activity Levels Vs Temperature Lab ReportDocument9 pagesEnzymatic Activity Levels Vs Temperature Lab Reportapi-387603251100% (1)

- Proteins PDFDocument11 pagesProteins PDFKimNo ratings yet

- BIO 462 Experiment 2Document6 pagesBIO 462 Experiment 2Nurul Farhah RadzuwanNo ratings yet