Professional Documents

Culture Documents

06.MSA Gauge R&R Variable.dvc

06.MSA Gauge R&R Variable.dvc

Uploaded by

sumit.kumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06.MSA Gauge R&R Variable.dvc

06.MSA Gauge R&R Variable.dvc

Uploaded by

sumit.kumarCopyright:

Available Formats

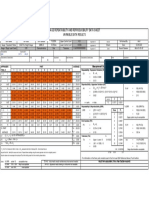

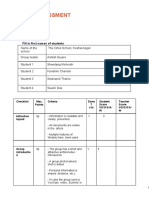

Doc. No.

- TACO/QA/F/04

Gauge Repeatability and Reproducibility Study ( Variable ) Rev. No - 00

Rev Date : 01.06.2020

Instrument Name : Digital vernier caliper 0 - 150 MM Specification : 12 ± 0.1 Report No. : 05

Instrument No. : DVC-01-05 Least count : 0.01mm. Date : 20.09.2022

Part Name & No. : Flexible busbar7 '5040020687' Tolerance : 0.20 Performed By : Shivani Godse

OPERATOR A : Shivraj MEASUREMENT UNIT ANALYSIS % PROCESS VARIATION

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE REPEATABILITY-EQUIPMENT VARIATION(EV) %EV= 100(EV/TV)

1 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 TRIAL: K1 = 8.31

2 12.03 12.01 12.04 12.03 12.02 12.02 12.03 12.02 12.03 12.04 2 0.8862 %AV= 100(AV/TV)

3 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 EV = R*K1 =0.0008 3 0.5908 = 5.30

Avg. 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 Xa = 12.0257 Actual 3 0.5908 %R&R = 100(GRR/TV)

Range 0.01 0.00 0.00 0.00 0.01 0.00 0.00 0.00 0.00 0.00 Ra = 0.0020 REPRODUCIBILITY-APPRAISER VARIATION = 9.85

OPERATOR B : Swati OPERATOR: K2 % PV= 100(PV/TV)

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE AV = [(Xdiff*K2)2-(EV2/nr)] 2 0.7071 = 99.51

1 12.01 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 AV = 0.0005 3 0.5231 ndc= 1.41 ( PV/ GRR )

2 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 Actual 3 0.5231 = 14.24

3 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 n=no. of parts r=no. of trials ndc = Number of distinct categories

Avg. 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 Xb = 12.0247 REPEATABILITY & REPRODUCIBILITY (ndc should be greater than 5 )

Range 0.01 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Rb = 0.0010 GRR = (EV2 + AV2)

OPERATOR C : Kaustav GRR 0.0009

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE PART VARIATION (PV) PART K3

1 12.02 12.01 12.04 12.02 12.01 12.02 12.03 12.02 12.03 12.04 PV = Rp*K3 0.0094 2 0.7071

2 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 3 0.5231 % TOLERANCE VARIATION

3 12.02 12.01 12.04 12.03 12.01 12.02 12.03 12.02 12.03 12.04 4 0.4467 %EV= 100(EV/TV)

Avg. 12.020 12.010 12.040 12.027 12.010 12.020 12.030 12.020 12.030 12.040 Xc = 12.0247 TOTAL VARIATION (TV) 5 0.4030 = 2.36

Range 0.000 0.000 0.000 0.010 0.000 0.000 0.000 0.000 0.000 0.000 Rc = 0.0010 TV = (GRR2 + PV2) 6 0.3742 %AV= 100(AV/TV)

Part

12.020 12.010 12.040 12.029 12.011 12.020 12.030 12.020 12.030 12.040 Rp= 0.0300 TV = 0.0095 7 0.3534 = 1.51

Avg.Xp

Total Varation: 8 0.3375 %R&R = 100(GRR/TV)

R = (Ra + Rb + Rc )/#OF OPR = 0.0013 NO.OF A2 D3 D4 TV = total tolerance/6 9 0.3249 = 2.80

X Diff = _(Max X - Min X) = 0.0010 TRIALS 0.03333 10 0.3146 % PV= 100(PV/TV)

UCL R = _(R*D4) = 0.0034 2 1.880 0 3.267 Actual 3 0.5231 = 28.31

LCL R = (R*D3) = 0.0000 3 1.020 0 2.580

Measurement System Acceptable

X = 12.0250 UCL X= 12.0264 LCL X = 12.0236

APPRAISER AVERAGE CHART

OPERATOR A OPERATOR B OPERATOR C

12.0450 12.0450 12.0450

12.0400 12.0400 12.0400

12.0350 12.0350 12.0350

12.0300 12.0300 12.0300

12.0250 12.0250 12.0250

X-BAR OP1 X-BAR OP2 X-BAR OP3

X-BAR CHART 12.0200 12.0200 12.0200

UCL X BAR 12.0150 UCL X BAR

12.0150 12.0150 UCL X BAR

12.0100 LCL X BAR 12.0100 LCL X BAR 12.0100 LCL X BAR

12.0050 X BAR AVG 12.0050 X BAR AVG

12.0050 X BAR AVG

12.0000 12.0000 12.0000

11.9950 11.9950 11.9950

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

REPEATABILITY RANGE CHART

0.0120 0.0120

0.0120

0.0100 0.0100

0.0100

R OP1 R OP2

0.0080 0.0080 0.0080

R OP3

UCL R UCL R

R- CHART 0.0060 0.0060

UCL R

LCL R LCL R 0.0060 LCL R

0.0040 R AVG 0.0040 R AVG

0.0040 R AVG

0.0020 0.0020 0.0020

0.0000 0.0000 0.0000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

REAPEATABILITY RANGE CHART: ALL RANGES MUST BE WITHIN CONTROL LIMITS. IF ANY RANGE IS BEYOND THE LIMIT, DISCARD THAT DATA AND RECALCULATE THE LIMITS

ANALYSIS: APPRAISER AVERAGE CHART: AT LEAST 50% DATA SHOULD BE OUT SIDE OF CONTROL LIMITS. IF NOT MEASUREMENT SYSTEM IS NOT CAPABLE FOR MEASURING PART TO PART VARIATION

R&R: IF MS IS USED FOR SPC, CALCULATE R&R AS "% PROCESS VARIATION" OTHERWISE AS "TOLERANCE VARIATION".

Prepared By :Shivani Godse Approved By : Mr. Mohit Sinha

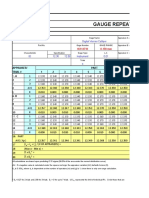

Doc. No. - F/QA/57

Gauge Repeatability and Reproducibility Study ( Variable ) Rev. No - 01

India Plastic Pvt. Ltd. Rev. Date - 25.06.2018

Instrument Name : Cubing fixture by taper scale (Point 11) Specification : 3±0.25 mm. Report No. : _

Instrument No. : NA Least count : 0.01 mm. Date : 19.03.2019

Part Name & No. : BFS Air Vent & 5E4.819.702.C Tolerance : 0.50 Performed By : Mr. Neha Jogdand

OPERATOR A : NEHA MEASUREMENT UNIT ANALYSIS % PROCESS VARIATION

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE REPEATABILITY-EQUIPMENT VARIATION(EV) %EV= 100(EV/TV)

1 3.10 2.80 3.10 2.80 3.00 2.90 3.00 3.00 2.80 3.00 TRIAL: K1 = 16.34

2 3.10 2.80 3.10 2.80 3.00 2.90 3.00 3.10 2.80 3.00 2 0.8862 %AV= 100(AV/TV)

3 3.10 2.80 3.10 2.80 3.10 2.90 3.00 3.00 2.80 3.00 EV = R*K1 =0.0158 3 0.5908 = 12.30

Avg. 3.10 2.80 3.10 2.80 3.03 2.90 3.00 3.03 2.80 3.00 Xa = 2.9567 Actual 3 0.5908 %R&R = 100(GRR/TV)

Range 0.00 0.00 0.00 0.00 0.10 0.00 0.00 0.10 0.00 0.00 Ra = 0.0200 REPRODUCIBILITY-APPRAISER VARIATION = 20.45

OPERATOR B : RAJESH OPERATOR: K2 % PV= 100(PV/TV)

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE AV = [(Xdiff*K2)2-(EV2/nr)] 2 0.7071 = 97.89

1 3.10 2.80 3.10 2.80 3.10 2.90 3.10 3.10 2.90 3.00 AV = 0.01186 3 0.5231 ndc= 1.41 ( PV/ GRR )

2 3.10 2.80 3.10 2.80 3.00 2.90 3.00 3.00 2.90 3.00 Actual 3 0.5231 = 6.75

3 3.10 2.80 3.10 2.80 3.00 2.90 3.10 3.00 2.90 3.00 n=no. of parts r=no. of trials ndc = Number of distinct categories

Avg. 3.10 2.80 3.10 2.80 3.03 2.90 3.07 3.03 2.90 3.00 Xb = 2.9733 REPEATABILITY & REPRODUCIBILITY (ndc should be greater than 5 )

Range 0.00 0.00 0.00 0.00 0.10 0.00 0.10 0.10 0.00 0.00 Rb = 0.0300 GRR = (EV2 + AV2) Measurement System Conditionally

OPERATOR C : DHANAJI GRR 0.0197 Acceptable

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE PART VARIATION (PV) PART K3

1 3.10 2.80 3.10 2.80 3.10 2.90 3.10 3.00 2.90 3.00 PV = Rp*K3 0.0944 2 0.7071

2 3.10 2.80 3.10 2.80 3.10 2.90 3.10 3.10 2.90 3.00 3 0.5231 % TOLERANCE VARIATION

3 3.10 2.80 3.10 2.80 3.00 2.90 3.00 3.10 2.90 3.00 4 0.4467 %EV= 100(EV/TV)

Avg. 3.100 2.800 3.100 2.800 3.067 2.900 3.067 3.067 2.900 3.000 Xc = 2.9800 TOTAL VARIATION (TV) 5 0.4030 = 18.91

Range 0.000 0.000 0.000 0.000 0.100 0.000 0.100 0.100 0.000 0.000 Rc = 0.0300 TV = (GRR2 + PV2) 6 0.3742 %AV= 100(AV/TV)

Part

3.100 2.800 3.100 2.800 3.044 2.900 3.044 3.044 2.867 3.000 Rp= 0.3000 TV = 0.0964 7 0.3534 = 14.23

Avg.Xp

Total Varation: 8 0.3375 %R&R = 100(GRR/TV)

R = (Ra + Rb + Rc )/#OF OPR = 0.0267 NO.OF A2 D3 D4 TV = total tolerance/6 9 0.3249 = 23.67

X Diff = _(Max X - Min X) = 0.0233 TRIALS 0.08333 10 0.3146 % PV= 100(PV/TV)

UCL R = _(R*D4) = 0.0688 2 1.880 0 3.267 Actual 3 0.5231 = 113.26

LCL R = (R*D3) = 0.0000 3 1.020 0 2.580 Measurement System Conditionally

X = 2.9700 UCL X= 2.9972 LCL X = 2.9428 Acceptable

APPRAISER AVERAGE CHART

OPERATOR A OPERATOR B OPERATOR C

3.2000 3.2000 3.2000

3.1000 3.1000 3.1000

3.0000 3.0000 3.0000

X-BAR OP1 X-BAR OP2 X-BAR OP3

X-BAR CHART 2.9000 2.9000 2.9000

UCL X BAR UCL X BAR UCL X BAR

2.8000 LCL X BAR 2.8000 2.8000 LCL X BAR

LCL X BAR

2.7000 X BAR AVG 2.7000 X BAR AVG 2.7000 X BAR AVG

2.6000 2.6000 2.6000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

REPEATABILITY RANGE CHART

0.1200 0.1200

0.1200

0.1000 0.1000

0.1000

R OP1 R OP2

0.0800 0.0800 0.0800

R OP3

UCL R UCL R

R- CHART 0.0600 0.0600

UCL R

LCL R LCL R 0.0600 LCL R

0.0400 R AVG 0.0400 R AVG

0.0400 R AVG

0.0200 0.0200 0.0200

0.0000 0.0000 0.0000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

REAPEATABILITY RANGE CHART: ALL RANGES MUST BE WITHIN CONTROL LIMITS. IF ANY RANGE IS BEYOND THE LIMIT, DISCARD THAT DATA AND RECALCULATE THE LIMITS

ANALYSIS: APPRAISER AVERAGE CHART: AT LEAST 50% DATA SHOULD BE OUT SIDE OF CONTROL LIMITS. IF NOT MEASUREMENT SYSTEM IS NOT CAPABLE FOR MEASURING PART TO PART VARIATION

R&R: IF MS IS USED FOR SPC, CALCULATE R&R AS "% PROCESS VARIATION" OTHERWISE AS "TOLERANCE VARIATION".

Prepared By : Mr. G. Alam Approved By : Mr. Virendra Patil

Doc. No. - F/QA/57

Gauge Repeatability and Reproducibility Study ( Variable ) Rev. No - 01

India Plastic Pvt. Ltd. Rev. Date - 25.06.2018

Instrument Name : Cubing fixture by taper scale (Point 12) Specification : 3±0.25 mm. Report No. : _

Instrument No. : NA Least count : 0.01 mm. Date : 19.03.2019

Part Name & No. : BFS Air Vent & 5E4.819.702.C Tolerance : 0.50 Performed By : Mr. Neha Jogdand

OPERATOR A : NEHA MEASUREMENT UNIT ANALYSIS % PROCESS VARIATION

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE REPEATABILITY-EQUIPMENT VARIATION(EV) %EV= 100(EV/TV)

1 2.90 3.20 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 TRIAL: K1 = 8.77

2 2.90 3.20 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 2 0.8862 %AV= 100(AV/TV)

3 2.90 3.20 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 EV = R*K1 =0.0098 3 0.5908 = 2.66

Avg. 2.90 3.20 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 Xa = 2.9600 Actual 3 0.5908 %R&R = 100(GRR/TV)

Range 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Ra = 0.0000 REPRODUCIBILITY-APPRAISER VARIATION = 9.16

OPERATOR B : RAJESH OPERATOR: K2 % PV= 100(PV/TV)

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE AV = [(Xdiff*K2)2-(EV2/nr)] 2 0.7071 = 99.58

1 2.90 3.10 2.90 3.00 3.10 2.80 2.90 3.10 2.80 3.10 AV = 0.00299 3 0.5231 ndc= 1.41 ( PV/ GRR )

2 2.90 3.10 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 Actual 3 0.5231 = 15.33

3 2.90 3.10 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 n=no. of parts r=no. of trials ndc = Number of distinct categories

Avg. 2.90 3.10 2.83 2.93 3.10 2.80 2.90 3.10 2.80 3.10 Xb = 2.9567 REPEATABILITY & REPRODUCIBILITY (ndc should be greater than 5 )

Range 0.00 0.00 0.10 0.10 0.00 0.00 0.00 0.00 0.00 0.00 Rb = 0.0200 GRR = (EV2 + AV2)

Measurement System Acceptable

OPERATOR C : DHANAJI GRR 0.0103

TRIAL 1 2 3 4 5 6 7 8 9 10 AVERAGE PART VARIATION (PV) PART K3

1 2.90 3.10 2.90 3.00 3.10 2.80 2.90 3.10 2.80 3.10 PV = Rp*K3 0.1119 2 0.7071

2 2.90 3.20 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 3 0.5231 % TOLERANCE VARIATION

3 2.90 3.20 2.80 2.90 3.10 2.80 2.90 3.10 2.80 3.10 4 0.4467 %EV= 100(EV/TV)

Avg. 2.900 3.167 2.833 2.933 3.100 2.800 2.900 3.100 2.800 3.100 Xc = 2.9633 TOTAL VARIATION (TV) 5 0.4030 = 11.82

Range 0.000 0.100 0.100 0.100 0.000 0.000 0.000 0.000 0.000 0.000 Rc = 0.0300 TV = (GRR2 + PV2) 6 0.3742 %AV= 100(AV/TV)

Part

2.900 3.156 2.822 2.922 3.100 2.800 2.900 3.100 2.800 3.100 Rp= 0.3556 TV = 0.1123 7 0.3534 = 3.59

Avg.Xp

Total Varation: 8 0.3375 %R&R = 100(GRR/TV)

R = (Ra + Rb + Rc )/#OF OPR = 0.0167 NO.OF A2 D3 D4 TV = total tolerance/6 9 0.3249 = 12.35

X Diff = _(Max X - Min X) = 0.0067 TRIALS 0.08333 10 0.3146 % PV= 100(PV/TV)

UCL R = _(R*D4) = 0.0430 2 1.880 0 3.267 Actual 3 0.5231 = 134.23

LCL R = (R*D3) = 0.0000 3 1.020 0 2.580 Measurement System Conditionally

X = 2.9600 UCL X= 2.9770 LCL X = 2.9430 Acceptable

APPRAISER AVERAGE CHART

OPERATOR A OPERATOR B OPERATOR C

3.3000 3.2000 3.2000

3.2000

3.1000 3.1000

3.1000

3.0000 3.0000 3.0000

X-BAR OP1 X-BAR OP2 X-BAR OP3

X-BAR CHART 2.9000 2.9000 2.9000

UCL X BAR UCL X BAR UCL X BAR

2.8000 2.8000

LCL X BAR 2.8000 LCL X BAR

LCL X BAR

2.7000

X BAR AVG 2.7000 X BAR AVG 2.7000 X BAR AVG

2.6000

2.5000 2.6000 2.6000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

REPEATABILITY RANGE CHART

0.0500 0.1200

0.1200

0.0400 0.1000

0.1000

R OP1 R OP2

0.0800 0.0800

R OP3

0.0300 UCL R UCL R

R- CHART 0.0600

UCL R

LCL R LCL R 0.0600 LCL R

0.0200

R AVG 0.0400 R AVG

0.0400 R AVG

0.0100 0.0200 0.0200

0.0000 0.0000 0.0000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

REAPEATABILITY RANGE CHART: ALL RANGES MUST BE WITHIN CONTROL LIMITS. IF ANY RANGE IS BEYOND THE LIMIT, DISCARD THAT DATA AND RECALCULATE THE LIMITS

ANALYSIS: APPRAISER AVERAGE CHART: AT LEAST 50% DATA SHOULD BE OUT SIDE OF CONTROL LIMITS. IF NOT MEASUREMENT SYSTEM IS NOT CAPABLE FOR MEASURING PART TO PART VARIATION

R&R: IF MS IS USED FOR SPC, CALCULATE R&R AS "% PROCESS VARIATION" OTHERWISE AS "TOLERANCE VARIATION".

Prepared By : Mr. G. Alam Approved By : Mr. Virendra Patil

You might also like

- Interview RubricDocument1 pageInterview RubricRemi Rajan100% (6)

- A View On Transformational Leadership: The Case of Jeff BezosDocument9 pagesA View On Transformational Leadership: The Case of Jeff BezosAkash BhatNo ratings yet

- The Problem and Its Background: A Feasibility Study of Mking Fish Dumplings With VegetablesDocument20 pagesThe Problem and Its Background: A Feasibility Study of Mking Fish Dumplings With VegetablesAngelica Valdez Bauto89% (9)

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- MSA FormatDocument4 pagesMSA FormatSaurabh PhandNo ratings yet

- Measurement System Analysis (R & R Study) DAP: ResultDocument2 pagesMeasurement System Analysis (R & R Study) DAP: Resultconversionbu2No ratings yet

- Measurement System Analysis - Gage R & R Study Data Sheet: AV EVDocument2 pagesMeasurement System Analysis - Gage R & R Study Data Sheet: AV EVKrishnaraj.C (INEL -Materials)No ratings yet

- MSA of Sealing Plate DC-12Document2 pagesMSA of Sealing Plate DC-12RahulNo ratings yet

- GR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationDocument4 pagesGR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationRahulNo ratings yet

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- Protocolo de Prueba - SE N 1 A SE N 2Document3 pagesProtocolo de Prueba - SE N 1 A SE N 2Jhonatan Eduardo Vasquez RosalesNo ratings yet

- Protocolo de Prueba - SE 3 - Celda PrincipalDocument3 pagesProtocolo de Prueba - SE 3 - Celda PrincipalJhonatan Eduardo Vasquez RosalesNo ratings yet

- NC-EL-LS-01 Electrical Load List NitrocelluloseDocument2 pagesNC-EL-LS-01 Electrical Load List NitrocelluloseAchmad Nur HusainiNo ratings yet

- Fairchild Semiconductor-Qsd123-DatasheetDocument4 pagesFairchild Semiconductor-Qsd123-Datasheetapi-349977362No ratings yet

- Gauge R&R (MSA) - GoodDocument1 pageGauge R&R (MSA) - Goodsdaruwale20No ratings yet

- Protocolo de Prueba - SE N2 - Celda de PrincipalDocument3 pagesProtocolo de Prueba - SE N2 - Celda de PrincipalJhonatan Eduardo Vasquez RosalesNo ratings yet

- Customer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionDocument14 pagesCustomer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionParama Ahmad ParahitaNo ratings yet

- Laporan Bulanan September 2021Document1 pageLaporan Bulanan September 2021satria widya hutamaNo ratings yet

- Protocolo de Prueba - SE N 2 A SE N 3Document3 pagesProtocolo de Prueba - SE N 2 A SE N 3Jhonatan Eduardo Vasquez RosalesNo ratings yet

- Msa hg01Document1 pageMsa hg01amitvohraNo ratings yet

- Gauge Repeatability & Reproduciability Study: Digital Vernier CalliperDocument6 pagesGauge Repeatability & Reproduciability Study: Digital Vernier CalliperAliNo ratings yet

- Gage Repeatability and Reproducibility Data SheetDocument12 pagesGage Repeatability and Reproducibility Data SheetDiiego LozadaNo ratings yet

- Standard Technical Specifications For Electrical Works: Transformers / Reactors / ResistorsDocument13 pagesStandard Technical Specifications For Electrical Works: Transformers / Reactors / ResistorsAnonymous kjvaeVJNNo ratings yet

- 63 123 186 10 Cable Entry: Reviser App .By Revision Date Mark 1 2 3Document1 page63 123 186 10 Cable Entry: Reviser App .By Revision Date Mark 1 2 3Rigoberto GomezNo ratings yet

- TPP1Document2 pagesTPP1Jagadesh PNo ratings yet

- Silika - DikonversiDocument30 pagesSilika - DikonversiMuhammad Yudi SaputraNo ratings yet

- 1000W Resonant Choke L=13uH Rev A -SPECDocument5 pages1000W Resonant Choke L=13uH Rev A -SPECCelilNo ratings yet

- R&R Probador de Fugas 5 Piezas, 3 Intentos, 2 Operadores, 0a4Document3 pagesR&R Probador de Fugas 5 Piezas, 3 Intentos, 2 Operadores, 0a4Jesus HernandezNo ratings yet

- Over Current & Earth FaultDocument1 pageOver Current & Earth FaultUmer EhsanNo ratings yet

- CondenserDocument9 pagesCondenserAzhar BudimanNo ratings yet

- Seismic Load Calculation 3.5: Page 15 of 152Document3 pagesSeismic Load Calculation 3.5: Page 15 of 152phanikrishnabNo ratings yet

- 10.MSA Analysis For ConturographDocument2 pages10.MSA Analysis For ConturographAdnin DelićNo ratings yet

- PAT 420-Calibration-CertificateDocument3 pagesPAT 420-Calibration-Certificatejames.rawcliffe123No ratings yet

- MVTU11 - 09BBC08-okDocument1 pageMVTU11 - 09BBC08-okMUHAMMAD FAHMINo ratings yet

- Form / Format Gauge Repeatability & Reproducibility Report: CapacitorDocument4 pagesForm / Format Gauge Repeatability & Reproducibility Report: CapacitorhimanshuNo ratings yet

- DS-351012 Layout ReportDocument1 pageDS-351012 Layout ReportDev vrat rajpootNo ratings yet

- PB04Document2 pagesPB04Jagadesh PNo ratings yet

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Document1 page(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8No ratings yet

- Özgüney: Test TransformerDocument1 pageÖzgüney: Test TransformermominzadahNo ratings yet

- Özgüney: Transformer TestDocument1 pageÖzgüney: Transformer TestmominzadahNo ratings yet

- 05 - MSA Variable GR&R templateDocument2 pages05 - MSA Variable GR&R templatefitri albaihaqiNo ratings yet

- UR7006HV Clear - TDSDocument2 pagesUR7006HV Clear - TDSLoco MtzNo ratings yet

- TPP2Document2 pagesTPP2Jagadesh PNo ratings yet

- Adobe Scan 09 Dec 2021Document2 pagesAdobe Scan 09 Dec 2021RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- HelloDocument10 pagesHelloPreetham KarthikNo ratings yet

- Astor: Test TransformerDocument1 pageAstor: Test TransformermominzadahNo ratings yet

- 09.MSA Analysis For 3DDocument2 pages09.MSA Analysis For 3DAdnin DelićNo ratings yet

- New LAOD CALCULATION & DETAILSDocument10 pagesNew LAOD CALCULATION & DETAILSDessouki SamakNo ratings yet

- Gauge Repeatability & Reproduceability Report (MSA Study)Document2 pagesGauge Repeatability & Reproduceability Report (MSA Study)Karan MalhiNo ratings yet

- ResistorDocument9 pagesResistorSakahi SharmaNo ratings yet

- ResistorDocument9 pagesResistordennis0611237No ratings yet

- Ot 26985Document1 pageOt 26985LEONARDO DIEGO ALBINAGORTA PAREDESNo ratings yet

- Reverse BiasedDocument1 pageReverse BiasedLakshayNo ratings yet

- LCD12864 STDocument18 pagesLCD12864 STCarlos MartinezNo ratings yet

- Restage Long Lash Mascara 15.6.1Document1 pageRestage Long Lash Mascara 15.6.1Anata Ramos Del RosarioNo ratings yet

- Lab Fl14a086cDocument5 pagesLab Fl14a086czyassNo ratings yet

- Gauge R&R FormulaDocument5 pagesGauge R&R FormulaBhoopathy JNo ratings yet

- 2023 Hvet - Ormspmi01Document5 pages2023 Hvet - Ormspmi01reyNo ratings yet

- Neutral OC Testing ResultsDocument1 pageNeutral OC Testing ResultsUmer EhsanNo ratings yet

- Method of Repeative Plate Bearing Test: ASTM D1195-21 / (DIN 18134)Document10 pagesMethod of Repeative Plate Bearing Test: ASTM D1195-21 / (DIN 18134)Mohamed BarakatNo ratings yet

- H02 Duobias Relay Report 87TDocument4 pagesH02 Duobias Relay Report 87TKalimuthuNo ratings yet

- Optical Performance of The Grating Light Valve TechnologyDocument8 pagesOptical Performance of The Grating Light Valve TechnologyelangovanNo ratings yet

- MallDocument22 pagesMallZee ZeeNo ratings yet

- Spss ResultDocument28 pagesSpss Resultapi-563385491No ratings yet

- QMMDocument54 pagesQMMgladwin thomasNo ratings yet

- Thesis WritingDocument13 pagesThesis WritingClaudette Faye CartabioNo ratings yet

- TiteDocument18 pagesTitetjybzenNo ratings yet

- Self Assessment ValuesDocument3 pagesSelf Assessment Valuesapi-568765062No ratings yet

- Review of Related Literature and StudiesDocument13 pagesReview of Related Literature and StudiesAlysa May MejoradaNo ratings yet

- Pham Le Thu Nga Hanoi University KM 9, Nguyen Trai ST., Thanh Xuan Dist., Hanoi Tel: (04) 3 5533560 Email: Ngaplt@hanu - Edu.vnDocument2 pagesPham Le Thu Nga Hanoi University KM 9, Nguyen Trai ST., Thanh Xuan Dist., Hanoi Tel: (04) 3 5533560 Email: Ngaplt@hanu - Edu.vnLan VuNo ratings yet

- Application of Linear Programming Techniques PDFDocument13 pagesApplication of Linear Programming Techniques PDFJuliusNo ratings yet

- Pain Community Centre - Who Analgesic Ladder - 2011-03-15Document3 pagesPain Community Centre - Who Analgesic Ladder - 2011-03-15Karina WibowoNo ratings yet

- Case Study On Tour Guiding PDFDocument13 pagesCase Study On Tour Guiding PDFNildaNo ratings yet

- Analisis Strategi Pesan Content Marketing Untuk Mempertahankan Brand EngagementDocument10 pagesAnalisis Strategi Pesan Content Marketing Untuk Mempertahankan Brand Engagementyus fianNo ratings yet

- Ahp Application To Define The Potential Field of Study For Senior High School StudentsDocument6 pagesAhp Application To Define The Potential Field of Study For Senior High School StudentsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Historical Investigation (IB History Internal Assessment) Student GuideDocument24 pagesHistorical Investigation (IB History Internal Assessment) Student GuideHayley NightmareHere100% (1)

- Using Mind Maps and Diagrams To Teach Vocabulary For First Year Mainstream Students, Felte - Dang Thanh DiDocument114 pagesUsing Mind Maps and Diagrams To Teach Vocabulary For First Year Mainstream Students, Felte - Dang Thanh DiHenryNo ratings yet

- Weekly Schedule of MBA 2016 SIIIA Week 1Document12 pagesWeekly Schedule of MBA 2016 SIIIA Week 1aadinNo ratings yet

- Communication TheoriesDocument4 pagesCommunication Theoriestokumaunity2No ratings yet

- The Key To Employability Developing A Practical Model of Graduate EmployabilityDocument14 pagesThe Key To Employability Developing A Practical Model of Graduate Employabilitymahdad777No ratings yet

- Architectural Design Process Case Study: Making Building From A Formal TypeDocument11 pagesArchitectural Design Process Case Study: Making Building From A Formal TypeHafiz Amirrol100% (3)

- 5-Cummings and Davies (2002)Document34 pages5-Cummings and Davies (2002)Eda ÇolakNo ratings yet

- Bharti Airtel Limited RMM Group6Document6 pagesBharti Airtel Limited RMM Group6Jyotiraditya Kumar JhaNo ratings yet

- Ratemaking Model of Usage Based Insurance Based On Driving Behaviors ClassificationDocument12 pagesRatemaking Model of Usage Based Insurance Based On Driving Behaviors ClassificationAarif Hussain A NassarNo ratings yet

- Low Back PainDocument17 pagesLow Back PainRamon Salinas AguileraNo ratings yet

- Design of The Literature ReviewDocument62 pagesDesign of The Literature ReviewIkram AminaNo ratings yet

- Abhishek Summer ProjectDocument70 pagesAbhishek Summer ProjectAbhishek SharmaNo ratings yet

- Hydro Mechanical Systems in Simulink in SL Part 2 PDFDocument20 pagesHydro Mechanical Systems in Simulink in SL Part 2 PDFAbdulhmeed MutalatNo ratings yet

- Investment Analysis - Chapter 4Document30 pagesInvestment Analysis - Chapter 4Linh MaiNo ratings yet