Professional Documents

Culture Documents

Analysis of precast plank (CASE 3b of 780mm) 60mm thick; 10mm bar

Analysis of precast plank (CASE 3b of 780mm) 60mm thick; 10mm bar

Uploaded by

Brian BachCopyright:

Available Formats

You might also like

- Perhitungan Kekuatan Pile Cap Kode Pondasi F2: A. Data Pondasi Tiang BorDocument9 pagesPerhitungan Kekuatan Pile Cap Kode Pondasi F2: A. Data Pondasi Tiang BorPuji Kurniawan100% (5)

- EN 566 enDocument1 pageEN 566 enMauricio GaviriaNo ratings yet

- Project: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)Document8 pagesProject: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)pakbilal1100% (1)

- Slab Bridge Design Example April - 2020Document18 pagesSlab Bridge Design Example April - 2020Alin Salagean100% (2)

- Pile Foundation Design SpreadsheetDocument7 pagesPile Foundation Design SpreadsheetmuhannedNo ratings yet

- RaftDocument5 pagesRaftvidyaNo ratings yet

- Structural Design and Analysis: Proposed 3-m Concrete Hollow Block WallDocument6 pagesStructural Design and Analysis: Proposed 3-m Concrete Hollow Block WallJay CuaNo ratings yet

- Deck Girder ExampleDocument28 pagesDeck Girder ExampleEng'r Mohammed HamzaNo ratings yet

- Design of Bore Pile-1Document13 pagesDesign of Bore Pile-1Sara NuonNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- Slab Bridge Example 19Document11 pagesSlab Bridge Example 19dereje werkuNo ratings yet

- T-Girder Bridge DesignDocument112 pagesT-Girder Bridge DesignAsfaw BelayNo ratings yet

- Design of Tie Beam (TB)Document3 pagesDesign of Tie Beam (TB)Khael Angelo Zheus JaclaNo ratings yet

- One Way SlabDocument3 pagesOne Way SlabDileep GowdaNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- Slab DesignDocument16 pagesSlab DesignpasangbhpNo ratings yet

- Pile Design SheetDocument14 pagesPile Design SheetKhader Abu-dagga75% (8)

- Singly Reinforced Beam-1Document25 pagesSingly Reinforced Beam-1EriswamyNo ratings yet

- Annex-1: Foundation DesignDocument24 pagesAnnex-1: Foundation DesignSudip ShresthaNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- 11 CulvertDesign v22Document2 pages11 CulvertDesign v22Lee See VoonNo ratings yet

- Oil SumpDocument4 pagesOil SumpSuchitra PandaNo ratings yet

- Design of RC Slab BridgeDocument16 pagesDesign of RC Slab BridgeRoberaNo ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Designed: Checked:: North Luzon Expressway Project Leighton Contractors / Maunsell / DCCDDocument2 pagesDesigned: Checked:: North Luzon Expressway Project Leighton Contractors / Maunsell / DCCDDan PeckleyNo ratings yet

- 8m Unipole Design Calculation (TM Kuala Kangsar) .Document25 pages8m Unipole Design Calculation (TM Kuala Kangsar) .Tam Eng Sun100% (1)

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- S-1 Stilt Floor: Edge ConditionDocument7 pagesS-1 Stilt Floor: Edge ConditionMohdDanishNo ratings yet

- Cover Slab: Dead Load DL Ts PC Live Load LL M K J RBDocument6 pagesCover Slab: Dead Load DL Ts PC Live Load LL M K J RBARSENo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Post Tension Girder (5 Tendon)Document77 pagesPost Tension Girder (5 Tendon)zaenal AbidinNo ratings yet

- 1 X 10 PDFDocument14 pages1 X 10 PDFTatsamYadavNo ratings yet

- Chapter 11 - Section DesignDocument8 pagesChapter 11 - Section DesignDavid SinambelaNo ratings yet

- 3 Redesign RC Slab BridgeDocument3 pages3 Redesign RC Slab BridgeAbel MulugetaNo ratings yet

- Two Way SlabDocument130 pagesTwo Way SlabMayank Rawat100% (1)

- Cantilever Slab (Modified)Document4 pagesCantilever Slab (Modified)WRay TanNo ratings yet

- BR No 290-Rev-01Document272 pagesBR No 290-Rev-01mohana tNo ratings yet

- Top Slab of Sludge Collection Tank SilcharDocument3 pagesTop Slab of Sludge Collection Tank SilcharAditya KumarNo ratings yet

- Intake Structure DesignDocument4 pagesIntake Structure DesignSripara KrishnaNo ratings yet

- Water Tank - Is 3370-Mbbr Tank - 1 & 2Document4 pagesWater Tank - Is 3370-Mbbr Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Water Tank - Is 3370-MBBR Tank - 1 & 2Document4 pagesWater Tank - Is 3370-MBBR Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Cantilever Slab GFDocument10 pagesCantilever Slab GFahmedhusseinkamelNo ratings yet

- 3.0 One Way SlabDocument20 pages3.0 One Way SlabAbhishek HulloliNo ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- 1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionDocument4 pages1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionMICHAEL MWONGANo ratings yet

- BR No 290-Rev-01Document164 pagesBR No 290-Rev-01mohana t100% (1)

- Singly Reinforcrd BeamDocument2 pagesSingly Reinforcrd BeamLikith Gowda MNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- Desingn of U.G TANK WALLDocument5 pagesDesingn of U.G TANK WALLnileshNo ratings yet

- Design Document of 24m Guyed MastDocument26 pagesDesign Document of 24m Guyed Mastdheeraj SureshNo ratings yet

- SdasdasdDocument18 pagesSdasdasddheeraj SureshNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Minimum Cover above buried pipesDocument2 pagesMinimum Cover above buried pipesBrian BachNo ratings yet

- 1-Sta. 85+280 Right-Side Slope 1.65H_1V Fellenius Method - computationDocument1 page1-Sta. 85+280 Right-Side Slope 1.65H_1V Fellenius Method - computationBrian BachNo ratings yet

- Time Lapse Camera PoleDocument1 pageTime Lapse Camera PoleBrian BachNo ratings yet

- Analysis of 125 Grade Slab With 8 Tons Crane LoadingDocument8 pagesAnalysis of 125 Grade Slab With 8 Tons Crane LoadingBrian BachNo ratings yet

- 5-LAD01132 Introduction Geotechnics U2 S5Document7 pages5-LAD01132 Introduction Geotechnics U2 S5Brian BachNo ratings yet

- 4-LAD01132 Introduction Geotechnics U2 S4Document13 pages4-LAD01132 Introduction Geotechnics U2 S4Brian BachNo ratings yet

- MAZAKDocument327 pagesMAZAKhectorigc1No ratings yet

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertrayNo ratings yet

- Reciprocating PumpDocument8 pagesReciprocating Pump123rahul456No ratings yet

- Infrared Thermography Report: ConditionDocument16 pagesInfrared Thermography Report: ConditionNuril AuliaNo ratings yet

- Shaft Hub Connections PDFDocument64 pagesShaft Hub Connections PDFTrung DũngNo ratings yet

- Manual de Partes (1997) - 2000 Series PDFDocument8 pagesManual de Partes (1997) - 2000 Series PDFmarlon diaz100% (1)

- Name: Vivek Vadake Veettil: Academic QualificationDocument6 pagesName: Vivek Vadake Veettil: Academic QualificationMohammedBujairNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Proposed Equipment & Piping Layout Rev2Document1 pageProposed Equipment & Piping Layout Rev2BalajiNo ratings yet

- Hand Tool SafetyDocument16 pagesHand Tool SafetyGallardo GarlanNo ratings yet

- Plastic Gear Prototype Tooling With MantleDocument2 pagesPlastic Gear Prototype Tooling With Mantleethan.rejtoNo ratings yet

- Bca Approved Training and Testing Centres (Attcs) in SingaporeDocument3 pagesBca Approved Training and Testing Centres (Attcs) in Singaporesuresh626550% (2)

- MTR-50, 90, 140 3-Position Swing Cylinders: Instruction & Repair Parts SheetDocument28 pagesMTR-50, 90, 140 3-Position Swing Cylinders: Instruction & Repair Parts SheetJesus D. Gutierrez G.No ratings yet

- Komatsu 0000279c H0120-001002A PageDocument2 pagesKomatsu 0000279c H0120-001002A PageCristhian Sullon SosaNo ratings yet

- Valve Stds AllDocument11 pagesValve Stds AllGohilakrishnan ThiagarajanNo ratings yet

- Boiler Controls: Low Water Cut-Offs - Mechanical For Steam BoilersDocument1 pageBoiler Controls: Low Water Cut-Offs - Mechanical For Steam BoilersAlfredo Mitzi HernandezNo ratings yet

- CVG2149 - LEC2 Civil Engineering Mechanics: - Analysis of Structures - Trusses - CablesDocument14 pagesCVG2149 - LEC2 Civil Engineering Mechanics: - Analysis of Structures - Trusses - CablesKaiss Nael OsmanNo ratings yet

- Shigley Chapter 8Document13 pagesShigley Chapter 8OLL OLLNo ratings yet

- Cut and Bend Stainless Steel RebarDocument2 pagesCut and Bend Stainless Steel RebarJohan ConradieNo ratings yet

- Constant Mesh Gearbox Components Working Principle Advantages Disadvantages Applications PDFDocument11 pagesConstant Mesh Gearbox Components Working Principle Advantages Disadvantages Applications PDFDarshan UghadeNo ratings yet

- Termooo StandardDocument106 pagesTermooo Standardlaguna028No ratings yet

- Guia Instalacao Guias Lineares Linear GuidewaypdfDocument88 pagesGuia Instalacao Guias Lineares Linear GuidewaypdfGabriel RamosNo ratings yet

- 6991 0389 01a OVER HAUL UNIDAD ROTACIONDocument8 pages6991 0389 01a OVER HAUL UNIDAD ROTACIONJhonatan rincon martinezNo ratings yet

- MachineProgram DMG MORI SPRINT 50 Version V1.1Document77 pagesMachineProgram DMG MORI SPRINT 50 Version V1.1gagan rajNo ratings yet

- Ll22 12en Eur Ks Tools LKW AchseDocument52 pagesLl22 12en Eur Ks Tools LKW AchseMarian TarasNo ratings yet

- Compressor Dry Gas SealsDocument54 pagesCompressor Dry Gas SealsfirmanNo ratings yet

- Fast Connectors On Howo Truck PDF DownloadDocument16 pagesFast Connectors On Howo Truck PDF DownloadAyane DejeneNo ratings yet

- Design Calculations Steel Wire and CradleDocument2 pagesDesign Calculations Steel Wire and CradleRanjit S KashyapNo ratings yet

Analysis of precast plank (CASE 3b of 780mm) 60mm thick; 10mm bar

Analysis of precast plank (CASE 3b of 780mm) 60mm thick; 10mm bar

Uploaded by

Brian BachCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of precast plank (CASE 3b of 780mm) 60mm thick; 10mm bar

Analysis of precast plank (CASE 3b of 780mm) 60mm thick; 10mm bar

Uploaded by

Brian BachCopyright:

Available Formats

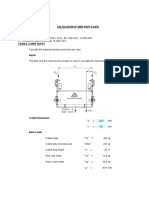

TITLE : Analysis of precast plank for PCI girder bridge Date : 1/26/2024

PROJECT : Malolos Clark Railway Project P4 Designed by :

CASE STUDY No.: Case 3 - Panel length of 780mm Checked by :

A. GEOMETRY

ts tcp

tpc

Girder S' Girder

S"

1. Center to center span of girders, s = 1.800 meters

3. Clear distance between girder flanges, s' = 0.700 meters

4. Effective span of precast panel, s" = 0.780 meters

5. Precast panel thickness, tpc = 0.060 meters

6. Cast-in-place slab thickness, tcp = 0.250 meters

7. Minimum Concrete Strength @ 28 days, fc' = 40.00 megapascals

8. Diameter of reinforcement, in mm. = 10.00 millimeters

9. Concrete cover at bottom, in mm. = 25.00 millimeters

C. MATERIALS

C.1 Concrete

Minimum Concrete Strength @ 28 days, fc' 40.00 MPa

C.2 Reinforcing Bars

Minimum Yield Stress of Bars, fy 275.8 MPa for f =< 16

Minimum Yield Stress of Bars, fy 413.7 MPa for f => 20

D. DESIGN

b=1.00

D.1 Proposed Plank Reinforcement Location d

TITLE : Analysis of precast plank for PCI girder bridge Date : 1/26/2024

PROJECT : Malolos Clark Railway Project P4 Designed by :

CASE STUDY No.: Case 3 - Panel length of 780mm Checked by :

D.2 Check Flexural Capacity of the Planks During Pouring of Concrete

D.2.1 Loads

D.2.1.1 Dead Load

1. Weight of planks = 0.06 m. x 1.00 m. x 24KN/m^3 = 1.44 KN/m

2. Wt. Of fresh Concrete = 0.25 m. x 1.00 m. x 24KN/m^3 = 6.00 KN/m

wDL = 7.44 KN/m

2

MDL = 1/8*wDL*S" = 0.57 KN-m.

D.2.1.2 Live Loads

Assumed weight of small equipment plus workers = 400kg. wLL = 3.92 KN/m

ex. Concrete trowel and other tools such as vibrator

MLL+I = 1/8*wLL*S"2 = 0.30 KN-m.

D.2.1.3 Ultimate Moment MU = 1.20*MDL + 1.6*MLL = 1.16 KN-m..

D.2.1.4 For uncertainties during implementation the Safety Factor (2.00 to 2.50) Mu = 2.89 KN-m..

ex. Impact load, accidental load, etc.

D.2.2 Flexural Reinforcement

MU = 2.89 KN-m. q = (1-sqrt (1-4*.59*Ku))/(2*0.59)

b= 1.00 m. q = 0.0945

d= 0.03 m. r = q*fc'/fy = 0.0137

2

Ku =MU/fbd2fc'= 0.089 As = r*b*d = 411.17 mm.

2

As 1 = 78.54 mm.

Rebar Spacing, sp= 0.19 m.

B2

B1 tpc

s'' = 0.780

b=1.00

Consider 0.780 m for the effective span of precast panel

Consider 1.00 m for the width of each precast panel

Consider 0.06 m for the thickness of precast panel

Adopt 10 mm f @ 0.19 m. o.c. cut short bars

(in each direction); B1 as the 1st layer

To implement 25 mm concrete cover at bottom of B1 rebars

15 mm concrete cover at top of B2 rebars

You might also like

- Perhitungan Kekuatan Pile Cap Kode Pondasi F2: A. Data Pondasi Tiang BorDocument9 pagesPerhitungan Kekuatan Pile Cap Kode Pondasi F2: A. Data Pondasi Tiang BorPuji Kurniawan100% (5)

- EN 566 enDocument1 pageEN 566 enMauricio GaviriaNo ratings yet

- Project: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)Document8 pagesProject: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)pakbilal1100% (1)

- Slab Bridge Design Example April - 2020Document18 pagesSlab Bridge Design Example April - 2020Alin Salagean100% (2)

- Pile Foundation Design SpreadsheetDocument7 pagesPile Foundation Design SpreadsheetmuhannedNo ratings yet

- RaftDocument5 pagesRaftvidyaNo ratings yet

- Structural Design and Analysis: Proposed 3-m Concrete Hollow Block WallDocument6 pagesStructural Design and Analysis: Proposed 3-m Concrete Hollow Block WallJay CuaNo ratings yet

- Deck Girder ExampleDocument28 pagesDeck Girder ExampleEng'r Mohammed HamzaNo ratings yet

- Design of Bore Pile-1Document13 pagesDesign of Bore Pile-1Sara NuonNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- Slab Bridge Example 19Document11 pagesSlab Bridge Example 19dereje werkuNo ratings yet

- T-Girder Bridge DesignDocument112 pagesT-Girder Bridge DesignAsfaw BelayNo ratings yet

- Design of Tie Beam (TB)Document3 pagesDesign of Tie Beam (TB)Khael Angelo Zheus JaclaNo ratings yet

- One Way SlabDocument3 pagesOne Way SlabDileep GowdaNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- Slab DesignDocument16 pagesSlab DesignpasangbhpNo ratings yet

- Pile Design SheetDocument14 pagesPile Design SheetKhader Abu-dagga75% (8)

- Singly Reinforced Beam-1Document25 pagesSingly Reinforced Beam-1EriswamyNo ratings yet

- Annex-1: Foundation DesignDocument24 pagesAnnex-1: Foundation DesignSudip ShresthaNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- 11 CulvertDesign v22Document2 pages11 CulvertDesign v22Lee See VoonNo ratings yet

- Oil SumpDocument4 pagesOil SumpSuchitra PandaNo ratings yet

- Design of RC Slab BridgeDocument16 pagesDesign of RC Slab BridgeRoberaNo ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Designed: Checked:: North Luzon Expressway Project Leighton Contractors / Maunsell / DCCDDocument2 pagesDesigned: Checked:: North Luzon Expressway Project Leighton Contractors / Maunsell / DCCDDan PeckleyNo ratings yet

- 8m Unipole Design Calculation (TM Kuala Kangsar) .Document25 pages8m Unipole Design Calculation (TM Kuala Kangsar) .Tam Eng Sun100% (1)

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- S-1 Stilt Floor: Edge ConditionDocument7 pagesS-1 Stilt Floor: Edge ConditionMohdDanishNo ratings yet

- Cover Slab: Dead Load DL Ts PC Live Load LL M K J RBDocument6 pagesCover Slab: Dead Load DL Ts PC Live Load LL M K J RBARSENo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Post Tension Girder (5 Tendon)Document77 pagesPost Tension Girder (5 Tendon)zaenal AbidinNo ratings yet

- 1 X 10 PDFDocument14 pages1 X 10 PDFTatsamYadavNo ratings yet

- Chapter 11 - Section DesignDocument8 pagesChapter 11 - Section DesignDavid SinambelaNo ratings yet

- 3 Redesign RC Slab BridgeDocument3 pages3 Redesign RC Slab BridgeAbel MulugetaNo ratings yet

- Two Way SlabDocument130 pagesTwo Way SlabMayank Rawat100% (1)

- Cantilever Slab (Modified)Document4 pagesCantilever Slab (Modified)WRay TanNo ratings yet

- BR No 290-Rev-01Document272 pagesBR No 290-Rev-01mohana tNo ratings yet

- Top Slab of Sludge Collection Tank SilcharDocument3 pagesTop Slab of Sludge Collection Tank SilcharAditya KumarNo ratings yet

- Intake Structure DesignDocument4 pagesIntake Structure DesignSripara KrishnaNo ratings yet

- Water Tank - Is 3370-Mbbr Tank - 1 & 2Document4 pagesWater Tank - Is 3370-Mbbr Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Water Tank - Is 3370-MBBR Tank - 1 & 2Document4 pagesWater Tank - Is 3370-MBBR Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Cantilever Slab GFDocument10 pagesCantilever Slab GFahmedhusseinkamelNo ratings yet

- 3.0 One Way SlabDocument20 pages3.0 One Way SlabAbhishek HulloliNo ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- 1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionDocument4 pages1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionMICHAEL MWONGANo ratings yet

- BR No 290-Rev-01Document164 pagesBR No 290-Rev-01mohana t100% (1)

- Singly Reinforcrd BeamDocument2 pagesSingly Reinforcrd BeamLikith Gowda MNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- Desingn of U.G TANK WALLDocument5 pagesDesingn of U.G TANK WALLnileshNo ratings yet

- Design Document of 24m Guyed MastDocument26 pagesDesign Document of 24m Guyed Mastdheeraj SureshNo ratings yet

- SdasdasdDocument18 pagesSdasdasddheeraj SureshNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Minimum Cover above buried pipesDocument2 pagesMinimum Cover above buried pipesBrian BachNo ratings yet

- 1-Sta. 85+280 Right-Side Slope 1.65H_1V Fellenius Method - computationDocument1 page1-Sta. 85+280 Right-Side Slope 1.65H_1V Fellenius Method - computationBrian BachNo ratings yet

- Time Lapse Camera PoleDocument1 pageTime Lapse Camera PoleBrian BachNo ratings yet

- Analysis of 125 Grade Slab With 8 Tons Crane LoadingDocument8 pagesAnalysis of 125 Grade Slab With 8 Tons Crane LoadingBrian BachNo ratings yet

- 5-LAD01132 Introduction Geotechnics U2 S5Document7 pages5-LAD01132 Introduction Geotechnics U2 S5Brian BachNo ratings yet

- 4-LAD01132 Introduction Geotechnics U2 S4Document13 pages4-LAD01132 Introduction Geotechnics U2 S4Brian BachNo ratings yet

- MAZAKDocument327 pagesMAZAKhectorigc1No ratings yet

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertrayNo ratings yet

- Reciprocating PumpDocument8 pagesReciprocating Pump123rahul456No ratings yet

- Infrared Thermography Report: ConditionDocument16 pagesInfrared Thermography Report: ConditionNuril AuliaNo ratings yet

- Shaft Hub Connections PDFDocument64 pagesShaft Hub Connections PDFTrung DũngNo ratings yet

- Manual de Partes (1997) - 2000 Series PDFDocument8 pagesManual de Partes (1997) - 2000 Series PDFmarlon diaz100% (1)

- Name: Vivek Vadake Veettil: Academic QualificationDocument6 pagesName: Vivek Vadake Veettil: Academic QualificationMohammedBujairNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Proposed Equipment & Piping Layout Rev2Document1 pageProposed Equipment & Piping Layout Rev2BalajiNo ratings yet

- Hand Tool SafetyDocument16 pagesHand Tool SafetyGallardo GarlanNo ratings yet

- Plastic Gear Prototype Tooling With MantleDocument2 pagesPlastic Gear Prototype Tooling With Mantleethan.rejtoNo ratings yet

- Bca Approved Training and Testing Centres (Attcs) in SingaporeDocument3 pagesBca Approved Training and Testing Centres (Attcs) in Singaporesuresh626550% (2)

- MTR-50, 90, 140 3-Position Swing Cylinders: Instruction & Repair Parts SheetDocument28 pagesMTR-50, 90, 140 3-Position Swing Cylinders: Instruction & Repair Parts SheetJesus D. Gutierrez G.No ratings yet

- Komatsu 0000279c H0120-001002A PageDocument2 pagesKomatsu 0000279c H0120-001002A PageCristhian Sullon SosaNo ratings yet

- Valve Stds AllDocument11 pagesValve Stds AllGohilakrishnan ThiagarajanNo ratings yet

- Boiler Controls: Low Water Cut-Offs - Mechanical For Steam BoilersDocument1 pageBoiler Controls: Low Water Cut-Offs - Mechanical For Steam BoilersAlfredo Mitzi HernandezNo ratings yet

- CVG2149 - LEC2 Civil Engineering Mechanics: - Analysis of Structures - Trusses - CablesDocument14 pagesCVG2149 - LEC2 Civil Engineering Mechanics: - Analysis of Structures - Trusses - CablesKaiss Nael OsmanNo ratings yet

- Shigley Chapter 8Document13 pagesShigley Chapter 8OLL OLLNo ratings yet

- Cut and Bend Stainless Steel RebarDocument2 pagesCut and Bend Stainless Steel RebarJohan ConradieNo ratings yet

- Constant Mesh Gearbox Components Working Principle Advantages Disadvantages Applications PDFDocument11 pagesConstant Mesh Gearbox Components Working Principle Advantages Disadvantages Applications PDFDarshan UghadeNo ratings yet

- Termooo StandardDocument106 pagesTermooo Standardlaguna028No ratings yet

- Guia Instalacao Guias Lineares Linear GuidewaypdfDocument88 pagesGuia Instalacao Guias Lineares Linear GuidewaypdfGabriel RamosNo ratings yet

- 6991 0389 01a OVER HAUL UNIDAD ROTACIONDocument8 pages6991 0389 01a OVER HAUL UNIDAD ROTACIONJhonatan rincon martinezNo ratings yet

- MachineProgram DMG MORI SPRINT 50 Version V1.1Document77 pagesMachineProgram DMG MORI SPRINT 50 Version V1.1gagan rajNo ratings yet

- Ll22 12en Eur Ks Tools LKW AchseDocument52 pagesLl22 12en Eur Ks Tools LKW AchseMarian TarasNo ratings yet

- Compressor Dry Gas SealsDocument54 pagesCompressor Dry Gas SealsfirmanNo ratings yet

- Fast Connectors On Howo Truck PDF DownloadDocument16 pagesFast Connectors On Howo Truck PDF DownloadAyane DejeneNo ratings yet

- Design Calculations Steel Wire and CradleDocument2 pagesDesign Calculations Steel Wire and CradleRanjit S KashyapNo ratings yet