Professional Documents

Culture Documents

Shore Pile Arrangement Drawing

Shore Pile Arrangement Drawing

Uploaded by

pravin awalkondeCopyright:

Available Formats

You might also like

- SITXMGT002 Assessment 2 Project FinishedDocument22 pagesSITXMGT002 Assessment 2 Project FinishedGorkhali GamingNo ratings yet

- Heriot-Watt University Dubai Campus: ReceiptDocument2 pagesHeriot-Watt University Dubai Campus: ReceiptMuhammadnasidiNo ratings yet

- Inhinyero Review Center: Provided MaxDocument2 pagesInhinyero Review Center: Provided MaxVincent NavaNo ratings yet

- Client: Title:: General Notes of Vehicular Under PassDocument10 pagesClient: Title:: General Notes of Vehicular Under PassPraveen CyssanNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Rock Anchor MethodologyDocument7 pagesRock Anchor Methodologyzee shanNo ratings yet

- Pile Capacity TableDocument1 pagePile Capacity TablepapaNo ratings yet

- Electrical BOQ Plot C LPSDocument5 pagesElectrical BOQ Plot C LPSAgrawal PrajaktaNo ratings yet

- Structural AnalysisnewDocument6 pagesStructural AnalysisnewJunith Jay CalinawanNo ratings yet

- A5 Koto Hand-Book For ContractorsDocument73 pagesA5 Koto Hand-Book For ContractorsYasher Meera SaibNo ratings yet

- Description of Item Unit Qty Supply Rate: Sl. NoDocument50 pagesDescription of Item Unit Qty Supply Rate: Sl. NoKrishan PandyaNo ratings yet

- TS-Gabion - 10x12 - Galmac+PolimacDocument8 pagesTS-Gabion - 10x12 - Galmac+Polimacdigvijay singhNo ratings yet

- Drainage B11 PDFDocument1 pageDrainage B11 PDFluongiccNo ratings yet

- Rock Anchor MethodologyDocument9 pagesRock Anchor Methodologykaleswara_tellakulaNo ratings yet

- iwCmY6WPaXBR - BOQ RABAI 220KV FINALDocument11 pagesiwCmY6WPaXBR - BOQ RABAI 220KV FINALkajale.shrikantNo ratings yet

- Division 3: Concrete SpecificationsDocument12 pagesDivision 3: Concrete SpecificationsKae MoNo ratings yet

- InterviewDocument18 pagesInterviewVIJAY BHILWADENo ratings yet

- Ashoka UniversityDocument4 pagesAshoka UniversityG.MurtazaNo ratings yet

- Construction Notes: Hurricane Ties Connection DetailDocument8 pagesConstruction Notes: Hurricane Ties Connection DetailCristina Dangla CruzNo ratings yet

- Single Post: Highways DepartmentDocument1 pageSingle Post: Highways DepartmentTsz Yu WanNo ratings yet

- Cablofil - Cable TrenchDocument2 pagesCablofil - Cable Trenchsubidubi99No ratings yet

- Concrete 2 November 2022Document2 pagesConcrete 2 November 2022ronnelNo ratings yet

- Promat FPH Chapter 9Document29 pagesPromat FPH Chapter 9Majid Hamidi DadgarNo ratings yet

- Specification Page 100-102Document3 pagesSpecification Page 100-102nazrulafizi.dkbjNo ratings yet

- Chennai BOQDocument8 pagesChennai BOQDharmendra SharmaNo ratings yet

- Diaphragm Wall ConstructionDocument9 pagesDiaphragm Wall Constructionmeladbelal1234No ratings yet

- 2.3. External Waterproofing SystemsDocument2 pages2.3. External Waterproofing SystemsKrishna SankarNo ratings yet

- BOQ-22-11-2019 Pile Foundation Option For Temporary WorksDocument35 pagesBOQ-22-11-2019 Pile Foundation Option For Temporary WorksAshish SrivastavaNo ratings yet

- 13155e74c - Pretressed Concrete StructuresDocument4 pages13155e74c - Pretressed Concrete StructuresarunNo ratings yet

- Division Iii-Concrete & MasonryDocument31 pagesDivision Iii-Concrete & MasonryClive Aaron GuanzonNo ratings yet

- BOQ - Gurgaon - 25.06.23Document3 pagesBOQ - Gurgaon - 25.06.23Anurag ZullurwarNo ratings yet

- Technical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersDocument1 pageTechnical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersBogdanBNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghNo ratings yet

- Tennis Court - CentComDocument4 pagesTennis Court - CentComEppNo ratings yet

- 168 Imi PolymatDocument4 pages168 Imi PolymatEngr KamalNo ratings yet

- CE305Document3 pagesCE305Shubham YadavNo ratings yet

- Specifications With Schedule of QuantityDocument4 pagesSpecifications With Schedule of QuantityFor PromotionNo ratings yet

- Is.2911.1.2.2010 Part3Document6 pagesIs.2911.1.2.2010 Part3Dixit JariwalaNo ratings yet

- Sarojini Nagar Under The Guidance of MR Laksham HansdashDocument37 pagesSarojini Nagar Under The Guidance of MR Laksham HansdashShubhanshu MishraNo ratings yet

- Annexure - XIII - Drawing - Mounting StructurelDocument1 pageAnnexure - XIII - Drawing - Mounting Structurelisan.structural TjsvgalavanNo ratings yet

- Rigging of Transmission TowerDocument31 pagesRigging of Transmission TowerSagar BhardwajNo ratings yet

- Rigging of Transmission TowerDocument31 pagesRigging of Transmission TowerSagar Bhardwaj100% (1)

- Engineering Academy: Civil Engineering ESE Conventional Revision TEST - VDocument6 pagesEngineering Academy: Civil Engineering ESE Conventional Revision TEST - Vsaxenaarpita41No ratings yet

- Omnia Bridge DeckDocument7 pagesOmnia Bridge DeckKsenia ProtcenkoNo ratings yet

- SMD TR60 DatasheetDocument4 pagesSMD TR60 DatasheetAlfred GandNo ratings yet

- Material Specification & TestDocument3 pagesMaterial Specification & TestmunimiutNo ratings yet

- Design of Prestressed Concrete Structures 15cese2005-1 PDFDocument2 pagesDesign of Prestressed Concrete Structures 15cese2005-1 PDFvineela saiNo ratings yet

- Minimum Acceptable Specifications and Design Criteria-RDocument25 pagesMinimum Acceptable Specifications and Design Criteria-Ranup singhNo ratings yet

- TS 526.3.2.3.i. On Door Anchor SupportDocument2 pagesTS 526.3.2.3.i. On Door Anchor SupportAdrianNodaloNo ratings yet

- Structural Notes: A. General: C. Concrete and Reinforcing SteelDocument1 pageStructural Notes: A. General: C. Concrete and Reinforcing SteelTitan AethelNo ratings yet

- Method Statement: Conceal PVC Conduit/Trunking and Junction Boxes in Concrete CeilingDocument2 pagesMethod Statement: Conceal PVC Conduit/Trunking and Junction Boxes in Concrete Ceilingfatinjamal22No ratings yet

- Cochrane Gulf ClearVu Brochure 2022Document22 pagesCochrane Gulf ClearVu Brochure 2022hani hannaNo ratings yet

- Box Culvert - Wall DetailingDocument1 pageBox Culvert - Wall DetailingJovn MushiNo ratings yet

- Echo Prestress Durban (Pty) LTD: A Name Truly Cast in ConcreteDocument8 pagesEcho Prestress Durban (Pty) LTD: A Name Truly Cast in ConcreteTino MatsvayiNo ratings yet

- 37 - MC Design Standards Transportation2013!09!04Document10 pages37 - MC Design Standards Transportation2013!09!04Sulohita SharmaNo ratings yet

- RANGS R.K SQUARE - BOQ - Plumbing - 140719Document18 pagesRANGS R.K SQUARE - BOQ - Plumbing - 140719Md. Mominul IslamNo ratings yet

- Clipsal 4CC AND 4FCC INSTALLATION ISTRUCTIONDocument2 pagesClipsal 4CC AND 4FCC INSTALLATION ISTRUCTIONducvuong99.vtNo ratings yet

- Cracking in BrickworkDocument2 pagesCracking in BrickworkruwanthaNo ratings yet

- Structural Notes 1Document1 pageStructural Notes 1missiklein3No ratings yet

- VTU Model Question PapersDocument50 pagesVTU Model Question PapersOmkarNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Train Ticket NageshDocument2 pagesTrain Ticket Nageshpravin awalkondeNo ratings yet

- CorrigendumIVPkgVIIIDocument1 pageCorrigendumIVPkgVIIIpravin awalkondeNo ratings yet

- CorrigendumI-PkgVIDocument1 pageCorrigendumI-PkgVIpravin awalkondeNo ratings yet

- U Clamp Fo Sabarmati River Test PileDocument1 pageU Clamp Fo Sabarmati River Test Pilepravin awalkondeNo ratings yet

- Pldedge 1Document5 pagesPldedge 1pravin awalkondeNo ratings yet

- Elevation: MP161 LHS MP162 LHS MP163 LHS MP164 LHS MP165 LHS MP166 LHSDocument1 pageElevation: MP161 LHS MP162 LHS MP163 LHS MP164 LHS MP165 LHS MP166 LHSpravin awalkondeNo ratings yet

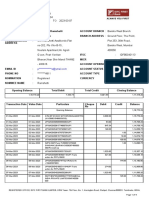

- Passbookstmt 1671020682146Document4 pagesPassbookstmt 1671020682146pravin awalkondeNo ratings yet

- BM2327I004378252Document6 pagesBM2327I004378252pravin awalkondeNo ratings yet

- NF2VEPL27UD9QGLG5952 ETicketDocument3 pagesNF2VEPL27UD9QGLG5952 ETicketpravin awalkondeNo ratings yet

- GoFirst - BoardingPass - Y77YSF - Mr. Pravin AwalkondeDocument1 pageGoFirst - BoardingPass - Y77YSF - Mr. Pravin Awalkondepravin awalkondeNo ratings yet

- NF2SPWD1B7UM68L62894 ETicket PDFDocument3 pagesNF2SPWD1B7UM68L62894 ETicket PDFpravin awalkondeNo ratings yet

- SR - No Comment Received ComplianceDocument2 pagesSR - No Comment Received Compliancepravin awalkondeNo ratings yet

- IDFCFIRSTBankstatement 10052774504 PDFDocument4 pagesIDFCFIRSTBankstatement 10052774504 PDFpravin awalkondeNo ratings yet

- Daksh InteriorsDocument10 pagesDaksh Interiorspravin awalkondeNo ratings yet

- Invoice # 23032 PDFDocument2 pagesInvoice # 23032 PDFpravin awalkondeNo ratings yet

- My ProjectDocument2 pagesMy Projectpravin awalkondeNo ratings yet

- Bm2327i002741932 PDFDocument4 pagesBm2327i002741932 PDFpravin awalkondeNo ratings yet

- Vaibhav .M. Gaykar: Key Skills: Personal SummaryDocument3 pagesVaibhav .M. Gaykar: Key Skills: Personal Summarypravin awalkondeNo ratings yet

- Invoice For MCN-SA M213A - Ipsum Designs PDFDocument2 pagesInvoice For MCN-SA M213A - Ipsum Designs PDFpravin awalkondeNo ratings yet

- My ProjectDocument2 pagesMy Projectpravin awalkondeNo ratings yet

- Abhay Consultants PVT LTD: Annexure-1Document2 pagesAbhay Consultants PVT LTD: Annexure-1pravin awalkondeNo ratings yet

- 6260 PDFDocument153 pages6260 PDFpravin awalkondeNo ratings yet

- Carlos Soubrier, P.Eng.: Materials Engineer, Materials Performance and Corrosion ControlDocument6 pagesCarlos Soubrier, P.Eng.: Materials Engineer, Materials Performance and Corrosion Controlpravin awalkondeNo ratings yet

- 188-E-DN-6003-Design of Elastomeric Bearing-R1Document30 pages188-E-DN-6003-Design of Elastomeric Bearing-R1pravin awalkondeNo ratings yet

- Subtr Code - UpdatedDocument60 pagesSubtr Code - Updatedpravin awalkondeNo ratings yet

- Control Perimeters For Punching Shear @2dDocument4 pagesControl Perimeters For Punching Shear @2dpravin awalkondeNo ratings yet

- RTA - Yahoo Mail - Amount Blocked For CAMS IPO Applied On 21 - 09 - 2020 - Ref No - IE295759Document2 pagesRTA - Yahoo Mail - Amount Blocked For CAMS IPO Applied On 21 - 09 - 2020 - Ref No - IE295759pravin awalkondeNo ratings yet

- GR Infra Projects LTDDocument23 pagesGR Infra Projects LTDpravin awalkondeNo ratings yet

- Section 1 FV With PV CalculatorDocument3 pagesSection 1 FV With PV Calculatorpravin awalkondeNo ratings yet

- Pravin R. AwalkondeDocument3 pagesPravin R. Awalkondepravin awalkondeNo ratings yet

- Applied Chemistry MCQsDocument10 pagesApplied Chemistry MCQsiangarvins100% (1)

- Scheme of Marking For 014 UPSR 2016 FormatDocument3 pagesScheme of Marking For 014 UPSR 2016 Formatawesome_teacher88% (8)

- C BAND Satellites Recivable in A INDIA PDFDocument3 pagesC BAND Satellites Recivable in A INDIA PDFchidambaram kasiNo ratings yet

- Insert A Pivot Table: Mba102-Advanced Statistics With Computer Application Module 4 Exercises Pivot TablesDocument12 pagesInsert A Pivot Table: Mba102-Advanced Statistics With Computer Application Module 4 Exercises Pivot TablesAdoree RamosNo ratings yet

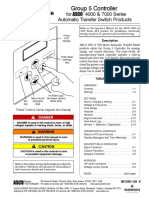

- Asco 7000 Series Operators Manual Group 5 ControllerDocument32 pagesAsco 7000 Series Operators Manual Group 5 ControllerAhmed Tarek100% (1)

- Agriculture AhmedabadDocument33 pagesAgriculture AhmedabadKrupam Thetenders.com100% (1)

- WPC Aco PDFDocument16 pagesWPC Aco PDFpetar spalevicNo ratings yet

- 1 SMDocument11 pages1 SMp25h4pdkb8No ratings yet

- THE ORGANIZATION STUDY OF ARGO HYTOS PRIVATE LIMITED (AutoRecovered)Document57 pagesTHE ORGANIZATION STUDY OF ARGO HYTOS PRIVATE LIMITED (AutoRecovered)selvarajmadhu6No ratings yet

- May 2024Document64 pagesMay 2024Eric SantiagoNo ratings yet

- Sip Design and Verification Using AdsDocument34 pagesSip Design and Verification Using AdsMaria Lavinia IordacheNo ratings yet

- Optical MSRDocument2 pagesOptical MSRexarchos26100% (2)

- Practice Paper XDocument14 pagesPractice Paper XRohit KumarNo ratings yet

- Bennett 2003Document8 pagesBennett 2003Emir OkucuNo ratings yet

- Action ResearchDocument27 pagesAction Researchreymarie hermosillaNo ratings yet

- 1 L.M. College of Pharmacy Gujarat (Government of Gujarat) Assistant Professor Recruitment Examination Question Paper 2016Document9 pages1 L.M. College of Pharmacy Gujarat (Government of Gujarat) Assistant Professor Recruitment Examination Question Paper 2016pratyush swarnkarNo ratings yet

- Example of Business Case ReportDocument3 pagesExample of Business Case ReportCORINE NDLOVUNo ratings yet

- m48t08 150pc1 PDFDocument31 pagesm48t08 150pc1 PDFMariuszChreptakNo ratings yet

- Skylab 3 PAO Mission Commentary 3 of 6Document851 pagesSkylab 3 PAO Mission Commentary 3 of 6Bob AndrepontNo ratings yet

- Instructions PDFDocument1 pageInstructions PDFNikola UroševićNo ratings yet

- BL M22 1011 PDFDocument46 pagesBL M22 1011 PDFDmitryNo ratings yet

- Cat 2007 Productline EnglishDocument24 pagesCat 2007 Productline EnglishDan PatchNo ratings yet

- Cse4001 Cloud-Computing TH 1.0 2 Cse4001Document2 pagesCse4001 Cloud-Computing TH 1.0 2 Cse4001sai22.ssbNo ratings yet

- Full Ebook of Daily Routines To Jump Start Math Class Elementary School 1St Edition John J Sangiovanni 2 Online PDF All ChapterDocument24 pagesFull Ebook of Daily Routines To Jump Start Math Class Elementary School 1St Edition John J Sangiovanni 2 Online PDF All Chapterandereabat100% (4)

- AsDocument602 pagesAsnareshNo ratings yet

- E JB TutorialDocument141 pagesE JB TutorialManikandan ChellaNo ratings yet

- HYUNDAI WIA Heavy Duty Cutting Horizontal Machining CenterDocument27 pagesHYUNDAI WIA Heavy Duty Cutting Horizontal Machining CentersrinivignaNo ratings yet

- Web Pages With MVC3 and Razor SyntaxDocument282 pagesWeb Pages With MVC3 and Razor Syntaxozamaro100% (1)

Shore Pile Arrangement Drawing

Shore Pile Arrangement Drawing

Uploaded by

pravin awalkondeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shore Pile Arrangement Drawing

Shore Pile Arrangement Drawing

Uploaded by

pravin awalkondeCopyright:

Available Formats

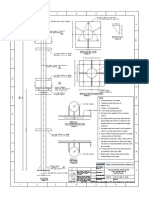

Notes:

1. Drawing Not to the scale.

2. The drawing is valid up to 6.00 m depth of excavation.

3. In case of any discrepancy shall be intimated brought to notice before start of work.

4. The yearly audit of enabling scheme must be done if the construction of permanent retaining

wall is not done immediately after excavation.

5. For Piles

5.1. Use M-30 grade Concrete (for pile and capping beam)and Fe-500 Steel.

GROUND LEVEL 0.00m 300 mm∅ PILE

5.2. Ref. Code : IS 456:2000, IS 2911 (Part 1/Sec 2) : 2010, IS10270:1982, IS14268:1995,

CAPPING BEAM IS3764:1992

5.3. The estimated pile depth length is around 7.20 m; however the pile depth shall be

(400X400) confirmed only after checking the quality of strata during execution. The pile lengths

6 NOS 20T

shall be measured using electronic depth meter attached on rig. The final depth shall be

confirmed by steel measuring chains.

5.4. Pile records like depth of pile, reinforcement details, penetration and concrete

10T MASTER RING @1 m 5mm THICK TEMPORARY

2500

consumption shall be maintained for each pile.

C-C LINER UP TO 5.5. Deflection shall be checked after suitable interval of time, by using Inclinometer or

WEATHERED other suitable instruments.

ROCK 5.6. The pile concreting shall be done on same day of pile drilling by tremmie concreting

method. The gap between tremmie pipe (or concrete) and pile bottom shall not exceed

150- 200mm.

8T HELICAL REINFORCEMENT 5.7. Clear Cover of 30 mm shall be provided to piles. At least four concrete cover blocks shall

@200 mm C-C WITH 10T MASTER be placed at each elevation at not more than 1.50m C-C spacing.

PRESTRESSED ROCK RING @1 m C-C 5.8. Clear Cover of 40 mm shall be provided to capping beam.

5.9. Lap Length - 50D shall be provided.

ANCHOR @ 4.50m C-C 6. Testing

SECTION X-X C/S OF 300mm∅

6000

6.1. Slump of concrete should be between 160 mm to 180mm. Concrete cubes shall be

SPACING AND WAILER prepared for each concrete batch (or RMC) for strength confirmation.

BEAM 2 ISMC 400 PILE@ 400mm C-C SPACING 6.2. Pile integrity test should be conducted on all piles.

6.3. The third party testing shall be carried out on 2% anchors.

300 mm ∅ PILE WITH

5mm THICK LINER UP TO 7200

WEATHERED ROCK

X X

EXCAVATION

LEVEL-6.00m 400

16 T 8 NOS

NO. REVISION DATE DESCRIPTION

8T HELICAL R0 08.05.2024 Drawing Issued.

REINFORCEMENT PILE REINFORCEMENT

400

@200 mm C-C

4 L 8 T LATERAL

1200

TIES @ 200 C-C

CLIENT -M/S. KAMAL PROPERTIES

6 NOS 20T

300 300 mm∅ PILE

SITE : PANVEL

DRAWING TITLE: ENABLING SYSTEM (SHORE PILE DETAILS)

DRAWN BY CHECKED BY CHECKED BY DRAWING NO.

SU RAC SG/24-25/KAMAL/01

SECTIONAL ELEVATION OF 300 mm ∅ CAPPING BEAM DETAIL

PILES AT 400 mm C-C SPACING SWASTIK GEOTECHNIQUE

Geotechnical Engineering Consultants

Address :

401, Sai Darshan Apartment, Suyog Nagar, Vasai (W) 401 202

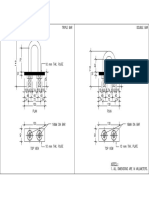

Notes:

ANCHOR AT 2.50M LEVEL 1. Drawing Not to the scale.

2. The drawing is valid up to 6.00m depth of excavation.

1. BOLTS 5.00 T 2. CURVED BASE PLATE 3. In case of any discrepancy shall be intimated brought to notice before start of work.

SHEAR CAPACITY 400 25mm THICK UPPER 25mm THICK SIDE

(16mm THICK STEEL PLATE) INCLINED PLATE PLATE

4. The yearly audit of enabling scheme must be done if the construction of permanent

PROVIDE 6 NOS (TRIANGULAR) retaining wall is not done immediately after excavation.

3. ISMC 400 25mm THICK

5. For Anchors

PLATES

250

The anchor lengths (fixed and free both) shall be grouted using Non-Shrinkable GP2 or

120mm∅ HOLE

4. ANCHOR BEARING PLATE equivalent grout mix.

(32mm THICK AND 150mm∅) 25mm THICK BOTTOM 5.1. Ref. Code : IS10270:1982, IS14268:1995.

INCLINED PLATE 5.2. The free and fixed length of anchor is 6.00 m to 7.00m for 2.50m level; however the

4. ANCHOR STRESS BOX

PLAN VIEW free anchor length shall be considered up to weathered rock encountering depth.

400

250

300

5.3. The anchors shall be pre-stressed after 7 days of grouting.

25mm THICK SIDE

PLATE (TRIANGULAR) 5.4. The adjacent building basement, foundations or any other structure shall be verified

4. ANCHOR STRESS BOX before commencement of shoring work.

5. ANCHOR STRESS BOX

ISOMETRIC VIEW 5.5. Anchor Stressing should be done using multipull jack.

(REFER DETAIL DRAWING)

6. Testing

300 mm∅ PILE 25

6. FRONT PLATE 250

6.1. Slump of concrete should be between 160 mm to 180mm. Concrete cubes shall be

(20mm THICK STEEL PLATE) 25mm THICK 25mm THICK SIDE prepared for each concrete batch (or RMC) for strength confirmation.

28

SIDE PLATE PLATE (TRIANGULAR)

7

Note : - 25mm THICK UPPER 6.2. Pile integrity test should be conducted on all piles.

7. SIDE STIFFENER PLATE

335

The steel plate and INCLINED PLATE 6.3. The third party testing shall be carried out on 2% anchors.

bolts may not be (16mm THICK STEEL PLATE) 25mm THICK UPPER

required where liner INCLINED PLATE 25mm THICK BOTTOM

INCLINED PLATE

2

is available

25

26

25mm THICK BOTTOM

PLAN VIEW OF ANCHOR BLOCK INCLINED PLATE

4. ANCHOR STRESS BOX

3. ISMC 400 4. ANCHOR STRESS BOX FRONT VIEW

SIDE VIEW

300 mm∅

PILE 4. ANCHOR BEARING PLATE

(32mm THICK AND 150mm∅) 1. BOLTS 5.00 T

28 50

30° 30° SHEAR CAPACITY

1

7

PROVIDE 6 NOS

16

16

236

2. CURVED 5. ANCHOR STRESS BOX 348

BASE PLATE (REFER DETAIL DRAWING) 261

2 8. BOTTOM BRACKET

26

2. CURVED BASE PLATE

(16mm THICK PLATE PLAN VIEW

880

700

PLAN VIEW

STEEL PLATE) 16 261 16

1320

348

7. SIDE STIFFENER PLATE

45° (16mm THICK STEEL PLATE)

Note : -

The steel plate and 6. FRONT PLATE

367

bolts may not be (20mm THICK STEEL PLATE)

367

required where liner

9

51

is available

45° 8. BOTTOM BRACKET PLATE 1. BOLTS 5.00 T

SHEAR CAPACITY

(16mm THICK STEEL PLATE) PROVIDE 6 NOS

1. BOLTS 5.00 T SHEAR CAPACITY 8. BOTTOM BRACKET 8. BOTTOM BRACKET

1320

1320

PROVIDE 6 NOS PLATE FRONT VIEW PLATE SIDE VIEW

SECTION X-X C/s. VIEW OF ANCHOR BLOCK

400 300

16 20

6. FRONT PLATE NO. REVISION DATE DESCRIPTION

7. SIDE STIFFENER PLATE PLAN VIEW

PLAN VIEW R0 08.05.2024 Drawing issued.

SHORE PILES 300 20

400 16

Note : -

The steel plate and

bolts may not be

2. CURVED BASE PLATE 2. CURVED BASE PLATE

required where liner 120mm∅ FRONT VIEW SIDE VIEW

is available 120mm∅ HOLE

HOLE

BOLTS S USE NON SHRINKABLE

CONNECTING PILE ANCHOR BEARING GROUT MIX

PLATE (GP2 OR EQUIVALENT) CLIENT -M/S. KAMAL PROPERTIES

STRANDS LOCKED

WITH WEDGES NO OF STRANDS 6 SITE : PANVEL

880

880

700

700

WELLER BEAM

SECTION 2 SECTIONS OF 12.7 mm ∅

ANCHOR GROUT PIPE HOLE

STRESSING BOX

DRAWING TITLE: ANCHOR DETAILS

END CURVED PLATE

DRAWN BY CHECKED BY CHECKED BY DRAWING NO.

FRONT PLATE

(WELDED TO HOLE DIA 120 mm SU RAC SG/24-25/KAMAL/02

BOTTOM BRACKET

WELLER BEAM)

PLATE

7. SIDE STIFFENER 7. SIDE STIFFENER 3. ANCHOR BEARING PLATE DETAILS

PLATE FRONT VIEW PLATE SIDE VIEW 6. FRONT PLATE 6. FRONT PLATE

VERTICAL BRACKET FRONT VIEW SIDE VIEW

PLATE 4 NOS

SWASTIK GEOTECHNIQUE

PRESTRESS ANCHOR SUMMARY Geotechnical Engineering Consultants

TYPICAL ANCHORING SYSTEM ANCHOR LEVEL ANCHOR LOCKING ANCHOR SPACING (m) ANCHOR HOLE FREE ANCHOR FIXED ANCHOR NO. OF Address:

401, Sai Darshan Apartment, Suyog Nagar, Vasai (W) 401 202

BELOW ROCK LEVEL STRANDS

ISOMETRIC VIEW FROM TOP (m) FORCE (T) AND INCLINATION(°) DIA. (mm) LENGTH(m) UP TO LENGTH(m) IN

WEATHERED ROCK WEATHERED ROCK

2.50 50.00 4.50 m c-c and 45° 120 6.00 - 7.00 7.00 6

You might also like

- SITXMGT002 Assessment 2 Project FinishedDocument22 pagesSITXMGT002 Assessment 2 Project FinishedGorkhali GamingNo ratings yet

- Heriot-Watt University Dubai Campus: ReceiptDocument2 pagesHeriot-Watt University Dubai Campus: ReceiptMuhammadnasidiNo ratings yet

- Inhinyero Review Center: Provided MaxDocument2 pagesInhinyero Review Center: Provided MaxVincent NavaNo ratings yet

- Client: Title:: General Notes of Vehicular Under PassDocument10 pagesClient: Title:: General Notes of Vehicular Under PassPraveen CyssanNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Rock Anchor MethodologyDocument7 pagesRock Anchor Methodologyzee shanNo ratings yet

- Pile Capacity TableDocument1 pagePile Capacity TablepapaNo ratings yet

- Electrical BOQ Plot C LPSDocument5 pagesElectrical BOQ Plot C LPSAgrawal PrajaktaNo ratings yet

- Structural AnalysisnewDocument6 pagesStructural AnalysisnewJunith Jay CalinawanNo ratings yet

- A5 Koto Hand-Book For ContractorsDocument73 pagesA5 Koto Hand-Book For ContractorsYasher Meera SaibNo ratings yet

- Description of Item Unit Qty Supply Rate: Sl. NoDocument50 pagesDescription of Item Unit Qty Supply Rate: Sl. NoKrishan PandyaNo ratings yet

- TS-Gabion - 10x12 - Galmac+PolimacDocument8 pagesTS-Gabion - 10x12 - Galmac+Polimacdigvijay singhNo ratings yet

- Drainage B11 PDFDocument1 pageDrainage B11 PDFluongiccNo ratings yet

- Rock Anchor MethodologyDocument9 pagesRock Anchor Methodologykaleswara_tellakulaNo ratings yet

- iwCmY6WPaXBR - BOQ RABAI 220KV FINALDocument11 pagesiwCmY6WPaXBR - BOQ RABAI 220KV FINALkajale.shrikantNo ratings yet

- Division 3: Concrete SpecificationsDocument12 pagesDivision 3: Concrete SpecificationsKae MoNo ratings yet

- InterviewDocument18 pagesInterviewVIJAY BHILWADENo ratings yet

- Ashoka UniversityDocument4 pagesAshoka UniversityG.MurtazaNo ratings yet

- Construction Notes: Hurricane Ties Connection DetailDocument8 pagesConstruction Notes: Hurricane Ties Connection DetailCristina Dangla CruzNo ratings yet

- Single Post: Highways DepartmentDocument1 pageSingle Post: Highways DepartmentTsz Yu WanNo ratings yet

- Cablofil - Cable TrenchDocument2 pagesCablofil - Cable Trenchsubidubi99No ratings yet

- Concrete 2 November 2022Document2 pagesConcrete 2 November 2022ronnelNo ratings yet

- Promat FPH Chapter 9Document29 pagesPromat FPH Chapter 9Majid Hamidi DadgarNo ratings yet

- Specification Page 100-102Document3 pagesSpecification Page 100-102nazrulafizi.dkbjNo ratings yet

- Chennai BOQDocument8 pagesChennai BOQDharmendra SharmaNo ratings yet

- Diaphragm Wall ConstructionDocument9 pagesDiaphragm Wall Constructionmeladbelal1234No ratings yet

- 2.3. External Waterproofing SystemsDocument2 pages2.3. External Waterproofing SystemsKrishna SankarNo ratings yet

- BOQ-22-11-2019 Pile Foundation Option For Temporary WorksDocument35 pagesBOQ-22-11-2019 Pile Foundation Option For Temporary WorksAshish SrivastavaNo ratings yet

- 13155e74c - Pretressed Concrete StructuresDocument4 pages13155e74c - Pretressed Concrete StructuresarunNo ratings yet

- Division Iii-Concrete & MasonryDocument31 pagesDivision Iii-Concrete & MasonryClive Aaron GuanzonNo ratings yet

- BOQ - Gurgaon - 25.06.23Document3 pagesBOQ - Gurgaon - 25.06.23Anurag ZullurwarNo ratings yet

- Technical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersDocument1 pageTechnical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersBogdanBNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghNo ratings yet

- Tennis Court - CentComDocument4 pagesTennis Court - CentComEppNo ratings yet

- 168 Imi PolymatDocument4 pages168 Imi PolymatEngr KamalNo ratings yet

- CE305Document3 pagesCE305Shubham YadavNo ratings yet

- Specifications With Schedule of QuantityDocument4 pagesSpecifications With Schedule of QuantityFor PromotionNo ratings yet

- Is.2911.1.2.2010 Part3Document6 pagesIs.2911.1.2.2010 Part3Dixit JariwalaNo ratings yet

- Sarojini Nagar Under The Guidance of MR Laksham HansdashDocument37 pagesSarojini Nagar Under The Guidance of MR Laksham HansdashShubhanshu MishraNo ratings yet

- Annexure - XIII - Drawing - Mounting StructurelDocument1 pageAnnexure - XIII - Drawing - Mounting Structurelisan.structural TjsvgalavanNo ratings yet

- Rigging of Transmission TowerDocument31 pagesRigging of Transmission TowerSagar BhardwajNo ratings yet

- Rigging of Transmission TowerDocument31 pagesRigging of Transmission TowerSagar Bhardwaj100% (1)

- Engineering Academy: Civil Engineering ESE Conventional Revision TEST - VDocument6 pagesEngineering Academy: Civil Engineering ESE Conventional Revision TEST - Vsaxenaarpita41No ratings yet

- Omnia Bridge DeckDocument7 pagesOmnia Bridge DeckKsenia ProtcenkoNo ratings yet

- SMD TR60 DatasheetDocument4 pagesSMD TR60 DatasheetAlfred GandNo ratings yet

- Material Specification & TestDocument3 pagesMaterial Specification & TestmunimiutNo ratings yet

- Design of Prestressed Concrete Structures 15cese2005-1 PDFDocument2 pagesDesign of Prestressed Concrete Structures 15cese2005-1 PDFvineela saiNo ratings yet

- Minimum Acceptable Specifications and Design Criteria-RDocument25 pagesMinimum Acceptable Specifications and Design Criteria-Ranup singhNo ratings yet

- TS 526.3.2.3.i. On Door Anchor SupportDocument2 pagesTS 526.3.2.3.i. On Door Anchor SupportAdrianNodaloNo ratings yet

- Structural Notes: A. General: C. Concrete and Reinforcing SteelDocument1 pageStructural Notes: A. General: C. Concrete and Reinforcing SteelTitan AethelNo ratings yet

- Method Statement: Conceal PVC Conduit/Trunking and Junction Boxes in Concrete CeilingDocument2 pagesMethod Statement: Conceal PVC Conduit/Trunking and Junction Boxes in Concrete Ceilingfatinjamal22No ratings yet

- Cochrane Gulf ClearVu Brochure 2022Document22 pagesCochrane Gulf ClearVu Brochure 2022hani hannaNo ratings yet

- Box Culvert - Wall DetailingDocument1 pageBox Culvert - Wall DetailingJovn MushiNo ratings yet

- Echo Prestress Durban (Pty) LTD: A Name Truly Cast in ConcreteDocument8 pagesEcho Prestress Durban (Pty) LTD: A Name Truly Cast in ConcreteTino MatsvayiNo ratings yet

- 37 - MC Design Standards Transportation2013!09!04Document10 pages37 - MC Design Standards Transportation2013!09!04Sulohita SharmaNo ratings yet

- RANGS R.K SQUARE - BOQ - Plumbing - 140719Document18 pagesRANGS R.K SQUARE - BOQ - Plumbing - 140719Md. Mominul IslamNo ratings yet

- Clipsal 4CC AND 4FCC INSTALLATION ISTRUCTIONDocument2 pagesClipsal 4CC AND 4FCC INSTALLATION ISTRUCTIONducvuong99.vtNo ratings yet

- Cracking in BrickworkDocument2 pagesCracking in BrickworkruwanthaNo ratings yet

- Structural Notes 1Document1 pageStructural Notes 1missiklein3No ratings yet

- VTU Model Question PapersDocument50 pagesVTU Model Question PapersOmkarNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Train Ticket NageshDocument2 pagesTrain Ticket Nageshpravin awalkondeNo ratings yet

- CorrigendumIVPkgVIIIDocument1 pageCorrigendumIVPkgVIIIpravin awalkondeNo ratings yet

- CorrigendumI-PkgVIDocument1 pageCorrigendumI-PkgVIpravin awalkondeNo ratings yet

- U Clamp Fo Sabarmati River Test PileDocument1 pageU Clamp Fo Sabarmati River Test Pilepravin awalkondeNo ratings yet

- Pldedge 1Document5 pagesPldedge 1pravin awalkondeNo ratings yet

- Elevation: MP161 LHS MP162 LHS MP163 LHS MP164 LHS MP165 LHS MP166 LHSDocument1 pageElevation: MP161 LHS MP162 LHS MP163 LHS MP164 LHS MP165 LHS MP166 LHSpravin awalkondeNo ratings yet

- Passbookstmt 1671020682146Document4 pagesPassbookstmt 1671020682146pravin awalkondeNo ratings yet

- BM2327I004378252Document6 pagesBM2327I004378252pravin awalkondeNo ratings yet

- NF2VEPL27UD9QGLG5952 ETicketDocument3 pagesNF2VEPL27UD9QGLG5952 ETicketpravin awalkondeNo ratings yet

- GoFirst - BoardingPass - Y77YSF - Mr. Pravin AwalkondeDocument1 pageGoFirst - BoardingPass - Y77YSF - Mr. Pravin Awalkondepravin awalkondeNo ratings yet

- NF2SPWD1B7UM68L62894 ETicket PDFDocument3 pagesNF2SPWD1B7UM68L62894 ETicket PDFpravin awalkondeNo ratings yet

- SR - No Comment Received ComplianceDocument2 pagesSR - No Comment Received Compliancepravin awalkondeNo ratings yet

- IDFCFIRSTBankstatement 10052774504 PDFDocument4 pagesIDFCFIRSTBankstatement 10052774504 PDFpravin awalkondeNo ratings yet

- Daksh InteriorsDocument10 pagesDaksh Interiorspravin awalkondeNo ratings yet

- Invoice # 23032 PDFDocument2 pagesInvoice # 23032 PDFpravin awalkondeNo ratings yet

- My ProjectDocument2 pagesMy Projectpravin awalkondeNo ratings yet

- Bm2327i002741932 PDFDocument4 pagesBm2327i002741932 PDFpravin awalkondeNo ratings yet

- Vaibhav .M. Gaykar: Key Skills: Personal SummaryDocument3 pagesVaibhav .M. Gaykar: Key Skills: Personal Summarypravin awalkondeNo ratings yet

- Invoice For MCN-SA M213A - Ipsum Designs PDFDocument2 pagesInvoice For MCN-SA M213A - Ipsum Designs PDFpravin awalkondeNo ratings yet

- My ProjectDocument2 pagesMy Projectpravin awalkondeNo ratings yet

- Abhay Consultants PVT LTD: Annexure-1Document2 pagesAbhay Consultants PVT LTD: Annexure-1pravin awalkondeNo ratings yet

- 6260 PDFDocument153 pages6260 PDFpravin awalkondeNo ratings yet

- Carlos Soubrier, P.Eng.: Materials Engineer, Materials Performance and Corrosion ControlDocument6 pagesCarlos Soubrier, P.Eng.: Materials Engineer, Materials Performance and Corrosion Controlpravin awalkondeNo ratings yet

- 188-E-DN-6003-Design of Elastomeric Bearing-R1Document30 pages188-E-DN-6003-Design of Elastomeric Bearing-R1pravin awalkondeNo ratings yet

- Subtr Code - UpdatedDocument60 pagesSubtr Code - Updatedpravin awalkondeNo ratings yet

- Control Perimeters For Punching Shear @2dDocument4 pagesControl Perimeters For Punching Shear @2dpravin awalkondeNo ratings yet

- RTA - Yahoo Mail - Amount Blocked For CAMS IPO Applied On 21 - 09 - 2020 - Ref No - IE295759Document2 pagesRTA - Yahoo Mail - Amount Blocked For CAMS IPO Applied On 21 - 09 - 2020 - Ref No - IE295759pravin awalkondeNo ratings yet

- GR Infra Projects LTDDocument23 pagesGR Infra Projects LTDpravin awalkondeNo ratings yet

- Section 1 FV With PV CalculatorDocument3 pagesSection 1 FV With PV Calculatorpravin awalkondeNo ratings yet

- Pravin R. AwalkondeDocument3 pagesPravin R. Awalkondepravin awalkondeNo ratings yet

- Applied Chemistry MCQsDocument10 pagesApplied Chemistry MCQsiangarvins100% (1)

- Scheme of Marking For 014 UPSR 2016 FormatDocument3 pagesScheme of Marking For 014 UPSR 2016 Formatawesome_teacher88% (8)

- C BAND Satellites Recivable in A INDIA PDFDocument3 pagesC BAND Satellites Recivable in A INDIA PDFchidambaram kasiNo ratings yet

- Insert A Pivot Table: Mba102-Advanced Statistics With Computer Application Module 4 Exercises Pivot TablesDocument12 pagesInsert A Pivot Table: Mba102-Advanced Statistics With Computer Application Module 4 Exercises Pivot TablesAdoree RamosNo ratings yet

- Asco 7000 Series Operators Manual Group 5 ControllerDocument32 pagesAsco 7000 Series Operators Manual Group 5 ControllerAhmed Tarek100% (1)

- Agriculture AhmedabadDocument33 pagesAgriculture AhmedabadKrupam Thetenders.com100% (1)

- WPC Aco PDFDocument16 pagesWPC Aco PDFpetar spalevicNo ratings yet

- 1 SMDocument11 pages1 SMp25h4pdkb8No ratings yet

- THE ORGANIZATION STUDY OF ARGO HYTOS PRIVATE LIMITED (AutoRecovered)Document57 pagesTHE ORGANIZATION STUDY OF ARGO HYTOS PRIVATE LIMITED (AutoRecovered)selvarajmadhu6No ratings yet

- May 2024Document64 pagesMay 2024Eric SantiagoNo ratings yet

- Sip Design and Verification Using AdsDocument34 pagesSip Design and Verification Using AdsMaria Lavinia IordacheNo ratings yet

- Optical MSRDocument2 pagesOptical MSRexarchos26100% (2)

- Practice Paper XDocument14 pagesPractice Paper XRohit KumarNo ratings yet

- Bennett 2003Document8 pagesBennett 2003Emir OkucuNo ratings yet

- Action ResearchDocument27 pagesAction Researchreymarie hermosillaNo ratings yet

- 1 L.M. College of Pharmacy Gujarat (Government of Gujarat) Assistant Professor Recruitment Examination Question Paper 2016Document9 pages1 L.M. College of Pharmacy Gujarat (Government of Gujarat) Assistant Professor Recruitment Examination Question Paper 2016pratyush swarnkarNo ratings yet

- Example of Business Case ReportDocument3 pagesExample of Business Case ReportCORINE NDLOVUNo ratings yet

- m48t08 150pc1 PDFDocument31 pagesm48t08 150pc1 PDFMariuszChreptakNo ratings yet

- Skylab 3 PAO Mission Commentary 3 of 6Document851 pagesSkylab 3 PAO Mission Commentary 3 of 6Bob AndrepontNo ratings yet

- Instructions PDFDocument1 pageInstructions PDFNikola UroševićNo ratings yet

- BL M22 1011 PDFDocument46 pagesBL M22 1011 PDFDmitryNo ratings yet

- Cat 2007 Productline EnglishDocument24 pagesCat 2007 Productline EnglishDan PatchNo ratings yet

- Cse4001 Cloud-Computing TH 1.0 2 Cse4001Document2 pagesCse4001 Cloud-Computing TH 1.0 2 Cse4001sai22.ssbNo ratings yet

- Full Ebook of Daily Routines To Jump Start Math Class Elementary School 1St Edition John J Sangiovanni 2 Online PDF All ChapterDocument24 pagesFull Ebook of Daily Routines To Jump Start Math Class Elementary School 1St Edition John J Sangiovanni 2 Online PDF All Chapterandereabat100% (4)

- AsDocument602 pagesAsnareshNo ratings yet

- E JB TutorialDocument141 pagesE JB TutorialManikandan ChellaNo ratings yet

- HYUNDAI WIA Heavy Duty Cutting Horizontal Machining CenterDocument27 pagesHYUNDAI WIA Heavy Duty Cutting Horizontal Machining CentersrinivignaNo ratings yet

- Web Pages With MVC3 and Razor SyntaxDocument282 pagesWeb Pages With MVC3 and Razor Syntaxozamaro100% (1)