Professional Documents

Culture Documents

Lesson-15_Roofing-Estimate-1-1

Lesson-15_Roofing-Estimate-1-1

Uploaded by

advinculajpoy0 ratings0% found this document useful (0 votes)

2 views11 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views11 pagesLesson-15_Roofing-Estimate-1-1

Lesson-15_Roofing-Estimate-1-1

Uploaded by

advinculajpoyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 11

ROOF ESTIMATING:

CORRUGATED & Plain

GALV. IRON sheets

Roofing sheet. The most common roofing material is

the corrugated metal sheet made of galvanized iron.

It is a roll formed roof made from cold rolled mild

steel sheet hot-dipped in zinc. Invented in the 1820's

by an Englishman, its manufacturing process

remained mechanically similar. This is easy to

transport and simple to install, making it the best

choice for temporary or rural housing. For roofing

purposes, its sheets are laid beside each other like

tiles, but unlike tiles one could cover 10 times the

area. This material could be reused as low cost

fences even after 10 years, and is also 100%

recyclable.

Aside from the corrugated type (see picture, top right) mostly

suitable for roofing and siding applications, these galvanized iron

(G.I.) sheets are also available in plain version (see picture, bottom

right). Also used for roofing, plain G.I. sheets are used for gutters,

flashing, leaders or downspouts, as well as for ridge, hip, and valley

rolls.

Corrugated sheets have a standard width of 80cm. with varying

commercial lengths, from 240cm to 360cm at consecutive 30-cm

intervals. However at present, in the Phils. these lengths are still

expressed in English measure, thus the lengths would be 8’, 9’, 10’

and 12’. Corrugated long-span sheets are also available and are

more popular nowadays as it is advantageous in terms of the

effective material coverage.

The thickness of the sheets is measured in terms of gauge. The

sheet becomes thinner as the number becomes larger. Gauge

26 is most suitable for roofing, flashing, ridge and hip rolls while

Gauge 24 is specified for gutters and valley rolls.

Before estimating the quantity of roofing components, the ff.

info should be obtained:

1) Verify the side lapping required for the roofing sheets (1-1/2

or 2-1/2 corrugations are recommended). The effective

width of the sheet is 70cm for 1-1/2 corr. and 60cm for 2-1/2

corr.

2) The standard end lapping for loose individual sheets is from

25cm to 30cm long. This is important in determining the

commercial length of the sheet to be used.

3) Spacing of the purlins should be in a way

that is proportionately adjusted to the

length of the sheet to avoid unnecessary

cutting or excessive overlapping. In short,

the length of the roof sheet governs the

spacing of the purlins. Refer to Table 6-2.

4) A good roofing design minimizes end

lapping joints. Longer lengths are

preferred for better material coverage.

For this consideration, choosing such

combinations of roof sheet lengths to

satisfy end lap requirements is made

convenient with the use of Table 6-5.

Determine the rafter or top chord length

for this purpose, to satisfy the previous

info no. 2.

5) Quantities of roofing accessories and

consumables such as nails, rivets and

washers are provided in Table 6-2 and

Table 6-3.

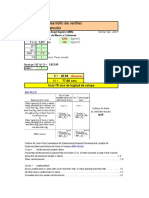

ILLUSTRATION A:

From the given building roof, find the number of corr.

G.I. roof sheets and its accessories required if the side

lapping specifies 1-1/2 corrugations with 30cm end

lapping.

SOLUTION:

1. Corr. G.I. Sheets. Divide the length of the roof by

the effective width of one sheet. Refer to Table 6-2

under 1-1/2 corr. The value is 0.70.

Qew = 14.00 ÷ 0.70 = 20 shts in one row

Refer to Table 6-5. Rafter length is 6.00m. so it is a

combination of 9’ (2.70m) and 12’ (3.60m)

ORDER: 20 shts. – Ga. 26 x 9’ Corr. G.I.

20 shts. – Ga. 26 x 12’ Corr. G.I.

2. Nails. Refer to Table 6-2, for a 12ft and 9ft sheet:

Qr1 = 20 shts x 26 nails = 520 pcs.

Qr2 = 20 shts x 22 nails = 440 pcs.

Total Nails Qrt = 960 pcs.

Refer to Table 6-3. Convert to kilos.

960 ÷ 120 = 8.00kgs.

ORDER: 8.00 kgs. – Tex screws (Roof Nails) with

rubber washers

Gutter, Flashing and Rolls. In roofing installations,

these items are categorized as roof accessories.

Estimating these components is simply done by

determining the number of plain G.I. sheets

needed for their fabrication, in accordance to the

form and shape shown in the working drawings.

The usual procedure is to find the total length of

each item and divide this by 2.35m which is the

effective length of one plain G.I. sheet ( 0.90m x

2.40m) given an end lap of 0.05m. Also find the

total width based on the cross-section of the item

(ex. Roof Gutter profile) that can be made out of

the standard width of one plain sheet.

ILLUSTRATION B:

From the given building roof, find the number of plain

G.I. sheets required to fabricate the gutter, end gable

flashing, and ridge roll.

SOLUTION:

1. Gutter:

a. Find the total length of gutter = 10m x 2 sides

= 20.00m.

b. Divide by effective length of one sheet:

20.00 ÷ 2.35 = 8.51 say 9 lgths. for the gutter.

c. Find the total width of the gutter cross-section:

Lgx = 2.5 + 5 + 2 + 13 + 7.5 + 15 = 45cm = 0.45m

Divide the width of one plain sheet:

0.90 ÷ 0.45 = 2pcs. derived from one sheet

d. Divide result in (b) by (c) = 9 ÷ 2 = 4.5 say 5 shts.

ORDER: 5 shts. – Ga. 26 x 8’ Plain G.I. for the gutter

2. Flashing:

a. Find the total length of flashing = 4.5m x 4 sides

= 18.00m.

b. Divide by effective length of one sheet:

18.00 ÷ 2.35 = 7.66 say 8 lgths. for the flashing.

c. Find the total width of the flashing cross-section:

Lfx = 23 + 5 + 2 + 15 = 45cm = 0.45m

Divide the width of one plain sheet:

0.90 ÷ 0.45 = 2pcs. derived from one sheet

d. Divide result in (b) by (c) = 8 ÷ 2 = 4 shts.

ORDER: 4 shts. – Ga. 26 x 8’ Plain G.I. for the flashing

Divide the width of one plain sheet:

3. Ridge roll: 0.90 ÷ 0.45 = 2pcs. derived from one sheet

a. Find the length of ridge roll = 10.00m. d. Divide result in (b) by (c) = 5 ÷ 2 = 2.5 say 3 shts.

b. Divide by effective length of one sheet:

10.00 ÷ 2.35 = 4.26 say 5 lgths. for the ridge roll. ORDER: 3 shts. – Ga. 26 x 8’ Plain G.I. for the ridge roll

c. Find the total width of the ridge roll cross-section:

Lrx = 45cm = 0.45m TOTAL NUMBER OF SHEETS: 5 + 4 + 3 = 12 shts.

You might also like

- Maharashtra HSC Chemistry Paper 1-Target PublicationDocument54 pagesMaharashtra HSC Chemistry Paper 1-Target PublicationKhanAbdullah78% (18)

- Glulam Curved Beam Design To EC5Document6 pagesGlulam Curved Beam Design To EC5Burak Kırcal100% (1)

- Roof EstimatesDocument34 pagesRoof EstimatesCharrie Mae67% (3)

- 3 End of Chapter3 Problems BULKDocument6 pages3 End of Chapter3 Problems BULKqusayNo ratings yet

- Strip Footing Design For WallDocument15 pagesStrip Footing Design For WallAnonymous xIh8FuDtNo ratings yet

- Flexural Design Procedure For Singly Reinforced Rectangular BeamsDocument3 pagesFlexural Design Procedure For Singly Reinforced Rectangular BeamstvelasquezNo ratings yet

- Tutorial MSEWDocument1 pageTutorial MSEWSUNDARAVELNo ratings yet

- Roofing Materials PresentationDocument76 pagesRoofing Materials PresentationMugiwara No Rufi100% (1)

- XDocument34 pagesXBalasubramaniam MuruganNo ratings yet

- 3 - Module 8 RoofingDocument35 pages3 - Module 8 RoofingallankatenguddoNo ratings yet

- Roofing Materials: Mapua Institute of TechnologyDocument20 pagesRoofing Materials: Mapua Institute of TechnologyJoshua Edward LaqueNo ratings yet

- Selection of Economical Span in RCC Building: SUST Studies, Vol. 12, No. 1, 2010 P:93-98Document7 pagesSelection of Economical Span in RCC Building: SUST Studies, Vol. 12, No. 1, 2010 P:93-98Syed Fahad AliNo ratings yet

- RC 133Document34 pagesRC 133sora maytaNo ratings yet

- 1.1 Problem Statement: CIE525: Assignment 5 Strut and Tie ModelsDocument8 pages1.1 Problem Statement: CIE525: Assignment 5 Strut and Tie ModelsYisus NuñezNo ratings yet

- ECS478 CHAPTER 3-Flat SlabDocument40 pagesECS478 CHAPTER 3-Flat SlabAmron Abubakar0% (1)

- Roofing Ver 2.0Document24 pagesRoofing Ver 2.0Euler RedobleNo ratings yet

- Design of Roof SlabDocument34 pagesDesign of Roof Slabhannan mohsinNo ratings yet

- Preliminary Sizing of Structural Members - Building Construction Principles, Materials, and SystemsDocument8 pagesPreliminary Sizing of Structural Members - Building Construction Principles, Materials, and SystemsaikalessNo ratings yet

- Design Procedure For Boiler JointsDocument3 pagesDesign Procedure For Boiler JointsNaveen A Cusat50% (2)

- Lecture Design of Boiler JointsDocument26 pagesLecture Design of Boiler JointsYOGESH CHHAGANRAO MULEY67% (3)

- 03 Section 2 Example Bridge (E)Document11 pages03 Section 2 Example Bridge (E)Diego Benavides KNo ratings yet

- Particular SpecificationsDocument8 pagesParticular SpecificationsmoumitaNo ratings yet

- SlabDocument60 pagesSlabAdigwe George ChimaNo ratings yet

- Effective Covering of G.I Sheets TableDocument5 pagesEffective Covering of G.I Sheets TablepainNo ratings yet

- Two Way Slab BestDocument25 pagesTwo Way Slab BestErnest Christian Nanola100% (1)

- Shed Storage2Document9 pagesShed Storage2Bob Pouliot88% (8)

- AE401 - Tee Spandrel and SlabsDocument13 pagesAE401 - Tee Spandrel and SlabsThomas MartinNo ratings yet

- L14-L15 Ch+16+Slab+with+beamsDocument10 pagesL14-L15 Ch+16+Slab+with+beamsPrateek Soumya SharmaNo ratings yet

- Unit 2 Design of Boiler Revited JointDocument7 pagesUnit 2 Design of Boiler Revited Jointaditya.1540011No ratings yet

- How To Design Concrete Structures Using Eurocode 2 - (3) SlabsDocument8 pagesHow To Design Concrete Structures Using Eurocode 2 - (3) Slabsbobbytirona566100% (1)

- Lecture 4-Bec411Document36 pagesLecture 4-Bec411Mohd Nizam ShakimonNo ratings yet

- Preboard Day 3 February 2018Document5 pagesPreboard Day 3 February 2018Justine Marowe AustriaNo ratings yet

- Drawing Forming Be 00 New yDocument44 pagesDrawing Forming Be 00 New yMarudhasalam VelusamyNo ratings yet

- Presented By: Irfan KhanDocument63 pagesPresented By: Irfan KhanIrfan KhanNo ratings yet

- Programa Logitud de Desarrollo en ColumnasDocument6 pagesPrograma Logitud de Desarrollo en ColumnasLeonardo PimentelNo ratings yet

- Assignment_3_Design_of_RCC_StructuresDocument3 pagesAssignment_3_Design_of_RCC_StructuresDHANASHREE TULANKARNo ratings yet

- How To Calculate or Estimate Longspan Aluminium Roofing SheetsDocument4 pagesHow To Calculate or Estimate Longspan Aluminium Roofing SheetsAgarry EmmanuelNo ratings yet

- Concrete Shear Wall Strip Footing Foundation Analysis Design ACI318 14Document15 pagesConcrete Shear Wall Strip Footing Foundation Analysis Design ACI318 14Fabian Poquechoque ArnezNo ratings yet

- Lesson-16_Hardware-Estimate-1Document6 pagesLesson-16_Hardware-Estimate-1advinculajpoyNo ratings yet

- Design of Machine Elements Sample QuestionsDocument9 pagesDesign of Machine Elements Sample Questionsblogger100% (1)

- #002bolted Connection-2019Document51 pages#002bolted Connection-2019PAVANPORENo ratings yet

- DR SaadDocument13 pagesDR SaadhawkarkoeyNo ratings yet

- Welding Rod CalculationDocument4 pagesWelding Rod Calculationuemaapl100% (1)

- Steel PR 6-RDocument29 pagesSteel PR 6-RTaimoor Shahid BajwaNo ratings yet

- Chapter 6 Ribbed Slab and Waffle SlabDocument15 pagesChapter 6 Ribbed Slab and Waffle Slaba20082909No ratings yet

- Potash CrystallizationDocument14 pagesPotash CrystallizationUditha Lakshan100% (1)

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Machine Design Questions PDFDocument5 pagesMachine Design Questions PDFrajibNo ratings yet

- Answer Key Area 2Document23 pagesAnswer Key Area 2ji piNo ratings yet

- Ce 124 - Forms, Scaffoldings and StagingDocument13 pagesCe 124 - Forms, Scaffoldings and StagingJacob John100% (1)

- Ot 1Document12 pagesOt 1ZZROTNo ratings yet

- Two Way Slab SystemsDocument264 pagesTwo Way Slab Systemsali hasanNo ratings yet

- كيفية حساب كمية سلك اللحام المطلوبةDocument6 pagesكيفية حساب كمية سلك اللحام المطلوبةMohamed Atef100% (1)

- Thin CylinderDocument10 pagesThin Cylinderarunnical100% (3)

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- Model Yachts and Boats: Their Designing, Making and SailingFrom EverandModel Yachts and Boats: Their Designing, Making and SailingNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Wrought Ironwork: A Manual of Instruction for CraftsmenFrom EverandWrought Ironwork: A Manual of Instruction for CraftsmenRating: 5 out of 5 stars5/5 (1)

- ASTM D 5383 - 02 R03 LightfastnessDocument6 pagesASTM D 5383 - 02 R03 LightfastnessJohnNo ratings yet

- Waste Management - WikipediaDocument38 pagesWaste Management - WikipediaVitthal ShikhareNo ratings yet

- Report FreundlicDocument16 pagesReport FreundlicMuhammad FahmiNo ratings yet

- Compressive Strength of BricksDocument5 pagesCompressive Strength of BricksDharmik Med BabraNo ratings yet

- 415 120 DB 0001Document30 pages415 120 DB 0001Mustafa AhsanNo ratings yet

- Shear Capacity of Self-Compacting ConcreteDocument10 pagesShear Capacity of Self-Compacting ConcreteHuda JawadNo ratings yet

- Advanced Manufacturing Question SampleDocument2 pagesAdvanced Manufacturing Question SampleBakul RoyNo ratings yet

- Petrified WoodDocument38 pagesPetrified WoodFabiando HendyNo ratings yet

- Beständigkeitsliste - Kunststoffe - Valvecenter UKDocument24 pagesBeständigkeitsliste - Kunststoffe - Valvecenter UKVelibor StokicNo ratings yet

- Ductility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedDocument11 pagesDuctility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedNorhafizah Bt SallehNo ratings yet

- Soma Sundar An 1979Document12 pagesSoma Sundar An 1979Antoni Budhi PrasetyoNo ratings yet

- Concrete Crack Repair MethodsDocument6 pagesConcrete Crack Repair MethodsCalvin ChanNo ratings yet

- CH311 - Experiment 6 - Sterol Extraction From Sea WaterDocument2 pagesCH311 - Experiment 6 - Sterol Extraction From Sea WaterNarelle IaumaNo ratings yet

- Materials Today JournalDocument10 pagesMaterials Today JournalOwent OvandyNo ratings yet

- Losses in PrestressDocument38 pagesLosses in PrestressKausalya PurushothamanNo ratings yet

- Nanotechnology in Temporary Anchorage Devices: Dr. Chelza X, Dr. Anand SivadasaDocument3 pagesNanotechnology in Temporary Anchorage Devices: Dr. Chelza X, Dr. Anand SivadasajayashreeNo ratings yet

- Material Safety Data Sheet: Section I: Product IdentificationDocument3 pagesMaterial Safety Data Sheet: Section I: Product IdentificationRendy SetiawanNo ratings yet

- Tecnologia TBM Epb HydroDocument88 pagesTecnologia TBM Epb HydrogifantaNo ratings yet

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocument12 pagesPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNo ratings yet

- Table For Angles in Compression PDFDocument4 pagesTable For Angles in Compression PDFMikeNo ratings yet

- B17 - 52 - A Guide To Heat Exchangers For Industrial Heat Recovery - State of New York PDFDocument24 pagesB17 - 52 - A Guide To Heat Exchangers For Industrial Heat Recovery - State of New York PDFKailas NimbalkarNo ratings yet

- Electrical Discharge Machining: Various Electric Discharge MachinesDocument40 pagesElectrical Discharge Machining: Various Electric Discharge MachinesArun PrasadNo ratings yet

- Sanitary Engineering Lec.: November 2015Document110 pagesSanitary Engineering Lec.: November 2015Dynamo DSNo ratings yet

- ENV CBC TG (2022) 25.enDocument23 pagesENV CBC TG (2022) 25.enFlahautNo ratings yet

- المحاظرة الثانية لدنتل متيريلDocument28 pagesالمحاظرة الثانية لدنتل متيريلsaifNo ratings yet

- Ibr CalculationsDocument9 pagesIbr CalculationsoperationmanagerNo ratings yet

- 263 269 JMTR Oct16Document7 pages263 269 JMTR Oct16Taniadi SuriaNo ratings yet

- ملزمة اسئلة على كل درس فى Science للصف الثانى الاعدادى اللغات الترم الاول-الامتحان التعليمىDocument22 pagesملزمة اسئلة على كل درس فى Science للصف الثانى الاعدادى اللغات الترم الاول-الامتحان التعليمىhend ahmed chemistry teacherNo ratings yet