Professional Documents

Culture Documents

Product-pdf-10218

Product-pdf-10218

Uploaded by

henryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product-pdf-10218

Product-pdf-10218

Uploaded by

henryCopyright:

Available Formats

Vectra® A430

Celanese Corporation - Liquid Crystal Polymer Friday, July 12, 2024

General Information

Product Description

LCP/PTFE, excellent wear & electrical properties at high frequencies

Provides many of the characteristics of A130 with added lubricity. Suitable for applications requiring excellent wear characteristics. Excellent electrical

properties at high frequencies. LCP/PTFE blend. Chemical abbreviation according to ISO 1043-1 : LCP Inherently flame retardant UL-Listing V-0 in

natural and black at 0.43mm thickness per UL 94 flame testing. Relative-Temperature-Index (RTI) according to UL 746B: electrical 130°C, mechanical

130°C. UL = Underwriters Laboratories (USA)

General

Material Status • Commercial: Active

• Africa & Middle East • Europe

Availability • North America

• Asia Pacific • Latin America

Additive • Flame Retardant • UV Stabilizer

• Flame Retardant • Low Friction

Features • Wear Resistant

• High Flow • UV Stabilized

Uses • Automotive Applications

Automotive Specifications • CONTINENTAL TST N 055 72.01-000

Forms • Pellets

Processing Method • Injection Molding

ASTM & ISO Properties 1

Physical Nominal Value Unit Test Method

Density 1.50 g/cm³ ISO 1183

Molding Shrinkage ISO 294-4

Across Flow 0.70 %

Flow 0.0 %

Mechanical Nominal Value Unit Test Method

Tensile Modulus 7000 MPa ISO 527-1

Tensile Stress (Break) 150 MPa ISO 527-2/5

Tensile Strain (Break) 5.8 % ISO 527-2/5

Flexural Modulus 7100 MPa ISO 178

Flexural Stress 120 MPa ISO 178

Compressive Modulus 6000 MPa ISO 604

Compressive Stress (1% Strain) 38.0 MPa ISO 604

Impact Nominal Value Unit Test Method

Charpy Notched Impact Strength (23°C) 47 kJ/m² ISO 179/1eA

Charpy Unnotched Impact Strength (23°C) 86 kJ/m² ISO 179/1eU

Notched Izod Impact Strength (23°C) 34 kJ/m² ISO 180/1A

Unnotched Izod Impact Strength (23°C) 67 kJ/m² ISO 180/1U

Hardness Nominal Value Unit Test Method

Rockwell Hardness (M-Scale) 55 ISO 2039-2

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load ISO 75-2/B

0.45 MPa, Unannealed 227 °C

Deflection Temperature Under Load ISO 75-2/A

1.8 MPa, Unannealed 165 °C

UL LLC ©2024. All rights reserved.

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL assumes no

responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product or material selection

information is validated with the manufacturer. This website provides links to other websites owned by third parties. The content of such third party sites is not within

www.ulprospector.com our control, and we cannot and will not take responsibility for the information or content.

Page: 1 of 2

Vectra® A430

Celanese Corporation - Liquid Crystal Polymer

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load ISO 75-2/C

8.0 MPa, Unannealed 89.0 °C

Melting Temperature 2 280 °C ISO 11357-3

CLTE - Flow 1.0E-6 cm/cm/°C ISO 11359-2

CLTE - Transverse 4.6E-5 cm/cm/°C ISO 11359-2

Electrical Nominal Value Unit Test Method

Surface Resistivity 1.0E+15 ohms IEC 62631-3-2

Volume Resistivity 1.0E+13 ohms·m IEC 62631-3-1

Electric Strength 36 kV/mm IEC 60243-1

Relative Permittivity IEC 60250

100 Hz 3.30

1 MHz 2.70

Dissipation Factor IEC 60250

100 Hz 0.030

1 MHz 0.016

Arc Resistance 130 sec Internal Method

3 PLC 3 UL 746A

Comparative Tracking Index (CTI)

Flammability Nominal Value Unit Test Method

Flame Rating V-0 UL 94

Processing Information

Injection Nominal Value Unit

Drying Temperature 150 °C

Drying Time 4.0 to 6.0 hr

Suggested Max Moisture 0.010 %

Hopper Temperature 20 to 30 °C

Injection Feed Temperature 60 to 80 °C

Rear Temperature 270 to 280 °C

Middle Temperature 275 to 285 °C

Front Temperature 280 to 290 °C

Injection Zone 4 Temperature 285 to 295 °C

Nozzle Temperature 290 to 300 °C

Processing (Melt) Temp 285 to 310 °C

Mold Temperature 80 to 120 °C

Injection Rate Fast

Back Pressure < 3.00 MPa

Hot Runner 285 to 295 °C

Screw Speed

1.60 cm 200

2.50 cm 140

4.00 cm 80

Notes

1

Typical properties: these are not to be construed as specifications.

2

10°C/min

3

23°C

UL LLC ©2024. All rights reserved.

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL assumes no

responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product or material selection

information is validated with the manufacturer. This website provides links to other websites owned by third parties. The content of such third party sites is not within

www.ulprospector.com our control, and we cannot and will not take responsibility for the information or content.

Page: 2 of 2

You might also like

- Xydar® SRT-900 by Syensqo ADPDocument3 pagesXydar® SRT-900 by Syensqo ADPFAUSANo ratings yet

- Nexeo Plastics Kingfa PBT RG151Document2 pagesNexeo Plastics Kingfa PBT RG151kls.thorodinsonNo ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- Product PDF 128Document3 pagesProduct PDF 128madkatteNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- Product PDF 14364Document2 pagesProduct PDF 14364Gerente IngenieriaNo ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- Product PDF 181Document2 pagesProduct PDF 181RicardoNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- SE-316 Parts Data SheetDocument27 pagesSE-316 Parts Data SheetElnBEKKARYNo ratings yet

- Product PDF 137904Document2 pagesProduct PDF 137904Igor GonçalvesNo ratings yet

- Kumho 750SWDocument1 pageKumho 750SWChu ChuNo ratings yet

- Product PDF 301308Document2 pagesProduct PDF 301308Andrew JacksonNo ratings yet

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDocument2 pagesInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan Manikandan0% (1)

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 pagesDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- Duracon® CP15XDocument3 pagesDuracon® CP15XRhekron PlasticsNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- Amcel KP20: Celanese Corporation - Acetal (POM) CopolymerDocument1 pageAmcel KP20: Celanese Corporation - Acetal (POM) CopolymerSamuelNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- Luran S757 GDocument5 pagesLuran S757 GPeter EvansNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- Delrin 500P NC010 (White)Document12 pagesDelrin 500P NC010 (White)humberto.ramirezNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- Spec Hopelen H1500Document2 pagesSpec Hopelen H1500trung.lam10992No ratings yet

- SD-0150W TDSDocument2 pagesSD-0150W TDSrtsultanNo ratings yet

- TECHNYL® A 216 Y10: DescriptionDocument2 pagesTECHNYL® A 216 Y10: DescriptionpaquienNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- ASA Styrolution: Luran® S 778 TDocument2 pagesASA Styrolution: Luran® S 778 TayyappanNo ratings yet

- Polyflam Rabs 90000 Uv5 LS (E128762)Document3 pagesPolyflam Rabs 90000 Uv5 LS (E128762)simonNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Delrin® 127UV NC010Document3 pagesDelrin® 127UV NC010alejandrocharlescollNo ratings yet

- 76 StyrolutionPS454NDocument5 pages76 StyrolutionPS454N59074No ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Celanese Corporation Celanex® 1400A Polybutylene TerephthalateDocument2 pagesCelanese Corporation Celanex® 1400A Polybutylene TerephthalateTomGaliciaNo ratings yet

- TDS Pa6 MVM2750LDocument1 pageTDS Pa6 MVM2750Lkls.thorodinsonNo ratings yet

- Panlite L-1250Y: TEIJIN LIMITED - PolycarbonateDocument2 pagesPanlite L-1250Y: TEIJIN LIMITED - PolycarbonateDamjan DespotovskiNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- PBT Valox 865 30% GLDocument4 pagesPBT Valox 865 30% GLcountzeroaslNo ratings yet

- SCG PP P483Ju: SCG Chemicals Co., LTDDocument2 pagesSCG PP P483Ju: SCG Chemicals Co., LTDTruc Thao NguyenNo ratings yet

- Santoprene 201 64 - MDS - ENDocument3 pagesSantoprene 201 64 - MDS - ENLITCoupie RAKVANNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Ultraform W 2320 003 UNC Q600Document3 pagesUltraform W 2320 003 UNC Q600Patricio Bravo CastilloNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- Dupont Zytel 70G30L NC010Document2 pagesDupont Zytel 70G30L NC010Dario de SantiagoNo ratings yet

- Hostalen H 2150Document3 pagesHostalen H 2150Silviu PadureanuNo ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- Eptfe Innovations PaperDocument16 pagesEptfe Innovations PaperrmnrajanNo ratings yet

- Material Description Color: Reinforced Teflon® (Rptfe) Chalky WhiteDocument1 pageMaterial Description Color: Reinforced Teflon® (Rptfe) Chalky WhitebondsivamaniNo ratings yet

- Fabric Expansion JointsDocument28 pagesFabric Expansion Jointswarmachine269889No ratings yet

- TomboDocument32 pagesTomboJef BudihartoNo ratings yet

- Fisher Valvula de Mariposa A41 BoletinDocument12 pagesFisher Valvula de Mariposa A41 BoletinJossi Perez ANo ratings yet

- Module-3 ME NotesDocument30 pagesModule-3 ME NotesdnalokeshNo ratings yet

- 3 A) PDS - E - JER - v4.1Document4 pages3 A) PDS - E - JER - v4.1Anish KarthikeyanNo ratings yet

- Id Number Title Year OrganizationDocument174 pagesId Number Title Year Organizationsaeedmahboob05No ratings yet

- Bearing of BridgesDocument39 pagesBearing of BridgesAbhishek100% (1)

- Dosing Pump BetaDocument4 pagesDosing Pump BetaGeorge CobraNo ratings yet

- Virgin and Filled PTFE (Teflon) New PDFDocument1 pageVirgin and Filled PTFE (Teflon) New PDFmohan115No ratings yet

- DSSV SDMDocument6 pagesDSSV SDMvishnunair27No ratings yet

- Valve Seat Seal Selection GuideDocument4 pagesValve Seat Seal Selection GuideDhim131267No ratings yet

- Transformer Temperature Monitoring System - Rugged MonitoringDocument6 pagesTransformer Temperature Monitoring System - Rugged MonitoringRugged MonitoringNo ratings yet

- Wessely GmbH-product CatalougueDocument52 pagesWessely GmbH-product CatalougueFurqan ShabbirNo ratings yet

- Yokogawa Eja 110aDocument8 pagesYokogawa Eja 110aivens94No ratings yet

- Seminar ReportDocument15 pagesSeminar ReportLikhit NaikNo ratings yet

- BUDWIG COMPLETE GUIDE, Budwig Center Natural Therapies by Budwig Center, Johanna Budwig - orDocument72 pagesBUDWIG COMPLETE GUIDE, Budwig Center Natural Therapies by Budwig Center, Johanna Budwig - orMarinel ManolacheNo ratings yet

- 34 ST 03 123Document19 pages34 ST 03 123Ricardo NapitupuluNo ratings yet

- S 000 5310 001 (Structual)Document33 pagesS 000 5310 001 (Structual)Midhun K ChandraboseNo ratings yet

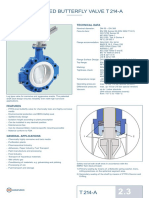

- Ptfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-ADocument6 pagesPtfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-ABobbie RuckNo ratings yet

- General Specifications: EJA110A Differential Pressure TransmitterDocument12 pagesGeneral Specifications: EJA110A Differential Pressure TransmitterWari Astuty ZNo ratings yet

- Bray B 1050 Resilient Valves 2020 08Document24 pagesBray B 1050 Resilient Valves 2020 08jacquesstrappe06No ratings yet

- Combustion and Flame: Jun Wang, Long Zhang, Yaofeng Mao, Feiyan GongDocument7 pagesCombustion and Flame: Jun Wang, Long Zhang, Yaofeng Mao, Feiyan GongKay WhiteNo ratings yet

- Catalogo Empaquetadura Trenzada MERKELDocument31 pagesCatalogo Empaquetadura Trenzada MERKELkerusacba_2011No ratings yet

- Brief DLC Presentation - ELecor PDFDocument16 pagesBrief DLC Presentation - ELecor PDFJoão TarelhoNo ratings yet

- MATLAB Solution To Microwave Engineering Pozar 4th Ed. Example 1.3Document13 pagesMATLAB Solution To Microwave Engineering Pozar 4th Ed. Example 1.3John Bofarull GuixNo ratings yet

- Chemical Compatibility TableDocument5 pagesChemical Compatibility TableMindy GuzmanNo ratings yet

- US 0926A Pot Bearing AapDocument58 pagesUS 0926A Pot Bearing AapMarco PintoNo ratings yet

- ManifoldDocument24 pagesManifoldpradeep123456No ratings yet