Professional Documents

Culture Documents

kel-f

kel-f

Uploaded by

victor ivan hernandez castelanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

kel-f

kel-f

Uploaded by

victor ivan hernandez castelanCopyright:

Available Formats

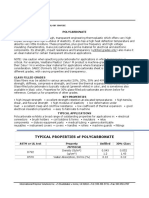

Technical Data Sheet

Kel-F (PCTFE)

(polychlorotrifluorethyene)

Kel-F is inert to chemicals and functions over a -400 degree to +400 degree F temperature range. Kel-F has excellent electri-

cal properties and may be machined to precise dimensions. It exhibits good compression, impact and tensile strength over a

wide temperature range. PCTFE is known by the trade name of Kel-F 81. This was produced by 3M but has been discontinued

since December 1995. Currently, PCTFE resin is produced by Daikin under the trade name Neoflon. Neoflon PCTFE resin has

the same chemical structure and properties as the original Kel-F® brand material. It has the same excellent performance as

PTFE in a wide range from extremely low to high temperatures. In addition, it has excellent transparency and mechanical

strength at high temperature.

TYPICAL PROPERTIES of PCTFE Benefits

ASTM or UL test Property PCTFE

Excellent chemical resistance

PHYSICAL No water absorption

Density (lb/in³) 0.077 Lowest water vapor permeability

D792

(g/cm³) 2.13 Excellent resistance to UV and X-ray

D570TYPICAL PROPERTIES Water of PCTFE 24 hrs (%)

Absorption, < 0.01 radiation.

MECHANICAL Excellent Barrier properties

ASTM or UL test Property PCTFE

D638 Tensile Strength (psi) 5,300

PHYSICAL Very low creep under load

D638 Tensile Modulus (psi)

Density (lb/in³) 0.077 207,000

D792

D638 Tensile Elongation at Break (%)

(g/cm³) 2.13 150

Non-Flammable

D570 D790 Water Absorption,Flexural

24 hrs (%) Strength (psi) < 0.01 8,500 FDA compliant

D790 MECHANICALFlexural Modulus (psi) 180,000 Good electrical insulating properties

D638 Tensile Strength (psi) 5,300

D695 Compressive Strength (psi) 5,500 Transparent

D638 Tensile Modulus (psi) 207,000

D638 D695 Tensile Elongation Compressive

at Break (%)Modulus (psi) 150 180,000

D790 D785 Flexural Strength Hardness,

(psi) Shore D 8,500 D90 Applications

D790 D256 Flexural IZOD

Modulus Notched

(psi) Impact (ft-lb/in)180,000 5 Moisture Barrier

D695 Compressive Strength THERMAL(psi) 5,500

D695 Compressive Modulus (psi) Thermal Expansion 180,000

LCD protection

Coefficient of Linear

D785 D696 Hardness, Shore 7.0 PCB Insulation

(xD10-5 in./in./°F) D90

D256 IZOD Notched Impact (ft-lb/in)

Heat Deflection Temp (°F / °C)

5 Wire and cable insulation

D648 THERMAL

at 264 psi

Coefficient of Linear Thermal Expansion

258 / 126 Phosphor coatings

D696 D3418 Melting Temp (°F / °C) 7.0 415 / 212

-5

(x 10 in./in./°F) Cryogenics

- Max Operating

Heat Deflection Temp (°F / °C) Temp (°F / °C) 270 / 132 Valves

D648

at 264 psiThermal Conductivity 258 / 126

D3418 C177 Melting Temp (°F(BTU-in/ft²-hr-°F)

/ °C) 415 / 212

Chemical tank lining

1.45

- Max Operating Temp (x 10(°F-4/cal/cm-sec-°C)

°C) 270 / 132 4.99 O-rings

UL94 Thermal Conductivity

Flammability Rating V-0 Gaskets

C177 (BTU-in/ft²-hr-°F) 1.45

-4 ELECTRICAL

(x 10 cal/cm-sec-°C) 4.99

UL94 D149 Dielectric Strength

Flammability Rating(V/mil) short time, 1/8" V-0 thick 500

D150 ELECTRICAL Dielectric Constant at 1 MHz -

D149 D150 Dielectric Strength (V/mil) short time,Factor

Dissipation 1/8" thick

at 1 MHz 500 -

D150 Dielectric Constant at 1 MHz - 18

D257 Volume Resistivity (ohm-cm)at 50% RH 10

D150 Dissipation Factor at 1 MHz -

D257 Volume Resistivity (ohm-cm)at 50% RH 1018

NOTE: The information contained herein are typical values intended for reference and

comparison purposes only. They

Shapes Available

NOTE: The information contained herein areshould

typical NOT beintended

values used as forareference

basis forand

design specifications or

comparisonquality

purposescontrol. Contact

only. They shouldusNOT

for be

manufacturers'

used as a basis complete material property

for design specifications or datasheets.

quality control. Contact us forAll values at 73°F

manufacturers' (23°C)

complete unless

material otherwise

property noted.

datasheets.

All values at 73°F (23°C) unless otherwise noted.

KEL-F is a registered trademark of 3M Company.

KEL-F is a registered trademark of 3M Company.

NEOFLON is a registered trademark of Daikin Industries.

NEOFLON is a registered trademark of Daikin Industries.

NOTE: The information contained herein are typical values intended for reference and comparison purposes only. They should NOT be

used as a basis for design specifications or quality control. Contact us for manufacturers’ complete material property datasheets.

All values at 73°F (23°C) unless otherwise noted.

You might also like

- Chromite Mining ProcessDocument2 pagesChromite Mining ProcessAndika Rizal83% (12)

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Data Sheet PPSUDocument2 pagesData Sheet PPSUluuiissNo ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- Teflon PTFE - PSG - Mechanical PropertyDocument1 pageTeflon PTFE - PSG - Mechanical PropertyGovarthanan GovaNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- Acetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Document1 pageAcetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Anonymous UcmNTu6rNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- CastacrylicDocument1 pageCastacrylicuyenNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocument1 pageVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986No ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemDocument1 pageStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanNo ratings yet

- Delrin - Mechanical PropertyDocument1 pageDelrin - Mechanical PropertyGovarthanan GovaNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsabhijitNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- PP TD20 Lotte JHC-372Document1 pagePP TD20 Lotte JHC-372Herman SujarwantoNo ratings yet

- Ptfe PDFDocument1 pagePtfe PDFXiwen CloudNo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Ethafoam Nova: Performance FoamsDocument2 pagesEthafoam Nova: Performance FoamsMina MagdyNo ratings yet

- Techtron PPS HPV & Ketron PEEK HPV SpecificationsDocument3 pagesTechtron PPS HPV & Ketron PEEK HPV SpecificationsPeterWayNo ratings yet

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Document3 pagesTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananNo ratings yet

- Tricolene LLB1918ADocument1 pageTricolene LLB1918ARoberto De Mesa PNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- Technical Data Sheet Nylon: (Polyamide)Document3 pagesTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyNo ratings yet

- Anti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeDocument1 pageAnti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeVC KannanNo ratings yet

- TDS HD T9 04052022Document2 pagesTDS HD T9 04052022tiger.patelNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- Halene - L : Technical Data SheetDocument1 pageHalene - L : Technical Data Sheetdharmendrasinh zalaNo ratings yet

- Delrin MaterialDocument2 pagesDelrin MaterialyajneshwaradixitNo ratings yet

- Delrin PDFDocument2 pagesDelrin PDFA. Kumar RaiNo ratings yet

- Delrin Mat PDFDocument2 pagesDelrin Mat PDFyajneshwaradixitNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Exelene Hdpe 5100MDocument1 pageExelene Hdpe 5100MAndres Quiroga JuarezNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- Delrin 150Document1 pageDelrin 150Sardar. Vikramjit Singh RandhawaNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- PP RANDOM Lotte - Ranpelen - J590K MI 44Document1 pagePP RANDOM Lotte - Ranpelen - J590K MI 44Luis LOZANONo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- 9803 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityDocument4 pages9803 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityAfzal ImamNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Ge Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Document2 pagesGe Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Ionut DeaconuNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- Exact 8201Document2 pagesExact 8201Kashif MuhammadNo ratings yet

- Material Spec For 6600Document1 pageMaterial Spec For 6600Namelezz ShadowwNo ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew Skillinpinchi877012No ratings yet

- TM 11-6625-3135-24P - AN - USM-488 - Oscilloscope - 1985Document62 pagesTM 11-6625-3135-24P - AN - USM-488 - Oscilloscope - 1985Wurzel1946No ratings yet

- Ombustion AND LameDocument13 pagesOmbustion AND LameSundeep GargNo ratings yet

- Metal Properties and Destructive TestingDocument84 pagesMetal Properties and Destructive Testingtuvu100% (3)

- Design and Fabrication of Cyanide Corrosive-Proof Coating Using Bitumen For Mill Plant Tailing Pipe SystemDocument53 pagesDesign and Fabrication of Cyanide Corrosive-Proof Coating Using Bitumen For Mill Plant Tailing Pipe SystemGwen Ibarra SuaybaguioNo ratings yet

- Cristallinité PBATDocument9 pagesCristallinité PBATverwan35999No ratings yet

- Panel BoardDocument6 pagesPanel BoardSherif M. ElgebalyNo ratings yet

- Iso 4997Document19 pagesIso 4997Aravind BabuNo ratings yet

- FBARDocument7 pagesFBARprabu1928No ratings yet

- Up 5604 GPDocument1 pageUp 5604 GPMena TharwatNo ratings yet

- ASTMC39Document5 pagesASTMC39Isaac NuñezNo ratings yet

- Triumph TR2, TR3, TR3ADocument456 pagesTriumph TR2, TR3, TR3Am_i_c_kNo ratings yet

- Speed Sensor and Cable Harness, Replace PDFDocument8 pagesSpeed Sensor and Cable Harness, Replace PDFEsam Phlipe0% (1)

- Engineering Materials - Mechanical Engineering Questions and AnswersDocument1 pageEngineering Materials - Mechanical Engineering Questions and AnswersEngr Primus ChinonyeNo ratings yet

- G6 Quarter 1 ScienceDocument10 pagesG6 Quarter 1 ScienceAdor IsipNo ratings yet

- PSMT Pallet and Pallet Load Requirements - Final In-CountryDocument12 pagesPSMT Pallet and Pallet Load Requirements - Final In-CountryMelissa SamarooNo ratings yet

- Special Manufacturing ProcessesDocument2 pagesSpecial Manufacturing ProcessesGopinath GangadhariNo ratings yet

- A Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Document9 pagesA Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Shreya Giri0% (1)

- DPLF Epoxy Primer: Features Compatible SurfacesDocument4 pagesDPLF Epoxy Primer: Features Compatible SurfacesRobert StarkNo ratings yet

- Short Notes Chapter 6Document2 pagesShort Notes Chapter 6alinNo ratings yet

- Electrico 777 PDFDocument2 pagesElectrico 777 PDFLaura CabarteNo ratings yet

- Cable LV PVC Cable Supreme 6Document1 pageCable LV PVC Cable Supreme 6ahmad fauzanNo ratings yet

- April 2015Document13 pagesApril 2015Pumper TraderNo ratings yet

- TDS - Protectosil CITDocument3 pagesTDS - Protectosil CITVenkata RaoNo ratings yet

- Al Mar Knives 2013 CatalogDocument20 pagesAl Mar Knives 2013 CatalogsolsysNo ratings yet

- Flame Retardant Epoxy Resin Based On Bisphenol A Epoxy ResinDocument7 pagesFlame Retardant Epoxy Resin Based On Bisphenol A Epoxy ResinGajaraj GajapathiNo ratings yet

- CSA VSD Brochure 2Document4 pagesCSA VSD Brochure 2fachjrianNo ratings yet

- Tri Seal Hub OdometerDocument2 pagesTri Seal Hub OdometerDaniel CoradoNo ratings yet

- DTC 1209Document4 pagesDTC 1209Christopher GarciaNo ratings yet