Professional Documents

Culture Documents

ur20_data_sheet

ur20_data_sheet

Uploaded by

jaalco70Copyright:

Available Formats

You might also like

- CM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NoteDocument2 pagesCM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NotemarklaforestNo ratings yet

- Group 00 M176en 2018-04Document24 pagesGroup 00 M176en 2018-04patitovera25% (4)

- Fruits and Vegetables Fourth Grade Reading Comprehension WorksheetDocument3 pagesFruits and Vegetables Fourth Grade Reading Comprehension WorksheetKesavan BalakrishnanNo ratings yet

- Ur20 Data SheetDocument1 pageUr20 Data SheetkodysNo ratings yet

- ur20_data_sheetDocument2 pagesur20_data_sheetmarc9sNo ratings yet

- Dong SeoDocument2 pagesDong Seofarroszysafana2008No ratings yet

- Lift Differnt Sze DetailDocument1 pageLift Differnt Sze Detailsumant giriNo ratings yet

- LR 5 72 HTD 560 585 M 30 30 and 15 Frame Explorer V19 5f05242ef6Document2 pagesLR 5 72 HTD 560 585 M 30 30 and 15 Frame Explorer V19 5f05242ef6Muhammad Omer PervaizNo ratings yet

- L Gi LE PM T PMD 059 F138 LR 5 72 HTH 565 585 M V2 30 30 and 15 Frame Explorer V19 Fb7474efd7Document2 pagesL Gi LE PM T PMD 059 F138 LR 5 72 HTH 565 585 M V2 30 30 and 15 Frame Explorer V19 Fb7474efd7Juan Paolo CapinNo ratings yet

- Profile 10 100x100 - ItemDocument1 pageProfile 10 100x100 - ItemZhangJiayongNo ratings yet

- Smartlase C350hdplus Ds HQ b1 Markem ImajeDocument2 pagesSmartlase C350hdplus Ds HQ b1 Markem ImajeIuri FernandesNo ratings yet

- EN-N Power Series TSBHNM-144HVG 575-595W 双面白色网格玻璃 - 海浪Document2 pagesEN-N Power Series TSBHNM-144HVG 575-595W 双面白色网格玻璃 - 海浪Christine May CagaraNo ratings yet

- Profile 8 120x120 - ItemDocument1 pageProfile 8 120x120 - ItemZhangJiayongNo ratings yet

- STC800 SanyDocument3 pagesSTC800 SanySwarup DasNo ratings yet

- Plano Piso 5 Conductos de Ventilación (Techo) LaredDocument1 pagePlano Piso 5 Conductos de Ventilación (Techo) Laredgotita55100% (1)

- Scheda Tecnica Pannelli TSHNM-108HV-415-435W-full-blackDocument2 pagesScheda Tecnica Pannelli TSHNM-108HV-415-435W-full-blackinfoNo ratings yet

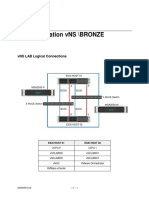

- BRONZE - VNS LAB InformationDocument6 pagesBRONZE - VNS LAB InformationClaudio SalinasNo ratings yet

- Sturaco 7098Document1 pageSturaco 7098Tudor RatiuNo ratings yet

- Inclined ConveyorDocument1 pageInclined ConveyorShaiju NarayananNo ratings yet

- E-5113 - b5 Cable Routing Plan With Mechanical Equipment OverallDocument1 pageE-5113 - b5 Cable Routing Plan With Mechanical Equipment Overallislam.mhmoudNo ratings yet

- 08 Wood Handling 9 Lines-36000 GTper DayDocument1 page08 Wood Handling 9 Lines-36000 GTper DayDeniNo ratings yet

- Flyer Robot MPX3500 EDocument4 pagesFlyer Robot MPX3500 Eamirtimes1372No ratings yet

- Sulky Linear Actuators (Six Versions)Document1 pageSulky Linear Actuators (Six Versions)Petro ServisasNo ratings yet

- Sulky Linear Actuators (Six Versions)Document1 pageSulky Linear Actuators (Six Versions)Petro ServisasNo ratings yet

- Appendix 13 5 6A 12 February 2013Document2 pagesAppendix 13 5 6A 12 February 2013Khawla EbrhimNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- 3MN0667 00 MN ARRAY 1550 M FAB ACR SERIES - CompressedDocument2 pages3MN0667 00 MN ARRAY 1550 M FAB ACR SERIES - CompressedMukhlas JauharNo ratings yet

- BMS Table-ModelDocument1 pageBMS Table-ModelGarlapati TrinadhNo ratings yet

- 0.contoh Soal Uji KompetensiDocument1 page0.contoh Soal Uji KompetensiAdhe Sri MarjukiNo ratings yet

- Vn-1977-X-8floor-Pln-5 6 7Document1 pageVn-1977-X-8floor-Pln-5 6 7Thinh NguyenNo ratings yet

- CH-SW240/2030S/D200AS: Product Data SheetDocument4 pagesCH-SW240/2030S/D200AS: Product Data Sheeticaro89No ratings yet

- Typical Arrangement: Shaft Section B-BDocument1 pageTypical Arrangement: Shaft Section B-Bsumant giriNo ratings yet

- BY1912-EL-SC-504Document1 pageBY1912-EL-SC-504nadim7862No ratings yet

- Flyer Robot Mpl300ii - 5afd8d21c6f97Document2 pagesFlyer Robot Mpl300ii - 5afd8d21c6f97Luisito Miguelito ErazoNo ratings yet

- Location MapDocument1 pageLocation MapMarc Dared CagaoanNo ratings yet

- Semhl 22 1226 - DR001Document1 pageSemhl 22 1226 - DR001BHIYA JINo ratings yet

- Mini VRF Carrier DC PD CPDocument5 pagesMini VRF Carrier DC PD CPRaul RamirezNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- Linease Actuator CAHB 22E - 17210 enDocument4 pagesLinease Actuator CAHB 22E - 17210 enAlvaro MunozNo ratings yet

- Réf. X90BPSI Supplied With Microfi Bre Pouch: Coatings Anti-Scratch, Anti-Fog, Anti-Static Ballistic LensDocument2 pagesRéf. X90BPSI Supplied With Microfi Bre Pouch: Coatings Anti-Scratch, Anti-Fog, Anti-Static Ballistic Lenskanine999No ratings yet

- Service and Repairs: X3 - X5 - X10 - X20 - X20 S Suppressor - X50 - Atac - Atac S Suppressor A30 - A30 S SuppressorDocument1 pageService and Repairs: X3 - X5 - X10 - X20 - X20 S Suppressor - X50 - Atac - Atac S Suppressor A30 - A30 S SuppressorBunyippyNo ratings yet

- 133 1st .Floor PlanDocument1 page133 1st .Floor PlanakashNo ratings yet

- +baader D ERF Dielectric Energy Rejection FiltersDocument1 page+baader D ERF Dielectric Energy Rejection FiltersJosip DASCOLINo ratings yet

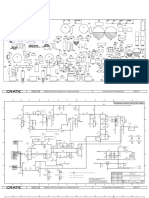

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréNo ratings yet

- Rear Elevation Left Side Elevation: A B C D 1 2 3 4Document1 pageRear Elevation Left Side Elevation: A B C D 1 2 3 4Kevin CondeNo ratings yet

- Panel 1Document1 pagePanel 1chaidir ciakNo ratings yet

- Mæt B NGDocument1 pageMæt B NGbanhbaonongNo ratings yet

- Ducting Plan As Per VendorDocument1 pageDucting Plan As Per VendorBiswanathMudiNo ratings yet

- MSL Rubber BrochureDocument33 pagesMSL Rubber BrochureInspektur Gadget100% (1)

- Intelposing Relay & Psu GaDocument1 pageIntelposing Relay & Psu GayodtosheetdigiNo ratings yet

- Tsurumi Pump Model, Model Pompa CelupDocument3 pagesTsurumi Pump Model, Model Pompa Celuparfan rijalNo ratings yet

- 01Document1 page01ARIFINNo ratings yet

- BR Lyobeta en 1117 PDFDocument6 pagesBR Lyobeta en 1117 PDFdanny diazNo ratings yet

- R580 Spec 06.30Document1 pageR580 Spec 06.30marinsservicosNo ratings yet

- Dyno Tracker para AnfoDocument2 pagesDyno Tracker para AnfoRene MoraNo ratings yet

- FuturaSun 108 390W Silk-Nova-Green ENDocument2 pagesFuturaSun 108 390W Silk-Nova-Green ENGhiban ConstantinNo ratings yet

- MVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Document1 pageMVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Yahya AteeniNo ratings yet

- Product Manual - Wires - Duraflex-10Document1 pageProduct Manual - Wires - Duraflex-10Yvan Glendell Mangune100% (1)

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- Technical Note Modbus Implementation Using 3gen DTU Pro V1.2Document33 pagesTechnical Note Modbus Implementation Using 3gen DTU Pro V1.2Cássio Marcel Corghi de CamposNo ratings yet

- Ifunny - The Best Memes, Video, Gifs and Funny Pics in One PlaceDocument1 pageIfunny - The Best Memes, Video, Gifs and Funny Pics in One PlaceFrost MourneNo ratings yet

- CHEG380 Fall 2013 Lecture #1Document9 pagesCHEG380 Fall 2013 Lecture #1hamada3434No ratings yet

- Smartclass Ethernet Tester: Download Manager and Upgrade InstructionsDocument6 pagesSmartclass Ethernet Tester: Download Manager and Upgrade InstructionsAnonymous 1OlQQ3cWNo ratings yet

- ClusterflumphDocument1 pageClusterflumphJohnNo ratings yet

- Vedant Pardeshi SYBBA 36 Business ExposureDocument61 pagesVedant Pardeshi SYBBA 36 Business ExposureSaheb RaoNo ratings yet

- Boost Internet SpeedDocument57 pagesBoost Internet SpeedSoumik MandalNo ratings yet

- Season 3 Book 1Document20 pagesSeason 3 Book 1Thái Trương0% (1)

- Sylvia WalkThrough Official September2019Document7 pagesSylvia WalkThrough Official September2019youngky100% (1)

- Solo Golden Hardcore 2.0Document6 pagesSolo Golden Hardcore 2.0elvisiprooYTNo ratings yet

- Computer Networks Group 6Document11 pagesComputer Networks Group 6Masood MughalNo ratings yet

- Drills and GamesDocument11 pagesDrills and Gamesapi-391225671No ratings yet

- 917 PaperpublishedDocument17 pages917 PaperpublishedTrixy013No ratings yet

- Sight Word Crossword PuzzleDocument1 pageSight Word Crossword PuzzleRiyanna Ehra IntalNo ratings yet

- UntitledDocument9 pagesUntitled8041Shruti JhaNo ratings yet

- Modals (Bat)Document5 pagesModals (Bat)Shayla Palao BoschNo ratings yet

- "I HEREBY RESIGN FROM NEW MUSIC" by Michael RebhahnDocument5 pages"I HEREBY RESIGN FROM NEW MUSIC" by Michael RebhahnRemy Siu100% (1)

- Delhi Public School Bangalore North (2021-2022) Topic: Light, Shadows & Reflections Answer Key Class: Vi Subject-ScienceDocument9 pagesDelhi Public School Bangalore North (2021-2022) Topic: Light, Shadows & Reflections Answer Key Class: Vi Subject-ScienceSumukh MullangiNo ratings yet

- Easy Whipped Ricotta Toast Recipe 5498683Document2 pagesEasy Whipped Ricotta Toast Recipe 5498683asia lilyNo ratings yet

- NORTHERN SKY CHORDS (Ver 2) by Nick Drake @Document3 pagesNORTHERN SKY CHORDS (Ver 2) by Nick Drake @Miss_AccountantNo ratings yet

- Materi 8 - New - Market - Leader - Elementary - Course - Book-52-63 - CH 6Document12 pagesMateri 8 - New - Market - Leader - Elementary - Course - Book-52-63 - CH 6Immanuel PaternuNo ratings yet

- Go To Market StrategyDocument10 pagesGo To Market Strategygod of thunder ThorNo ratings yet

- Ge Logic 7Document394 pagesGe Logic 7Sergio MontesNo ratings yet

- Coffee Shop Feasibility StudyDocument38 pagesCoffee Shop Feasibility StudyAca Save100% (1)

- Scent of Apples SummaryDocument2 pagesScent of Apples SummaryAldine bartolazoNo ratings yet

- Custom Meal Plan 6n892357j12dDocument20 pagesCustom Meal Plan 6n892357j12dAJ VelasquezNo ratings yet

- EVC130 User ManualDocument89 pagesEVC130 User ManualBùi Quang NamNo ratings yet

- How To Make Fried RiceDocument6 pagesHow To Make Fried RiceArya UtamaNo ratings yet

- Basketball PPTDocument10 pagesBasketball PPTLaura BaltazarNo ratings yet

ur20_data_sheet

ur20_data_sheet

Uploaded by

jaalco70Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ur20_data_sheet

ur20_data_sheet

Uploaded by

jaalco70Copyright:

Available Formats

3-Position Enabling Teach Pendant Recommended hole pattern for robot base

Features

UR20 IP classification

Humidity

IP54 water protection

≤ 90% RH (non-condensing)

95 95

30°

Display resolution 1280 x 800 pixels

Technical Specification Physical

5x

The UR20, the first of our next-generation high Materials Plastic

60°

performance cobots, has been redesigned from the Teach pendant size (W x H x D)

300 mm x 231 mm x 50 mm +0,030

8 FG8 +0,008 9,5 ±0,5

(11,8 in x 9,1 in x 1,97 in)

ground up to provide up to 30% more speed and torque,

210

Weight 1,8 kg (3.961 lbs)

advanced motion control capabilities, and first-class including 1 m of teach pendant cable +0,030

8 FG8 +0,008 x 13 9,5 ±0,5

10

user experience. Cable length 4,5 m (177,17 in)

UR cobots bring incredible versatility and unparalleled

ease of use to your applications. The UR20 is no

exception - its 20 kg payload and 1750 mm reach make it 6x 10,50 THRU ALL

an ideal match for applications ranging from palletizing Control Box

to machine loading. Mounting plate with pins for robot base

Features

Updated October 2023.

5 ±1

0,05

IP Classification IP44 water protection 8 h6 0-0,009

Humidity ≤ 90% RH (non-condensing)

I/O Ports 190

Digital In 16

Digital Out 16

Analog In 2 UR20 tool flange

Analog Out 2

UR20 Quadrature digital inputs

I/O Power Supply

4

24V, 2A

+0,015

8 H7 0 8±0,2

0,4 D E

F A

6 x M8 - 6H 10,6

0,4 D E F 17,60

General specification Features Communication 500 Hz Control frequency

6,20

20 kg (44,1 lbs) in the IP classification IP65 water protection Modbus TCP

Payload

entire workspace Noise < 65 dB(A) PROFINET, PROFIsafe

Reach 1750 mm (68,9 in) Arm mounting Any orientation (optional)

Degrees of freedom 6 rotating joints I/O Ports Ethernet/IP

4x

12 inch touchscreen with PolyScope Digital In 2

60

80

Programming

°

graphical user interface USB 2.0, USB 3.0

Digital Out 2

Power consumption (average) ROS/ROS2 driver support

Analog In 2 50 H7 56,50

Maximum power 750 W (optional, open source)

Tool I/O power supply voltage 12/24 V 80 ±0,1 SECTION A-A

Moderate operating settings 300 W 100 h8

Tool I/O power supply 2 A (Dual pin), 1 A (Single pin) Injection Molding Machine

Ambient temperature:

Operating temperature range Interface (IMMI, optional)

0-50˚C (32-122˚F)

Safety functions 17 configurable safety functions Power Source 100-240 VAC, 47-440 Hz

EN ISO 13849-1 (PLd Category 3) 201

In compliance with

and EN ISO 10218-1

Physical Physical

UR20 arm Footprint Ø 245 mm; 6 x M10, 60° Control Box Size (W x H x D) 460 mm x 449 mm x 254 mm

(18,2 in x 17,6 in x 10 in)

105 mm center

Weight 12 kg (26,5 lbs)

Performance Materials Aluminum, plastic, steel

888

Tool flange EN ISO-9409-1-80-6-M8 Materials Powder coated steel

Force sensing, tool Connector type M8 | M8 8-pin female

728,7 159,3

Force, x-y-z Torque, x-y-z

flange/torque sensor

Cable length (robot arm) 6 m (236 in)

Range 200,0 N 20,0 Nm

Weight including cable 64 kg (141,1 lbs)

Precision 5,5 N 0,2 Nm

Humidity ≤ 90% RH (non-condensing) UR20 payload curve

Accuracy 10,0 N 0,1 Nm

25

Movement

862

0

20 75

R1

Typical TPC speed 2 m/s

Payload (kg)

Pose repeatability per 15

± 0,1 mm

ISO 9283

Axis movement Working range Maximum speed

236,3

Base ± 360° ± 120˚/s Contact 10

Shoulder ± 360° ± 120˚/s 245

5

Elbow ± 360° ± 150˚/s Universal Robots A/S

Wrist 1 ± 360° ± 210˚/s Energivej 25 +45 89 93 89 89

0

Wrist 2 ± 360° ± 210˚/s 5260 Odense sales@universal-robots.com 0 100 200 300 400 500 600 700 800

Wrist 3 ± 360° ± 210˚/s Denmark universal-robots.com Center of gravity offset (mm) UNLESS OTHERWISE SPECIFIED:

Dimensions are in millimeters. Tolerance ± 0,1 mm ± 0,5˚

3-Position Enabling Teach Pendant Recommended hole pattern for robot base

Features

UR20 IP classification

Humidity

IP54 water protection

≤ 90% RH (non-condensing)

95 95

30°

Display resolution 1280 x 800 pixels

Technical Specification Physical

5x

The UR20, the first of our next-generation high Materials Plastic

60°

Teach pendant size (W x H x D) 11.8 in x 9.1 in x 1.97 in

performance cobots, has been redesigned from the +0.030

8 FG8 +0.008 9.5 ±0.5

Weight 3.961 lbs

ground up to provide up to 30% more speed and torque,

210

including 1 m of teach pendant cable

advanced motion control capabilities, and first-class Cable length 177.17 in +0.030

8 FG8 +0.008 x 13 9.5 ±0.5

10

user experience.

UR cobots bring incredible versatility and unparalleled

ease of use to your applications. The UR20 is no

exception - its 20 kg payload and 1750 mm reach make it 6x 10.50 THRU ALL

an ideal match for applications ranging from palletizing

to machine loading. Control Box Mounting plate with pins for robot base

Updated October 2023. Features

5 ±1

0.05 8 h6 0-0.009

IP Classification IP44 water protection

Humidity ≤ 90% RH (non-condensing) 190

I/O Ports

Digital In 16

Digital Out 16 UR20 tool flange

Analog In 2

UR20 Analog Out

Quadrature digital inputs

2

4

+0.015

8 H7 0 8±0.2

0.4 D E

F A

6 x M8 - 6H 10.6

0.4 D E F 17.60

General specification Features I/O Power Supply 24V, 2A

Communication 6.20

Payload 20 kg (44.1 lbs) in the IP classification IP65 water protection 500 Hz Control frequency

entire workspace Noise < 65 dB(A) Modbus TCP

Reach 68.9 in Arm mounting Any orientation PROFINET, PROFIsafe

Degrees of freedom 6 rotating joints I/O Ports (optional)

4x

Programming 12 inch touchscreen with PolyScope Digital In 2

60

Ethernet/IP 80

°

graphical user interface

Digital Out 2 USB 2.0, USB 3.0

Power consumption (average)

Analog In 2 50 H7 56.50

Maximum power 750 W ROS/ROS2 driver support

Tool I/O power supply voltage 12/24 V 80 ±0,1 SECTION A-A

Moderate operating settings 300 W (optional, open source) 100 h8

Tool I/O power supply 2 A (Dual pin), 1 A (Single pin)

Operating temperature range Ambient temperature:

Injection Molding Machine

0-50˚C (32-122˚F)

Interface (IMMI, optional)

Safety functions 17 configurable safety functions

EN ISO 13849-1 (PLd Category 3) Power Source 100-240 VAC, 47-440 Hz 201

In comliance with

and EN ISO 10218-1

Physical

Physical

UR20 arm Footprint Ø 9.65 in 6 x M10 60° 4.13 in center

Materials Aluminum, plastic, steel Control Box Size (W x H x D) 18.2 in x 17.6 in x 10 in

Performance Tool flange EN ISO-9409-1-80-6-M8 Weight 26.5 lbs

888

Connector type M8 | M8 8-pin female Materials Powder coated steel

Force sensing tool flange/ Force, x-y-z Torque, x-y-z 728.7 159.3

Cable length (robot arm) 236 in

torque sensor

Weight including cable 141.1 lbs

Range 200.0 N 20.0 Nm

Humidity ≤ 90% RH (non-condensing)

Precision 5.5 N 0.2 Nm

UR20 payload curve

Accuracy 10.0 N 0.1 Nm

25

Movement

862

0

20 75

R1

Typical TCP speed 2 m/s

Payload (kg)

Pose repeatability per 15

± 0.1 mm

ISO 9283

Axis movement Working range Maximum speed

236.3

Base ± 360° ± 120˚/s Contact 10

Shoulder ± 360° ± 120˚/s 245

5

Elbow ± 360° ± 150˚/s Universal Robots A/S

Wrist 1 ± 360° ± 210˚/s Energivej 25 +45 89 93 89 89

0

Wrist 2 ± 360° ± 210˚/s 5260 Odense sales@universal-robots.com 0 100 200 300 400 500 600 700 800

Wrist 3 ± 360° ± 210˚/s Denmark universal-robots.com Center of gravity offset (mm) UNLESS OTHERWISE SPECIFIED:

Dimensions are in millimeters. Tolerance ± 0.1 mm ± 0.5˚

You might also like

- CM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NoteDocument2 pagesCM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NotemarklaforestNo ratings yet

- Group 00 M176en 2018-04Document24 pagesGroup 00 M176en 2018-04patitovera25% (4)

- Fruits and Vegetables Fourth Grade Reading Comprehension WorksheetDocument3 pagesFruits and Vegetables Fourth Grade Reading Comprehension WorksheetKesavan BalakrishnanNo ratings yet

- Ur20 Data SheetDocument1 pageUr20 Data SheetkodysNo ratings yet

- ur20_data_sheetDocument2 pagesur20_data_sheetmarc9sNo ratings yet

- Dong SeoDocument2 pagesDong Seofarroszysafana2008No ratings yet

- Lift Differnt Sze DetailDocument1 pageLift Differnt Sze Detailsumant giriNo ratings yet

- LR 5 72 HTD 560 585 M 30 30 and 15 Frame Explorer V19 5f05242ef6Document2 pagesLR 5 72 HTD 560 585 M 30 30 and 15 Frame Explorer V19 5f05242ef6Muhammad Omer PervaizNo ratings yet

- L Gi LE PM T PMD 059 F138 LR 5 72 HTH 565 585 M V2 30 30 and 15 Frame Explorer V19 Fb7474efd7Document2 pagesL Gi LE PM T PMD 059 F138 LR 5 72 HTH 565 585 M V2 30 30 and 15 Frame Explorer V19 Fb7474efd7Juan Paolo CapinNo ratings yet

- Profile 10 100x100 - ItemDocument1 pageProfile 10 100x100 - ItemZhangJiayongNo ratings yet

- Smartlase C350hdplus Ds HQ b1 Markem ImajeDocument2 pagesSmartlase C350hdplus Ds HQ b1 Markem ImajeIuri FernandesNo ratings yet

- EN-N Power Series TSBHNM-144HVG 575-595W 双面白色网格玻璃 - 海浪Document2 pagesEN-N Power Series TSBHNM-144HVG 575-595W 双面白色网格玻璃 - 海浪Christine May CagaraNo ratings yet

- Profile 8 120x120 - ItemDocument1 pageProfile 8 120x120 - ItemZhangJiayongNo ratings yet

- STC800 SanyDocument3 pagesSTC800 SanySwarup DasNo ratings yet

- Plano Piso 5 Conductos de Ventilación (Techo) LaredDocument1 pagePlano Piso 5 Conductos de Ventilación (Techo) Laredgotita55100% (1)

- Scheda Tecnica Pannelli TSHNM-108HV-415-435W-full-blackDocument2 pagesScheda Tecnica Pannelli TSHNM-108HV-415-435W-full-blackinfoNo ratings yet

- BRONZE - VNS LAB InformationDocument6 pagesBRONZE - VNS LAB InformationClaudio SalinasNo ratings yet

- Sturaco 7098Document1 pageSturaco 7098Tudor RatiuNo ratings yet

- Inclined ConveyorDocument1 pageInclined ConveyorShaiju NarayananNo ratings yet

- E-5113 - b5 Cable Routing Plan With Mechanical Equipment OverallDocument1 pageE-5113 - b5 Cable Routing Plan With Mechanical Equipment Overallislam.mhmoudNo ratings yet

- 08 Wood Handling 9 Lines-36000 GTper DayDocument1 page08 Wood Handling 9 Lines-36000 GTper DayDeniNo ratings yet

- Flyer Robot MPX3500 EDocument4 pagesFlyer Robot MPX3500 Eamirtimes1372No ratings yet

- Sulky Linear Actuators (Six Versions)Document1 pageSulky Linear Actuators (Six Versions)Petro ServisasNo ratings yet

- Sulky Linear Actuators (Six Versions)Document1 pageSulky Linear Actuators (Six Versions)Petro ServisasNo ratings yet

- Appendix 13 5 6A 12 February 2013Document2 pagesAppendix 13 5 6A 12 February 2013Khawla EbrhimNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- 3MN0667 00 MN ARRAY 1550 M FAB ACR SERIES - CompressedDocument2 pages3MN0667 00 MN ARRAY 1550 M FAB ACR SERIES - CompressedMukhlas JauharNo ratings yet

- BMS Table-ModelDocument1 pageBMS Table-ModelGarlapati TrinadhNo ratings yet

- 0.contoh Soal Uji KompetensiDocument1 page0.contoh Soal Uji KompetensiAdhe Sri MarjukiNo ratings yet

- Vn-1977-X-8floor-Pln-5 6 7Document1 pageVn-1977-X-8floor-Pln-5 6 7Thinh NguyenNo ratings yet

- CH-SW240/2030S/D200AS: Product Data SheetDocument4 pagesCH-SW240/2030S/D200AS: Product Data Sheeticaro89No ratings yet

- Typical Arrangement: Shaft Section B-BDocument1 pageTypical Arrangement: Shaft Section B-Bsumant giriNo ratings yet

- BY1912-EL-SC-504Document1 pageBY1912-EL-SC-504nadim7862No ratings yet

- Flyer Robot Mpl300ii - 5afd8d21c6f97Document2 pagesFlyer Robot Mpl300ii - 5afd8d21c6f97Luisito Miguelito ErazoNo ratings yet

- Location MapDocument1 pageLocation MapMarc Dared CagaoanNo ratings yet

- Semhl 22 1226 - DR001Document1 pageSemhl 22 1226 - DR001BHIYA JINo ratings yet

- Mini VRF Carrier DC PD CPDocument5 pagesMini VRF Carrier DC PD CPRaul RamirezNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- Linease Actuator CAHB 22E - 17210 enDocument4 pagesLinease Actuator CAHB 22E - 17210 enAlvaro MunozNo ratings yet

- Réf. X90BPSI Supplied With Microfi Bre Pouch: Coatings Anti-Scratch, Anti-Fog, Anti-Static Ballistic LensDocument2 pagesRéf. X90BPSI Supplied With Microfi Bre Pouch: Coatings Anti-Scratch, Anti-Fog, Anti-Static Ballistic Lenskanine999No ratings yet

- Service and Repairs: X3 - X5 - X10 - X20 - X20 S Suppressor - X50 - Atac - Atac S Suppressor A30 - A30 S SuppressorDocument1 pageService and Repairs: X3 - X5 - X10 - X20 - X20 S Suppressor - X50 - Atac - Atac S Suppressor A30 - A30 S SuppressorBunyippyNo ratings yet

- 133 1st .Floor PlanDocument1 page133 1st .Floor PlanakashNo ratings yet

- +baader D ERF Dielectric Energy Rejection FiltersDocument1 page+baader D ERF Dielectric Energy Rejection FiltersJosip DASCOLINo ratings yet

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréNo ratings yet

- Rear Elevation Left Side Elevation: A B C D 1 2 3 4Document1 pageRear Elevation Left Side Elevation: A B C D 1 2 3 4Kevin CondeNo ratings yet

- Panel 1Document1 pagePanel 1chaidir ciakNo ratings yet

- Mæt B NGDocument1 pageMæt B NGbanhbaonongNo ratings yet

- Ducting Plan As Per VendorDocument1 pageDucting Plan As Per VendorBiswanathMudiNo ratings yet

- MSL Rubber BrochureDocument33 pagesMSL Rubber BrochureInspektur Gadget100% (1)

- Intelposing Relay & Psu GaDocument1 pageIntelposing Relay & Psu GayodtosheetdigiNo ratings yet

- Tsurumi Pump Model, Model Pompa CelupDocument3 pagesTsurumi Pump Model, Model Pompa Celuparfan rijalNo ratings yet

- 01Document1 page01ARIFINNo ratings yet

- BR Lyobeta en 1117 PDFDocument6 pagesBR Lyobeta en 1117 PDFdanny diazNo ratings yet

- R580 Spec 06.30Document1 pageR580 Spec 06.30marinsservicosNo ratings yet

- Dyno Tracker para AnfoDocument2 pagesDyno Tracker para AnfoRene MoraNo ratings yet

- FuturaSun 108 390W Silk-Nova-Green ENDocument2 pagesFuturaSun 108 390W Silk-Nova-Green ENGhiban ConstantinNo ratings yet

- MVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Document1 pageMVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Yahya AteeniNo ratings yet

- Product Manual - Wires - Duraflex-10Document1 pageProduct Manual - Wires - Duraflex-10Yvan Glendell Mangune100% (1)

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- Technical Note Modbus Implementation Using 3gen DTU Pro V1.2Document33 pagesTechnical Note Modbus Implementation Using 3gen DTU Pro V1.2Cássio Marcel Corghi de CamposNo ratings yet

- Ifunny - The Best Memes, Video, Gifs and Funny Pics in One PlaceDocument1 pageIfunny - The Best Memes, Video, Gifs and Funny Pics in One PlaceFrost MourneNo ratings yet

- CHEG380 Fall 2013 Lecture #1Document9 pagesCHEG380 Fall 2013 Lecture #1hamada3434No ratings yet

- Smartclass Ethernet Tester: Download Manager and Upgrade InstructionsDocument6 pagesSmartclass Ethernet Tester: Download Manager and Upgrade InstructionsAnonymous 1OlQQ3cWNo ratings yet

- ClusterflumphDocument1 pageClusterflumphJohnNo ratings yet

- Vedant Pardeshi SYBBA 36 Business ExposureDocument61 pagesVedant Pardeshi SYBBA 36 Business ExposureSaheb RaoNo ratings yet

- Boost Internet SpeedDocument57 pagesBoost Internet SpeedSoumik MandalNo ratings yet

- Season 3 Book 1Document20 pagesSeason 3 Book 1Thái Trương0% (1)

- Sylvia WalkThrough Official September2019Document7 pagesSylvia WalkThrough Official September2019youngky100% (1)

- Solo Golden Hardcore 2.0Document6 pagesSolo Golden Hardcore 2.0elvisiprooYTNo ratings yet

- Computer Networks Group 6Document11 pagesComputer Networks Group 6Masood MughalNo ratings yet

- Drills and GamesDocument11 pagesDrills and Gamesapi-391225671No ratings yet

- 917 PaperpublishedDocument17 pages917 PaperpublishedTrixy013No ratings yet

- Sight Word Crossword PuzzleDocument1 pageSight Word Crossword PuzzleRiyanna Ehra IntalNo ratings yet

- UntitledDocument9 pagesUntitled8041Shruti JhaNo ratings yet

- Modals (Bat)Document5 pagesModals (Bat)Shayla Palao BoschNo ratings yet

- "I HEREBY RESIGN FROM NEW MUSIC" by Michael RebhahnDocument5 pages"I HEREBY RESIGN FROM NEW MUSIC" by Michael RebhahnRemy Siu100% (1)

- Delhi Public School Bangalore North (2021-2022) Topic: Light, Shadows & Reflections Answer Key Class: Vi Subject-ScienceDocument9 pagesDelhi Public School Bangalore North (2021-2022) Topic: Light, Shadows & Reflections Answer Key Class: Vi Subject-ScienceSumukh MullangiNo ratings yet

- Easy Whipped Ricotta Toast Recipe 5498683Document2 pagesEasy Whipped Ricotta Toast Recipe 5498683asia lilyNo ratings yet

- NORTHERN SKY CHORDS (Ver 2) by Nick Drake @Document3 pagesNORTHERN SKY CHORDS (Ver 2) by Nick Drake @Miss_AccountantNo ratings yet

- Materi 8 - New - Market - Leader - Elementary - Course - Book-52-63 - CH 6Document12 pagesMateri 8 - New - Market - Leader - Elementary - Course - Book-52-63 - CH 6Immanuel PaternuNo ratings yet

- Go To Market StrategyDocument10 pagesGo To Market Strategygod of thunder ThorNo ratings yet

- Ge Logic 7Document394 pagesGe Logic 7Sergio MontesNo ratings yet

- Coffee Shop Feasibility StudyDocument38 pagesCoffee Shop Feasibility StudyAca Save100% (1)

- Scent of Apples SummaryDocument2 pagesScent of Apples SummaryAldine bartolazoNo ratings yet

- Custom Meal Plan 6n892357j12dDocument20 pagesCustom Meal Plan 6n892357j12dAJ VelasquezNo ratings yet

- EVC130 User ManualDocument89 pagesEVC130 User ManualBùi Quang NamNo ratings yet

- How To Make Fried RiceDocument6 pagesHow To Make Fried RiceArya UtamaNo ratings yet

- Basketball PPTDocument10 pagesBasketball PPTLaura BaltazarNo ratings yet