Professional Documents

Culture Documents

38_7-PDF_NSRs-2021-Final-Publication

38_7-PDF_NSRs-2021-Final-Publication

Uploaded by

trungCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

38_7-PDF_NSRs-2021-Final-Publication

38_7-PDF_NSRs-2021-Final-Publication

Uploaded by

trungCopyright:

Available Formats

Supporting Documentation, Forms or Reference for Section 8.

3:

• www.aiag.org

• APQP and Current Production Cycle Forms – located on Nexteer.com, Suppliers, Quality Processes:

http://www.nexteer.com/quality-processes/

• Global Sample and PPAP Label – Located on Nexteer.com, Suppliers, Quality Processes:

http://www.nexteer.com/shipping-labeling-processes/

• AIAG Production Part Approval Process (PPAP) manual, AIAG Service Production Part Approval Process (Service

PPAP) manual.

8.4 Control of Externally Provided Processes, Products and Services

8.4.1 General

8.4.1.1 General – Supplemental

No Nexteer specific requirements for this section

8.4.1.2 Supplier Selection Process

The supplier shall be responsible for the quality of the parts it produces, their sub-supplier’s quality and

delivery performance, and subcontracted services, including sub-suppliers directed by Nexteer.

When the supplier determines incoming inspection of sub-supplier material is necessary, this activity

shall be consistent with the risk and quality impact of the supplier. These inspections shall include

variable data where appropriate and be used as a key indicator for sub-supplier quality management.

Where high risk has been identified in the sub-contracted process, the supplier shall ensure

containment is in place to protect the customer. For incoming receiving and inspection, the acceptance

level shall be zero defects.

Suppliers are responsible to select sub-suppliers (e. g. Heat Treat, Plating) based on the expectation

of Zero Defects, and on the sub-supplier’s capability to continually maintain robust processes

throughout the life of the product that meet all Nexteer’s product requirements.

The Manufacturing Capability Assessment is available as a tool to assist in the selection and evaluation

of sub-suppliers. The Nexteer Supplier Quality Engineer may elect to participate in sub-supplier on site

visits and/or audits. The AIAG CQI-19, Sub-tier Supplier Management Process Guideline, should be

used as a tool for quality system development of a sub-supplier. The CQI-8, Layered Process Audit

Guideline may also be used for sub tier supplier QMS development.

CQI-9, CQI-11, CQI-12, CQI-14, CQI-15, CQI-17, CQI-23, and CQI-27 shall apply to any sub-tier

suppliers in the value stream. Suppliers are required to review and update their suppliers’ assessments

on an annual basis.

Suppliers should seek any additional expertise that is necessary, based on the particular sub-

processing technology to ensure they are able to select a capable supplier and ensure on-going

performance.

The Supplier shall complete a financial assessment of their supply chain at a minimum annually to

evaluate and mitigate risk in the supply chain. The supplier shall be required to supply evidence of this

evaluation upon request.

38

You might also like

- Qualification of Equipment - A Risk-Based ApproachDocument6 pagesQualification of Equipment - A Risk-Based ApproachJorge Humberto Herrera100% (9)

- Vendor Selection and Evaluation PDFDocument3 pagesVendor Selection and Evaluation PDFJayant Kumar Jha100% (1)

- QA QC PresentationDocument109 pagesQA QC Presentationklibi89% (9)

- Supplier Audit ProcedureDocument4 pagesSupplier Audit Proceduresakshi patil100% (2)

- Pass Through CharacteristicsDocument10 pagesPass Through CharacteristicsmirosekNo ratings yet

- Microcontroller Lab ManualDocument127 pagesMicrocontroller Lab Manualsiri.pogula100% (2)

- Building An Effective Supplier Control Program:: A Review of Key Program Elements & Their ImplementationDocument37 pagesBuilding An Effective Supplier Control Program:: A Review of Key Program Elements & Their Implementationmulyana-No ratings yet

- Supplier Quality System AssessmentDocument47 pagesSupplier Quality System Assessmentmehdi810No ratings yet

- Vendor Audit Question Air ReDocument10 pagesVendor Audit Question Air ReMohit Saxena100% (1)

- QAF-080 Supplier Requirement Manual 03-20-09 Rev PDocument38 pagesQAF-080 Supplier Requirement Manual 03-20-09 Rev PJesus SanchezNo ratings yet

- The Addendum 2 Brings Changes To The Following Sections of API Spec Q1Document4 pagesThe Addendum 2 Brings Changes To The Following Sections of API Spec Q1Shahnawaz PathanNo ratings yet

- 42_7-PDF_NSRs-2021-Final-PublicationDocument1 page42_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- Clasues Applicale IATF 16949 REQUIREMENTS FOR PURCHASING DEPARTMENTDocument5 pagesClasues Applicale IATF 16949 REQUIREMENTS FOR PURCHASING DEPARTMENTVeni NaidooNo ratings yet

- 1.2 CG4355 GM 1927 03 Sub Tier Supplier Management Rev 7Document5 pages1.2 CG4355 GM 1927 03 Sub Tier Supplier Management Rev 7Salvador Molina100% (1)

- Vendor Selection in Pharmaceutical Industry: by Aqsa Fatima M.Pharmacy 2 Semester Sultan Ul Uloom Colllege of PharmacyDocument30 pagesVendor Selection in Pharmaceutical Industry: by Aqsa Fatima M.Pharmacy 2 Semester Sultan Ul Uloom Colllege of PharmacyKaushlendra SinghNo ratings yet

- Automotive Auditor TrainingDocument46 pagesAutomotive Auditor TrainingJoherNo ratings yet

- Aptiv Customer Specific Requirements June 20th 2022Document15 pagesAptiv Customer Specific Requirements June 20th 2022Hosam Elden Mostafa MasaranyNo ratings yet

- Supplier Selection by KetanDocument37 pagesSupplier Selection by KetanKetan PatelNo ratings yet

- SG Supplier Quality ManualDocument16 pagesSG Supplier Quality ManualrafecarNo ratings yet

- 1 GM 1927-03 Statement of Requirements For Sub-Tier Supplier Management (CG4355)Document6 pages1 GM 1927-03 Statement of Requirements For Sub-Tier Supplier Management (CG4355)Salvador MolinaNo ratings yet

- GTC Annex 1 Quality Requirements R3 Eng 180501 01Document9 pagesGTC Annex 1 Quality Requirements R3 Eng 180501 01Chiheb GNo ratings yet

- Supplier Manual: Table of ContentsDocument10 pagesSupplier Manual: Table of Contentspeyush kumar mehtoNo ratings yet

- Supplier Quality ManualDocument29 pagesSupplier Quality Manualppanambo100% (2)

- Waupaca_Foundry_Supplier_ManualDocument19 pagesWaupaca_Foundry_Supplier_Manualthamizhsrini21No ratings yet

- Quality Assurance Manual - MN Fashion - OCSDocument72 pagesQuality Assurance Manual - MN Fashion - OCSHadee SaberNo ratings yet

- Supplier Quality Statement of RequirementsDocument9 pagesSupplier Quality Statement of RequirementsKarely HuertaNo ratings yet

- Functional Assurance TablesDocument6 pagesFunctional Assurance Tables44abcNo ratings yet

- Aptive Customer Specific RequirementsDocument13 pagesAptive Customer Specific RequirementsyatheendravarmaNo ratings yet

- Customer Specific RequirementsDocument13 pagesCustomer Specific RequirementsSenthil_KNo ratings yet

- Best Practices in Supplier Quality ManagementDocument4 pagesBest Practices in Supplier Quality ManagementAnonymous 3tOWlL6L0UNo ratings yet

- Qop 74 02Document3 pagesQop 74 02Ajay SivaramanNo ratings yet

- 40_7-PDF_NSRs-2021-Final-PublicationDocument1 page40_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- Supplier Parts Quality ManualDocument41 pagesSupplier Parts Quality Manualkyu999950% (2)

- Supplier Quality ManualDocument24 pagesSupplier Quality Manualshobhit2310100% (1)

- Cma Cable Supplier Quality ManualDocument26 pagesCma Cable Supplier Quality ManualtimkoidNo ratings yet

- QMS 050 SampleDocument2 pagesQMS 050 SampleMostafa FawzyNo ratings yet

- APQPDocument2 pagesAPQPdanielsasikumarNo ratings yet

- AS9145 - Easy GuideDocument16 pagesAS9145 - Easy Guidemizar.g91No ratings yet

- Supplier Quality Manual Rev FDocument23 pagesSupplier Quality Manual Rev Fisrael afolayan mayomiNo ratings yet

- Lead Auditors Training CourseDocument94 pagesLead Auditors Training CourseCherryRoseSaguinsin100% (5)

- Supplier Quality Manual - Edition 3 - April 2010Document14 pagesSupplier Quality Manual - Edition 3 - April 2010sosobigmanNo ratings yet

- Vendor Rating and Buyer Vendor RelationsDocument9 pagesVendor Rating and Buyer Vendor Relationsricha_yaduvanshiNo ratings yet

- Quality ManagmentDocument19 pagesQuality ManagmentVenkat MuraliNo ratings yet

- F1021 PPAP Check List Instructions 04JN18Document9 pagesF1021 PPAP Check List Instructions 04JN18Sharmad TamhaneNo ratings yet

- Quality ManualDocument37 pagesQuality ManualSalil BiswasNo ratings yet

- 41_7-PDF_NSRs-2021-Final-PublicationDocument1 page41_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- Question 2 Supplier Quality Management AssignmentDocument8 pagesQuestion 2 Supplier Quality Management AssignmentABDULLAH BIN SHAFUDIN STUDENTNo ratings yet

- Global Supplier Quality Manual: Revision 5Document14 pagesGlobal Supplier Quality Manual: Revision 5Avinash SilimkarNo ratings yet

- Automating The Supplier Corrective Action Request Lyons Quality Audit Tracking SystemDocument9 pagesAutomating The Supplier Corrective Action Request Lyons Quality Audit Tracking SystemLyons Information SystemsNo ratings yet

- Vendor Qualification ProcDocument3 pagesVendor Qualification ProcSa Ra100% (1)

- Global Supplier Quality Manual 02-18-2020Document13 pagesGlobal Supplier Quality Manual 02-18-2020Emre TekinNo ratings yet

- CFUSA Supplier HandbookDocument24 pagesCFUSA Supplier HandbookBrenda GillNo ratings yet

- Resume Abhishek SqaDocument4 pagesResume Abhishek SqaMinakshi MishraNo ratings yet

- Gip 1Document29 pagesGip 1miladrahimianNo ratings yet

- Minimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFDocument9 pagesMinimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFFer Jesus Nieves UribeNo ratings yet

- PPAP - Production Part Approval Process - Quality-OneDocument7 pagesPPAP - Production Part Approval Process - Quality-OneVarun RaoNo ratings yet

- FDA Guidance Part 6Document7 pagesFDA Guidance Part 6Thrinath KumarNo ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Corrective Action and Preventive Action (CAPA) in Pharmaceutical IndustryFrom EverandCorrective Action and Preventive Action (CAPA) in Pharmaceutical IndustryNo ratings yet

- Plantwide Control: Recent Developments and ApplicationsFrom EverandPlantwide Control: Recent Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- 3_7-PDF_T-QA029Document1 page3_7-PDF_T-QA029trungNo ratings yet

- 36_7-PDF_NSRs-2021-Final-PublicationDocument1 page36_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- 5_7-PDF_T-QA029Document1 page5_7-PDF_T-QA029trungNo ratings yet

- 26_7-PDF_NSRs-2021-Final-PublicationDocument1 page26_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- 21_7-PDF_NSRs-2021-Final-PublicationDocument1 page21_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- 35_7-PDF_NSRs-2021-Final-PublicationDocument1 page35_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 pagesDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNo ratings yet

- 25_7-PDF_NSRs-2021-Final-PublicationDocument1 page25_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- 22_7-PDF_NSRs-2021-Final-PublicationDocument1 page22_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- 12_7-PDF_NSRs-2021-Final-PublicationDocument1 page12_7-PDF_NSRs-2021-Final-PublicationtrungNo ratings yet

- Landscape of Planning Activity Ver. 04: Core PhaseDocument1 pageLandscape of Planning Activity Ver. 04: Core PhasetrungNo ratings yet

- Identification of Certified Material After ComplaintDocument1 pageIdentification of Certified Material After ComplainttrungNo ratings yet

- Immediate Measures (Within 1 Working Day) Information Sheet 8D-Reporting" Immediate Measures (Within 1 Working Day) Information Sheet 8D-Reporting"Document2 pagesImmediate Measures (Within 1 Working Day) Information Sheet 8D-Reporting" Immediate Measures (Within 1 Working Day) Information Sheet 8D-Reporting"trungNo ratings yet

- Waiver of Reference Samples: German English Russian ChineseDocument1 pageWaiver of Reference Samples: German English Russian ChinesetrungNo ratings yet

- F2.31B Identification of PrototypesDocument1 pageF2.31B Identification of PrototypestrungNo ratings yet

- APQP GoodDocument70 pagesAPQP Goodtrung100% (1)

- History of Telecom & ElectronicsDocument90 pagesHistory of Telecom & ElectronicsRajuraji100% (1)

- Hec Boq SubconDocument25 pagesHec Boq SubconSHRIYA POWERNo ratings yet

- Ace Plast Ram Bs2Document1 pageAce Plast Ram Bs2pulakjaiswal85No ratings yet

- Cabinet Simulators For AllDocument12 pagesCabinet Simulators For AllDimasAnandaPutraNo ratings yet

- Is 4082 1996 PDFDocument17 pagesIs 4082 1996 PDFNatarajan SaravananNo ratings yet

- RICOH FX 16 Service ManualDocument160 pagesRICOH FX 16 Service ManualNenad SikimićNo ratings yet

- Replacing Nintendo DS Lite Touchscreen: Written By: Matt NewsomDocument13 pagesReplacing Nintendo DS Lite Touchscreen: Written By: Matt Newsomdp500No ratings yet

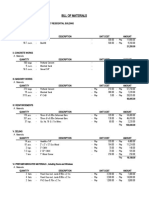

- Bill of MaterialsDocument3 pagesBill of MaterialsRany YambaoNo ratings yet

- 3.0 Roof: Building Technology (EG 626 CE)Document14 pages3.0 Roof: Building Technology (EG 626 CE)Romharsh OliNo ratings yet

- 002 Sax in The CityDocument1 page002 Sax in The CityMarc StepmanNo ratings yet

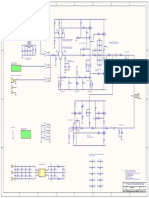

- El FF TD 01Document2 pagesEl FF TD 01Masood Alam FarooquiNo ratings yet

- Learn To Fly RC Airplanes Rev1.2Document65 pagesLearn To Fly RC Airplanes Rev1.2Glendula100% (1)

- GA 75L VSD Plus Pack Metric Dimension Drawing Antwerp 9820300117-01 Ed05Document1 pageGA 75L VSD Plus Pack Metric Dimension Drawing Antwerp 9820300117-01 Ed05marcoNo ratings yet

- Presented By:: Pranay Diwakar EC-3 Yr 0802931062Document20 pagesPresented By:: Pranay Diwakar EC-3 Yr 0802931062Arjun AryaNo ratings yet

- FMEA TemplateDocument54 pagesFMEA TemplateKaty SanchezNo ratings yet

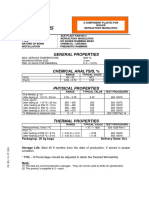

- Msds Energol THB 46Document5 pagesMsds Energol THB 46Teguh SNo ratings yet

- Technical Test Fuze MT XM-595Document46 pagesTechnical Test Fuze MT XM-595Indiodyc69No ratings yet

- Hart Communication ProtocolDocument12 pagesHart Communication ProtocolZujali ValopiNo ratings yet

- Prime Web Brochure PDFDocument14 pagesPrime Web Brochure PDFDnyaneshwar ChincholikarNo ratings yet

- Cambio Rapido Lado Robot AsrDocument1 pageCambio Rapido Lado Robot AsrHIDRAFLUIDNo ratings yet

- How To Disassemble Dell Studio 1555 Laptop - Inside My LaptopDocument22 pagesHow To Disassemble Dell Studio 1555 Laptop - Inside My Laptopizharmn4067No ratings yet

- Moving Magnet Rev 3Document1 pageMoving Magnet Rev 3Onet DorelNo ratings yet

- QGD37风冷外形图Document1 pageQGD37风冷外形图RUN GONo ratings yet

- Annual Report Analysis For FMCG CompaniesDocument5 pagesAnnual Report Analysis For FMCG CompaniesJyoti GuptaNo ratings yet

- BUS 352 AID Peer EducatorDocument17 pagesBUS 352 AID Peer Educatorbase6No ratings yet

- Hydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDocument1 pageHydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDuc NguyenNo ratings yet

- Taax TranscriptDocument1 pageTaax TranscriptmichaelNo ratings yet

- BCH/SX Hoses and Fittings: EMEA Distribution ProgramDocument20 pagesBCH/SX Hoses and Fittings: EMEA Distribution Programhoussem houssemNo ratings yet

- Yearly Plan Form 1 IctlDocument9 pagesYearly Plan Form 1 IctlrokhmahisahakNo ratings yet