Professional Documents

Culture Documents

steam boiler

steam boiler

Uploaded by

Muhamad YousafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

steam boiler

steam boiler

Uploaded by

Muhamad YousafCopyright:

Available Formats

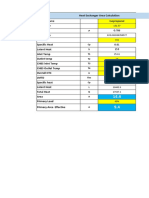

E-01 calculations

Steam Boiler

Fluid allocation

Tube side Hot Fluid

Shell side Cold Fluid

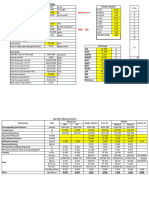

Shell side data

mass flow rate 331 lb/hr 150.139253 kg/hr

Temperature in 100 Deg. F 37.7777778 Deg. C

Pressure 300 psig 2068.428 kPa

Cp 0.537 Btu/lb.F 2248.31776 J/kg.C

Viscosity 0.0222 cP 0.0000222 Pa.s

k 0.0298 Btu/hr.ft.F 0.0515761 W/m.C

Temperature out 420 Deg. F 215.555556 Deg. C

Tube side data

mass flow rate 747 lb/hr 338.833903 kg/hr

Temperature in 662 Deg. F 350 Deg. C

Pressure 300 psig 2068.428 kPa

Cp 0.436 Btu/lb.F 1825.4498 J/kg.C

Viscosity 0.0247 cP 0.0000247 Pa.s

k 0.0547 Btu/hr.ft.F 0.09467156 W/m.C

Temperature out 542 Deg. F 283.333333 Deg. C

Tube Shell

Tin 350 37.7777777778 C

Tout 283.333333 215.555555556 C

DT1 245.555556

DT2 134.444444

LMTD 184.455922 C

Heat Transfer calculation

Q 41234952 Watt 41234.95 kW 140.699496 MMBtu/hr

Assume

Ud 1350 kJ/hr.m2.K 375 W/m2.K

Heat transfer area 596.13088909 m2

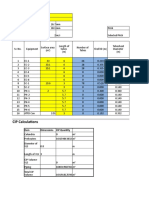

Tube side Specifications

Consider 1(1/2)" 18BWG tubes

OD 1.498 in 0.038049 m

ID 1.4 in 0.03556 m

Pitch 2 in 0.0508 m

L 18 ft 5.4864 m

Tube passes 2

Nt 200

Visc. Tube si 0.0000247 Pa.s 0.08892 Pa.h

Flow area of one tube Af 0.000993 m2

Total flow area 0.099315 m2

mass velocity 3411.724 kg/h.m2

Re 53715.85 (turbulent flow)

ht 159.946548 W/m2.K

Shell side specifications

Flowrate on shell side 150.14 kg/hr

Viscosity 0.0222 cP 0.07992 Pa.h

Shell diameter 24 in 0.6096 m

Baffle spacing 14 in 0.3556 m

Clearance 0.25 in 0.00635 m

Deq 1.49580655829 m

Flow area 0.02709672 m2

Mass velocity 5,540.86 kg/h.m2

Re 42,263.65 Turbulent

hs 133.36 W/m2.K

Check:

Uc 72.7235081554 W/m2.K

0.00088

Ud 68.3493746098 W/m2.K

You might also like

- Fire Tube Boiler DesignDocument3 pagesFire Tube Boiler DesignRajendraNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- Battery area (on stream 1)Document2 pagesBattery area (on stream 1)Muhamad YousafNo ratings yet

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDocument12 pagesA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- Desing of HEDocument25 pagesDesing of HEmeetNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Perhitungan Dan Disain HeaterDocument19 pagesPerhitungan Dan Disain HeatersehonoNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Helical Super Heater DesignDocument13 pagesHelical Super Heater DesignG S DeshpandeNo ratings yet

- MeOH CondenserDocument3 pagesMeOH CondenserShivam PandyaNo ratings yet

- Error 10% Ok: TP TP 2 2 EDocument1 pageError 10% Ok: TP TP 2 2 EWicky0% (1)

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNo ratings yet

- Design Case - A-SH1-45Document1 pageDesign Case - A-SH1-45Rufus D SNo ratings yet

- WOrd TADocument61 pagesWOrd TAFaizal AdityaNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- Secondary SH SummaryDocument2 pagesSecondary SH SummaryRufus D SNo ratings yet

- By DR Reyad: Grafik (Y - Z)Document22 pagesBy DR Reyad: Grafik (Y - Z)Reza SaifulNo ratings yet

- Calculation of Heat Transfer Coefficients in Agitated VesselsDocument4 pagesCalculation of Heat Transfer Coefficients in Agitated Vesselsdesignselva100% (1)

- Mixer MelterDocument28 pagesMixer MelterLendy KartikiNo ratings yet

- Condenser DesignDocument25 pagesCondenser DesignmohsinziaNo ratings yet

- IPA HeaterDocument14 pagesIPA HeaterNitin KurupNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Heat BalanceDocument33 pagesHeat BalanceIrshad Hussain100% (2)

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Vessel NewDocument16 pagesVessel NewakshaybhuranNo ratings yet

- Calculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesDocument3 pagesCalculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesBagadi AvinashNo ratings yet

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 pagesHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyNo ratings yet

- Heat Requirement Calculations For ReepDocument8 pagesHeat Requirement Calculations For ReeplkchoudhuryNo ratings yet

- The correct mean ΔTDocument4 pagesThe correct mean ΔTManoj ManivasagamNo ratings yet

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- Steam Coil SizingDocument21 pagesSteam Coil SizingMildogg100% (1)

- PAP 2 DISTILASI PACKED IYAH DKKDocument254 pagesPAP 2 DISTILASI PACKED IYAH DKKRifah Rizkiyah HasibuanNo ratings yet

- Hot Gas Recuperator Specification SheetDocument1 pageHot Gas Recuperator Specification Sheetmjaric81No ratings yet

- Water CirculationDocument22 pagesWater CirculationjehadyamNo ratings yet

- Evaporator DesignDocument1 pageEvaporator DesignNaqqash SajidNo ratings yet

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- Calculation Sheet V1Document14 pagesCalculation Sheet V1Muhammad Umer RanaNo ratings yet

- Crude Oil Storage Tank Heating CoilDocument3 pagesCrude Oil Storage Tank Heating CoilbadelitamariusNo ratings yet

- LAMPIRAN C Spesifikasi PeralatanDocument89 pagesLAMPIRAN C Spesifikasi PeralatanRahmaisa HarahapNo ratings yet

- Book 2Document15 pagesBook 2futhanul weweNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Lampiran 1: Perhitungan Nilai RD Dan Pressure Drop DesainDocument21 pagesLampiran 1: Perhitungan Nilai RD Dan Pressure Drop DesainAdiyat AdiNo ratings yet

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Gas Flow Rate Mass Flow Mol Flow Gas Volume FlowDocument9 pagesGas Flow Rate Mass Flow Mol Flow Gas Volume FlownivethithaNo ratings yet

- Unut Conversion 2Document1 pageUnut Conversion 2Vincent SangNo ratings yet

- Pressur Drop Calculation For DS Unit Vessels With F ProductsDocument9 pagesPressur Drop Calculation For DS Unit Vessels With F ProductsMaryam vafaee.nNo ratings yet

- Unit Conversion Table.Document1 pageUnit Conversion Table.muthukumarm4023No ratings yet

- IPA PreheaterDocument9 pagesIPA PreheaterNitin KurupNo ratings yet

- Flash CalculationsDocument10 pagesFlash CalculationsHamza AliNo ratings yet

- TRVDocument3 pagesTRVbadelitamariusNo ratings yet

- Densitas Li Compone NtsDocument6 pagesDensitas Li Compone NtsReskiNo ratings yet

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossNo ratings yet

- Calculations For Heat Exchanger, CIP & ATFD (Master Copy)Document21 pagesCalculations For Heat Exchanger, CIP & ATFD (Master Copy)saurabhzalte100% (1)

- 5TR CondenserDocument1 page5TR CondenserbevarsiNo ratings yet

- HydraulicDocument10 pagesHydraulicjema.jampit.cocNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- Solver for CoefficientDocument3 pagesSolver for CoefficientLuqman Al-MinawyNo ratings yet

- Kinetic Reactor Ejercicio..Document1 pageKinetic Reactor Ejercicio..Emanuel SalinasNo ratings yet

- Tube Rating: Properties of Fluid Inside TubeDocument4 pagesTube Rating: Properties of Fluid Inside Tubesiti_zubaidah_37No ratings yet

- Pierre Sagaut, Sebastien Deck, Marc Terracol - Multiscale and Multiresolution Approaches in Turbulence - LES, DES and Hybrid RANS_LES Methods_ Applications and Guidelines (2013, Imperial College Press)Document446 pagesPierre Sagaut, Sebastien Deck, Marc Terracol - Multiscale and Multiresolution Approaches in Turbulence - LES, DES and Hybrid RANS_LES Methods_ Applications and Guidelines (2013, Imperial College Press)kesavaero1No ratings yet

- Workshop Practical Globe ValveDocument5 pagesWorkshop Practical Globe Valvethakurdeependra6969No ratings yet

- Explicit Friction Factor Accuracy and Computational Efficiency For Turbulent Flow in PipesDocument27 pagesExplicit Friction Factor Accuracy and Computational Efficiency For Turbulent Flow in PipesJoão Rubens MartinsNo ratings yet

- Act1 2Document3 pagesAct1 2dracarysNo ratings yet

- Application of CFD For Torpedo Hydrodynamics: Presented By: Mohit Nigam, SC-B, CFD Division, HR Wing, NSTLDocument29 pagesApplication of CFD For Torpedo Hydrodynamics: Presented By: Mohit Nigam, SC-B, CFD Division, HR Wing, NSTLHN DasNo ratings yet

- Jan 2006 Fluid FlowDocument15 pagesJan 2006 Fluid Flownurfara39No ratings yet

- CC Giacomini Bola FMDocument2 pagesCC Giacomini Bola FMMaisonNo ratings yet

- The Size of CombustorDocument3 pagesThe Size of Combustorzia_ghiasiNo ratings yet

- SK330 Trouble Shoot (By Trouble)Document36 pagesSK330 Trouble Shoot (By Trouble)ferdyak1No ratings yet

- Catalogo DlineDocument5 pagesCatalogo DlinejojojoyNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- On The Identification of A VortexDocument26 pagesOn The Identification of A VortexZaka MuhammadNo ratings yet

- 325 Hydraulic SystemDocument7 pages325 Hydraulic SystemUMA AKANDU UCHENo ratings yet

- Resume-Gede Andi - Construction Supervisor For PIPING MECHANICALDocument7 pagesResume-Gede Andi - Construction Supervisor For PIPING MECHANICALandidipayadnyaNo ratings yet

- 4 SolutionDocument9 pages4 SolutionDÈènvêËr 빛 사랑No ratings yet

- Desc 1569254035000 1026809Document5 pagesDesc 1569254035000 1026809jose GilNo ratings yet

- Se Supreme Price List 15-02-2016 PDFDocument20 pagesSe Supreme Price List 15-02-2016 PDFsdagnihotri86% (7)

- Progress and Future Prospects of CFD in Aerospace - Wind Tunnel and BeyondDocument16 pagesProgress and Future Prospects of CFD in Aerospace - Wind Tunnel and BeyondIván SuárezNo ratings yet

- Hydraulic Basics KnowladgeDocument72 pagesHydraulic Basics KnowladgeVanHieu Luyen100% (1)

- Pre-Inspection Checklist For Low Pressure Steam Boilers: Chapter 296-104 WAC Chapter 70.79 RCWDocument4 pagesPre-Inspection Checklist For Low Pressure Steam Boilers: Chapter 296-104 WAC Chapter 70.79 RCWMohammedNo ratings yet

- Fluid Mechanics Lect Notes With Sample QuesDocument96 pagesFluid Mechanics Lect Notes With Sample QuesMahin Samuel John 74No ratings yet

- Masoneilan - 78 Series Air Filter Regulators IOMDocument8 pagesMasoneilan - 78 Series Air Filter Regulators IOMNithyANo ratings yet

- Chart Industries - VS01Document2 pagesChart Industries - VS01criuvosNo ratings yet

- Ch-Four Potential Flow (Rankine Oval Etc) FinalDocument51 pagesCh-Four Potential Flow (Rankine Oval Etc) FinalnunuNo ratings yet

- Hydraulic Eguipment For Reel Stand RS-M Automatic Operation: Part List Hydraulic Power Unit 2059 148 00Document1 pageHydraulic Eguipment For Reel Stand RS-M Automatic Operation: Part List Hydraulic Power Unit 2059 148 00Poposki PetreNo ratings yet

- Nakamura 1988Document7 pagesNakamura 1988Kashaf ChNo ratings yet

- Sluice Gate Module-6Document4 pagesSluice Gate Module-6CHEL TAK50% (2)

- Project Name: Arneplant Vietnam Company Limited Area Reference: Most UnfavourableDocument6 pagesProject Name: Arneplant Vietnam Company Limited Area Reference: Most UnfavourablenhacotungNo ratings yet

- Monthly Report September 2017 PDFDocument68 pagesMonthly Report September 2017 PDFJamal SabirNo ratings yet

- National Oilwell Varco 22t 2 and 32t 2 Parts List 1Document63 pagesNational Oilwell Varco 22t 2 and 32t 2 Parts List 1FaroukNo ratings yet