Professional Documents

Culture Documents

Laboratory test

Laboratory test

Uploaded by

venses1cpecc0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageLaboratory test

Laboratory test

Uploaded by

venses1cpeccCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

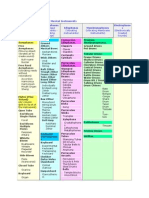

Laboratory test

S.NO Test Chemical Sampling Required

point Sample

location

1 CRUDE OIL 1.342001VS001 1ST STAGE SEPARATOR Unprocessed

deforming rate INLET crude oil

2. 342001VS002 2ND STAGE SEPARATOR

INLET

3. TEST SEPARATOR

2 Oxygen 1.345200TA002 (WASH WATER TANK INLET ) Onsite oxygenated

removal effect 2.345550TA001A/B inlet(INTERMEDIATE PW water sample

TANKS)

3 Bacterial effect 1.POTABLE WATER VESSEL 345300VA001 On site Processed

2. WASH WATER TANK inlet 345200TA002 Water sample

3. DESALINATED FEED WATER TANK inlet

345200TA001

4 Asphalt 1. 1ST STAGE SEPARATOR INLET Asphaltene crude

Inhibitory 2. TEST SEPARATOR INLET oil

effect

5. Static 1. TEST SEPARATOR 342000VP001(OIL Onsite

Corrosion INLET) Unprocessed

evaluation 2. TO TEST SEPARATOR 342000VP001 water sample

(WATER OUTLET)

3. TO 1ST STAGE SEPARATOR

342001VS001 (OIL INLET)

4. TO 1ST STAGE SEPARATOR

342001VS001 (WATER OUTLET)

5. TO 2ND STAGE SEPARATOR

342001VS002 (OIL INLET)

6. TO 2ND STAGE SEPARATOR

342001VS002 (WATER OUTLET)

7. DESALTER WATER OUTLET

8. DEHYDRATOR WATER OUTLET,

UPSTREAM WASH WATER

ECONOMIZER

9. DESALTER INLET UPSTREAM THE

MIXING VALVE

10. TEST SEPARATOR INLET

11. TEST SEPARATOR WATER OUTLET

DEMULSIFIER 1. 1st Stage Separator inlet 1.UNPROCESSED

2. 2nd Stage Separator inlet CRUDE OIL

3. Dehydrator inlet upstream the BEFORE THREE

mixing valve PHASE

4. Desalter inlet upstream the mixing SEPERATOR

valve 2.ONSITE WATER

SAMPLES

5.

You might also like

- Campbell - Walsh-Wein UROLOGY 12th Ed (Dragged)Document20 pagesCampbell - Walsh-Wein UROLOGY 12th Ed (Dragged)revanth kallaNo ratings yet

- Denison Filterability TP-02100 PDFDocument2 pagesDenison Filterability TP-02100 PDFRIZKY FIQRINo ratings yet

- Power Wizard 2.1: CTA CTB CTCDocument2 pagesPower Wizard 2.1: CTA CTB CTCOsanebi Chukwudi Lucky80% (10)

- Different Classification of FeedstuffDocument13 pagesDifferent Classification of FeedstuffNiño Joshua Ong Balbin67% (6)

- Daihatsu Sirion Model m300 Series Service Manual No9890 EngineDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 EngineJakub TarasinNo ratings yet

- Sop WTP CombinedDocument17 pagesSop WTP CombinedsiccppNo ratings yet

- Comet ZWD 4030 Pump Service ManualDocument17 pagesComet ZWD 4030 Pump Service ManualrocketIINo ratings yet

- Operation Principal of Sewage Treatmentplant and Point of MDocument12 pagesOperation Principal of Sewage Treatmentplant and Point of MKo Gyi BakaNo ratings yet

- Managerial Level-1: Part - Aweightage 20%Document6 pagesManagerial Level-1: Part - Aweightage 20%fawad aslamNo ratings yet

- Water Purification: Turnkey System Design, Assembly, Install and Technical SupportDocument7 pagesWater Purification: Turnkey System Design, Assembly, Install and Technical SupportFinca La JuanitaNo ratings yet

- BHELDocument26 pagesBHELVishal ChoudharyNo ratings yet

- 10-900 Series Pilot Operated Safety Relief Valve InspectionDocument3 pages10-900 Series Pilot Operated Safety Relief Valve InspectionMAT-LIONNo ratings yet

- Avon UTC 1535c12Document31 pagesAvon UTC 1535c12juanaNo ratings yet

- Desalado de CrudoDocument9 pagesDesalado de CrudoAngélica RamírezNo ratings yet

- Vessel Internal &functionDocument31 pagesVessel Internal &functionnawarsNo ratings yet

- O&G Produced WaterDocument23 pagesO&G Produced WaterLuan NguyenNo ratings yet

- HT64-132 OWS Final Drawings150525Document24 pagesHT64-132 OWS Final Drawings150525jamukanak padNo ratings yet

- Separator Purifier TrainingDocument39 pagesSeparator Purifier TrainingDesron SamuelNo ratings yet

- JKL-M Non-Electric Automatic Water SoftenerDocument16 pagesJKL-M Non-Electric Automatic Water Softenerbig lasagnaNo ratings yet

- PRD Doc Epr 7563-00001 Sen Ain V3Document3 pagesPRD Doc Epr 7563-00001 Sen Ain V3Service - Anda Hydraulics Asia Pte LtdNo ratings yet

- Sieve Plate ColumnDocument14 pagesSieve Plate ColumnShamini Sathivel0% (1)

- Comet Plunger Pump Service Manual IndexDocument9 pagesComet Plunger Pump Service Manual IndexKashimura KeiNo ratings yet

- Alfa Laval MAB 340PD18en - MABDocument2 pagesAlfa Laval MAB 340PD18en - MABSundarNo ratings yet

- ZJA6BY Instuction ManualDocument22 pagesZJA6BY Instuction ManualAous H100% (1)

- Manipal International University: Lab ReportDocument12 pagesManipal International University: Lab ReportPavan ChinnaNo ratings yet

- Aquaphor ManualDocument16 pagesAquaphor ManualDomNo ratings yet

- E39 Ahsop 03Document3 pagesE39 Ahsop 03Sanjit SinghNo ratings yet

- Sanitaire Pemberville Presentation PDFDocument38 pagesSanitaire Pemberville Presentation PDFjvan migvelNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Lab Manual - FM and M LabDocument64 pagesLab Manual - FM and M LabRavichandran GNo ratings yet

- Certificate of Analysis: Suzhou Yaxin Medical Products Co., LTDDocument2 pagesCertificate of Analysis: Suzhou Yaxin Medical Products Co., LTDVictor AlarcónNo ratings yet

- BP100 ManualDocument23 pagesBP100 ManualFadhli JapryNo ratings yet

- HFM 15ppm Bilge Separator Operation ManualDocument24 pagesHFM 15ppm Bilge Separator Operation ManualNguyen Phuoc HoNo ratings yet

- 15 PPM BILGE SEPARATOR OPERATION MANUAL PDFDocument22 pages15 PPM BILGE SEPARATOR OPERATION MANUAL PDFPrince DhakaNo ratings yet

- Misc PaperDocument8 pagesMisc PaperASHOK ARJUNRAO TAYADENo ratings yet

- Autoclave ManualDocument17 pagesAutoclave Manualkuraido garciaNo ratings yet

- Work Instructions (W.I.)Document18 pagesWork Instructions (W.I.)Shamsul Azhar MohdNo ratings yet

- Operation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFDocument19 pagesOperation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFShiva Kumar S MNo ratings yet

- Process Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingDocument3 pagesProcess Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingT. LimNo ratings yet

- Transformer OilDocument12 pagesTransformer OilVenkata Lakshmanarao N100% (2)

- Name: Quirante, Jany Paulenne S. Date Submitted: August 2, 2016 Subject & Schedule: CE 411BL/ Tue 1:30-4:30 PM Instructor: Engr. Michael BarrigaDocument8 pagesName: Quirante, Jany Paulenne S. Date Submitted: August 2, 2016 Subject & Schedule: CE 411BL/ Tue 1:30-4:30 PM Instructor: Engr. Michael BarrigaHeliosNo ratings yet

- Auxiliary RelayDocument1 pageAuxiliary RelaySanjay Kumar KanaujiaNo ratings yet

- Introduction For Test Separator: CNPCIC Field ProductionDocument18 pagesIntroduction For Test Separator: CNPCIC Field Productionsalahadine maideNo ratings yet

- Group 2 (Lab 3)Document25 pagesGroup 2 (Lab 3)Riethanelia UsunNo ratings yet

- Cpfnilepet 140929165258 Phpapp01Document36 pagesCpfnilepet 140929165258 Phpapp01IVANNo ratings yet

- CSmanian Load CalculationDocument9 pagesCSmanian Load CalculationPrasadNo ratings yet

- Astm D 2711Document8 pagesAstm D 2711aleiviNo ratings yet

- FM11 Complete ManualDocument12 pagesFM11 Complete ManualRudy P. JongNo ratings yet

- Toaz - Info Packed Bed Distillation Column Lab Report PRDocument13 pagesToaz - Info Packed Bed Distillation Column Lab Report PRHusna Hafiza Bt. R.AzamiNo ratings yet

- Packed Bed Distillation Column Lab ReportDocument13 pagesPacked Bed Distillation Column Lab ReportShamini Sathivel100% (6)

- 5b. STP Weekly Log BookDocument1 page5b. STP Weekly Log BookNISHANTH GANESHNo ratings yet

- MM-18 - Bilge Separator - OPERATION MANUALDocument24 pagesMM-18 - Bilge Separator - OPERATION MANUALKyaw Swar Latt100% (2)

- Maintenance-Guide-for-VTLFDocument18 pagesMaintenance-Guide-for-VTLFrubinisilvaNo ratings yet

- SA 836 - Separation System - Installation - 2005Document51 pagesSA 836 - Separation System - Installation - 2005Centrifugal SeparatorNo ratings yet

- Manual Al430Document5 pagesManual Al430syaputra kurniaNo ratings yet

- TOO Catalog File 2022 - 30.10.22Document6 pagesTOO Catalog File 2022 - 30.10.22Hen BenjaminNo ratings yet

- Tecnair H Humidifier User Manual EngDocument24 pagesTecnair H Humidifier User Manual EngpersosamsicNo ratings yet

- Spareparts ListDocument5 pagesSpareparts ListsitaNo ratings yet

- 0808 133 M200J 01Document125 pages0808 133 M200J 01Franklin LibreNo ratings yet

- VLB 103BDocument2 pagesVLB 103BRaghunath Majee0% (1)

- STC Cleaning ProcedureDocument1 pageSTC Cleaning Procedurejuan saezNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Nitrification and Denitrification in the Activated Sludge ProcessFrom EverandNitrification and Denitrification in the Activated Sludge ProcessNo ratings yet

- GSM System Fundamental TrainingDocument144 pagesGSM System Fundamental Trainingmansonbazzokka100% (2)

- Mccsemi: 1N746 A Thru 1N759 ADocument3 pagesMccsemi: 1N746 A Thru 1N759 AЕвгений ИвановNo ratings yet

- KX71 3 en - HDDocument8 pagesKX71 3 en - HDסטניסלב טלשבסקיNo ratings yet

- TTD Series Configurable Fault AnnunciatorDocument4 pagesTTD Series Configurable Fault AnnunciatorAlejandroMuñozNo ratings yet

- PoonamDocument54 pagesPoonamCH Rajan GujjarNo ratings yet

- Classification of Common Musical InstrumentsDocument3 pagesClassification of Common Musical InstrumentsFabian FebianoNo ratings yet

- Roles of Physiotherapy in Intensive Care Unit (Document28 pagesRoles of Physiotherapy in Intensive Care Unit (Chukwuemeka ChidogoNo ratings yet

- Pre Project ActivitiesDocument20 pagesPre Project ActivitiesAlexcorbinNo ratings yet

- Death of A Salesman by Arthur MillerDocument125 pagesDeath of A Salesman by Arthur MillerNaman VasalNo ratings yet

- Orange3 Text PDFDocument53 pagesOrange3 Text PDFfajrina rinaNo ratings yet

- Mage Wars: Variant With No Dice: Basic RulesDocument8 pagesMage Wars: Variant With No Dice: Basic RulesMáté BoaNo ratings yet

- Home Assignment - JUNK BOND Subject: Corporate FinanceDocument3 pagesHome Assignment - JUNK BOND Subject: Corporate FinanceAsad Mazhar100% (1)

- Impromptu SpeechDocument25 pagesImpromptu SpeechJerome Bulaun100% (1)

- (REVIEW) KENDALL, Stuart - The Philosophy of Design by Glenn ParsonsDocument5 pages(REVIEW) KENDALL, Stuart - The Philosophy of Design by Glenn ParsonsOmega ZeroNo ratings yet

- Features of Edpuzzle PDFDocument5 pagesFeatures of Edpuzzle PDFLailaniNo ratings yet

- CapacitorsDocument86 pagesCapacitorsarunNo ratings yet

- A Generalization of Wilson's Theorem: R. Andrew Ohana June 3, 2009Document13 pagesA Generalization of Wilson's Theorem: R. Andrew Ohana June 3, 2009Ramón Darío CarrasqueroNo ratings yet

- Housing and Land Use Regulatory Board: Lupong Nangangasiwa Sa Pabahay at Gamit NG LupaDocument36 pagesHousing and Land Use Regulatory Board: Lupong Nangangasiwa Sa Pabahay at Gamit NG LupaJoseph Raymund BautistaNo ratings yet

- Schaum's Outline Theory and Problems of Fourier AnalysisDocument12 pagesSchaum's Outline Theory and Problems of Fourier AnalysisMagno Junior0% (1)

- New Arrivals in Women's Ready-to-Wear - Self-PortraitDocument1 pageNew Arrivals in Women's Ready-to-Wear - Self-PortraitaymiemyriamNo ratings yet

- Applied Economics Module 3 Q1Document21 pagesApplied Economics Module 3 Q1Jefferson Del Rosario100% (1)

- Physics Investigatory Project: Made by - Abhishek Choudhary Roll No. - 1 Class - 12 ADocument21 pagesPhysics Investigatory Project: Made by - Abhishek Choudhary Roll No. - 1 Class - 12 AShubham BaghelNo ratings yet

- RMO 2016 Detailed AnalysisDocument6 pagesRMO 2016 Detailed AnalysisSaksham HoodaNo ratings yet

- 0809 KarlsenDocument5 pages0809 KarlsenprateekbaldwaNo ratings yet

- 3 Asch - The Metaphor - 1958Document10 pages3 Asch - The Metaphor - 1958Aysen Ece BörkNo ratings yet

- Superficial Fungal Infections (2019)Document6 pagesSuperficial Fungal Infections (2019)mustika rachmaNo ratings yet