Professional Documents

Culture Documents

Waste generation to disposal V1

Waste generation to disposal V1

Uploaded by

ghostscythe2870 ratings0% found this document useful (0 votes)

1 views23 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views23 pagesWaste generation to disposal V1

Waste generation to disposal V1

Uploaded by

ghostscythe287Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 23

Functional Elements in the

management:

Waste generation: Activities that identify objects as no

longer of use and therefore to be discarded

On site handling, storage and processing: processing

activities taking place near the point of generation

Collection: gathering the waste and hauling to where

the collection vehicle is to be emptied

Transfer and transport: (1) transfer of waster from

small vehicles to large transport equipment; (2)

subsequent transport over long distance, to disposal

sites

Processing and Recovery: to recover usable materials,

conversion products as well as energy from solid waste

Disposal: associated with ultimate disposal i.e.

transport to landfill, compost, incinerator residue etc.

On site storage Collection

Transfer/Transport Ultimate disposal - landfill

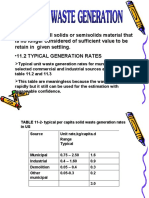

Typical generation rates: per capita

waste generation rates: Table 1

Unit rate, kg/capita/ day

Source

Range Typical

Municipal 0.75-2.50 1.6

Industrial 0.4-1.6 0.9

Demolition 0.05-0.4 0.3

Other municipal 0.05-0.3 0.2

3.0

Typical commercial and industrial

unit waste generation rates: table 2

Source Unit Range

Office buildings Kg/employee/ day 0.5-1.1

Restaurants Kg/customer/ day 0.2-0.8

Canned and frozen food Tonnes/ tonne of raw 0.04-0.06

product

Printing and publishing Tonnes/ tonne of raw 0.08-1.0

paper

Automotive Tonnes/ vehicle produced 0.6-0.8

Petroleum refining Tonnes/ employee/ day 0.04-0.05

Rubber Tonnes/ tonne of raw 0.01-0.3

rubber

Estimation of solid waste

quantities

The quantity and general composition data are of

critical importance in the design and operation of a

solid waste management system

However, obtaining reliable data is quite challenging

and can only be measured from collected waste and

waste transported to landfills.

All methods employed for measurement are subject to

some form of limitations.

Recommended methods

Load- Count Analysis: Quantity and composition

determined by recording

- the estimated volume and general composition of

each load of waste delivered to a landfill or transfer

station

-during a specified period of time.

-Total mass distribution is obtained by average density

data (as discussed in previous chapter).

Mass-volume analysis: Similar procedure to the above

mentioned.

As a added feature, mass of each load is also recorded.

Factors affecting generation rates

1. Geographic location

2. Season of the year

3. Collection frequency

4. Use of kitchen waste grinder

5. Characteristics of populace

6. Extent of salvage and recycling

7. Public attitudes

8. legislation

On-site Handling, Storage, and

Processing

On-site handling: associated with handling solid waste

until they are placed in the containers used for their

storage before collection.

Domestic Solid waste: Usually stored in large

containers that await removal by waste-collection

agency.

In large residential buildings, waste is usually stored at

the basement level, carried by building caretaker or

the tenants themselves.

Commercial and industrial waste: Usually collected in

large containers mounted on rollers.

Once filled these are emptied in large storage

containers.

Or compactors asssociated with these containers

Or other processing equipment such as incinerators.

On-site Processing of Solid Waste

The objective being –

To recover usable materials from solid wastes

To reduce the volume

Or to alter the physical form

Most common forms of on-site processing –

Manual sorting

Compaction

Incineration

Collection Services

Municipal collection

services

Curb/Alley collection:

Collection bins placed by

home owners at the curb/

alley

No need for collectors to

enter property

Home owner responsible

for taking back empty

container.

Collection Services

Backyard collection:

Worker with the

vehicle carry a bin,

wheel-barrow or sack

to the yard and empty

the solid waste

container in it.

Collector has to enter

the property.

Commercial-Industrial Collection

services

For large apartment

buildings, residential

complexes, and commercial

and industrial activities.

Large, movable/ stationary

containers/ compactors

Compress directly in the

container to form bales

Types of collection Systems

Hauled-Container Systems: Collection systems where

containers used for the storage of wastes are hauled to the

processing, transfer, or disposal site, emptied and returned

to either their original location or some other location are

defined as hauled container systems.

Two main types: (a) tilt-frame container

(b) trash-trailer

The collector is responsible for driving, loading full

containers, and unloading empty containers, and emptying

the contents of the container at the disposal site

Stationary compactor system: where containers

used for the storages of wastes remain at the point of

waste generation, except when moved for collection.

Labor requirements are same

Two types – (1) with self-loading compactors

(2) those in which manually loaded

vehicles are used

Containers size of less importance compared to the

hauled system.

Example 11-1: Analysis of a hauled container

collection system: Solid waste from a new industrial

park is to be collected in large containers (drop boxes),

some of which will be used in conjunction with

stationary compactors. Based on traffic studies at

similar parks, it is estimated that the average time to

drive from the garage to the first container (t1) and

from the last container (t2) to the garage each day will

be 15 and 20 mins. Respectively. If the average time

required to drive between container is 6 min and the

one way distance to the disposal site is 25 km, speed

limit: 88 km/hr), determine the number of containers

that can be emptied per day, based on a 8-h workday.

To determine:

Pickup time per trip: P(hcs)

Total time per trip

Number of trips

Comment on the actual length of the workday

You might also like

- BIO102 Practice ExamDocument10 pagesBIO102 Practice ExamKathy YuNo ratings yet

- Home Automation SystemDocument18 pagesHome Automation SystemChandrika Dalakoti77% (13)

- Adding and Subtracting Polynomials LessonDocument4 pagesAdding and Subtracting Polynomials Lessonapi-249037964100% (4)

- Evolution of Investment Banking in IndiaDocument3 pagesEvolution of Investment Banking in IndiaChsudarshanDhaveji100% (2)

- Index - Sybase 15.0 Replication Server AdministrationDocument29 pagesIndex - Sybase 15.0 Replication Server AdministrationAnonymous pJqNn8esMNo ratings yet

- Solid Waste ManagementDocument72 pagesSolid Waste ManagementMuhamad Baihakhi ShamsudinNo ratings yet

- Collection of Solid WasteDocument38 pagesCollection of Solid WasteMuhammad UsmanNo ratings yet

- School of Civil Engineering Solid Waste & Hazardous Waste ManagementDocument26 pagesSchool of Civil Engineering Solid Waste & Hazardous Waste Managementbhavuk purbiaNo ratings yet

- SWM Unit-2Document25 pagesSWM Unit-2thanushree n gowdaNo ratings yet

- Note For Solid Waste Collection and TransportDocument40 pagesNote For Solid Waste Collection and TransportZeck ZaeightNo ratings yet

- Collection and Transport of Solid WasteDocument28 pagesCollection and Transport of Solid WasteFaye Y. Santiago100% (1)

- Gert Man 0810 RRDocument4 pagesGert Man 0810 RRRaguvaran_ArumugamNo ratings yet

- 2-On Site Storage Methods: 1.containersDocument12 pages2-On Site Storage Methods: 1.containersPenchalaiah100% (1)

- Solid Waste CollectionDocument20 pagesSolid Waste CollectionhopeNo ratings yet

- Chapter 7 SWMDocument10 pagesChapter 7 SWMdaabgchiNo ratings yet

- Solid Waste ManagementDocument36 pagesSolid Waste ManagementNursyahira Abd GhaniNo ratings yet

- Engineered System For Solid Waste Management: Nurhusna BT Abu Bakar (Gnab)Document74 pagesEngineered System For Solid Waste Management: Nurhusna BT Abu Bakar (Gnab)Eyra syahiraNo ratings yet

- Chapter 5Document29 pagesChapter 5Shita AlemieNo ratings yet

- Module-85A: Sub: Environmental Engineering Topic: Municipal SolidwastesDocument4 pagesModule-85A: Sub: Environmental Engineering Topic: Municipal SolidwastesjhacademyhydNo ratings yet

- Solid Waste (Compatibility Mode)Document6 pagesSolid Waste (Compatibility Mode)^nana^No ratings yet

- Civil EngineeringDocument24 pagesCivil Engineeringuttama villanNo ratings yet

- UNIt 2 - SWMDocument38 pagesUNIt 2 - SWMmorsalin2715No ratings yet

- Note For Solid Waste Collection and TransportDocument40 pagesNote For Solid Waste Collection and TransportRaven SynthxNo ratings yet

- Practical No.4 PDFDocument9 pagesPractical No.4 PDFSwarupa ChanchalwadNo ratings yet

- Chapter 3Document47 pagesChapter 3tilahunkasaNo ratings yet

- 11-12 Phases of Solis Waste Collection and Composting.Document32 pages11-12 Phases of Solis Waste Collection and Composting.eng zamNo ratings yet

- QB103762Document17 pagesQB103762TijaNo ratings yet

- Clean MRF: Recyclable Single Stream Ferrous Metal Aluminum PET HdpeDocument28 pagesClean MRF: Recyclable Single Stream Ferrous Metal Aluminum PET HdpeJoyce T. ParejaNo ratings yet

- Tutorial Topic 4Document4 pagesTutorial Topic 4Afiq ArsyadNo ratings yet

- Microsoft Powerpoint - Solid Waste Management Collection - pptx1 PDFDocument49 pagesMicrosoft Powerpoint - Solid Waste Management Collection - pptx1 PDFMohamed HamdyNo ratings yet

- Solid Creat Mod-3Document17 pagesSolid Creat Mod-3md shakil ahsan mazumderNo ratings yet

- Chapter 3Document47 pagesChapter 3Veshal Purshothama SeelanNo ratings yet

- Solid Waste Management SystemDocument45 pagesSolid Waste Management Systemmuci0% (1)

- Municipal Solid Waste Conversion Donald K. WalterDocument34 pagesMunicipal Solid Waste Conversion Donald K. WalterRifal MilanistiNo ratings yet

- Soild Waste Management Q and ADocument19 pagesSoild Waste Management Q and AHamed FaragNo ratings yet

- Scientific Travel To Kwashe Leachate Treatment Plant and Landfill ImprovementDocument15 pagesScientific Travel To Kwashe Leachate Treatment Plant and Landfill Improvementhayder alaliNo ratings yet

- Solid Waste Management, Lec-5Document34 pagesSolid Waste Management, Lec-5প্রিন্স রেজাNo ratings yet

- Solid Waste Collection, Transport and Recycling, Transferstation (Final Version)Document137 pagesSolid Waste Collection, Transport and Recycling, Transferstation (Final Version)Executive Engineer Mechanical Irrigation DivisionNo ratings yet

- Module - 12 SWM-1Document14 pagesModule - 12 SWM-1Faran MasoodNo ratings yet

- CHAPTER 5 - Solid WasteDocument28 pagesCHAPTER 5 - Solid WastesyakirohNo ratings yet

- SWMM3FDocument5 pagesSWMM3FSAI PRATHEESH R JUNo ratings yet

- 10 - Municipal Solid Waste Management Plan, Nashik ParanvDocument18 pages10 - Municipal Solid Waste Management Plan, Nashik ParanvVivek PardhiNo ratings yet

- Urban Waste Management 2018Document31 pagesUrban Waste Management 2018Eugen DucaNo ratings yet

- 2 ModDocument16 pages2 ModIrfan PeruvallithodiNo ratings yet

- 01solid and Hazardous Waste Management L-1Document55 pages01solid and Hazardous Waste Management L-1getahun083No ratings yet

- Chapter Six Collection of Solid Waste: Cti NDocument13 pagesChapter Six Collection of Solid Waste: Cti NAwadhNo ratings yet

- Functional Element of Solid Waste 1Document61 pagesFunctional Element of Solid Waste 1Raj KumarNo ratings yet

- WM Class 1 IntroductionDocument154 pagesWM Class 1 IntroductionJacky TamNo ratings yet

- Unit-Ii Syllabus: Basic Elements in Solid Waste ManagementDocument14 pagesUnit-Ii Syllabus: Basic Elements in Solid Waste ManagementChaitanya KadambalaNo ratings yet

- Cpe 406 6060 Lecture 1 HandoutDocument24 pagesCpe 406 6060 Lecture 1 HandoutAlejandro Amigo DotrasNo ratings yet

- Solid Creat Mod-2Document35 pagesSolid Creat Mod-2md shakil ahsan mazumderNo ratings yet

- EN6501 UnitDocument117 pagesEN6501 Unitpradeep vijayNo ratings yet

- Solid Waste ManagementDocument8 pagesSolid Waste ManagementIsaac Kwabena HinnehNo ratings yet

- Anna University, Chennai-Affiliated Institutions R - 2013 B.E. Civil Engineering Semester-Vii - Syllabus Elective - IiiDocument28 pagesAnna University, Chennai-Affiliated Institutions R - 2013 B.E. Civil Engineering Semester-Vii - Syllabus Elective - Iiipraveen murugesanNo ratings yet

- Salient Features RA 9003Document62 pagesSalient Features RA 9003bingkydoodle1012No ratings yet

- Waste Generation: Waste Generation Encompasses Activities in Which MaterialsDocument3 pagesWaste Generation: Waste Generation Encompasses Activities in Which MaterialsVibhash NithNo ratings yet

- Chapter 5 Solid Waste Manaement FullDocument19 pagesChapter 5 Solid Waste Manaement FullfaiselansuarNo ratings yet

- 2019 Winter Model Answer PapeDocument19 pages2019 Winter Model Answer PapeSupreet GharatNo ratings yet

- Class SW SysstemDocument56 pagesClass SW SysstemAine JeremyNo ratings yet

- SW Collection & TransportDocument57 pagesSW Collection & Transportzemen TadesseNo ratings yet

- Solid Waste Management: Shree K.K. Shashtri Gov. Sci. College Environmental ScienceDocument22 pagesSolid Waste Management: Shree K.K. Shashtri Gov. Sci. College Environmental Sciencesubrata19599214No ratings yet

- Lecture - 2 Generation and Collection of Solid WastesDocument23 pagesLecture - 2 Generation and Collection of Solid WastesumeshviswanthaNo ratings yet

- Separation and Processing and Transformation of Solid WasteDocument10 pagesSeparation and Processing and Transformation of Solid WasteKind Red50% (2)

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument10 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesSama UmateNo ratings yet

- BidarDocument20 pagesBidardwijomalaNo ratings yet

- Ruppur Nuclear Power PlantDocument4 pagesRuppur Nuclear Power PlantShafi Muhammad IstiakNo ratings yet

- Welding FundamentalsDocument44 pagesWelding FundamentalsDhinasuga DhinakaranNo ratings yet

- Subjective Tests vs. Objective Tests: Multiple-Choice TestDocument19 pagesSubjective Tests vs. Objective Tests: Multiple-Choice TestMuhammad Hidayatul RifqiNo ratings yet

- FINAL CONCEPT PAPER Edit 8 PDFDocument10 pagesFINAL CONCEPT PAPER Edit 8 PDFJABUNAN, JOHNREX M.No ratings yet

- Sales ManagementDocument26 pagesSales ManagementBenita S MonicaNo ratings yet

- Clinical Audit Where ToDocument13 pagesClinical Audit Where ToMulugeta DagneNo ratings yet

- Notes Industrial Security ConceptsDocument40 pagesNotes Industrial Security ConceptsAC GonzagaNo ratings yet

- GTNetS ManualDocument148 pagesGTNetS ManualJatin JaniNo ratings yet

- Report - SharifDocument58 pagesReport - SharifNabilNo ratings yet

- TW Supplement WSA 02-2002 V2 3 MRWA - DRAFT 05 Sewerage CodeDocument35 pagesTW Supplement WSA 02-2002 V2 3 MRWA - DRAFT 05 Sewerage CodeDivesh rahulNo ratings yet

- DTU EE 4th Sem Midsem SyllabusDocument5 pagesDTU EE 4th Sem Midsem SyllabusHimanshu GuptaNo ratings yet

- Chapter Three Edited - Public EnterpriseDocument9 pagesChapter Three Edited - Public EnterpriseMarah Moses BallaNo ratings yet

- 42 Solar Water Heating and The Plant EngineerDocument8 pages42 Solar Water Heating and The Plant Engineerdumitrescu viorelNo ratings yet

- Date - 1 - 9 - 2024 Time - 8 - 42 - 56 - 850Document1 pageDate - 1 - 9 - 2024 Time - 8 - 42 - 56 - 850ANKUSH 87205312No ratings yet

- Foreign Trade Law: The Agreement On Trade-Related Investment Measures (Trims)Document15 pagesForeign Trade Law: The Agreement On Trade-Related Investment Measures (Trims)TanuNo ratings yet

- Css Subject Economics Syllabus DownloadDocument3 pagesCss Subject Economics Syllabus Downloadsadaf naeemNo ratings yet

- Compressed Gas Cylinder Safety GuideDocument1 pageCompressed Gas Cylinder Safety GuideNguyenLinh27No ratings yet

- 02 Energy Harvesting For Aut. SystemsDocument304 pages02 Energy Harvesting For Aut. SystemsJúlio Véras100% (2)

- Oana Adriana GICADocument42 pagesOana Adriana GICAPhilippe BrunoNo ratings yet

- Guidelinefor CentreSuperintendentPrac9.02.2013Document120 pagesGuidelinefor CentreSuperintendentPrac9.02.2013JasmineNo ratings yet

- Peter Wicke - Rock Music Culture Aesthetic and SociologyDocument121 pagesPeter Wicke - Rock Music Culture Aesthetic and SociologyFelipeNo ratings yet

- English 8 Third Quarter Curriculum MapDocument5 pagesEnglish 8 Third Quarter Curriculum MapAgnes Gebone TaneoNo ratings yet

- Appliacation LetterDocument7 pagesAppliacation LetterTriantoNo ratings yet