Professional Documents

Culture Documents

scope113_03

scope113_03

Uploaded by

long0200405Copyright:

Available Formats

You might also like

- 4G15 DiagramaDocument1 page4G15 Diagramaalirio83% (6)

- Test Bank For Essentials of Genetics 10th Edition William S KlugDocument9 pagesTest Bank For Essentials of Genetics 10th Edition William S KlugBarbara Hinkle100% (41)

- Becoming Cancer-Free ManuscriptDocument149 pagesBecoming Cancer-Free ManuscriptD100% (1)

- CATERPILLAR GAS ENGINE 3516 Schematic DIAGRAM PDFDocument2 pagesCATERPILLAR GAS ENGINE 3516 Schematic DIAGRAM PDFwaqqasalisyed83% (6)

- d8n Wiring HardnessDocument2 pagesd8n Wiring HardnessandraNo ratings yet

- Tim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Document534 pagesTim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Carlos Diaz Huerta100% (1)

- ELCOS 3000 RPM INTEL Light RUDocument3 pagesELCOS 3000 RPM INTEL Light RUandreyNo ratings yet

- Diagrama Electrico 320c PDFDocument2 pagesDiagrama Electrico 320c PDFPutra Jawa100% (2)

- Product Realization Process - MapDocument1 pageProduct Realization Process - Mapsenthildurai0% (1)

- Fungi Coloring WorksheetDocument7 pagesFungi Coloring WorksheetKarl DelgadoNo ratings yet

- Pco Controller +Document164 pagesPco Controller +Luis Fernando Mateus Delgado0% (1)

- App2 Architect RFP Response Evaluation FormDocument4 pagesApp2 Architect RFP Response Evaluation FormElliot MunNo ratings yet

- Chapter 6 Momentum & Collisions Nice Check ItDocument67 pagesChapter 6 Momentum & Collisions Nice Check Itvenkateshyadav2116100% (1)

- EMP Bentu Process Flow 2022Document1 pageEMP Bentu Process Flow 2022Maintenance BentuNo ratings yet

- Aerosila NPP JSC: Gas Turbine Power PlantsDocument30 pagesAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- EngRange Industry 06Document1 pageEngRange Industry 06FRANCISCO JAVIER BARRIENTOS GONZALESNo ratings yet

- Get More With The Glanza: Technical SpecificationsDocument6 pagesGet More With The Glanza: Technical Specificationssai vivekNo ratings yet

- Folha 01 Diagrama Painel PDFDocument1 pageFolha 01 Diagrama Painel PDFOreonnyr SouzaNo ratings yet

- Finite Element Solutions For Geotechnical EngineeringDocument24 pagesFinite Element Solutions For Geotechnical EngineeringSevinc Ünsal OralNo ratings yet

- Finite Element Solutions For Geotechnical EngineeringDocument24 pagesFinite Element Solutions For Geotechnical EngineeringMARCOSNo ratings yet

- Specification TSG-416Document2 pagesSpecification TSG-416MárcioNo ratings yet

- 4CHLDocument1 page4CHLZNC Plamo and ToyzNo ratings yet

- TRW Cross ReferenceDocument2 pagesTRW Cross Referenceeloyabner75% (4)

- Codigos RMC Componente Ingles Espanol V2Document120 pagesCodigos RMC Componente Ingles Espanol V2Esteban PerezNo ratings yet

- Astraflame BurnerDocument2 pagesAstraflame BurnerEdson AguirreNo ratings yet

- Engine View: 563C and 573C Electrical System Wheel Feller BuncherDocument2 pagesEngine View: 563C and 573C Electrical System Wheel Feller Bunchermrcruzito_2099No ratings yet

- Can Lvcan200 2017 08 18 enDocument26 pagesCan Lvcan200 2017 08 18 enmccm77No ratings yet

- Despiece y Funciomamiento Carburador Honda gx25 gx35 Ingles PDFDocument1 pageDespiece y Funciomamiento Carburador Honda gx25 gx35 Ingles PDFkexavadasNo ratings yet

- Skill Matrix 2023Document23 pagesSkill Matrix 2023Bondville ComplienceNo ratings yet

- ACPLDocument47 pagesACPLAmit BiswasNo ratings yet

- KatalogDocument4 pagesKatalog강동혁No ratings yet

- MBM38202931 03 141107Document2 pagesMBM38202931 03 141107Jose Alvarez VegaNo ratings yet

- QC Staff Rizqi FatullohDocument11 pagesQC Staff Rizqi FatullohRizqiNo ratings yet

- 7350-DRG-009Document1 page7350-DRG-009suhyyNo ratings yet

- Mon Nov 26 13:05:35 2018 Case: D:/BENZENE222.HSC Flowsheet: Case (Main)Document1 pageMon Nov 26 13:05:35 2018 Case: D:/BENZENE222.HSC Flowsheet: Case (Main)Hardika BayuNo ratings yet

- HP DesignJet 5100Document6 pagesHP DesignJet 5100gandharv vatsNo ratings yet

- M402.00 Schedule Sheet-2Document1 pageM402.00 Schedule Sheet-2Shweta KamatNo ratings yet

- Acc GX SeriesDocument4 pagesAcc GX SeriesWandresNo ratings yet

- MTU Series 4000 Tier 4i: Designed For The Future. Built For Your SuccessDocument3 pagesMTU Series 4000 Tier 4i: Designed For The Future. Built For Your Success桂腾明No ratings yet

- Generac's Position in The Market: Demand ResponseDocument2 pagesGenerac's Position in The Market: Demand ResponseJuly E. Maldonado M.No ratings yet

- 07h2append WL 1a EsDocument2 pages07h2append WL 1a EsMark FonsNo ratings yet

- DG SchematicDocument1 pageDG SchematicsubhashNo ratings yet

- Data Sheet Enclosure DOMH12112F DATASHEET ID in-IDDocument1 pageData Sheet Enclosure DOMH12112F DATASHEET ID in-IDNelyana UnoNo ratings yet

- Product Fiche: P/NO: MBM38202931 (1408-REV02) Printed in KoreaDocument2 pagesProduct Fiche: P/NO: MBM38202931 (1408-REV02) Printed in KoreaAlexandru CămuiNo ratings yet

- Session 7 Power CycleDocument146 pagesSession 7 Power CycleHanda Bin AdiNo ratings yet

- Bore Pump Lookup Data (MC Rev B)Document12 pagesBore Pump Lookup Data (MC Rev B)chrisNo ratings yet

- Familiarization For NEW Joiners 2017Document1 pageFamiliarization For NEW Joiners 2017Invatamant PpNo ratings yet

- đông cơ sau khi cải tạoDocument1 pageđông cơ sau khi cải tạothanhlocpt2205No ratings yet

- 12aym WGTDocument2 pages12aym WGTMuhammad KarimNo ratings yet

- 4g93 1996 Diagrama EléctricoDocument5 pages4g93 1996 Diagrama EléctricoRodríguez Andrés100% (1)

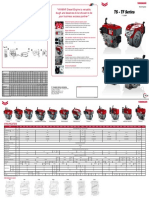

- TS - TF Series: "YANMAR Diesel Engine Is Versatile, Tough and Deserves To Be Chosen To Be Your Business Success Partner "Document1 pageTS - TF Series: "YANMAR Diesel Engine Is Versatile, Tough and Deserves To Be Chosen To Be Your Business Success Partner "Faiz FadhillahNo ratings yet

- 321d MDT Serial WiringDocument2 pages321d MDT Serial WiringjulianNo ratings yet

- Safety ConceptDocument61 pagesSafety Conceptandreylikestolearn5No ratings yet

- Chln-Hal2n-Ayl AgregatyDocument2 pagesChln-Hal2n-Ayl AgregatyMarek PiznalNo ratings yet

- Bulletin - High Efficiency Fan MotorsDocument3 pagesBulletin - High Efficiency Fan Motorsd44n 1122No ratings yet

- Crude Oil QPDocument12 pagesCrude Oil QPBethNo ratings yet

- Crude Oil QPDocument10 pagesCrude Oil QPSreeja Sen Year 10No ratings yet

- Product Data Sheet: 35A 440V Surface Mount Triple Pole Isolating Switch IP66Document1 pageProduct Data Sheet: 35A 440V Surface Mount Triple Pole Isolating Switch IP66tonielhageNo ratings yet

- Proton Persona 2016 PDFDocument2 pagesProton Persona 2016 PDFveltr0No ratings yet

- HD Rim Valve Guard PorosityDocument3 pagesHD Rim Valve Guard PorosityDurai NaiduNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enaliomairNo ratings yet

- 12aym WGTDocument2 pages12aym WGTkhuong phamNo ratings yet

- XV. 473 Engine and Liandian Electric Injection SystemDocument1 pageXV. 473 Engine and Liandian Electric Injection SystemJose Luis Velasquez Romero100% (1)

- T5 EVO Fiche TechniqueDocument2 pagesT5 EVO Fiche TechniqueFateh DjNo ratings yet

- JW Pump Curve - F3514g-F3524g-F3524gsiDocument1 pageJW Pump Curve - F3514g-F3524g-F3524gsikman548No ratings yet

- E91-04Document4 pagesE91-04long0200405No ratings yet

- kolibrik-case-study-IEN-25092025Document1 pagekolibrik-case-study-IEN-25092025long0200405No ratings yet

- 5e.-SFBP-Nav-Tech-Program-Status_UpdateDocument4 pages5e.-SFBP-Nav-Tech-Program-Status_Updatelong0200405No ratings yet

- SecureSync M-CodeDocument4 pagesSecureSync M-Codelong0200405No ratings yet

- Thera TM015XP PDFDocument2 pagesThera TM015XP PDFAlvin Novandi Ega PradanaNo ratings yet

- Injector - Procedure 1kd FTVDocument16 pagesInjector - Procedure 1kd FTVMarcin ŚciegiennyNo ratings yet

- KARTHADocument2 pagesKARTHADebasis GoswamiNo ratings yet

- Computer System ServicingDocument11 pagesComputer System ServicingArman Santiago100% (1)

- Artistic AnalysisDocument6 pagesArtistic AnalysisMirela SinghNo ratings yet

- Lesson Plan Preparing For Parenthood Pregnancy and Labor - 0Document15 pagesLesson Plan Preparing For Parenthood Pregnancy and Labor - 0Sweta ManandharNo ratings yet

- SketchUp Tutorial 1 - TableDocument19 pagesSketchUp Tutorial 1 - TablenphilippNo ratings yet

- TM103 Chapter 1Document24 pagesTM103 Chapter 1johnnader1254No ratings yet

- Appendix XIV A - BP Microbiological Assay MethodsDocument6 pagesAppendix XIV A - BP Microbiological Assay MethodsSantosh Kumar TataNo ratings yet

- Linear Regression Analysis McqsDocument2 pagesLinear Regression Analysis McqsEngr Mujahid Iqbal80% (5)

- Advances in Upconversion Enhanced Solar Cell PerformanceDocument15 pagesAdvances in Upconversion Enhanced Solar Cell PerformanceMuhamad SulaemanNo ratings yet

- Cloud WarsDocument10 pagesCloud WarsAtharva Sachin KulkarniNo ratings yet

- 490806Document2 pages490806Informative InsaanNo ratings yet

- Jawaban Bahasa InggrisDocument9 pagesJawaban Bahasa InggrisHusnul KhotimahNo ratings yet

- Aem 499 Final Powerpoint Andrewdelili 4-28-2021Document20 pagesAem 499 Final Powerpoint Andrewdelili 4-28-2021api-548751501No ratings yet

- 1 s2.0 S0738081X01001997 MainDocument6 pages1 s2.0 S0738081X01001997 MainymiyazyNo ratings yet

- Cervical Myelopathy - ERHDocument42 pagesCervical Myelopathy - ERHAries RHNo ratings yet

- Parts List: Model: Apw-895N List No: 1657-04Document197 pagesParts List: Model: Apw-895N List No: 1657-04Mounir SassiNo ratings yet

- Google - Cloud Digital Leader.v2023 06 22.q106Document50 pagesGoogle - Cloud Digital Leader.v2023 06 22.q106peacegroupngNo ratings yet

- Manual de Calidad de Cerveza de Barril-2019 PDFDocument122 pagesManual de Calidad de Cerveza de Barril-2019 PDFAndrey Giovanny Riveros MerchanNo ratings yet

- Catalogue of Fittings - Orient ChinaDocument83 pagesCatalogue of Fittings - Orient Chinapham thangNo ratings yet

- SJT224Document4 pagesSJT224Shrishty RawatNo ratings yet

- Haemoglobin EstimationDocument20 pagesHaemoglobin Estimationanon_719505684No ratings yet

scope113_03

scope113_03

Uploaded by

long0200405Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

scope113_03

scope113_03

Uploaded by

long0200405Copyright:

Available Formats

Engine room Kawasaki’

s Superior Technology

Fuel oil

Vaporizer Gas heater Generator

engine G

1 4

Fuel gas

Generator

A cutting-edge, energy-saving

engine G

engine that achieves

Generator

engine G

the world’s lowest boil-off rate

Kawasaki’s Liquefied Boil-off

gas

Gas combustion unit

Fuel oil

No. 1

main engine

Dual-fuel, slow-speed, gas injection marine

diesel (ME-GI) engines are becoming main-

stream for LNG carriers. The use of both

Natural Gas (LNG) Carriers:

No. 1

high-pressure

Fuel gas boil-off gas (BOG) boiled off from the LNG

High-performance compressor Propellers

heat exchanger in the cargo tank and marine fuel oil,

Tank dome Partial No. 2 combined with the ship’s unique struc-

main engine

reliquefaction ture, results in a significant improvement

Packed with Innovations to Accommodate Located at the tank’s top,

it holds various pipes

system

No. 2 in fuel-efficiency. Moreover, by adding

the World’s Energy Supply Needs Cargo high-pressure

housed in the tank and Kawasaki’s own BOG partial reliquefaction

Pipe tower the service entryway.

tank compressor

system to the propulsion plant, the com-

A tower placed vertically in the LNG

fuel pump pany has achieved the world’s lowest

center of the tank, housing pipes

Commentary boil-off rate at 0.05% per day, an impres-

for loading/unloading the LNG, The evolution

Takumi Nozaki Manager (left) cargo pumps to discharge the LNG of main engines sive improvement from the 0.075%

to onshore facilities, a stairwell, achieved by the tank's insulation perfor-

Naoko Indoh Assistant Manager (right) and instrumentation. The cargo

never stops!

mance alone. The system is designed to

Initial Planning Section 2 pumps are located at the bottom

reliquefy BOG that was not used as fuel,

Initial Design Department, Engineering Division of the pipe tower to improve

Ship & Offshore Structure Company so the system can be defined as one

discharge performance.

Kawasaki Heavy Industries, Ltd. which completely eliminates waste.

A leader in Superior Energy-saving,

ever-evolving Propulsive Performance

LNG carrier designs

LNG

(liquefied natural gas)

Liquefied natural gas (LNG) carriers are marine vessels

designed to transport natural gas liquefied at a cryogenic

temperature of -162 ℃ at atmospheric pressure. Kawasaki is

the first company to have built domestically-produced LNG

carriers in Japan.

These vessels have three technological features: Kawasaki’

s Superior Technology

1. High-speed, energy-saving propulsive performance.

2. The use of Moss spherical tanks, to achieve both a larger

tank capacity and a reduced boil-off rate of LNG. Tank Performance

3. Operational performance that achieves improved maneu-

verability and efficient transport operations. Reshaped tanks for use in a 180,000 m3

Shipbuilders achieve good propulsive performance by Kawasaki’ s

LNG carrier that meets the New Panamax requirements

optimizing the design of the underwater portion of the LNG carrier

has become Achieving a 15% increase in capacity compared to a conventional spherical tank of the same diam-

ship, in order to reduce hydraulic resistance during naviga- the global eter and height, this newly-developed tank can be installed on ships that meet the breadth require-

tion, and also by improving engine performance. Optimi- standard! ments (i.e., the “New Panamax”) to pass through the renovated Panama Canal. The combined volume

zation of ship structure, in particular, calls for time-tested of four of these tanks is 180,000 m3, an increase in capacity of 25,000 m3. The tank has been

awarded Approval in Principle (AiP) from major ship classification societies.

technological expertise in LNG carrier building and ample

The new tank’s design is based on the conventional spherical Moss tank, but viewed in vertical

navigational experience. The level of such expertise directly cross section, it is shaped more like a square rather than a circle. As a result, the space between the

affects the design capability of shipbuilders. As the builder of tank and the hull is reduced, allowing for excellent anti-sloshing performance (a prominent feature

Japan’s first LNG carrier, Kawasaki boasts an unrivaled accumulation of of the Moss tank), ease of inspection, and improved volumetric efficiency. The tank’s reduced height

knowledge and expertise in this field. gives ships improved visibility from the navigation bridge, as well as increased stability.

Kawasaki’s proprietary thermal insulation panel system, with one of the world’s best insulation

One invention that epitomizes this expertise is successful development of a Tank contraction performances, has also been adopted for the new tank.

proprietary propulsion system, powered by an electronically-controlled gas injec- The tank contracts about

The LNG 150 mm in diameter when

tion marine diesel (ME-GI) engine, which is capable of using boiled-off gas as fuel Cargo tank insulation system

carrier’s hull, engine, it is loaded with LNG at

and re-liquefying the excess gas. This system results in the world’s lowest boil-off approximately -162°C. The tanks are covered with thermal insulation panels based on Kawasaki’s proprietary panel system

and tanks are the However, this deformation technology (“Kawasaki Panel System”). Each multilayer panel is composed of phenolic resin foam on the

rate. Moreover, Kawasaki has developed a new non-spherical tank that allows

fruit of Kawasaki’s is absorbed naturally by tank side, polyurethane foam in the middle, and an aluminum-plastic sheet on the exterior. The insulation

for a ship design that enables it to maintain the required size to access major the upper part of the panel is between 200 and 360 mm thick, achieving an excellent boil-off rate (thermal insulation perfor-

technological

LNG terminals in the world and pass through the expanded Panama Canal, “skirt” that holds the tank, mance) of less than 0.075% per day. Because of this performance superiority, the panel is being adopted

expertise! which also contracts as a 42 meters wide widely by LNG carrier builders other than Kawasaki.

and, at the same time, achieves a larger carrying capacity of 180,000 m3.

result of being cooled.

This advantage makes the tank suited to marine vessel application.

10 Scope 113 Scope 113 11

You might also like

- 4G15 DiagramaDocument1 page4G15 Diagramaalirio83% (6)

- Test Bank For Essentials of Genetics 10th Edition William S KlugDocument9 pagesTest Bank For Essentials of Genetics 10th Edition William S KlugBarbara Hinkle100% (41)

- Becoming Cancer-Free ManuscriptDocument149 pagesBecoming Cancer-Free ManuscriptD100% (1)

- CATERPILLAR GAS ENGINE 3516 Schematic DIAGRAM PDFDocument2 pagesCATERPILLAR GAS ENGINE 3516 Schematic DIAGRAM PDFwaqqasalisyed83% (6)

- d8n Wiring HardnessDocument2 pagesd8n Wiring HardnessandraNo ratings yet

- Tim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Document534 pagesTim Button, Sean Walsh - Philosophy and Model Theory (2018, Oxford University Press)Carlos Diaz Huerta100% (1)

- ELCOS 3000 RPM INTEL Light RUDocument3 pagesELCOS 3000 RPM INTEL Light RUandreyNo ratings yet

- Diagrama Electrico 320c PDFDocument2 pagesDiagrama Electrico 320c PDFPutra Jawa100% (2)

- Product Realization Process - MapDocument1 pageProduct Realization Process - Mapsenthildurai0% (1)

- Fungi Coloring WorksheetDocument7 pagesFungi Coloring WorksheetKarl DelgadoNo ratings yet

- Pco Controller +Document164 pagesPco Controller +Luis Fernando Mateus Delgado0% (1)

- App2 Architect RFP Response Evaluation FormDocument4 pagesApp2 Architect RFP Response Evaluation FormElliot MunNo ratings yet

- Chapter 6 Momentum & Collisions Nice Check ItDocument67 pagesChapter 6 Momentum & Collisions Nice Check Itvenkateshyadav2116100% (1)

- EMP Bentu Process Flow 2022Document1 pageEMP Bentu Process Flow 2022Maintenance BentuNo ratings yet

- Aerosila NPP JSC: Gas Turbine Power PlantsDocument30 pagesAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- EngRange Industry 06Document1 pageEngRange Industry 06FRANCISCO JAVIER BARRIENTOS GONZALESNo ratings yet

- Get More With The Glanza: Technical SpecificationsDocument6 pagesGet More With The Glanza: Technical Specificationssai vivekNo ratings yet

- Folha 01 Diagrama Painel PDFDocument1 pageFolha 01 Diagrama Painel PDFOreonnyr SouzaNo ratings yet

- Finite Element Solutions For Geotechnical EngineeringDocument24 pagesFinite Element Solutions For Geotechnical EngineeringSevinc Ünsal OralNo ratings yet

- Finite Element Solutions For Geotechnical EngineeringDocument24 pagesFinite Element Solutions For Geotechnical EngineeringMARCOSNo ratings yet

- Specification TSG-416Document2 pagesSpecification TSG-416MárcioNo ratings yet

- 4CHLDocument1 page4CHLZNC Plamo and ToyzNo ratings yet

- TRW Cross ReferenceDocument2 pagesTRW Cross Referenceeloyabner75% (4)

- Codigos RMC Componente Ingles Espanol V2Document120 pagesCodigos RMC Componente Ingles Espanol V2Esteban PerezNo ratings yet

- Astraflame BurnerDocument2 pagesAstraflame BurnerEdson AguirreNo ratings yet

- Engine View: 563C and 573C Electrical System Wheel Feller BuncherDocument2 pagesEngine View: 563C and 573C Electrical System Wheel Feller Bunchermrcruzito_2099No ratings yet

- Can Lvcan200 2017 08 18 enDocument26 pagesCan Lvcan200 2017 08 18 enmccm77No ratings yet

- Despiece y Funciomamiento Carburador Honda gx25 gx35 Ingles PDFDocument1 pageDespiece y Funciomamiento Carburador Honda gx25 gx35 Ingles PDFkexavadasNo ratings yet

- Skill Matrix 2023Document23 pagesSkill Matrix 2023Bondville ComplienceNo ratings yet

- ACPLDocument47 pagesACPLAmit BiswasNo ratings yet

- KatalogDocument4 pagesKatalog강동혁No ratings yet

- MBM38202931 03 141107Document2 pagesMBM38202931 03 141107Jose Alvarez VegaNo ratings yet

- QC Staff Rizqi FatullohDocument11 pagesQC Staff Rizqi FatullohRizqiNo ratings yet

- 7350-DRG-009Document1 page7350-DRG-009suhyyNo ratings yet

- Mon Nov 26 13:05:35 2018 Case: D:/BENZENE222.HSC Flowsheet: Case (Main)Document1 pageMon Nov 26 13:05:35 2018 Case: D:/BENZENE222.HSC Flowsheet: Case (Main)Hardika BayuNo ratings yet

- HP DesignJet 5100Document6 pagesHP DesignJet 5100gandharv vatsNo ratings yet

- M402.00 Schedule Sheet-2Document1 pageM402.00 Schedule Sheet-2Shweta KamatNo ratings yet

- Acc GX SeriesDocument4 pagesAcc GX SeriesWandresNo ratings yet

- MTU Series 4000 Tier 4i: Designed For The Future. Built For Your SuccessDocument3 pagesMTU Series 4000 Tier 4i: Designed For The Future. Built For Your Success桂腾明No ratings yet

- Generac's Position in The Market: Demand ResponseDocument2 pagesGenerac's Position in The Market: Demand ResponseJuly E. Maldonado M.No ratings yet

- 07h2append WL 1a EsDocument2 pages07h2append WL 1a EsMark FonsNo ratings yet

- DG SchematicDocument1 pageDG SchematicsubhashNo ratings yet

- Data Sheet Enclosure DOMH12112F DATASHEET ID in-IDDocument1 pageData Sheet Enclosure DOMH12112F DATASHEET ID in-IDNelyana UnoNo ratings yet

- Product Fiche: P/NO: MBM38202931 (1408-REV02) Printed in KoreaDocument2 pagesProduct Fiche: P/NO: MBM38202931 (1408-REV02) Printed in KoreaAlexandru CămuiNo ratings yet

- Session 7 Power CycleDocument146 pagesSession 7 Power CycleHanda Bin AdiNo ratings yet

- Bore Pump Lookup Data (MC Rev B)Document12 pagesBore Pump Lookup Data (MC Rev B)chrisNo ratings yet

- Familiarization For NEW Joiners 2017Document1 pageFamiliarization For NEW Joiners 2017Invatamant PpNo ratings yet

- đông cơ sau khi cải tạoDocument1 pageđông cơ sau khi cải tạothanhlocpt2205No ratings yet

- 12aym WGTDocument2 pages12aym WGTMuhammad KarimNo ratings yet

- 4g93 1996 Diagrama EléctricoDocument5 pages4g93 1996 Diagrama EléctricoRodríguez Andrés100% (1)

- TS - TF Series: "YANMAR Diesel Engine Is Versatile, Tough and Deserves To Be Chosen To Be Your Business Success Partner "Document1 pageTS - TF Series: "YANMAR Diesel Engine Is Versatile, Tough and Deserves To Be Chosen To Be Your Business Success Partner "Faiz FadhillahNo ratings yet

- 321d MDT Serial WiringDocument2 pages321d MDT Serial WiringjulianNo ratings yet

- Safety ConceptDocument61 pagesSafety Conceptandreylikestolearn5No ratings yet

- Chln-Hal2n-Ayl AgregatyDocument2 pagesChln-Hal2n-Ayl AgregatyMarek PiznalNo ratings yet

- Bulletin - High Efficiency Fan MotorsDocument3 pagesBulletin - High Efficiency Fan Motorsd44n 1122No ratings yet

- Crude Oil QPDocument12 pagesCrude Oil QPBethNo ratings yet

- Crude Oil QPDocument10 pagesCrude Oil QPSreeja Sen Year 10No ratings yet

- Product Data Sheet: 35A 440V Surface Mount Triple Pole Isolating Switch IP66Document1 pageProduct Data Sheet: 35A 440V Surface Mount Triple Pole Isolating Switch IP66tonielhageNo ratings yet

- Proton Persona 2016 PDFDocument2 pagesProton Persona 2016 PDFveltr0No ratings yet

- HD Rim Valve Guard PorosityDocument3 pagesHD Rim Valve Guard PorosityDurai NaiduNo ratings yet

- Selec Chart Concrete enDocument1 pageSelec Chart Concrete enaliomairNo ratings yet

- 12aym WGTDocument2 pages12aym WGTkhuong phamNo ratings yet

- XV. 473 Engine and Liandian Electric Injection SystemDocument1 pageXV. 473 Engine and Liandian Electric Injection SystemJose Luis Velasquez Romero100% (1)

- T5 EVO Fiche TechniqueDocument2 pagesT5 EVO Fiche TechniqueFateh DjNo ratings yet

- JW Pump Curve - F3514g-F3524g-F3524gsiDocument1 pageJW Pump Curve - F3514g-F3524g-F3524gsikman548No ratings yet

- E91-04Document4 pagesE91-04long0200405No ratings yet

- kolibrik-case-study-IEN-25092025Document1 pagekolibrik-case-study-IEN-25092025long0200405No ratings yet

- 5e.-SFBP-Nav-Tech-Program-Status_UpdateDocument4 pages5e.-SFBP-Nav-Tech-Program-Status_Updatelong0200405No ratings yet

- SecureSync M-CodeDocument4 pagesSecureSync M-Codelong0200405No ratings yet

- Thera TM015XP PDFDocument2 pagesThera TM015XP PDFAlvin Novandi Ega PradanaNo ratings yet

- Injector - Procedure 1kd FTVDocument16 pagesInjector - Procedure 1kd FTVMarcin ŚciegiennyNo ratings yet

- KARTHADocument2 pagesKARTHADebasis GoswamiNo ratings yet

- Computer System ServicingDocument11 pagesComputer System ServicingArman Santiago100% (1)

- Artistic AnalysisDocument6 pagesArtistic AnalysisMirela SinghNo ratings yet

- Lesson Plan Preparing For Parenthood Pregnancy and Labor - 0Document15 pagesLesson Plan Preparing For Parenthood Pregnancy and Labor - 0Sweta ManandharNo ratings yet

- SketchUp Tutorial 1 - TableDocument19 pagesSketchUp Tutorial 1 - TablenphilippNo ratings yet

- TM103 Chapter 1Document24 pagesTM103 Chapter 1johnnader1254No ratings yet

- Appendix XIV A - BP Microbiological Assay MethodsDocument6 pagesAppendix XIV A - BP Microbiological Assay MethodsSantosh Kumar TataNo ratings yet

- Linear Regression Analysis McqsDocument2 pagesLinear Regression Analysis McqsEngr Mujahid Iqbal80% (5)

- Advances in Upconversion Enhanced Solar Cell PerformanceDocument15 pagesAdvances in Upconversion Enhanced Solar Cell PerformanceMuhamad SulaemanNo ratings yet

- Cloud WarsDocument10 pagesCloud WarsAtharva Sachin KulkarniNo ratings yet

- 490806Document2 pages490806Informative InsaanNo ratings yet

- Jawaban Bahasa InggrisDocument9 pagesJawaban Bahasa InggrisHusnul KhotimahNo ratings yet

- Aem 499 Final Powerpoint Andrewdelili 4-28-2021Document20 pagesAem 499 Final Powerpoint Andrewdelili 4-28-2021api-548751501No ratings yet

- 1 s2.0 S0738081X01001997 MainDocument6 pages1 s2.0 S0738081X01001997 MainymiyazyNo ratings yet

- Cervical Myelopathy - ERHDocument42 pagesCervical Myelopathy - ERHAries RHNo ratings yet

- Parts List: Model: Apw-895N List No: 1657-04Document197 pagesParts List: Model: Apw-895N List No: 1657-04Mounir SassiNo ratings yet

- Google - Cloud Digital Leader.v2023 06 22.q106Document50 pagesGoogle - Cloud Digital Leader.v2023 06 22.q106peacegroupngNo ratings yet

- Manual de Calidad de Cerveza de Barril-2019 PDFDocument122 pagesManual de Calidad de Cerveza de Barril-2019 PDFAndrey Giovanny Riveros MerchanNo ratings yet

- Catalogue of Fittings - Orient ChinaDocument83 pagesCatalogue of Fittings - Orient Chinapham thangNo ratings yet

- SJT224Document4 pagesSJT224Shrishty RawatNo ratings yet

- Haemoglobin EstimationDocument20 pagesHaemoglobin Estimationanon_719505684No ratings yet