Professional Documents

Culture Documents

crude oil desalter

crude oil desalter

Uploaded by

ali aljifriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

crude oil desalter

crude oil desalter

Uploaded by

ali aljifriCopyright:

Available Formats

CRUDE OIL DESALTING

The desalting of crude oil is a process that does not have a high profile, but is vital to the

operation of the modern-day petroleum refinery. Desalters provide more protection to

costly refinery equipment than any other single piece of process hardware. Refining

Process Services and Ondeo Nalco Energy Services have developed this program to

provide an in-depth yet practical review of both the art and science of crude oil desalting.

Maintaining smooth operation of crude oil desalting units is both critically important and

quite difficult. Since there are so many significant variables to control, desalter operation

must constantly be adjusted to maintain optimum performance with the ever-changing

sources of crude oil.

The program's content is both comprehensive and wide-ranging. Sessions begin with a

discussion of the fundamentals of the desalting process including crude oil quality impact,

the operating variables, key equipment, various design options and the major process

variables. Once the fundamentals are established, discussion moves into the topics of unit

operations, monitoring, and process troubleshooting. An experienced group of industry

professionals has been assembled for the presentation of this program. The speakers are

Mr. Maury Goode of Howe-Baker Engineers, Ltd., Mr. Richard Pearson, an industry

consultant, and Mr. Gregg McAteer of Ondeo Nalco Energy Services, L.P.

Program participants will have the opportunity to obtain a broad working knowledge of

desalter operations, to gain insight into advancements in the field, and to interact with

others working in this area. The program is ideal for personnel involved in refinery process

engineering, plant operations, and technical service. Process engineers from design and

construction companies as well as those providing services to the refining industry should

also find this program beneficial.

PROGRAM OUTLINE

1. BENEFITS OF CRUDE OIL DESALTING

¾ Economic Impact on Downstream Units

¾ Desalting Performance Benchmarks

2. IMPACT OF CRUDE OIL QUALITY ON

DESALTER PERFORMANCE

¾ Impact of Crude Oil Density, Viscosity, and Asphaltenes

¾ Crude Oil Impurities: Water, Salt and Solids

¾ Impact of Organic Acids

¾ Desalting Heavy and Opportunity Crudes

3. FUNDAMENTALS OF ELECTRICAL DESALTING

¾ Wash Water Addition

+ Rate and Wash Water Quality

¾ Mixing/Contact

+ Mix Valves

+ Static Mixer

¾ Coalescence

+ Stoke's Law and Electrical Voltage

¾ Performance Control Variables

¾ Dehydration Efficiency vs. Salt Removal Efficiency

4. TYPES OF APPLICATIONS

¾ Single-Stage Dehydrator

¾ Single-Stage Desalter

¾ Two-Stage Desalter

¾ Three-Stage Desalter

¾ Typical Operating Conditions and Performance

5. DESALTER COMPONENTS

¾ Process Vessel

¾ Distribution System

¾ Electrodes

¾ Transactor

¾ Special Headers

6. DESALTER DESIGN CONSIDERATIONS

¾ Factors Determining Vessel Size

¾ Factors Determining Number of Stages

¾ Factors Determining Transactor Size

¾ Power Consumption

7. COMMERCIAL DESALTER DESIGNS

¾ Howe-Baker

¾ Petreco

¾ Other

8. FACTORS THAT AFFECT DESALTER OPERATION

AND PERFORMANCE

¾ Crude Oil Feed Rate and Quality

¾ Temperature/Viscosity/Density Relationships

¾ Electrical Field Intensity

¾ Wash Water Rate, Quality and Flow Configuration

¾ Emulsion Formation (Pumps, Exchangers, Valves, Mixers)

¾ Control of Water Level and Emulsion Layers

¾ Demulsifier Technology and Addition Rate

¾ Mud Washing and Brine Recycle

9. TROUBLESHOOTING THE DESALTER

¾ Oily Effluent

¾ Poor Dehydration and/or Desalting

10. OTHER ELECTROSTATIC TREATING APPLICATIONS

¾ FCC Feed Desalting

¾ Distillate Treating

PROGRAM SPEAKERS

Maury Goode, P.E., is a Product Development Engineer for Howe-Baker Engineers, Ltd.,

Tyler, Texas. He is responsible for the process and equipment design for Howe-Baker's

Separation Technologies Division, which includes crude oil dehydration and desalting

equipment. He has held a variety of engineering positions in the areas of oil and gas

exploration and production, control systems engineering, project management, process

design, technical sales, and system troubleshooting. Mr. Goode recently authored a paper

on crude oil desalting. He holds a BS degree in petroleum engineering from Texas A&M

University and has over 17 years of experience in the hydrocarbon processing industry.

Gregg McAteer is Worldwide Crude Unit Business Manager for Ondeo Nalco Energy

Services, L.P., Sugar Land, Texas. He is responsible for marketing and strategic planning

of the company's refinery process chemical programs used in refinery crude units. Other

responsibilities include program performance benchmarking and new technology

development. Mr. McAteer holds a BS degree in petroleum engineering from Texas A&M

University and has over 14 years experience in the hydrocarbon processing industry.

Richard Pearson is a consultant to Ondeo Nalco Energy Services, L.P. For 33 years he

was employed by Nalco Chemical Company in various field positions including Regional

Technical Manager. Since his retirement in 1990, he has assisted in refineries in 31

countries and the U.S. as a refinery process chemical consultant. These assignments have

included technical audits, customer seminars, and problem solving. His primary areas of

experience are crude oil desalting and recovered oil emulsion, and the practical applied

chemistry of crude unit corrosion control. He holds a BS degree in engineering from Penn

State University.

You might also like

- Wastewater Engineering - Treatment and Resource Recovery-Metcalf and Eddy 5th Ed (2014) Seccion 8.1 Cap 8Document30 pagesWastewater Engineering - Treatment and Resource Recovery-Metcalf and Eddy 5th Ed (2014) Seccion 8.1 Cap 8Ricardo Javier PlasenciaNo ratings yet

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementFrom EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementNo ratings yet

- Lead Commissioning Engineer - Process Bala ResumeDocument5 pagesLead Commissioning Engineer - Process Bala ResumeMidha Neer50% (2)

- Solid Control Catalog - v5Document163 pagesSolid Control Catalog - v5super2274100% (1)

- PromaxDocument20 pagesPromaxehsan_sa405100% (1)

- Profil Perusahaan PT. Frata Bayutama Prima PDFDocument20 pagesProfil Perusahaan PT. Frata Bayutama Prima PDFSuhairi AnasNo ratings yet

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Packing Brochure SADocument20 pagesPacking Brochure SAfrederick alayonNo ratings yet

- Description of Crude Oil Desalting 10-30-09Document3 pagesDescription of Crude Oil Desalting 10-30-09Amrut Dixit0% (1)

- Crude Oil Desalting-Barcelona, Spain 2005Document2 pagesCrude Oil Desalting-Barcelona, Spain 2005Mohamed Sayed AbdoNo ratings yet

- HAZOPDocument20 pagesHAZOPFATHYNo ratings yet

- BREAXIT Emulsion Breakers: Oilfield Separation TechnologiesDocument8 pagesBREAXIT Emulsion Breakers: Oilfield Separation TechnologiesptstradingNo ratings yet

- SUEZ Upstream OG Chemicals PDFDocument9 pagesSUEZ Upstream OG Chemicals PDFMoujahed FarésNo ratings yet

- Oil and Gas Process ChemistryDocument123 pagesOil and Gas Process Chemistryjps21100% (1)

- Gas Conditioning & Processing - GLOMACSDocument5 pagesGas Conditioning & Processing - GLOMACSCHO ACHIRI HUMPHREYNo ratings yet

- Fundamentals of Pump and Fundamentals of Pump and Compressor Systems - ME-Compressor Systems - ME - 44 44Document4 pagesFundamentals of Pump and Fundamentals of Pump and Compressor Systems - ME-Compressor Systems - ME - 44 44Hayderr HassNo ratings yet

- Description of Basics of Petroleum 6-19-08Document3 pagesDescription of Basics of Petroleum 6-19-08tanajibandal1986No ratings yet

- 6th Annual Global Improved Oil Recovery Praxis Interactive Technology Workshop - BrochureDocument8 pages6th Annual Global Improved Oil Recovery Praxis Interactive Technology Workshop - BrochureAlAbriBaderNo ratings yet

- Usama - Clariant Prod SupDocument4 pagesUsama - Clariant Prod SuposamaNo ratings yet

- Data Overview - FIELD OPERATOR IDocument2 pagesData Overview - FIELD OPERATOR IBhdNo ratings yet

- Enhanced Oil RecoveryDocument18 pagesEnhanced Oil RecoveryBankaram ChoudharyNo ratings yet

- Fuel AnalysisDocument17 pagesFuel Analysiseigersumarly100% (1)

- 2015 09Document189 pages2015 09nikhil_barshettiwatNo ratings yet

- Drilling Supervisor Well Leader in Qatar Resume Ossama M Gamal AlyDocument4 pagesDrilling Supervisor Well Leader in Qatar Resume Ossama M Gamal AlyOssamaMGamalAlyNo ratings yet

- Chemical Processing Magazine - 012013Document54 pagesChemical Processing Magazine - 012013selereak100% (1)

- 4f59a2f56193c Proces Plant Commissioning Start-Up and Troubleshooting Nel 12 4smDocument4 pages4f59a2f56193c Proces Plant Commissioning Start-Up and Troubleshooting Nel 12 4smrakeshengg25No ratings yet

- (V) Residue Upgrading Using Ebullated Bed Hydrocracking - CriterionDocument2 pages(V) Residue Upgrading Using Ebullated Bed Hydrocracking - CriterionKwangsjungNo ratings yet

- Quality Control: Aneshy Onsultants NternationalDocument20 pagesQuality Control: Aneshy Onsultants NternationalUdiNo ratings yet

- Dokumen - Tips Jeff Tyus Resume Plant ManagerDocument2 pagesDokumen - Tips Jeff Tyus Resume Plant ManagerDenisse WeeNo ratings yet

- JPT May16Document104 pagesJPT May16Hari TharanNo ratings yet

- Bebin Field OperatorDocument5 pagesBebin Field Operatorjohn MNo ratings yet

- Unitoperations and ProcessesDocument19 pagesUnitoperations and ProcessesnirbhaykumarNo ratings yet

- Usama Process HeadDocument3 pagesUsama Process HeadusamampkNo ratings yet

- ConstantDocument8 pagesConstantAshish SrivastavaNo ratings yet

- Senior Petroleum Engineer: Emad El Din SaadDocument10 pagesSenior Petroleum Engineer: Emad El Din SaadEmad MabroukNo ratings yet

- Technical Summary of Oil & Gas Produced Water Treatment TechnologiesDocument53 pagesTechnical Summary of Oil & Gas Produced Water Treatment TechnologiesPrie TeaNo ratings yet

- DEMTROL™ High PerformanceDocument8 pagesDEMTROL™ High Performancetahera aqeel100% (2)

- CFC 1criterionbrochureDocument19 pagesCFC 1criterionbrochureSuraj Amin100% (1)

- Ronald George ResumeDocument3 pagesRonald George ResumeRonald GeorgeNo ratings yet

- Flow Assurance For Offshore Flow Assurance For Offshore Production - FAOP Production - FAOPDocument2 pagesFlow Assurance For Offshore Flow Assurance For Offshore Production - FAOP Production - FAOPAhmed RamadanNo ratings yet

- Old CopiesDocument22 pagesOld CopiesMuhammad DaudNo ratings yet

- 2014 PTQ q4Document156 pages2014 PTQ q4digeca100% (1)

- Ameer - Mechanical LeadDocument4 pagesAmeer - Mechanical Leadbahardeen1998No ratings yet

- Refining Process HBDocument296 pagesRefining Process HBsomucdm602367% (3)

- ProMax 3 BrochureDocument20 pagesProMax 3 BrochureNila Gama100% (2)

- JohnFailingResume 2021Document5 pagesJohnFailingResume 2021Manas RanjanNo ratings yet

- FW Solvent DeasphaltingDocument11 pagesFW Solvent Deasphaltingapminshull100% (1)

- December 2016 - Intl.Document208 pagesDecember 2016 - Intl.Karem Jeanette Saenz Bernal100% (1)

- Sample Resume Process Engineer Economic RecoveryDocument3 pagesSample Resume Process Engineer Economic RecoverySiva KumarNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Career Change From Real Estate to Oil and Gas ProjectsFrom EverandCareer Change From Real Estate to Oil and Gas ProjectsRating: 5 out of 5 stars5/5 (1)

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Pollution Control Technologies for Small-Scale OperationsFrom EverandPollution Control Technologies for Small-Scale OperationsNo ratings yet

- Lubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6From EverandLubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6Rating: 5 out of 5 stars5/5 (1)

- Maltol (10 deg, Pyro)Document1 pageMaltol (10 deg, Pyro)ali aljifriNo ratings yet

- Maltol (5 deg, Pyro)Document1 pageMaltol (5 deg, Pyro)ali aljifriNo ratings yet

- Lecture 1Document2 pagesLecture 1ali aljifriNo ratings yet

- Maltol (5 Deg, OXO)Document1,004 pagesMaltol (5 Deg, OXO)ali aljifriNo ratings yet

- Do you have what it takes to be a leaderDocument2 pagesDo you have what it takes to be a leaderali aljifriNo ratings yet

- Reaction of Hydroperoxy Radicals With Primary C Alcohols: A Profound E Ffect On Ignition Delay TimesDocument14 pagesReaction of Hydroperoxy Radicals With Primary C Alcohols: A Profound E Ffect On Ignition Delay Timesali aljifriNo ratings yet

- Tutorial 3Document2 pagesTutorial 3ali aljifriNo ratings yet

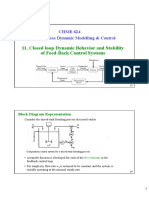

- Frequency Response Analysis & Control System Design: CHME 624 Advance Process Dynamic Modelling & ControlDocument25 pagesFrequency Response Analysis & Control System Design: CHME 624 Advance Process Dynamic Modelling & Controlali aljifriNo ratings yet

- Controller Tuning: CHME 624 Advance Process Dynamic Modelling & ControlDocument15 pagesController Tuning: CHME 624 Advance Process Dynamic Modelling & Controlali aljifriNo ratings yet

- Closed Loop Dynamic Behavior and Stability of Feed-Back Control SystemsDocument21 pagesClosed Loop Dynamic Behavior and Stability of Feed-Back Control Systemsali aljifriNo ratings yet

- Joy T - Petr. Ref.-Introduction-Chapter 1 &2-Session 2Document47 pagesJoy T - Petr. Ref.-Introduction-Chapter 1 &2-Session 2ali aljifriNo ratings yet

- Most and Least Learned Competencies: Republic of The PhilippinesDocument5 pagesMost and Least Learned Competencies: Republic of The PhilippinesLorena De BelenNo ratings yet

- h1 PDFDocument124 pagesh1 PDFMuhammad AminNo ratings yet

- Unit 1 Molecules Diet Transport and HealthDocument61 pagesUnit 1 Molecules Diet Transport and HealthKevir ManNo ratings yet

- Simulacion RecuperacionDocument2 pagesSimulacion RecuperacionVivi RochaNo ratings yet

- China Gasification Database: Existing and Developmental Plants and ProjectsDocument7 pagesChina Gasification Database: Existing and Developmental Plants and ProjectsUmar HayatNo ratings yet

- Vol1i7x ECCC RecommandationsDocument21 pagesVol1i7x ECCC RecommandationsRami GhorbelNo ratings yet

- Product DataDocument2 pagesProduct DataegomoNo ratings yet

- WHO - JECFA Arsenic 2011Document165 pagesWHO - JECFA Arsenic 2011Wilmer Amed Cardozo EspinozaNo ratings yet

- G-03 Model Z05 Rigid Coupling - Rev N PDFDocument3 pagesG-03 Model Z05 Rigid Coupling - Rev N PDFDaniel SanNo ratings yet

- Experiment 1: Change of Iron (Ii) Ion To Iron (Iii) IonDocument12 pagesExperiment 1: Change of Iron (Ii) Ion To Iron (Iii) Ionryder1man6433100% (1)

- Bioavailable Curcumin FormulationsDocument9 pagesBioavailable Curcumin Formulationsciprian72No ratings yet

- Pengaruh Suhu Dan Waktu Pelapisan Tembaga Pada Baja Karbon Rendah Secara Elektroplating Terhadap Korosi Dewi SasmitaDocument7 pagesPengaruh Suhu Dan Waktu Pelapisan Tembaga Pada Baja Karbon Rendah Secara Elektroplating Terhadap Korosi Dewi SasmitaAndika SuryaNo ratings yet

- Different Raw Material Chemical Composition Their Equivalent Materials and Mechanical PropertiesDocument32,767 pagesDifferent Raw Material Chemical Composition Their Equivalent Materials and Mechanical PropertiesRebekah WilsonNo ratings yet

- MMO titanium anodes, cathodes, HHO Generator, Fuel Cell Kits, Dry Cell Kit , H2O statuary engines, fuel benefits pollution free exhaust, Water4gas, fuel saver, wate car, Hydrogen and Oxygen, Green Gas, Brown's Gas, Rhodes Gas, Bubbler, Hydrogen Generator, Water reservoir, dryer, Increase the Mileage, electrolyzer.Document24 pagesMMO titanium anodes, cathodes, HHO Generator, Fuel Cell Kits, Dry Cell Kit , H2O statuary engines, fuel benefits pollution free exhaust, Water4gas, fuel saver, wate car, Hydrogen and Oxygen, Green Gas, Brown's Gas, Rhodes Gas, Bubbler, Hydrogen Generator, Water reservoir, dryer, Increase the Mileage, electrolyzer.Mr. Velappan JeyakummarNo ratings yet

- PeristalticDocument12 pagesPeristalticAnonymous ItzBhUGoiNo ratings yet

- Mining: Supercritical Flow Critical Flow Subcritical FlowDocument3 pagesMining: Supercritical Flow Critical Flow Subcritical FlowBoonsita NammanaNo ratings yet

- Chemistry Notes (Chapter 1)Document14 pagesChemistry Notes (Chapter 1)NiranjanNo ratings yet

- Ioesolutions Esign Com NP Contents Sanitary Engineering Ce 656Document5 pagesIoesolutions Esign Com NP Contents Sanitary Engineering Ce 656Ranjit MahatoNo ratings yet

- Titration of Iodine With Standard Thisulphate SolutionDocument3 pagesTitration of Iodine With Standard Thisulphate Solutiondhungelsubhash8154No ratings yet

- IIT JEE RoadmapDocument3 pagesIIT JEE RoadmapAj StylesNo ratings yet

- B V P Vacuum Pump Company ProfileDocument10 pagesB V P Vacuum Pump Company ProfileravishankarNo ratings yet

- 5 - 1 - Sealed - Radiation - Sources - Product InformationDocument40 pages5 - 1 - Sealed - Radiation - Sources - Product InformationasdtwrNo ratings yet

- World Journal of Pharmaceutical ResearchDocument14 pagesWorld Journal of Pharmaceutical ResearchDevanandDongreNo ratings yet

- Piu RajakDocument18 pagesPiu Rajakpiu_rajakNo ratings yet

- Explaination of Primary & Secondary Stress With ExampleDocument4 pagesExplaination of Primary & Secondary Stress With ExampleAndrewNo ratings yet

- Piping, Modules & Skids: PrefabricatedDocument2 pagesPiping, Modules & Skids: PrefabricatedRevankar B R ShetNo ratings yet

- GT Fuel Nozzle RefurbishmentDocument3 pagesGT Fuel Nozzle Refurbishmentnabil160874No ratings yet

- Voltaic CellsDocument10 pagesVoltaic CellsJm EscobarNo ratings yet