Professional Documents

Culture Documents

Weekly planning_10

Weekly planning_10

Uploaded by

SADMAN AOWAL0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageWeekly planning_10

Weekly planning_10

Uploaded by

SADMAN AOWALCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 1

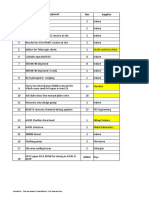

Mechanical Department Weekly Work Planning(14 July to 18 July)

Sl No. Work Details Responsible Engineer Remarks

1. V-100 nozzle cutting completed except LG point

2. V-101 nozzle cutting completed except LG point

1 SWS plant structure & vessel-tower fabrication follow-up Arabinda & Sadman

3. V-102 welding ongoing

2 10000 BPD plant equipment(Vessel) modelling & PV Elite analysis 3 out of 11

3 Store Rack drawing finalization with supplier and technical communication follow up

4 LPG pump house to filling station pipe line fabrication work Follow-up

5 10000 BPD plant open drain-closed drain material procurement follow up

Sadman

6 Power House-2 generator erection & commissioning project planning & schedule update

7 New Power-house electrical support work (fabrication drawing updating).

8 Day tank diesel line routing layout drawing for approval

9 Tank farm area pipeline fabrication supervision and planning

10 10,000 BPD plant fabrication & installation schedule detailing as per manpower

11 10,000 BPD plant procurement(local & foreign) follow-up and technical communication

12 Other foreign procurement follow-up

13 10,000 BPD plant precurement master file updating

14 10,000 BPD plant 2D layout drawing for 1st floor and 2nd floor

15 Commercial 2D/3D layout revision as per their feedback to get duty benefit

16 C-7001 technical communication follow-up Keron

17 New hot oil heater technical communication with SBMC

18 10,000 BPD plant exchanger revised GA check and approval KK sheet approved, revised GA received last Thursday

19 10,000 BPD plant heater files check and feedback to Heatec Feedback sent, waiting for response

20 10,000 BPD plant pump feedback check and approve remaining pump GAs Sundyne Pump Items received last Friday(Sulzer completed)

21 Local CFU Diesel pump location confirmation with process department to procure new one

Process department support needed

22 Flare area pump permanent base and pit location confirmation with process department

23 10000 BPD plant equipment positon finalization in layout of Tower 03 out of 06

10000 BPD plant equipment modelling of Aerocooler

24 10000 BPD plant equipment modelling of Pump Arabinda

25 New LPG vessel Pipe line erection work follow up

28 Ship maintenance look after

29 10000 BPD plant structure and OD-CD fabrication follow-up Keron & Sadman

30 Rotating items stock checking Kaisar

31 Contractors bill checking Arabinda & Sadman

32 Padma Meghna, Jamuna pipline survey and drawing preparation Surveyor Zelan

33 Rotating work list

34 Work Details Man power

35 H-301 blower fan maintenance work Aziz 70% complete

36 Cooling tower pump inter-change( spx to deepblue) Waiting for manpower Waiting for manpower.

37 Reformer-2 oil h-2 compressor dismental for scraping Jashim, Puloq Start on Sunday

38 Agitator motor installation work Jashim Waiting for approval.

39 Mechanical items house kepping work. Bela, Mijan 30%

40 Flare pump ready work. 4set completed, 2set running Aziz 80%

41 Development work list Group Nos

42 SWS Vessel, Gusset Make, shell plate preparation, Saddle making

43 SWS Structure top bottom base plate cutting drilling, Gusset making

44 SWS Platform, railing making

45 SWS Ladder making 3

46 Old gate valve, fittings segregating for counting

47 Old Flare pipe line cutting and open

48 Old Flare Structure cutting and open 3

49 Flare fire water line making 1

50 Dyke-1 water flushing line, cooling line tie inn

51 Dyke -5 Fire, Foam line Fabrication & Fitting

52 Dyke -5 Beam Make for Tank Farm Pipe line Support fitting

4

53 Dyke-5 Tank 6" pipe line fabrication

54 Tank to tank Circulation line Fabrication as instructed

55 fire line around Dyke-5

56 New Exchanger Tube Bundle Make for RF-2 1

57 New Gate Make for Store and pocket gate, MCC Door Making 1

58 H-3001 to E-6015 Supply and return 6'' pipe line fabrication 2

59 RF-2 to CMX BT Tower 2" Line fabrication 1

You might also like

- Work Procedure For Repair, Revision of Steel Structures & Painting For STB, STG, CCB, WWTB and FWPHDocument14 pagesWork Procedure For Repair, Revision of Steel Structures & Painting For STB, STG, CCB, WWTB and FWPHResearcherNo ratings yet

- The Accuracy of Measurement Systems in The Steady State: Exercise 1Document4 pagesThe Accuracy of Measurement Systems in The Steady State: Exercise 1siennaNo ratings yet

- Qcp-Pipeline ConstructionDocument20 pagesQcp-Pipeline Constructionbelhaska100% (2)

- Weekly Planning 6-1Document1 pageWeekly Planning 6-1SADMAN AOWALNo ratings yet

- Weekly Planning 2-1Document1 pageWeekly Planning 2-1SADMAN AOWALNo ratings yet

- Weekly Planning 3Document1 pageWeekly Planning 3SADMAN AOWALNo ratings yet

- HVAC - QueriesDocument4 pagesHVAC - Queriesharicv019No ratings yet

- List of Prs 22,2021 SR - No. PR Details States SupplierDocument4 pagesList of Prs 22,2021 SR - No. PR Details States SupplierSaurabh Kumar SinghNo ratings yet

- 3967-19-PL19060108 - 0025 - CRS - Rev ADocument2 pages3967-19-PL19060108 - 0025 - CRS - Rev AAlaguraja SubramanianNo ratings yet

- Mechanical Out Standing 12.07.2020-ListDocument1 pageMechanical Out Standing 12.07.2020-ListAltaf KhanNo ratings yet

- SN 006Document10 pagesSN 006dikiNo ratings yet

- NrlContracts Above 5lakh Awarded Dec-2022Document45 pagesNrlContracts Above 5lakh Awarded Dec-2022Akash RajputNo ratings yet

- A2A4E7 - 01 - Project OverviewDocument4 pagesA2A4E7 - 01 - Project OverviewrizalziNo ratings yet

- Ls ScheduleDocument42 pagesLs ScheduleChandra Sekhar BoyinaNo ratings yet

- G&J Contractors Profile 20082018 Reliance VadodaraDocument16 pagesG&J Contractors Profile 20082018 Reliance VadodaranirdoshkumarNo ratings yet

- OMJ-MAN-SRT-QA-1964-Updated-AG FF Pipes. REPAIR WELDING PROCEDUREDocument10 pagesOMJ-MAN-SRT-QA-1964-Updated-AG FF Pipes. REPAIR WELDING PROCEDUREMostafa NabilNo ratings yet

- Annex#3 Erection EngineeringDocument5 pagesAnnex#3 Erection EngineeringNasim KurdistanNo ratings yet

- 19 Epe CMWSSB STP 120MLD GHT (RCC) SDC 10Document36 pages19 Epe CMWSSB STP 120MLD GHT (RCC) SDC 10epe civil1No ratings yet

- Standardization of Discipline ActivityDocument1 pageStandardization of Discipline ActivityNirmalNo ratings yet

- Vol III B Technical Specification For Mech WorksDocument217 pagesVol III B Technical Specification For Mech WorksPC Snehal Construction Pvt. Ltd. JhalawarNo ratings yet

- HFY-3800-0000-PPL-PD-0009 - 0 Pipeline Crossings Procedure Including HDD, Code-ADocument11 pagesHFY-3800-0000-PPL-PD-0009 - 0 Pipeline Crossings Procedure Including HDD, Code-AYousif AlmusawiNo ratings yet

- Standard 1103Document27 pagesStandard 1103Sulist N WahyudieNo ratings yet

- West African Gas Pipeline Company Line Sizing ReportDocument7 pagesWest African Gas Pipeline Company Line Sizing ReportPaul OhiorNo ratings yet

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- EBS1-FSFA11-SAPR-PRTS-1002-D03-RTP Hydrostatic Test ProcedureDocument18 pagesEBS1-FSFA11-SAPR-PRTS-1002-D03-RTP Hydrostatic Test ProcedureYousif AlmusawiNo ratings yet

- Engineering Design For Construction of MHL Beira Fuel Terminal at Beira Port, Mozambique Documents & DrawingsDocument4 pagesEngineering Design For Construction of MHL Beira Fuel Terminal at Beira Port, Mozambique Documents & DrawingsAnoop PrajapatiNo ratings yet

- Colorado School of MinesDocument4 pagesColorado School of Mineshsalehiz5001No ratings yet

- Available Staircase in BuildingsDocument1 pageAvailable Staircase in Buildingssuresh787898No ratings yet

- 26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ADocument13 pages26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ARezky BaskoroNo ratings yet

- Section 3 - Scope of WorkDocument14 pagesSection 3 - Scope of Worktrung nguyen tranNo ratings yet

- MR Project July20-June21Document31 pagesMR Project July20-June21mnur selamitNo ratings yet

- Chapter Ind 42 Welded Repairs and AlterationsDocument58 pagesChapter Ind 42 Welded Repairs and AlterationsGuillermo ZaragozaNo ratings yet

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Document1 pageTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaNo ratings yet

- Heat Exchanger: Data Sheet ForDocument1 pageHeat Exchanger: Data Sheet ForAmanNo ratings yet

- Weekly Activity Report 13-01-2024 To 19-01-2024Document5 pagesWeekly Activity Report 13-01-2024 To 19-01-2024أسامه محمد عونNo ratings yet

- BES-SEG-RHB-PR-COM-001-0Document44 pagesBES-SEG-RHB-PR-COM-001-0cina.mpegNo ratings yet

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument2 pagesBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- SoR Chattis PH 2015 - Schedule of Rates - ChattisgarhDocument377 pagesSoR Chattis PH 2015 - Schedule of Rates - Chattisgarhnimm1962100% (1)

- Boiler-2 Area Punch List (17-02-2024) - 1Document1 pageBoiler-2 Area Punch List (17-02-2024) - 1Syed Muhammad Saqib BariNo ratings yet

- SOW KJI KJC Flare System Improvement - Rev0a-Approved - CommDocument13 pagesSOW KJI KJC Flare System Improvement - Rev0a-Approved - CommKuncoro Hadi WibowoNo ratings yet

- VEN 3250 HGE 5-26-0019 1 GRV Pipe and ElbowDocument34 pagesVEN 3250 HGE 5-26-0019 1 GRV Pipe and ElbowOiltech EngineeringNo ratings yet

- Refcon QuoteDocument4 pagesRefcon QuoteamitNo ratings yet

- Sow-Process EngineeringDocument38 pagesSow-Process EngineeringPaary AtNo ratings yet

- Weld Repair Proce - Code-BDocument7 pagesWeld Repair Proce - Code-BMohamed FarisNo ratings yet

- AgitatorDocument19 pagesAgitatorPrashanth ChinthallapallyNo ratings yet

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Document33 pages26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyrisky100% (1)

- Work Planning Schedule For Season 2076-2077 of Electrical DepartmentDocument8 pagesWork Planning Schedule For Season 2076-2077 of Electrical DepartmentEngineer Reliance Sugar Pvt. Ltd.No ratings yet

- SL - No. Location Description Manpower Engaged Saiz: United Cements Pvt. LTDDocument4 pagesSL - No. Location Description Manpower Engaged Saiz: United Cements Pvt. LTDvinodsnNo ratings yet

- Wind Example EBook Release 2.0 Preview 1Document4 pagesWind Example EBook Release 2.0 Preview 1Shital ChaudhariNo ratings yet

- NJBP Restoration Daily Highlights Sep 15 2022 IJNDocument1 pageNJBP Restoration Daily Highlights Sep 15 2022 IJNRenante GordoveNo ratings yet

- Equipment Nos Supplier: Sensitivity: This Document Is Classified As "LNT Internal Use"Document2 pagesEquipment Nos Supplier: Sensitivity: This Document Is Classified As "LNT Internal Use"arkaprava paulNo ratings yet

- Daily Report: M Tower Project (4 Basement + 26 Storey Steel Office Building)Document5 pagesDaily Report: M Tower Project (4 Basement + 26 Storey Steel Office Building)phyo7799No ratings yet

- FP SRU PidemcoDocument2 pagesFP SRU PidemcoTuesou MachereNo ratings yet

- NTP & Site InfrastructureDocument11,523 pagesNTP & Site InfrastructurechanakyasatyaNo ratings yet

- Corrigendum 01 Amendmentin TCCDocument258 pagesCorrigendum 01 Amendmentin TCCrverma2528No ratings yet

- E - C Manual - R1 - 28.8.18Document86 pagesE - C Manual - R1 - 28.8.18Bruno LopezNo ratings yet

- MAINTENANCEDocument12 pagesMAINTENANCEsabir hussainNo ratings yet

- Hydrualic ReportDocument13 pagesHydrualic ReportPaul OhiorNo ratings yet

- 00 - Dri Operations Update To Damam Delegation - Aak - 04102010Document27 pages00 - Dri Operations Update To Damam Delegation - Aak - 04102010SalmanEjazNo ratings yet

- Stress 1Document6 pagesStress 1azhagu durai100% (1)

- Golf Course Irrigation: Environmental Design and Management PracticesFrom EverandGolf Course Irrigation: Environmental Design and Management PracticesNo ratings yet

- Customized Job Form 3Document4 pagesCustomized Job Form 3SADMAN AOWALNo ratings yet

- Progress Status SWS Plant LPG Vessel 23.06.2024Document2 pagesProgress Status SWS Plant LPG Vessel 23.06.2024SADMAN AOWALNo ratings yet

- Actual Total Budget (New NHT & Reformer) UpdatedDocument7 pagesActual Total Budget (New NHT & Reformer) UpdatedSADMAN AOWALNo ratings yet

- Customized Job Form 3Document4 pagesCustomized Job Form 3SADMAN AOWALNo ratings yet

- Revise Offer MTCL HDR SPLDocument4 pagesRevise Offer MTCL HDR SPLSADMAN AOWALNo ratings yet

- Weekly Planning 6-1Document1 pageWeekly Planning 6-1SADMAN AOWALNo ratings yet

- SL No. Tank Details Description Amount (BDT)Document11 pagesSL No. Tank Details Description Amount (BDT)SADMAN AOWALNo ratings yet

- Final BillDocument1 pageFinal BillSADMAN AOWALNo ratings yet

- Warning LetterDocument1 pageWarning LetterSADMAN AOWALNo ratings yet

- BOM For Tank 139, Tank 140 & Tank 141: SL - No Description Size Unit Tank 139-D-13M, H-12.6M Foreign MaterialDocument1 pageBOM For Tank 139, Tank 140 & Tank 141: SL - No Description Size Unit Tank 139-D-13M, H-12.6M Foreign MaterialSADMAN AOWALNo ratings yet

- Tank Wise BOQDocument5 pagesTank Wise BOQSADMAN AOWALNo ratings yet

- Old Workshop Layout-ModelDocument1 pageOld Workshop Layout-ModelSADMAN AOWALNo ratings yet

- Progression (In Minute) : Completion SequenceDocument1 pageProgression (In Minute) : Completion SequenceSADMAN AOWALNo ratings yet

- Condition Based Maintenance On Board, Vibration & Shock Pulse MonitoringDocument61 pagesCondition Based Maintenance On Board, Vibration & Shock Pulse MonitoringSADMAN AOWALNo ratings yet

- Changeover Job PlanDocument1 pageChangeover Job PlanSADMAN AOWALNo ratings yet

- Progression (In Minute) : Completion SequenceDocument1 pageProgression (In Minute) : Completion SequenceSADMAN AOWALNo ratings yet

- Fasteners - Hexagon Head Screws - Product Grades A and B (ISO 4017:2014)Document14 pagesFasteners - Hexagon Head Screws - Product Grades A and B (ISO 4017:2014)SADMAN AOWALNo ratings yet

- Progression (In Minute) : Completion SequenceDocument1 pageProgression (In Minute) : Completion SequenceSADMAN AOWALNo ratings yet

- 750cc Ural ManualDocument128 pages750cc Ural ManualCammac69No ratings yet

- CCPR Question BankDocument5 pagesCCPR Question BankEthan FernandesNo ratings yet

- Independent University, Bangladesh Lean Manufacturing, Just in Time and Kanban: Case Study of Toyota Production System (TPS)Document17 pagesIndependent University, Bangladesh Lean Manufacturing, Just in Time and Kanban: Case Study of Toyota Production System (TPS)MASHIUR RAHMANNo ratings yet

- App12 - ACI Meshed Slab and Wall DesignDocument51 pagesApp12 - ACI Meshed Slab and Wall DesignDario Manrique GamarraNo ratings yet

- Connection Data For Induction Motor PDFDocument38 pagesConnection Data For Induction Motor PDFCris DucusinNo ratings yet

- Pre Test Post TestDocument2 pagesPre Test Post TestAnaleen NolascoNo ratings yet

- Louis Kahn: FisherDocument9 pagesLouis Kahn: FisherVivien ClaudiaNo ratings yet

- Symphonie eDocument4 pagesSymphonie enainoNo ratings yet

- Circular W.E.F 19th May'22Document224 pagesCircular W.E.F 19th May'22Mohit MohataNo ratings yet

- Nike Case StudyDocument2 pagesNike Case StudyWengFungNgNo ratings yet

- PMD 3D Sensor Brochure UKDocument6 pagesPMD 3D Sensor Brochure UKifm electronicNo ratings yet

- UNI 20221023062620796796 CA0047060 uniROB IpayobDocument2 pagesUNI 20221023062620796796 CA0047060 uniROB IpayobIssey YaacobNo ratings yet

- Recoverit User Manual PortuguesDocument93 pagesRecoverit User Manual Portuguespedro netoNo ratings yet

- Corporatre ValuationDocument46 pagesCorporatre ValuationVipin MehtaNo ratings yet

- Chapter 10 HKAS 38 Intangible Assets: 1. ObjectivesDocument19 pagesChapter 10 HKAS 38 Intangible Assets: 1. ObjectivesAmrita TamangNo ratings yet

- Synchroteq® Plus: © 2020, Vizimax Inc. - Proprietary and Confidential 1Document10 pagesSynchroteq® Plus: © 2020, Vizimax Inc. - Proprietary and Confidential 1Cô Nàng Song TửNo ratings yet

- Ireshark: Software The Wireshark TeamDocument7 pagesIreshark: Software The Wireshark TeamalanmatrixNo ratings yet

- 275HDV High Voltage DetectorDocument5 pages275HDV High Voltage DetectorByron PanchiNo ratings yet

- Es WQ Lcta 100Document3 pagesEs WQ Lcta 100WattsNo ratings yet

- Hopcraft Et Al-2008-Australian Dental Journal PDFDocument7 pagesHopcraft Et Al-2008-Australian Dental Journal PDFtea metaNo ratings yet

- TCS Application FormDocument73 pagesTCS Application FormAsif KhanNo ratings yet

- Open Position SchlumbergerDocument2 pagesOpen Position SchlumbergerAnkit SharmaNo ratings yet

- CS8491 Ca Unit 1Document32 pagesCS8491 Ca Unit 1Laks SadeeshNo ratings yet

- Coke One Data Enablement StrategyDocument109 pagesCoke One Data Enablement StrategyScott BeckettNo ratings yet

- Falls Chirm Pionier KompanieDocument18 pagesFalls Chirm Pionier KompanieUrantia Aureo100% (3)

- Tlprlp434a Tlprlp418aDocument1 pageTlprlp434a Tlprlp418aOVALLEPANo ratings yet

- Glosario en Ingles-Español de Terminologia ForestalDocument61 pagesGlosario en Ingles-Español de Terminologia ForestalHeiver Sebastián Moreno GiraldoNo ratings yet

- Supraventricular Tachycardia (DynaMed)Document13 pagesSupraventricular Tachycardia (DynaMed)Yonathan ArdhanaNo ratings yet

- D 2661 - 00 - Rdi2njetmda - PDFDocument9 pagesD 2661 - 00 - Rdi2njetmda - PDFAndre CasteloNo ratings yet