Professional Documents

Culture Documents

BPC CW Permit Form_revised 290819_printout_Original.docx 4.2.22

BPC CW Permit Form_revised 290819_printout_Original.docx 4.2.22

Uploaded by

MC BaarathCopyright:

Available Formats

You might also like

- Cold Work PermitDocument2 pagesCold Work Permitloveson glariyans100% (7)

- Work at Heights PermitDocument4 pagesWork at Heights Permitrashid zamanNo ratings yet

- Cold Work Permit - Typical FormatDocument1 pageCold Work Permit - Typical FormatNagabhushanam Tammana100% (8)

- Measuring Team ProductivityDocument27 pagesMeasuring Team ProductivityAdhitya Setyo Pamungkas100% (1)

- Site Inspection Report TemplateDocument13 pagesSite Inspection Report TemplateGunprida Teu Bara OTAZENNo ratings yet

- Confined Space Entry Permit Rev 01Document3 pagesConfined Space Entry Permit Rev 01Neel Vadera100% (1)

- Work at Heights PermitDocument4 pagesWork at Heights PermitFerdinand M. TurbanosNo ratings yet

- Annex VI Hot Works in Areas Containing Inflammable MaterialDocument1 pageAnnex VI Hot Works in Areas Containing Inflammable MaterialPutri aulia akramNo ratings yet

- Safety Pre-Task AssignmentDocument2 pagesSafety Pre-Task AssignmentSathiya Seelan100% (1)

- Annex V Confined SpaceDocument1 pageAnnex V Confined SpacePutri aulia akramNo ratings yet

- 01 General Permit To WorkDocument2 pages01 General Permit To WorkAndre TaulaniNo ratings yet

- Toaz - Info Cold Work Permit PRDocument2 pagesToaz - Info Cold Work Permit PRYexiong YIALENGNo ratings yet

- Permit To Work Application: Vistamarine Shipbuilding and Shiprepair IncDocument2 pagesPermit To Work Application: Vistamarine Shipbuilding and Shiprepair IncJezreel TolentinoNo ratings yet

- APM-OPL-ALL-001Document2 pagesAPM-OPL-ALL-001Samundeswaran SatiwasilanNo ratings yet

- Annex VII Lockout Tagout Identification and Zero EnergyDocument1 pageAnnex VII Lockout Tagout Identification and Zero EnergyPutri aulia akramNo ratings yet

- Permit To Work: 2.0 Cold Work Hot Work Confined Space Entry Excavation Permit NumberDocument10 pagesPermit To Work: 2.0 Cold Work Hot Work Confined Space Entry Excavation Permit NumberMoustapha BakoNo ratings yet

- CAR FORM (For Customer)Document1 pageCAR FORM (For Customer)bambang sugionoNo ratings yet

- Cold Work Permit (Ogf-Hse-19)Document2 pagesCold Work Permit (Ogf-Hse-19)Furqan ShabbirNo ratings yet

- Facility Security Manual ChecklistsDocument16 pagesFacility Security Manual ChecklistsEtana100% (1)

- 08C Supbook STADocument2 pages08C Supbook STAMohammed MinhajNo ratings yet

- (HSE) Permit To Work-General v2Document4 pages(HSE) Permit To Work-General v2Faizan AliNo ratings yet

- HSE Officer Interview Form Rev 2Document1 pageHSE Officer Interview Form Rev 2dcjupiterarunNo ratings yet

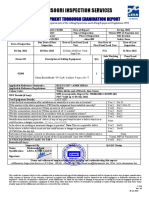

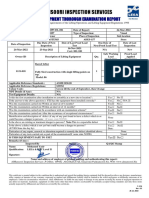

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Workplace Security ChecklistDocument3 pagesWorkplace Security ChecklistAnonymous 6pn00AfL0% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Hot Work PermitDocument4 pagesHot Work PermitMichael RujuwaNo ratings yet

- Line Break, Equip Opening PermitDocument1 pageLine Break, Equip Opening PermitSyed Mustafa HussainNo ratings yet

- CV3038 Stair Tower Bracing JSEA REV.ADocument13 pagesCV3038 Stair Tower Bracing JSEA REV.ADavid ThomasNo ratings yet

- Neste LMRA Form - Rev4Document4 pagesNeste LMRA Form - Rev4eshnsloilchemNo ratings yet

- ,QGLD&DQ (Gxfdwlrq3Yw/Wg: No Dues Checklist (NDC)Document5 pages,QGLD&DQ (Gxfdwlrq3Yw/Wg: No Dues Checklist (NDC)Nirbhay KumarNo ratings yet

- Maneuver Tagging Peralatan Tagging EquipmentDocument2 pagesManeuver Tagging Peralatan Tagging EquipmentDEDYNo ratings yet

- ELECTRONIC EQUIPMENT INSURANCE Proposal FormseeiDocument2 pagesELECTRONIC EQUIPMENT INSURANCE Proposal Formseeim_dattaiasNo ratings yet

- Obtain and Convey Workplace Information. Date of IADocument4 pagesObtain and Convey Workplace Information. Date of IAAljurie Rosquites GalosNo ratings yet

- Radiography Work Permit (OGF-HSE-23)Document3 pagesRadiography Work Permit (OGF-HSE-23)Mock ProjectNo ratings yet

- FRM-9114-0201 Safe Work PermitDocument5 pagesFRM-9114-0201 Safe Work PermitNat OffeiNo ratings yet

- Contractors EHS Clearance - RevisedDocument2 pagesContractors EHS Clearance - RevisedJohn Rheynor MayoNo ratings yet

- HSE-FRM-021-01 - Rev. 00 - General Permit To WorkDocument2 pagesHSE-FRM-021-01 - Rev. 00 - General Permit To Workmalikshoaib8528No ratings yet

- Barrel Lifter VisualDocument1 pageBarrel Lifter VisualRanjithNo ratings yet

- Electrical Work Permit - Sub IDNDocument4 pagesElectrical Work Permit - Sub IDNandiNo ratings yet

- C 029 RW Hammer12 Rev.1Document1 pageC 029 RW Hammer12 Rev.1slamet4riadiNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- D1 - Establish The Team: PSA Incident N°815 2008 502 (Poissy) : Clear Coat Run SubjectDocument6 pagesD1 - Establish The Team: PSA Incident N°815 2008 502 (Poissy) : Clear Coat Run Subject57641No ratings yet

- Use of Restraint Form - Education Points For CompletionDocument2 pagesUse of Restraint Form - Education Points For Completionnostra83No ratings yet

- Ochid Hot-Work-PermitDocument3 pagesOchid Hot-Work-PermitRehan AbbasiNo ratings yet

- Walk Through SurveyDocument4 pagesWalk Through SurveyKan Bee100% (1)

- 8d Report New R5270Document3 pages8d Report New R5270muthuselvanNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Lifting Work PermitDocument1 pageLifting Work PermitRadha BuildtechNo ratings yet

- T07 - Sample Incident and Deviation ReportDocument1 pageT07 - Sample Incident and Deviation ReportfarheenNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 02 Confined Space Entry PermitDocument2 pages02 Confined Space Entry PermitAndre TaulaniNo ratings yet

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDocument2 pagesThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNo ratings yet

- PTO Control SheetDocument5 pagesPTO Control SheetsalomonbeleckNo ratings yet

- 24 - Hole Protection-Grating Removal Permit (A4)Document1 page24 - Hole Protection-Grating Removal Permit (A4)Jianping KeNo ratings yet

- Working at Height PermitDocument1 pageWorking at Height Permitk.bosanoNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- Work Permit IifeDocument12 pagesWork Permit IifeKhursheed AhmadNo ratings yet

- Honour Lab Limited (Unit-V)Document6 pagesHonour Lab Limited (Unit-V)Krishna Kishore MalladiNo ratings yet

- JAS-WW-BMS-FRM-5.1 - Non-Conformity - Corrective - Preventive Action FormDocument2 pagesJAS-WW-BMS-FRM-5.1 - Non-Conformity - Corrective - Preventive Action FormCemac Moreno AceroNo ratings yet

- 12feb Quickref Views enDocument148 pages12feb Quickref Views enprakash2709No ratings yet

- Microsoft Project TOCDocument5 pagesMicrosoft Project TOCali_zulfikarNo ratings yet

- 03 - Literature ReviewDocument9 pages03 - Literature ReviewKhant Wai YanNo ratings yet

- BNVD Eaufrance Metadonnees Vente 20230130Document16 pagesBNVD Eaufrance Metadonnees Vente 20230130moussaouiNo ratings yet

- Strength of Materialspretest Assignment1Document2 pagesStrength of Materialspretest Assignment1Nellai VprNo ratings yet

- OpenFOAM编程指南Document100 pagesOpenFOAM编程指南Feishi XuNo ratings yet

- Task 6 - Leave Type Safety ValveDocument3 pagesTask 6 - Leave Type Safety ValveTeguh RaharjoNo ratings yet

- HD Consumer Behavior AssignmentDocument9 pagesHD Consumer Behavior AssignmentAishwaryaNo ratings yet

- SPECALOG Hitachi Ex2600-6Document7 pagesSPECALOG Hitachi Ex2600-6andrefilthNo ratings yet

- Lesson Plan Sience - Body PartsDocument4 pagesLesson Plan Sience - Body Partsapi-307376252No ratings yet

- Clique Student Sheet (Manteran Lamo)Document4 pagesClique Student Sheet (Manteran Lamo)Dina Rizkia RachmahNo ratings yet

- MTCNA Lab Guide INTRA 1st Edition - Id.en PDFDocument87 pagesMTCNA Lab Guide INTRA 1st Edition - Id.en PDFreyandyNo ratings yet

- 21CC 4 U6Document10 pages21CC 4 U6Adrian Spanu100% (1)

- Indian Standard: Methods of Test For Stabilized SoilsDocument10 pagesIndian Standard: Methods of Test For Stabilized Soilsphanendra kumarNo ratings yet

- Getting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFDocument7 pagesGetting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFoktaNo ratings yet

- Laboratorium Pengujian Teknik Sipil Universitas Bandar LampungDocument1 pageLaboratorium Pengujian Teknik Sipil Universitas Bandar LampungPanji OctaWirawanNo ratings yet

- Ent Secretory Otitis MediaDocument3 pagesEnt Secretory Otitis MediaIrena DayehNo ratings yet

- The-Impact-On-Load-balancing-In-Cloud-Computing 2020Document5 pagesThe-Impact-On-Load-balancing-In-Cloud-Computing 2020Nikola JovanovicNo ratings yet

- Final PDF - To Be Hard BindDocument59 pagesFinal PDF - To Be Hard BindShobhit GuptaNo ratings yet

- Jyotish - Hindu Panchangam & MuhurtasDocument40 pagesJyotish - Hindu Panchangam & MuhurtasSamir Kadiya100% (1)

- AfPS&CS Ch-01Document10 pagesAfPS&CS Ch-01Amelwork AlchoNo ratings yet

- Rahmania Tbi 6 D Soe...Document9 pagesRahmania Tbi 6 D Soe...Rahmania Aulia PurwagunifaNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- In Search of Colonial El Ni No Events and A Brief History of Meteorology in EcuadorDocument7 pagesIn Search of Colonial El Ni No Events and A Brief History of Meteorology in EcuadorDanielNo ratings yet

- Decantador Intermedio IsDocument38 pagesDecantador Intermedio IsAlessacolNo ratings yet

- CCC-BMG MOON 3-2 - Within Dwarvenholm v2.0Document30 pagesCCC-BMG MOON 3-2 - Within Dwarvenholm v2.0MarianoNo ratings yet

- Parasnis - 1951 - Study Rock MidlandsDocument20 pagesParasnis - 1951 - Study Rock MidlandsIsaac KandaNo ratings yet

- Ged Test Accom App AdhdDocument7 pagesGed Test Accom App AdhdJeannette DorfmanNo ratings yet

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)

BPC CW Permit Form_revised 290819_printout_Original.docx 4.2.22

BPC CW Permit Form_revised 290819_printout_Original.docx 4.2.22

Uploaded by

MC BaarathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BPC CW Permit Form_revised 290819_printout_Original.docx 4.2.22

BPC CW Permit Form_revised 290819_printout_Original.docx 4.2.22

Uploaded by

MC BaarathCopyright:

Available Formats

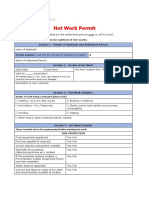

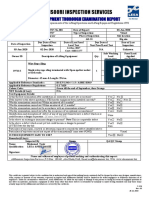

COLD WORK PERMIT BASF PETRONAS Chemicals Sdn Bhd Assembly point no.

: ____________________________________________ ☒ NA

Hazard Assessment and Protective Measures Measure Implemented Measure Normalized

ORIGINAL (Receiving Party) CW NNNNN Yes No

Check boxes using “x” only (Name, Date & Sign.) (Name, Date & Sign.)

A - General information 5 Additional organisational measures:

☐ New ☐ Continuation from no. CW: ___________ Dept. / Company Name Contact No 5.1 Identification of the plant component before removal / line cutting ☒ ☐

1. Permit Issuing Supervisor Atlas copco (M) Kuilan A/L Gengan 0193466047 5.2 Other: _______________________________________________________ ☐ ☐

2. Receiving Authority 6 Other units affected: ☐ Yes ☐ No

3. Job Coordinator required? ☒ Yes ☐ No Unit/Dept. Responsible Person Safety Measures Date/Sign.

6.1 Mr.Ahmad Shauqi Safuan

B - Work description

6.2

1. Equipment tag / Name: Air Compressor Specific Location: Comp.Room

2. Proposed Work (to specify clearly): Service job E - Protective measures during work

Yes No Yes No

1 Personal Protective Equipment 1.10 Fall protection gear, type: ☐ ☒

3. MOC Related: ☐ Yes ☒ No (if tick Yes, MOC No: ____________________________________) 1.1 PPE required for a limited time only ☒ ☐ ☐ Safety harness ☐ ______________________

4. Override or Bypass Permit related: ☐ Yes ☒ No (if tick Yes, Ref No: ______________________) During: ____Working___________________; Refer Line: 1.11 Other: ____________________________________ ☐ ☒

5. Line cutting (tagging no.): __________________________________________________________ ________

6. Valid on Date (date of section H approval): Time from (use 24hr clock): Time to (use 24hr clock): 1.2 ☒ Safety glass ☒ Safety helmet ☒ Safety shoe ☒ ☐ 2 Continuous Supervision (if required)

7. Extension Date: (valid until 7 consecutive days from B6. Valid on Date) 1.3 ☐ Safety goggle ☐ Face shield ☐ ☒ 2.1 Supervision by (Name & Sign.): ☒ ☐

1 2 3 4 5 1.4 Protective gloves, type: _____Cotton ☒ ☐

glove________________________

1.5 Rubber safety boots ☒ ☐ __________________________________________

C – Hazard Identification 1.6 Apron, type: ______________________________________ ☐ ☐ 3 Ventilation Measures

Substance during normal operation: ___________________________________ Flushing / Washing / Rinsing medium during work: ___________________________ 1.7 Protective suit, type: ________________________________ ☐ ☐ 3.1 Ventilation type: Forced Natural ☒ ☐

1.8 Respiratory protection device, type: ____________________ ☐ ☐ 4 Other measures

1.9 Hearing protection: ☒ Ear plug ☒ Ear muff ☒ ☐ 4.1 __________________________________________ ☐ ☐

! If anything unexpected happens, stop work immediately and notify Permit Issuing Supervisor

Toxic Explosive Flammable Corrosive Liquified Gas Oxidizing

Specific Target Dangerous to Irritant / Harmful F - Post work protective measures

Organ Environment Yes No

☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ ☐ 1. Leak test with medium: _______________________________________________________________________________________________ x

The Proposed Work require protection against hazardous substances: ☐ Yes ☐ No (if No, specify reason: _____________________________________________) 2. All tools and work equipment to be removed and area cleaned to original state (housekeeping) x

☐ Hazard due to flushing medium, during work: ______________________________________________________________________________________________________ 3. Report status of work to D6.1, D6.2 by: ________________________________________________________ Daily Work completion x

☐ Product residue may be present: __________________________________________________________________________________________________________ 4. Other: _____________________________________________________________________________________________________________

☐ Hazardous reaction upon contact with water ☐ Hazardous reaction upon contact with organic substances (e.g. Oil) G - Verification of hazard assessment and approval of protective measures listed in sections C, D, E, F

☐ Height ☐ Sharp edge ☒ Dust ☒ Noise ☒ High temperature

_____________Kuilan.g________________________________________________ ________________Mr.Ahmad_Shauqi

☐ Trap pressure ☐ Hot surface ☒ Cold surface ☐ Voltage ☐ Moving parts _____ Safuan_______________________________________________

☐ Pinch point ☐ Tripping ☐ Slippery ☐ Radiation exposure ☐ Heat stress 1. Name / Date / Signature of Permit Issuing Supervisor – A1 2. Name / Date / Signature of Approving Authority

☐ Other hazards: ________________________________________________________________________________________________________________________ H - Approval for work to be undertaken (Measures as per D implemented & physically checked)

____________________________ ; __________________________; ____________________________; _________________________; I / We confirmed that I / We had briefed and informed the Receiving Authority for acceptance.

☐ Hazard in accordance with permit No:

____________________________ ; __________________________; ____________________________; _________________________;

__________________________________________________________________ ________________________________________________________________

D - Pre-work protective measures

1. Name / Date / Signature of Permit Issuing Supervisor – A1 2. Name / Date / Signature of Job Coordinator – A3

Yes No Measure Implemented Measure Normalized

I - Acceptance of permit to conduct work as per B2

(Name, Date & Sign.) (Name, Date & Sign.)

I have been briefed, understood and shall comply with all requirements. I shall brief all working employees prior to start work and attached the On-Site Safety Briefing

1 Isolation list available. ☐ ☒

attendance forms.

Isolation Document No: _________________________________________

1.1 Isolation list attached (mandatory for blinding / de-blinding PTW) ☐ ☐

________Kuilan.g__________________________________________________________

1.2 Personnel Padlock no: __________________________________ ☐ ☐

1. Name / Date / Signature of Receiving Authority – A2

2 Making plant equipment safe:

2.1 Depressurize ☒ ☐ NA J1 - Interim energization of E&I for test purposes Not Applicable J2 - System de-energized again

2.2 Moving parts secured with: ___________pallet ☒ ☐

jack____________________________

___________________________________________ ______________________________________ _________________________________

2.3 Other: _______________________________________________________ ☐ ☒ 1. Name / Date / Time / Signature of Receiving 2. Name / Date / Time / Signature of Permit Issuing 1. Name / Date / Time / Signature of Chargeman /

3 Draining/cleaning of process equipment: Authority – A2) Supervisor – A1 Radiation Protection Supervisor (RPO)

3.1 Drain ☒ ☐ NA K - Confirmation of post work protective measures as per “F” and proposed work as per “B2” has been completed

3.2 Purge with: ___________________________________________________ ☐ ☒ NA The protective measures listed in “Section F” have been completed successfully: ☒ Yes ☐ No

4 Making the work location safe: The proposed work listed in “Section B2” has been completed successfully: ☒ Yes ☐ No

4.1 Barricade with: ________________________________________________ ☒ ☐

4.2 Container for bolts and nuts ☒ ☒

4.3 Covering for pipes, equipment, electrical cables, grates, drains, pit, shafts, wall ☐ ☒ _______________Kuilan.g___________________________________________________

and traffic routes in vicinity and below 1. Name / Date / Signature of Receiving Authority – A3 2

4.4 Leak / Gas test if required. Reading: _______________________________ ☐ ☒ NA L – Approval for normalizing of protective measures under section D and permit closure

4.5 Job Safety Analysis(JSA) / procedure required and attached ☒ ☐ NA Other permits using protective measures listed in Section D: ____________________________; ______________________________; __________________________

4.6 Emergency measures: Job completed? ☐ Yes ☐ No (if “No”, continue with No. CW: _______________________________________)

Nearest Safety Shower available ☒ ☒ NA Did normalization of protective measures are required? ☐ Yes ☐ No (if “No”, Reason: _______________________________________________________________)

Escape Route communicated ☒ NA

1|P a g e Cold Work Permit / Issue Jul 2019

__________________________________________________________ Name / Date / Signature of Permit Issuing Supervisor – A1

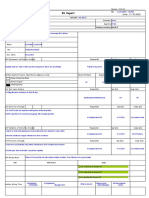

Cold Work Permit Extension

Extension Number: 1 2 3 4 5

Date (dd/mm/yyyy): / / / / / / / / / /

Time From (use 24hr clock): : : : :

Time To (use 24hr clock): : : : :

☒ The Scope of Work (B), Hazards (C) and Protective

Measures (D, E & F) unchanged?

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

[G1: Permit Issuing Supervisor] Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☒ Protective measures according to D verified and

approved again?

[H1: Permit issuing Supervisor] _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☐ Hazard in accordance with other permit no. (Section

C): [G1: Permit Issuing Supervisor]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☐ Responsible Person for other units affected notified?

D 6.1

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

D 6.2

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☒ Permit Issuing Supervisor [A1]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☒ Receiving Authority [A2]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☐ Job Coordinator [A3]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☐ Continuous Supervision by as per [E2.1]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☐ J1 Interim Energization:

Receiving Authority [A2]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

Permit Issuing Supervisor [A1]

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

☐ J2 System de-energized again by Chargeman /

Radiation Protection Supervisor

_______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

Change of Personnel – this table to be filled if there is change of personnel within shift (Permit Issuing Supervisor is to notify all persons involved with the work of the change in personnel)

Change Number: 1 2 3 4 5

Date (dd/mm/yyyy): / / / / / / / / / /

Time of change (use 24hr clock) : : : : : :

From : From : From : From : From :

Change of Permit Issuing Supervisor [A1]

To: To : To: To: To:

From : From : From : From : From :

Change of Receiving Authority [A2]

To: To: To: To: To:

From : From : From : From : From :

Change of Job Coordinator [A3]

To: To: To: To: To:

From : From : From : From : From :

Change of Continuous Supervision by as per [E2.1]

To: To: To: To: To:

Approval by Permit Issuing Supervisor [A1]

(If the change is a change of Permit Issuing Supervisor, the new _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________

Permit Issuing Supervisor will sign here) Name & Sign. Name & Sign. Name & Sign. Name & Sign. Name & Sign.

NOTES

1. This permit expires upon: (i) as specified above, (ii) any incident, (ii) activation of emergency alarm or (iv) 7 consecutive days after start date of H.

2. In case of (i) any incident (ii) any conditions not fulfilled under D, E & F or (iii) any change in work condition, immediately stops work and notify the Permit Issuing Supervisor.

2|P a g e Cold Work Permit / Issue Jul 2019

3. The original copy of this permit shall be visibly displayed all the times at the work place.

4. PTW shall be returned to the Permit Issuing Supervisor or his designated person at the end of the validity period.

3|P a g e Cold Work Permit / Issue Jul 2019

You might also like

- Cold Work PermitDocument2 pagesCold Work Permitloveson glariyans100% (7)

- Work at Heights PermitDocument4 pagesWork at Heights Permitrashid zamanNo ratings yet

- Cold Work Permit - Typical FormatDocument1 pageCold Work Permit - Typical FormatNagabhushanam Tammana100% (8)

- Measuring Team ProductivityDocument27 pagesMeasuring Team ProductivityAdhitya Setyo Pamungkas100% (1)

- Site Inspection Report TemplateDocument13 pagesSite Inspection Report TemplateGunprida Teu Bara OTAZENNo ratings yet

- Confined Space Entry Permit Rev 01Document3 pagesConfined Space Entry Permit Rev 01Neel Vadera100% (1)

- Work at Heights PermitDocument4 pagesWork at Heights PermitFerdinand M. TurbanosNo ratings yet

- Annex VI Hot Works in Areas Containing Inflammable MaterialDocument1 pageAnnex VI Hot Works in Areas Containing Inflammable MaterialPutri aulia akramNo ratings yet

- Safety Pre-Task AssignmentDocument2 pagesSafety Pre-Task AssignmentSathiya Seelan100% (1)

- Annex V Confined SpaceDocument1 pageAnnex V Confined SpacePutri aulia akramNo ratings yet

- 01 General Permit To WorkDocument2 pages01 General Permit To WorkAndre TaulaniNo ratings yet

- Toaz - Info Cold Work Permit PRDocument2 pagesToaz - Info Cold Work Permit PRYexiong YIALENGNo ratings yet

- Permit To Work Application: Vistamarine Shipbuilding and Shiprepair IncDocument2 pagesPermit To Work Application: Vistamarine Shipbuilding and Shiprepair IncJezreel TolentinoNo ratings yet

- APM-OPL-ALL-001Document2 pagesAPM-OPL-ALL-001Samundeswaran SatiwasilanNo ratings yet

- Annex VII Lockout Tagout Identification and Zero EnergyDocument1 pageAnnex VII Lockout Tagout Identification and Zero EnergyPutri aulia akramNo ratings yet

- Permit To Work: 2.0 Cold Work Hot Work Confined Space Entry Excavation Permit NumberDocument10 pagesPermit To Work: 2.0 Cold Work Hot Work Confined Space Entry Excavation Permit NumberMoustapha BakoNo ratings yet

- CAR FORM (For Customer)Document1 pageCAR FORM (For Customer)bambang sugionoNo ratings yet

- Cold Work Permit (Ogf-Hse-19)Document2 pagesCold Work Permit (Ogf-Hse-19)Furqan ShabbirNo ratings yet

- Facility Security Manual ChecklistsDocument16 pagesFacility Security Manual ChecklistsEtana100% (1)

- 08C Supbook STADocument2 pages08C Supbook STAMohammed MinhajNo ratings yet

- (HSE) Permit To Work-General v2Document4 pages(HSE) Permit To Work-General v2Faizan AliNo ratings yet

- HSE Officer Interview Form Rev 2Document1 pageHSE Officer Interview Form Rev 2dcjupiterarunNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Workplace Security ChecklistDocument3 pagesWorkplace Security ChecklistAnonymous 6pn00AfL0% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Hot Work PermitDocument4 pagesHot Work PermitMichael RujuwaNo ratings yet

- Line Break, Equip Opening PermitDocument1 pageLine Break, Equip Opening PermitSyed Mustafa HussainNo ratings yet

- CV3038 Stair Tower Bracing JSEA REV.ADocument13 pagesCV3038 Stair Tower Bracing JSEA REV.ADavid ThomasNo ratings yet

- Neste LMRA Form - Rev4Document4 pagesNeste LMRA Form - Rev4eshnsloilchemNo ratings yet

- ,QGLD&DQ (Gxfdwlrq3Yw/Wg: No Dues Checklist (NDC)Document5 pages,QGLD&DQ (Gxfdwlrq3Yw/Wg: No Dues Checklist (NDC)Nirbhay KumarNo ratings yet

- Maneuver Tagging Peralatan Tagging EquipmentDocument2 pagesManeuver Tagging Peralatan Tagging EquipmentDEDYNo ratings yet

- ELECTRONIC EQUIPMENT INSURANCE Proposal FormseeiDocument2 pagesELECTRONIC EQUIPMENT INSURANCE Proposal Formseeim_dattaiasNo ratings yet

- Obtain and Convey Workplace Information. Date of IADocument4 pagesObtain and Convey Workplace Information. Date of IAAljurie Rosquites GalosNo ratings yet

- Radiography Work Permit (OGF-HSE-23)Document3 pagesRadiography Work Permit (OGF-HSE-23)Mock ProjectNo ratings yet

- FRM-9114-0201 Safe Work PermitDocument5 pagesFRM-9114-0201 Safe Work PermitNat OffeiNo ratings yet

- Contractors EHS Clearance - RevisedDocument2 pagesContractors EHS Clearance - RevisedJohn Rheynor MayoNo ratings yet

- HSE-FRM-021-01 - Rev. 00 - General Permit To WorkDocument2 pagesHSE-FRM-021-01 - Rev. 00 - General Permit To Workmalikshoaib8528No ratings yet

- Barrel Lifter VisualDocument1 pageBarrel Lifter VisualRanjithNo ratings yet

- Electrical Work Permit - Sub IDNDocument4 pagesElectrical Work Permit - Sub IDNandiNo ratings yet

- C 029 RW Hammer12 Rev.1Document1 pageC 029 RW Hammer12 Rev.1slamet4riadiNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- D1 - Establish The Team: PSA Incident N°815 2008 502 (Poissy) : Clear Coat Run SubjectDocument6 pagesD1 - Establish The Team: PSA Incident N°815 2008 502 (Poissy) : Clear Coat Run Subject57641No ratings yet

- Use of Restraint Form - Education Points For CompletionDocument2 pagesUse of Restraint Form - Education Points For Completionnostra83No ratings yet

- Ochid Hot-Work-PermitDocument3 pagesOchid Hot-Work-PermitRehan AbbasiNo ratings yet

- Walk Through SurveyDocument4 pagesWalk Through SurveyKan Bee100% (1)

- 8d Report New R5270Document3 pages8d Report New R5270muthuselvanNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Lifting Work PermitDocument1 pageLifting Work PermitRadha BuildtechNo ratings yet

- T07 - Sample Incident and Deviation ReportDocument1 pageT07 - Sample Incident and Deviation ReportfarheenNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 02 Confined Space Entry PermitDocument2 pages02 Confined Space Entry PermitAndre TaulaniNo ratings yet

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDocument2 pagesThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNo ratings yet

- PTO Control SheetDocument5 pagesPTO Control SheetsalomonbeleckNo ratings yet

- 24 - Hole Protection-Grating Removal Permit (A4)Document1 page24 - Hole Protection-Grating Removal Permit (A4)Jianping KeNo ratings yet

- Working at Height PermitDocument1 pageWorking at Height Permitk.bosanoNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- Work Permit IifeDocument12 pagesWork Permit IifeKhursheed AhmadNo ratings yet

- Honour Lab Limited (Unit-V)Document6 pagesHonour Lab Limited (Unit-V)Krishna Kishore MalladiNo ratings yet

- JAS-WW-BMS-FRM-5.1 - Non-Conformity - Corrective - Preventive Action FormDocument2 pagesJAS-WW-BMS-FRM-5.1 - Non-Conformity - Corrective - Preventive Action FormCemac Moreno AceroNo ratings yet

- 12feb Quickref Views enDocument148 pages12feb Quickref Views enprakash2709No ratings yet

- Microsoft Project TOCDocument5 pagesMicrosoft Project TOCali_zulfikarNo ratings yet

- 03 - Literature ReviewDocument9 pages03 - Literature ReviewKhant Wai YanNo ratings yet

- BNVD Eaufrance Metadonnees Vente 20230130Document16 pagesBNVD Eaufrance Metadonnees Vente 20230130moussaouiNo ratings yet

- Strength of Materialspretest Assignment1Document2 pagesStrength of Materialspretest Assignment1Nellai VprNo ratings yet

- OpenFOAM编程指南Document100 pagesOpenFOAM编程指南Feishi XuNo ratings yet

- Task 6 - Leave Type Safety ValveDocument3 pagesTask 6 - Leave Type Safety ValveTeguh RaharjoNo ratings yet

- HD Consumer Behavior AssignmentDocument9 pagesHD Consumer Behavior AssignmentAishwaryaNo ratings yet

- SPECALOG Hitachi Ex2600-6Document7 pagesSPECALOG Hitachi Ex2600-6andrefilthNo ratings yet

- Lesson Plan Sience - Body PartsDocument4 pagesLesson Plan Sience - Body Partsapi-307376252No ratings yet

- Clique Student Sheet (Manteran Lamo)Document4 pagesClique Student Sheet (Manteran Lamo)Dina Rizkia RachmahNo ratings yet

- MTCNA Lab Guide INTRA 1st Edition - Id.en PDFDocument87 pagesMTCNA Lab Guide INTRA 1st Edition - Id.en PDFreyandyNo ratings yet

- 21CC 4 U6Document10 pages21CC 4 U6Adrian Spanu100% (1)

- Indian Standard: Methods of Test For Stabilized SoilsDocument10 pagesIndian Standard: Methods of Test For Stabilized Soilsphanendra kumarNo ratings yet

- Getting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFDocument7 pagesGetting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFoktaNo ratings yet

- Laboratorium Pengujian Teknik Sipil Universitas Bandar LampungDocument1 pageLaboratorium Pengujian Teknik Sipil Universitas Bandar LampungPanji OctaWirawanNo ratings yet

- Ent Secretory Otitis MediaDocument3 pagesEnt Secretory Otitis MediaIrena DayehNo ratings yet

- The-Impact-On-Load-balancing-In-Cloud-Computing 2020Document5 pagesThe-Impact-On-Load-balancing-In-Cloud-Computing 2020Nikola JovanovicNo ratings yet

- Final PDF - To Be Hard BindDocument59 pagesFinal PDF - To Be Hard BindShobhit GuptaNo ratings yet

- Jyotish - Hindu Panchangam & MuhurtasDocument40 pagesJyotish - Hindu Panchangam & MuhurtasSamir Kadiya100% (1)

- AfPS&CS Ch-01Document10 pagesAfPS&CS Ch-01Amelwork AlchoNo ratings yet

- Rahmania Tbi 6 D Soe...Document9 pagesRahmania Tbi 6 D Soe...Rahmania Aulia PurwagunifaNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- In Search of Colonial El Ni No Events and A Brief History of Meteorology in EcuadorDocument7 pagesIn Search of Colonial El Ni No Events and A Brief History of Meteorology in EcuadorDanielNo ratings yet

- Decantador Intermedio IsDocument38 pagesDecantador Intermedio IsAlessacolNo ratings yet

- CCC-BMG MOON 3-2 - Within Dwarvenholm v2.0Document30 pagesCCC-BMG MOON 3-2 - Within Dwarvenholm v2.0MarianoNo ratings yet

- Parasnis - 1951 - Study Rock MidlandsDocument20 pagesParasnis - 1951 - Study Rock MidlandsIsaac KandaNo ratings yet

- Ged Test Accom App AdhdDocument7 pagesGed Test Accom App AdhdJeannette DorfmanNo ratings yet

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)