Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

0 viewsadnoc1

adnoc1

Uploaded by

BALAKRISHNANCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Sankey Diagrams WorksheetDocument4 pagesSankey Diagrams WorksheetDora Aye100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Calculation Methods For Structural Fire ProtectionDocument72 pagesCalculation Methods For Structural Fire ProtectionShabin Shabi100% (2)

- Pipe Rack Rack PipingDocument23 pagesPipe Rack Rack PipingAlessandro1975No ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 pagesPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFSaidFerdjallahNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFAmjadali ChoudhariNo ratings yet

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDocument21 pagesChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNo ratings yet

- Pipe Rack LAYOUTDocument25 pagesPipe Rack LAYOUTSAMI UR RAHMANNo ratings yet

- Piperack Planning GuideDocument4 pagesPiperack Planning GuideryncscNo ratings yet

- Pipe Rack 1Document17 pagesPipe Rack 1bipin_pmkNo ratings yet

- Pipe Rack & Rack PipingDocument22 pagesPipe Rack & Rack PipingOmar Mokhtar100% (1)

- Rack DesignDocument8 pagesRack DesignMayank Sethi100% (1)

- Pipe RackDocument20 pagesPipe RackKehinde AdebayoNo ratings yet

- PVE Piping Layout Presentation - Part 1Document68 pagesPVE Piping Layout Presentation - Part 1Nguyen Quang Nghia100% (1)

- Design PipelineDocument9 pagesDesign Pipelineengr_asad364No ratings yet

- Pipe Rack Sizing and Loading DataDocument7 pagesPipe Rack Sizing and Loading DataRambabuNo ratings yet

- Pipeline EngineeringDocument52 pagesPipeline Engineeringhamid sobirinNo ratings yet

- Facility ManagementDocument7 pagesFacility ManagementTajudeen IbrahimNo ratings yet

- File 70516Document6 pagesFile 70516Arturo Valles TerrazasNo ratings yet

- Cable Tray SystemDocument26 pagesCable Tray SystemAldrien CabinteNo ratings yet

- SECTION 16114 Cable Tray: Part 1 - General Related DocumentsDocument5 pagesSECTION 16114 Cable Tray: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- 1 PiperackDocument8 pages1 PiperackDinesh Kumar JdNo ratings yet

- Bends - Route SelectionDocument6 pagesBends - Route SelectionanishsrNo ratings yet

- Pipe Rack PresentationDocument19 pagesPipe Rack Presentationkaushalacharya67% (3)

- DBR For PipingDocument50 pagesDBR For Pipingrajachem100% (1)

- 2-Plant Layout - Pipeway DesignDocument25 pages2-Plant Layout - Pipeway DesignLaxmikant Sawleshwarkar100% (1)

- Pipe RackDocument25 pagesPipe RackVernie SorianoNo ratings yet

- TESP11920R0 LV Raceways & Cable InstallationDocument20 pagesTESP11920R0 LV Raceways & Cable InstallationPERVEZ AHMAD KHANNo ratings yet

- 764 15.dynamic Analysis of Pipe Rack System Subjected To 858585Document9 pages764 15.dynamic Analysis of Pipe Rack System Subjected To 858585pankaj645924No ratings yet

- Underground Piping (U/G) : Cooling Tower PipelineDocument9 pagesUnderground Piping (U/G) : Cooling Tower PipelineMayank KumarNo ratings yet

- Pipe Racks ArrangementDocument42 pagesPipe Racks ArrangementShailin ShahNo ratings yet

- 1.1 Design of Pipe Racks Writeup PDFDocument5 pages1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- Improvements in Offshore Pipeline Cathodic ProtectionDocument6 pagesImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoNo ratings yet

- Pipe Racks ArrangementDocument42 pagesPipe Racks ArrangementHary adiNo ratings yet

- Busbar Size and CalculationDocument8 pagesBusbar Size and Calculationandro max100% (1)

- Piping Engineering - Piping Layout Procedure and Pipe Rack - XyntechDocument14 pagesPiping Engineering - Piping Layout Procedure and Pipe Rack - XyntechKeiko DavilaNo ratings yet

- Dr. Chen's NotesDocument2 pagesDr. Chen's NoteskesharinareshNo ratings yet

- Duct BankDocument7 pagesDuct BankAwotiku AbimbolaNo ratings yet

- Pipe RackDocument33 pagesPipe RackSaid Ahmed Salem100% (1)

- Cable TraysDocument6 pagesCable TrayssallammohamedNo ratings yet

- Sub Station DesignDocument43 pagesSub Station DesignZIPDASH88% (8)

- Pipe Ways Steel Structures in Industry: 10.3.4 Pipe-Rack Elevation 5.4.1 Pipe Rack Design GuideDocument8 pagesPipe Ways Steel Structures in Industry: 10.3.4 Pipe-Rack Elevation 5.4.1 Pipe Rack Design GuidesinisacarNo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- Pipeline DesignDocument46 pagesPipeline Designprisen24No ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- B5D ElDocument6 pagesB5D ElBALAKRISHNANNo ratings yet

- B5M ElDocument3 pagesB5M ElBALAKRISHNANNo ratings yet

- B2a ElDocument5 pagesB2a ElBALAKRISHNANNo ratings yet

- A95a ElDocument5 pagesA95a ElBALAKRISHNANNo ratings yet

- J2a ElDocument5 pagesJ2a ElBALAKRISHNANNo ratings yet

- B1K ElDocument5 pagesB1K ElBALAKRISHNANNo ratings yet

- A96a ElDocument5 pagesA96a ElBALAKRISHNANNo ratings yet

- Fire Protection SystemDocument29 pagesFire Protection SystemBALAKRISHNANNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- D 2199 - 03 - RdixotkDocument2 pagesD 2199 - 03 - Rdixotkphaindika100% (1)

- Start Here:: Safety Glass Meets The Requirements of Every SituationDocument2 pagesStart Here:: Safety Glass Meets The Requirements of Every SituationFALwilliamsNo ratings yet

- Systems GuideDocument237 pagesSystems GuideingrbarrosNo ratings yet

- Physics, Form 4: Specific Heat CapacityDocument18 pagesPhysics, Form 4: Specific Heat CapacitydharrineshnarenNo ratings yet

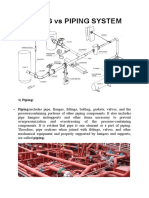

- Piping Vs Piping SystemDocument4 pagesPiping Vs Piping SystemViệt Đặng XuânNo ratings yet

- International Seminar On Computer Aided Analysis and Design of Building StructuresDocument147 pagesInternational Seminar On Computer Aided Analysis and Design of Building StructuresOscarKonzultNo ratings yet

- POSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Document1 pagePOSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Murti WisnuNo ratings yet

- Chhattisgarh: Operatlon Engineer EngineerlngDocument3 pagesChhattisgarh: Operatlon Engineer Engineerlngpadmashree sonawaneNo ratings yet

- Demolitionofbuilding AyDocument22 pagesDemolitionofbuilding Ay1DS19CV043 Kajal Godbole100% (1)

- Analisa Harga Satuan (Student Version)Document115 pagesAnalisa Harga Satuan (Student Version)endi_putra_1No ratings yet

- Materials Today: ProceedingsDocument5 pagesMaterials Today: ProceedingsraulNo ratings yet

- LRFD Aisc Manual of Steel ConstructionDocument54 pagesLRFD Aisc Manual of Steel ConstructionFer Rivas NietoNo ratings yet

- Design and Control of A Cryogenic Multi-Stage Compression Refrigeration ProcessDocument8 pagesDesign and Control of A Cryogenic Multi-Stage Compression Refrigeration ProcessGezu AcuñaNo ratings yet

- Element Solid65 in AnsysDocument10 pagesElement Solid65 in AnsyspadashtNo ratings yet

- Hitachi 12k InverterDocument74 pagesHitachi 12k InverterDaio AlvaresNo ratings yet

- Chapter 9-10 (MD) Reinzo GallegoDocument45 pagesChapter 9-10 (MD) Reinzo GallegoReinzo GallegoNo ratings yet

- 6 CHAPTER 5 Design Computation NewDocument19 pages6 CHAPTER 5 Design Computation NewChristophel FloresNo ratings yet

- Nitric Acid PlantDocument31 pagesNitric Acid Plantejaz khanNo ratings yet

- Busines Proposal For Residential ConstructionDocument7 pagesBusines Proposal For Residential ConstructionNatsu Trojanlee QuiritNo ratings yet

- New Voltas AC - Tech - SpecsDocument1 pageNew Voltas AC - Tech - Specsmohamad chaudhariNo ratings yet

- Official ISRO Previous Paper 2008 - Download Now!Document11 pagesOfficial ISRO Previous Paper 2008 - Download Now!nidhi tripathiNo ratings yet

- External Pressure VESSEL DESIGNDocument11 pagesExternal Pressure VESSEL DESIGNmsaadullah100% (1)

- Lecture Class 4 - ME F 112Document43 pagesLecture Class 4 - ME F 112Vivekananda NandamNo ratings yet

- Connectors Design Guide VU 1.3Document16 pagesConnectors Design Guide VU 1.3civiliiiNo ratings yet

- RabDocument3 pagesRabAna YulianaNo ratings yet

- Specification For Architectural WorksDocument82 pagesSpecification For Architectural WorksVJ QatarNo ratings yet

- Purmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLDocument52 pagesPurmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLMetin TamNo ratings yet

adnoc1

adnoc1

Uploaded by

BALAKRISHNAN0 ratings0% found this document useful (0 votes)

0 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views1 pageadnoc1

adnoc1

Uploaded by

BALAKRISHNANCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

ADNOC Classification: Public

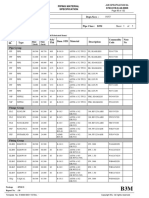

11.4 Pipe Rack Dimensions & Piping

Dimensions of Racks

a) Generally, most inline plant arrangements are furnished with a central pipe rack system that

acts as the main artery of the unit supporting process interconnection, feeds, product and

utility piping, instrument and electrical cables, and, sometimes, air coolers and drums.

b) Usually, the pipe rack is made of structural steel, either single level or multi-level, to suit the

width and capacity for the units it is serving. Typically pipe racks are upto 4 tier and widths

of 6m, 8m or 10m for single bays and 12m, 16m or 20m for double bays having 4 tiers

maximum

c) The width is determined by factors such as the quantity of piping and cabling to be carried

on the main run of the pipe rack (with an allowance for future expansion), access way

located beneath the pipe rack, or the equipment (if any) supported above the pipe rack. The

layout that results in the most economical design should be chosen.

d) The requirements of expansion bays, anchor bays, bracing pattern, etc., shall be arrived

upon consultation with piping stress engineer and structural engineer at the beginning of

the pipe rack layout.

e) All piping on pipe racks shall be routed to avoid blocking access for further additions,

modifications or repair. Piping on pipe racks shall change elevation at each change in

direction, using a 90° elbow in each vertical plane concurrent with each pipe direction except

for no pocket lines and flare headers. Individual piping coming into (or out of) a main pipe

rack shall enter (or leave) perpendicular to the pipe rack direction using typically two 90°

elbows to place the line at an elevation above or below the main pipe rack elevation.

f) Piping shall be laid out parallel or perpendicular to plant North to maximum extent feasible.

All uninsulated lines shall be arranged such that the bottoms of pipe (B.O.P.) are at the

same elevation. All principal lines running from north to south shall have a minimum

difference in elevation from lines running east to west of at least 3 times the largest nominal

pipe size, and in no case less than 600 mm difference in elevation.

Capacity for Future Expansion

a) Minimum spare space provision on major/main piperack shall be 25% and shall be

maintained during end of FEED Engineering and 20% spare space shall be maintained

during end of EPC on each tier of piperack. However for sub/unit pipe racks this shall be

20% in FEED and 15% in EPC respectively on each tier of piperack This does not include

known future pipes indicated in P&ID/project documentation. No cantilevers extenstions

allowed on new piperacks.

b) The load critera for this future space shall be as described in Structural design basis AGES-

SP-01-003

c) To optimise the pipe support span, minimum line size on piperack shall be maintained as

NPS 2. Intermediate beams of pipe racks shall be sized for supporting lines NPS 3 & below

or non metallic pipe as applicable

d) In a pipe rack the heaviest and / or the hottest pipes should be located at the outer edges

of the pipe rack to provide space for expansion loops and to reduce the moments in the

beams caused by the weight and thermal expansion of the pipes.

AGES-SP-09-001 Rev. No: 1

Page 36 of 116

You might also like

- Sankey Diagrams WorksheetDocument4 pagesSankey Diagrams WorksheetDora Aye100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Calculation Methods For Structural Fire ProtectionDocument72 pagesCalculation Methods For Structural Fire ProtectionShabin Shabi100% (2)

- Pipe Rack Rack PipingDocument23 pagesPipe Rack Rack PipingAlessandro1975No ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 pagesPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFSaidFerdjallahNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFAmjadali ChoudhariNo ratings yet

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDocument21 pagesChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNo ratings yet

- Pipe Rack LAYOUTDocument25 pagesPipe Rack LAYOUTSAMI UR RAHMANNo ratings yet

- Piperack Planning GuideDocument4 pagesPiperack Planning GuideryncscNo ratings yet

- Pipe Rack 1Document17 pagesPipe Rack 1bipin_pmkNo ratings yet

- Pipe Rack & Rack PipingDocument22 pagesPipe Rack & Rack PipingOmar Mokhtar100% (1)

- Rack DesignDocument8 pagesRack DesignMayank Sethi100% (1)

- Pipe RackDocument20 pagesPipe RackKehinde AdebayoNo ratings yet

- PVE Piping Layout Presentation - Part 1Document68 pagesPVE Piping Layout Presentation - Part 1Nguyen Quang Nghia100% (1)

- Design PipelineDocument9 pagesDesign Pipelineengr_asad364No ratings yet

- Pipe Rack Sizing and Loading DataDocument7 pagesPipe Rack Sizing and Loading DataRambabuNo ratings yet

- Pipeline EngineeringDocument52 pagesPipeline Engineeringhamid sobirinNo ratings yet

- Facility ManagementDocument7 pagesFacility ManagementTajudeen IbrahimNo ratings yet

- File 70516Document6 pagesFile 70516Arturo Valles TerrazasNo ratings yet

- Cable Tray SystemDocument26 pagesCable Tray SystemAldrien CabinteNo ratings yet

- SECTION 16114 Cable Tray: Part 1 - General Related DocumentsDocument5 pagesSECTION 16114 Cable Tray: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- 1 PiperackDocument8 pages1 PiperackDinesh Kumar JdNo ratings yet

- Bends - Route SelectionDocument6 pagesBends - Route SelectionanishsrNo ratings yet

- Pipe Rack PresentationDocument19 pagesPipe Rack Presentationkaushalacharya67% (3)

- DBR For PipingDocument50 pagesDBR For Pipingrajachem100% (1)

- 2-Plant Layout - Pipeway DesignDocument25 pages2-Plant Layout - Pipeway DesignLaxmikant Sawleshwarkar100% (1)

- Pipe RackDocument25 pagesPipe RackVernie SorianoNo ratings yet

- TESP11920R0 LV Raceways & Cable InstallationDocument20 pagesTESP11920R0 LV Raceways & Cable InstallationPERVEZ AHMAD KHANNo ratings yet

- 764 15.dynamic Analysis of Pipe Rack System Subjected To 858585Document9 pages764 15.dynamic Analysis of Pipe Rack System Subjected To 858585pankaj645924No ratings yet

- Underground Piping (U/G) : Cooling Tower PipelineDocument9 pagesUnderground Piping (U/G) : Cooling Tower PipelineMayank KumarNo ratings yet

- Pipe Racks ArrangementDocument42 pagesPipe Racks ArrangementShailin ShahNo ratings yet

- 1.1 Design of Pipe Racks Writeup PDFDocument5 pages1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- Improvements in Offshore Pipeline Cathodic ProtectionDocument6 pagesImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoNo ratings yet

- Pipe Racks ArrangementDocument42 pagesPipe Racks ArrangementHary adiNo ratings yet

- Busbar Size and CalculationDocument8 pagesBusbar Size and Calculationandro max100% (1)

- Piping Engineering - Piping Layout Procedure and Pipe Rack - XyntechDocument14 pagesPiping Engineering - Piping Layout Procedure and Pipe Rack - XyntechKeiko DavilaNo ratings yet

- Dr. Chen's NotesDocument2 pagesDr. Chen's NoteskesharinareshNo ratings yet

- Duct BankDocument7 pagesDuct BankAwotiku AbimbolaNo ratings yet

- Pipe RackDocument33 pagesPipe RackSaid Ahmed Salem100% (1)

- Cable TraysDocument6 pagesCable TrayssallammohamedNo ratings yet

- Sub Station DesignDocument43 pagesSub Station DesignZIPDASH88% (8)

- Pipe Ways Steel Structures in Industry: 10.3.4 Pipe-Rack Elevation 5.4.1 Pipe Rack Design GuideDocument8 pagesPipe Ways Steel Structures in Industry: 10.3.4 Pipe-Rack Elevation 5.4.1 Pipe Rack Design GuidesinisacarNo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- Pipeline DesignDocument46 pagesPipeline Designprisen24No ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- B5D ElDocument6 pagesB5D ElBALAKRISHNANNo ratings yet

- B5M ElDocument3 pagesB5M ElBALAKRISHNANNo ratings yet

- B2a ElDocument5 pagesB2a ElBALAKRISHNANNo ratings yet

- A95a ElDocument5 pagesA95a ElBALAKRISHNANNo ratings yet

- J2a ElDocument5 pagesJ2a ElBALAKRISHNANNo ratings yet

- B1K ElDocument5 pagesB1K ElBALAKRISHNANNo ratings yet

- A96a ElDocument5 pagesA96a ElBALAKRISHNANNo ratings yet

- Fire Protection SystemDocument29 pagesFire Protection SystemBALAKRISHNANNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- D 2199 - 03 - RdixotkDocument2 pagesD 2199 - 03 - Rdixotkphaindika100% (1)

- Start Here:: Safety Glass Meets The Requirements of Every SituationDocument2 pagesStart Here:: Safety Glass Meets The Requirements of Every SituationFALwilliamsNo ratings yet

- Systems GuideDocument237 pagesSystems GuideingrbarrosNo ratings yet

- Physics, Form 4: Specific Heat CapacityDocument18 pagesPhysics, Form 4: Specific Heat CapacitydharrineshnarenNo ratings yet

- Piping Vs Piping SystemDocument4 pagesPiping Vs Piping SystemViệt Đặng XuânNo ratings yet

- International Seminar On Computer Aided Analysis and Design of Building StructuresDocument147 pagesInternational Seminar On Computer Aided Analysis and Design of Building StructuresOscarKonzultNo ratings yet

- POSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Document1 pagePOSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Murti WisnuNo ratings yet

- Chhattisgarh: Operatlon Engineer EngineerlngDocument3 pagesChhattisgarh: Operatlon Engineer Engineerlngpadmashree sonawaneNo ratings yet

- Demolitionofbuilding AyDocument22 pagesDemolitionofbuilding Ay1DS19CV043 Kajal Godbole100% (1)

- Analisa Harga Satuan (Student Version)Document115 pagesAnalisa Harga Satuan (Student Version)endi_putra_1No ratings yet

- Materials Today: ProceedingsDocument5 pagesMaterials Today: ProceedingsraulNo ratings yet

- LRFD Aisc Manual of Steel ConstructionDocument54 pagesLRFD Aisc Manual of Steel ConstructionFer Rivas NietoNo ratings yet

- Design and Control of A Cryogenic Multi-Stage Compression Refrigeration ProcessDocument8 pagesDesign and Control of A Cryogenic Multi-Stage Compression Refrigeration ProcessGezu AcuñaNo ratings yet

- Element Solid65 in AnsysDocument10 pagesElement Solid65 in AnsyspadashtNo ratings yet

- Hitachi 12k InverterDocument74 pagesHitachi 12k InverterDaio AlvaresNo ratings yet

- Chapter 9-10 (MD) Reinzo GallegoDocument45 pagesChapter 9-10 (MD) Reinzo GallegoReinzo GallegoNo ratings yet

- 6 CHAPTER 5 Design Computation NewDocument19 pages6 CHAPTER 5 Design Computation NewChristophel FloresNo ratings yet

- Nitric Acid PlantDocument31 pagesNitric Acid Plantejaz khanNo ratings yet

- Busines Proposal For Residential ConstructionDocument7 pagesBusines Proposal For Residential ConstructionNatsu Trojanlee QuiritNo ratings yet

- New Voltas AC - Tech - SpecsDocument1 pageNew Voltas AC - Tech - Specsmohamad chaudhariNo ratings yet

- Official ISRO Previous Paper 2008 - Download Now!Document11 pagesOfficial ISRO Previous Paper 2008 - Download Now!nidhi tripathiNo ratings yet

- External Pressure VESSEL DESIGNDocument11 pagesExternal Pressure VESSEL DESIGNmsaadullah100% (1)

- Lecture Class 4 - ME F 112Document43 pagesLecture Class 4 - ME F 112Vivekananda NandamNo ratings yet

- Connectors Design Guide VU 1.3Document16 pagesConnectors Design Guide VU 1.3civiliiiNo ratings yet

- RabDocument3 pagesRabAna YulianaNo ratings yet

- Specification For Architectural WorksDocument82 pagesSpecification For Architectural WorksVJ QatarNo ratings yet

- Purmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLDocument52 pagesPurmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLMetin TamNo ratings yet