Professional Documents

Culture Documents

13. MHS16_Felling & Clearing

13. MHS16_Felling & Clearing

Uploaded by

andairawan60Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13. MHS16_Felling & Clearing

13. MHS16_Felling & Clearing

Uploaded by

andairawan60Copyright:

Available Formats

NO: INS-004-VIEHS-MHS-16 Page: 1 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

REVISION HISTORY

Date of

Revision Index Subject Issued by

Application

Minor changes, including changes to

1.1 PTVI COO 14/01/2006

titles/ positions

1.2 Changes to accountabilities PTVI COO 19/05/2006

1.3 Minor update PTVI COO 01/08/2007

1.4 Changes to titles/ positions PTVI COO 01/09/2007

1.5 Minor update PTVI COO 7/11/2007

2 Minor update PTVI COO August 2008

Major update for Vale Global and local

3 PTVI COO October 2016

requirements

Approved by:

Next review date: October 2018

COO & Director

Lovro Paulic

Responsible Person: All Managers & Project Target Audience: All PTVI and Contractor

Managers Employees

Technical Responsible :

Roimon Barus

Manager EHS & Deputy COO, KTT PTVI

Key words: EHS, Major Hazard Standards, Clearing, Felling, Chainsaw

NO: INS-004-VIEHS-MHS-16 Page: 2 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

DETAILED REVISION HISTORY

Revision

Subject

Index

Added caveat “About the PT Inco Major Hazard Standards”.

1.1

Section 9.1 Changed accountability from “All Personnel” to “PTI General Managers”

Rationalised inconsistent descriptors for accountabilities. (e.g. All Managers, All PTI Managers and Relevant Managers

1.2

were changed to PTI Managers to be consistent descriptors in all standards) Note: No actual accountability was changed.

Revision in section 2.1

Relevant operational experience was changed to Possessing relevant area, operational or system experience.

Add Hold the relevant qualification.

1.3

Have completed training in identifying the hazards associated with clearing operations and Successfully completed a

recognised risk assessment training course was changed to Having 2 or more people trained in PTI Risk Assessment

(SP01) and nominated by their manager as competent in this role.

1.4 Position Retitling (Managers were changed to General Managers)

1.5 Section 1.3 removed – Change management does not apply to changes in SOPs

Section 2.2 revised to reflect new training and competency requirements.

2

Section 2.3 incorporated into sections 2.2 and revised to reflect new workplace assessor requirements

Changed title from “Clearing Operations” to “Felling and Clearing”. To provide a clearer description of the tasks managed

by the MHS.

Changed to a single language document.

Minor changes to the ‘about the MHS section’

Expanded the contents page to show more headings.

Updated the ‘purpose’ section.

Updated the ‘scope’ section.

Added the following sections:

o References

o Terminology

o Accountabilities

Deleted the ‘accountabilities’ and ‘tools’ columns from the ‘requirements’ section. Accountabilities and Tools are now included

in the text of the document when appropriate.

Changed PT Inco (PTI) to PT Vale Indonesia (PTVI).

Section 1.1: New section for “Clearing and Felling Equipment Register”.

Section 1.2 Risk Assessment (previously 1.1).

o Additional risks to consider during risk assessments.

o Highlighted the need to select mechanical tree felling methods over chainsaws.

3 Section 1.3: New section requiring a visual assessment of each tree prior to commencing work.

Section 1.4: Previously 1.2.

o Previously stated that a JSA was required. Updated to state ‘approved work procedures’ to align with PTVI Permit to

Work requirements.

o Stated that controls must include those identified in risk assessments and EHS Standards and Procedures.

Section 1.5: New section for Change Management.

Section 1.6: New section: Added Permit to Work requirements for felling and clearing operations.

Section 2.1: Changed the qualification requirements for teams conducting risk assessments.

Section 2.2: New section for Medical Assessment requirements.

Section 2.3: Previously 2.2. Updated the training and competency requirements and reference PTVI documents.

Section 3.1: New section for pre-start briefing.

Section 3.2: Previously 3.1.

o Stated that delivery of hazard information to workers to be based on the risk profile of each department.

o Removed reference to ‘remote locations’.

Section 3.3: New section for Communication Tools.

Section 4.1: Added specifications for Dozers.

Section 4.2: New section for Felling and Clearing Equipment Specifications and procurement process outcomes.

Section 4.3: Previously 4.2. Updated the specifications for chainsaws.

Section 4.4: Previously 4.3. Updated PPE requirements for chainsaw operators.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 3 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Section 5.1: Clearing Plan, must now include ‘Location of refuge area in the event of an electrical storm’.

Section 5.2: Added requirements for SOP development.

Section 5.3: New section for Operational requirements for chainsaw use.

Section 5.4: New section on Clearing Trees Near Overhead Power Lines.

Section 6.1: Added requirements related to maintenance processes.

Section 8.1: Added reference to SP 14 inspections and audits and requirements for responsible managers to comply with

SP14 and Contractor Management.

Section 8.2: Removed ‘remote locations’ from text. Added the requirement to ensure identified hazards ar e included in

approved work procedures.

Section 8.3: New section for Pre-start inspections.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 4 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

ABOUT PT VALE INDONESIA MAJOR HAZARD STANDARDS

These Standards are designed to address the major safety hazards at PT Vale Indonesia (PTVI) and

their implementation is intended to prevent fatalities and serious injuries from the relevant hazard. The

MHS have been identified and developed based on critical operational hazards identified at PTVI and

other similar mining/ processing operations. For each major hazard they define minimum performance

outcomes and the range of available controls that could be implemented to address key aspects of the

hazard in the context of industry best-practice.

The MHS need to be understood and implemented in conjunction with the full range of General EHS

Standards and Standard Procedures that are available on the PTVI Intranet.

These Standards will be updated regularly to align with applicable Indonesian EHS Legal requirements

and Vale Global requirements.

Compliance with these Standards comprises a long-term management goal for the site, as does our

commitment to zero harm for all workers. It is not expected that all areas of PTVI’s operation could be

in complete compliance with all aspects of each Standard, just as it is not expected that all risk can be

eliminated from any mining and processing operation.

However, the concept of best practice includes a commitment to ongoing improvement, and these

Standards provide a means of measuring and guiding that progress. Periodic audits will be conducted

to measure compliance with all Major hazard Standards, and this in turn will form the basis for

improvement plans in all Departments that will result in progressive reduction of risk of injury from

incidents.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 5 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Contents

Detailed Revision History .............................................................................................................. 2

About PT Vale Indonesia Major Hazard Standards ...................................................................... 4

Purpose .......................................................................................................................................... 7

Scope .............................................................................................................................................. 7

References ..................................................................................................................................... 7

Terminology ................................................................................................................................... 8

Accountabilities ............................................................................................................................. 8

Requirements ................................................................................................................................. 9

1 Hazard Identification, Risk Assessment and Control ....................................................................................... 9

1.1 Clearing and Felling Equipment Register ................................................................................................... 9

1.2 Risk Assessment ...................................................................................................................................... 9

1.3 Visual Tree Assessment ............................................................................................................................ 9

1.4 Approved Work Procedures..................................................................................................................... 10

1.5 Change Management .............................................................................................................................. 10

1.6 Permit to Work ........................................................................................................................................ 10

2 Selection, Training, Competency and Authorisation...................................................................................... 10

2.1 Risk Assessment Competency ................................................................................................................ 10

2.2 Medical Assessment Program ................................................................................................................. 11

2.3 Training and Competency ....................................................................................................................... 11

3 Communication and Awareness ..................................................................................................................... 12

3.1 Pre-Start Work Briefing ........................................................................................................................... 12

3.2 Awareness for Personnel Conducting Felling and Clearing ....................................................................... 12

4 Specifications ................................................................................................................................................. 12

4.1 Specifications and Commissioning for Mobile Equipment ......................................................................... 12

4.2 Purchasing Felling and Clearing Equipment ............................................................................................. 12

4.3 Specifications for Chainsaws ................................................................................................................... 13

4.4 Chainsaw Operator PPE and Clothing ..................................................................................................... 13

5 Work Method and Condition Control .............................................................................................................. 13

5.1 Clearing Plan .......................................................................................................................................... 13

5.2 Standard Operating Procedures .............................................................................................................. 14

5.3 Chainsaw Operation................................................................................................................................ 14

5.4 Clearing Trees near Overhead Power Lines ............................................................................................. 15

6 Maintenance .................................................................................................................................................... 15

6.1 Maintenance Program ............................................................................................................................. 15

7 Emergency Controls ....................................................................................................................................... 15

7.1 Emergency Procedures ........................................................................................................................... 15

7.2 Fire and Emergency Services .................................................................................................................. 16

8 Monitoring, Inspections and Audits................................................................................................................ 16

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 6 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

8.1 Inspection and Auditing ........................................................................................................................... 16

8.2 Routine Inspection of Work Areas ............................................................................................................ 16

8.3 Pre-Start Inspections............................................................................................................................... 16

9 Reporting, Assessment and Corrective Actions ............................................................................................ 16

9.1 Hazards and Defects............................................................................................................................... 16

9.2 Incident Reporting and Corrective Actions................................................................................................ 17

Appendix A: Decree of the Minister of Mines and Energy ....................................................... 18

Tables & Figures

Table 1: Felling and Clearing Competencies ................................................................................................................. 11

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 7 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

PURPOSE

To define the requirements to manage safety risks associated with felling and clearing trees with the intention to eliminate

fatalities, serious injuries and significantly reduce felling and clearing related incidents from within PTVI operations.

SCOPE

This Standard applies to all tree felling and clearing operations on PTVI lease areas. Such operations generally include the

following:

Using mobile equipment such as dozers to fell trees.

Using chainsaws or mechanised equipment (mobile equipment attachments) to fell trees.

Removal of branches from trees (limbing or trimming).

Cutting trunks and limbs of felled trees into smaller lengths (bucking).

Removal of felled trees.

Additional requirements related to felling and clearing are addressed in the following PTVI Standards and these should be read

in consultation with this MHS:

MHS 01 Working at Heights: Details requirements for working at heights e.g. accessing tree limbs for removal.

MHS 03 Mobile Equipment: Details requirements for the condition, training/ competency requirements and operation of

mobile equipment used for clearing operations e.g. dozers and for using working at heights platforms.

MHS 08 Slope Stability: Details requirement for workers in active mining areas.

MHS 10 Electrical: Details requirements for working near power lines, including exclusion zones and isolation

requirements.

MHS 14 Working Near or On Water: Details additional requirements for working near water e.g. lakes and rivers.

EHS Standard 09 Personal Protective Equipment: Mandatory specifications for PPE to be used at PTVI.

REFERENCES

Legal:

Act No. 1 year 1970 on Occupational Safety.

Decree of The Minister of Mines and Energy No. 555.K/26/M.PE/1995 on General Mining Occupational Safety and

Health.

Vale:

Tree Cutting Instruction 2014.

PT Vale Indonesia:

Standard Procedure 01 Risk Assessment.

Standard Procedure 02 Job Safety Analysis.

Standard Procedure 04 Permit to Work.

Standard Procedure 09 Isolation and Lockout.

Standard Procedure 10 Change Management.

Standard Procedure 11 Incident Management.

Standard Procedure 14 Inspection and Audit.

PTVI Competency Training Standard.

SOP 0002 EHS Training Requirement and Guideline.

PTVI Contractor Safety Management System.

Technical:

ANSI/ ISEA Z89.1-2014 American National Standard for Industrial Head Protection.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 8 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Guide To Managing Risks Of Tree Trimming And Removal Work; Safe Work Australia 2016

TERMINOLOGY

Approved Work Refers to a documented work procedure that has been approved to guide persons to undertake

Procedure hazardous work safely, including all relevant risk controls identified within the corresponding risk

assessment.

Approved Work Procedures can include Standard Operating Procedures (SOPs), Work Instructions

(WIs) and Job Safety Analyses (JSAs).

Certified Structures A certified structure refers to main chassis, and structural members including “Roll Over Protection

Structures” (ROPS) and “Falling Object Protection Structures” (FOPS).

Cross-Cutting Cross-cutting is cutting wood fibres across the grain and is the most common practice carried out by

a chainsaw operator in tree trimming and removal work

Kick Back The reaction known as kickback may occur when the saw chain on the upper quadrant of the guide

bar tip touches an object. In some cases tip contact may cause a rapid reverse reaction, kicking the

guide bar up and back towards the operator.

Lightning/ Electrical Adverse atmospheric conditions producing very intense electrical discharges (lightning), which may

Storm occur between clouds (cloud flash) or between clouds and ground (ground flash).

Felling and Clearing Mechanical equipment used for the felling, cutting and clearing of trees. Examples include:

Equipment Chainsaws.

Dozers and other mobile equipment.

Mechanized felling equipment e.g. Cutting attachment mounted on mobile equipment.

Jungle Canopy Structure fitted to mobile equipment, designed to protect operators by preventing objects such as tree

limbs from entering the equipment cabin.

Push Back Pushback may occur when the chain on top of the guide bar is suddenly stopped due to being pinched,

caught or encountering a foreign object in the wood. The sudden reaction of the saw chain pushes the

chainsaw back. Pushback can also occur when the saw chain is not rotating at full speed before it

contacts the wood or when the saw is not held securely against the tree or limb being cut.

Pull-In Pull-in may occur when the chain on the bottom of the guide bar is suddenly stopped due to being

pinched, caught or encountering a foreign object in the wood. The sudden reaction of the saw chain

pulls the chainsaw forward. Pull-in can also occur when the saw chain is not rotating at full speed

before it contacts the wood or when the saw is not held securely against the tree or limb being cut.

Responsible The manager responsible for management of the equipment, work environment, and/ or workers in a

Manager particular area. This is generally the Department Manager, Project Manager or Contractor Company

Manager.

ACCOUNTABILITIES

PTVI’s Board of Directors, Chief Operating Officer, Technical Mine Manager (KTT) and Manager EHS are responsible for the

broader MHS program, including allocation of sufficient resources for implementation, monitoring of Department programs for

MHS compliance and facilitating the MHS audit program.

Responsible Managers e.g. PTVI Department Managers, Project Managers and Contractor Company Managers are accountable

for implementing the requirements of this MHS within their areas of responsibility.

Whenever possible, accountability for requirements in the MHS has been assigned to specific positions. For example, section

8.1 assigns the Department Manager EHS as accountable for fulfilling that MHS outcome.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 9 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

REQUIREMENTS

1 HAZARD IDENTIFICATION, RISK ASSESSMENT AND CONTROL

Objectives

To ensure all felling and clearing equipment are identified and recorded on a register.

To ensure a risk management process is applied for all felling and clearing operations.

To require an approved work procedure e.g. JSA, SOP to be in place for all clearing activities.

To ensure the PTVI change management process is applied.

To require a PTVI Permit to Work for felling and clearing activities.

1.1 Clearing and Felling Equipment Register

Responsible Managers shall register all tree felling and clearing equipment approved for use at PTVI. The registers shall be

accessible and kept up to date, detailing equipment identification numbers and inspection details. Registration shall be done in

accordance with the following:

Mobile equipment and attachments shall be registered as per the requirements of MHS 03 Mobile Equipment.

Other equipment, such as chainsaws shall be registered in the relevant PTVI Departments or by the Contractor Company.

1.2 Risk Assessment

Responsible Managers shall risk assess felling and clearing activities.

As a minimum, risk assessments shall address the following hazards when applicable:

Falling trees and tree branches.

Hazards specific to tree condition e.g. dead trees, unusual tree shape.

Operating on unstable ground or slopes e.g. risks of equipment rollover, specific tree cutting techniques required, land slide

potential.

Vehicle and mobile equipment operation e.g. Ground conditions, clearing methods, felled tree placement, interaction with

workers.

Using hazardous hand tools e.g. chainsaw, cutting tools (parang).

Working in isolated locations.

Manual tasks i.e. lifting, pushing, pulling, repetitive movements, holding machinery

Lightning / electrical storms and severe weather.

Worker competence and behaviours.

Insects and other wildlife.

Allergic reactions to trees and poisonous plants.

Risk assessments shall follow the process outlined in the PTVI Risk Assessment Procedure (SP01).

Use of mobile equipment is the preferred method for felling trees. The use of chainsaws can be a very hazardous activity and

they may be used only after use of mobile equipment has been considered and deemed not suitable for the task. The selected

methodology must be documented in Department Procedures.

1.3 Visual Tree Assessment

Before working on or accessing a tree by any method, a thorough visual assessment of the tree shall be carried out by a

competent person. This assessment must form the basis of a site-specific risk assessment and decision-making on whether the

tree is safe to access, the method chosen to access the tree and the safe systems of work to be used on the site.

The assessment must consider atleast the following:

The stability and integrity of the tree: Is the tree decayed or dead and unsafe to climb or be attached to?

Is the species or the particular tree susceptible to branch failure when under load?

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 10 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Is the tree stable in the ground?

Is the crown of the tree leaning heavily in one direction?

Is the tree suitable to be climbed?

Ensure that no person, plant or thing will come within an unsafe distance of an overhead electric line.

Ground surface condition including type of soil, underground services, underground tanks, leach drains and gradients of

ground surface.

Access by people and management of traffic.

Animal and insect management e.g. are there insects or other animals in the tree that may be a risk to a worker?

Common hazards like vines, creepers in crown, nails and wire are identified and removed or controlled.

Establishment of exclusion zones.

1.4 Approved Work Procedures

An approved work procedure e.g. JSA, SOP, must be in place for all felling and clearing activities. The procedures shall address

safe working requirements and management of site specific hazards, including controls identified in relevant risk assessments,

this MHS and other related EHS standards and procedures.

If during the work there is a change in scope, methodology or work environment that isn’t already assessed and managed, work

shall stop, the procedures updated, approved and socialised prior to re-commencing the work.

JSA’s shall be developed in accordance with the PTVI JSA Procedure (SP02).

1.5 Change Management

The PTVI Change Management Procedure (SP10) must be followed to authorise changes related to felling and clearing

equipment and management. Examples of applicable changes include, but are not limited to the following:

If mobile equipment has been defined as the preferred method of felling trees for particular operations e.g. in exploration

and mining operations; approval by the EHS Committee must be obtained prior to adopting the use of other methods such

as chainsaws.

Purchase of new types of tree felling equipment.

Modifications to equipment.

Operating/ using equipment outside defined safe operating parameters.

Changes to equipment purchasing/ engineering specifications.

Changes to organisational/ human resources with responsibilities to manage or supervise activities under the scope of this

MHS.

1.6 Permit to Work

Use of chainsaws for felling and clearing operations shall be authorised and conducted under the control of a PTVI Permit to

Work in accordance with PTVI Permit to Work Procedure (SP04).

2 SELECTION, TRAINING, COMPETENCY AND AUTHORISATION

Objectives

To ensure personnel required to conduct risk assessments are competent.

To ensure personnel required to perform felling and clearing are medically fit.

To ensure a training and competency system is established and applied for persons involved in felling and clearing.

2.1 Risk Assessment Competency

Risk assessments must be conducted by teams with relevant felling and clearing experience and qualifications and include

members of the workforce. The facilitator must be trained in PTVI Risk Assessment Procedure (SP01).

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 11 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

2.2 Medical Assessment Program

The Manager responsible for medical services shall implement a medical assessment program to assess workers engaged in

operational tasks such as felling and clearing. The program must include initial pre-employment assessment, change of position

assessment and periodic re-assessment.

Assessments shall be conducted at the PTVI Hospital or other approved medical facility.

Department and/ or Project Managers shall ensure all relevant personnel have completed the required PTVI medical and

received medical clearance to work in the role.

2.3 Training and Competency

Personnel must be trained, assessed as competent and authorised to perform felling and clearing.

Training and competency assessment must be undertaken in accordance with the PTVI Competency Training Standard.

Centralised EHS training in felling and clearing risk prevention must be undertaken in accordance with EHS 0002 EHS Training

Requirement and Guideline.

Workers must carry their competency card on their persons when clearing and felling trees. The competencies listed in Table 1

are applicable to chainsaw operators and personnel conducting clearing operations.

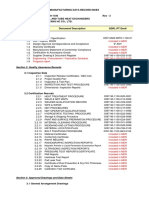

Title Training Provider Required Participants PTVI Course ID

EHS Technical

Chainsaw Operator PTVI Mines and Exploration Chainsaw operators. N/A

Basic Permit System – EHS & PTVI Authorised All persons required to work under a EHS0000002

Worker Trainers PTVI Permit to Work.

Permit System for EHS & PTVI Authorised Persons required to issue or accept TTPERMTOWO

Supervisor Trainers permit to work.

(Issuer/Acceptor)

Table 1: Felling and Clearing Competencies

Note: Competencies for mobile equipment operation are detailed in MHS 03 Mobile Equipment.

Department training programs shall address the following:

Include a Training Needs Analysis, identifying applicable training for felling and clearing activities.

Induction/ orientation processes shall be in place to educate personnel regarding felling and clearing risks and controls;

this shall include SOP training.

Training and assessment for workers required to:

Assess the condition of potentially unstable slopes in clearing locations.

Inspect and maintain mobile clearing equipment.

Direct mobile clearing equipment and loading operations.

Operate mobile clearing equipment and attachments.

Operate and maintain chainsaws and other cutting tools.

Conduct tree felling, log cutting and disposal operations.

Training must be specific to each type and model of equipment used by workers.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 12 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

3 COMMUNICATION AND AWARENESS

Objectives

To ensure communication of site specific hazards and controls are provided to workers on a daily basis.

To ensure all involved in felling and clearing understand the hazards, risks and controls relevant to their work.

3.1 Pre-Start Work Briefing

Each shift, prior to commencing felling and clearing work, supervisors must assess that all their workers are fit for work and

conduct a worker activity briefing to address hazards and controls relevant to the shift’s activities. Communication shall include

the following as a minimum:

Hazards at the worksite e.g. landslide potential, working on slopes, water bodies, infrastructure/ buildings that require

protection, higher risk trees requiring clearing.

Work methods required for the work site e.g. cutting methods, clearance requirements.

Emergency requirements, including medical evacuation (as required).

Expected weather conditions e.g. potential for inclement weather.

Location of refuge area in the event of a lightning storm.

3.2 Awareness for Personnel Conducting Felling and Clearing

Information must be provided on a regular basis (frequency to be based on department risk exposure) through consultative

forums and SOP refreshing for all personnel who perform felling and clearing work.

Information topics should detail:

Hazards associated with felling and clearing.

Hazards associated with work in remote locations.

Demarcation and prohibited areas.

Applicable SOPs.

Requirements when working with chainsaws and mobile clearing equipment.

4 SPECIFICATIONS

Objectives

To ensure all mobile equipment used in felling and clearing meet PTVI requirements.

To require special safety features for felling and clearing equipment.

To define the minimum Personal Protective Equipment (PPE) for chainsaw operators.

4.1 Specifications and Commissioning for Mobile Equipment

All mobile equipment used for felling and clearing activities must meet the requirements of MHS 03 Mobile Equipment.

In addition, dozers used for clearing trees shall be fitted with the following features:

Jungle canopy to prevent trees and debris intruding into the cabin.

Cabin fitted with certified ROPS and FOPS. FOPS specifications shall be suitable for the expected areas of operations i.e.

tree size and potential impact on equipment.

4.2 Purchasing Felling and Clearing Equipment

Personnel responsible for procurement shall implement processes to address the following:

All relevant safety controls relating to the equipment specifications identified by the engineer / project manager are

conveyed in full to the supplier.

No changes are to take place to equipment ordered with respect to safety features without approval from the originator or

a competent person who is familiar with the original equipment design considerations and relevant technical specifications.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 13 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

If changes are made to any safety controls specified for equipment, then all documentation and rationale for the decision

must be kept.

Prior to being released to users, equipment shall be assessed, to verify that adequate safeguarding is fitted to the

equipment.

Department responsibilities for verifying equipment condition for products provided directly to users, such as consumables,

are defined.

4.3 Specifications for Chainsaws

Chainsaws shall have the following safety features:

Front and rear hand guard.

Chain brake.

Chain catcher.

Throttle trigger lockout (must be pressed to activate the throttle trigger).

Anti-vibration device.

Guide bar cover.

Muffler with spark arrestor.

4.4 Chainsaw Operator PPE and Clothing

The following PPE and clothing requirements shall be complied with by chainsaw operators:

High visibility hard-hat with chin strap (ANSI/ ISEA Z89.1-2014).

Safety glasses with safety shields (refer EHS Standard 09 Personal Protective Equipment).

Face shield – mandatory when using chainsaw.

Hearing protection (refer EHS Standard 09 Personal Protective Equipment).

Hard ‘steel’ toe / chainsaw resistant safety boots (refer EHS Standard 09 Personal Protective Equipment).

Good fitting leather work gloves or saw mittens.

Leg coverings (chaps), designed for chainsaw operators.

Bee net (must be on the worker at all times, and worn when risk of bees is identified).

Long sleeves and long trousers.

Loose fitting jewellery, clothing or other items that might become entangled in the chainsaw shall not be worn and long hair

shall be restrained to prevent entanglement.

5 WORK METHOD AND CONDITION CONTROL

Objectives

To require the development of Clearing Plans prior to conducting felling and clearing activities.

To require the development and application of Approved Work Procedures, by defining the minimum safety controls

for felling and clearing activities.

To support the development of risk assessments and to ensure precautions are in place to protect workers felling

trees during electrical storm events.

5.1 Clearing Plan

A Clearing Plan shall be developed, based on the outcomes of the risk assessment (Section 1.2) for all felling and clearing. The

plan shall provide a detailed map or diagram outlining:

The location of the clearing activity and area to be cleared.

Sign posting at all entry points.

Boundary markers.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 14 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Limitations for the clearing technique due to slope or other hazards.

Location of refuge area in the event of an electrical storm.

5.2 Standard Operating Procedures

SOPs shall be developed, based on the outcomes risk assessments (Section 1.2). As a minimum, the SOPs shall cover:

Planning operations:

Notification and signage.

Site inspection (section 8.2).

Safe boundaries (Access control).

Inspection of areas with potentially unstable slopes to evaluate risk of landslide.

Clearance zones for protection of workers around tree felling and clearing operations; for both mobile equipment and

chainsaw operations.

Using mobile equipment/ mechanised equipment for felling, limbing and bucking.

Using mobile equipment for tree and vegetation removal.

Manual tree felling, limbing and bucking.

Manual clearing and disposal (lifting and loading techniques).

Requirements for working in potentially hazardous areas, for example:

On slopes.

Near facilities, installation and buildings.

Near overhead power lines.

Near water bodies.

Requirements to cease work in the event of an approaching lightning/ electrical storm or other severe weather.

Communication methods between workers, supervisors and emergency services.

Medical evacuation.

5.3 Chainsaw Operation

SOPs for chainsaw operation shall be developed based on the outcomes of risk assessments (section 1.2). As a minimum, the

SOPs shall cover:

For the purposes of supervision, Supervisors must be at the worksite, whilst remaining outside of exclusion zones, at all

times when chainsaws are being operated.

Conduct a visual assessment of each tree prior to cutting (section 1.3).

Selection of chainsaws suitable for the task e.g. size suitable for the tree truck diameter.

Ensuring an escape path is in place when felling trees, which allows the worker access to an area away from the planned

fall direction of the tree.

Process to safely cut logs to shorter lengths (cross cutting).

When walking with a chainsaw, carry it by the front handle only. If carrying over long distances e.g. further than 5 metres

or over difficult terrain, chainsaws must be turned off.

Have the chain brake in the locked or ‘on’ position when not cutting.

Instruction for safely approaching another operator. The noise of the chain saw and the concentration required may make

the operator oblivious to someone approaching.

Understand the bar's kickback zone and avoid getting into kickback situations.

Never cut above shoulder height.

Work on the uphill side of trees so they'll roll away from you instead of over you.

Start all cuts with a full throttle before touching the wood.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 15 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Avoid touching the ground with the chain because even a brief encounter will severely dull the cutting teeth.

Keep the chain sharp. A dull chain is unsafe, making use more difficult on the machine and operator.

Required fuel levels; to allow completion of each cut without refuelling.

Controls and methods for felling high risk trees, which may include the following:

Trees with a heavy lean.

A tree propped or leaning against another tree, or under tension.

Abnormally large trees.

Trees on steep terrain or unstable ground, and

Trees with hollow, split or otherwise defective trunks.

Protect your back. When trying to move logs, use a lever or get help.

Chainsaw selection when working at heights, shall allow the workers to maintain 3 points of contact and / or safe use of fall

protection equipment.

5.4 Clearing Trees near Overhead Power Lines

Any work conducted near power lines must be done in accordance with MHS10 Electrical.

When assessing the risks of working near overhead electric lines the following must be considered:

Overhead electric lines hidden in trees

De-energising overhead electric lines running through tree branches before accessing the tree.

6 MAINTENANCE

Objectives

To maintain felling and clearing machinery in a fit for purpose condition.

6.1 Maintenance Program

Maintenance requirements for mobile equipment and mechanised attachments are specified in MHS 03 Mobile Equipment

Condition.

Standard Operating Procedures (SOP’s) shall be developed for maintenance activities associated with power tools (Chainsaws).

The following activities as a minimum must be addressed:

Schedule for routine equipment inspections and planned maintenance in accordance with original manufacturer’s

specifications, risk assessments, operating experience and applicable standards.

Chain replacement, tensioning and sharpening.

Re-fuelling.

Repairs and tuning.

Routine safety inspection.

Safety critical components and systems are identified and adequately maintained.

Note: Chainsaws must be shut off prior to commencing any inspection or maintenance task.

7 EMERGENCY CONTROLS

Objectives

To ensure planning for emergencies when conducting felling and clearing.

To ensure FES have the capability to respond to emergencies in remote locations.

7.1 Emergency Procedures

Responsible Managers shall develop and implement emergency procedures. The procedures shall include controls identified by

a risk assessment (Section 1.2) and address at least the following:

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 16 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Communications, including the radio call sign, map of location and access to muster point.

Remote area access.

Extraction of injured workers.

First aid provisions in remote locations.

7.2 Fire and Emergency Services

The Department Manager EHS shall implement FES procedures to enable the response to an emergency. The emergency

procedures must include as a minimum:

Communication.

Remote area access.

Extraction of injured workers.

First aid provision in remote locations.

8 MONITORING, INSPECTIONS AND AUDITS

Objectives

To require the auditing and inspection of compliance to this Standard.

To require review of contractor performance.

To require the inspection of work areas every shift and the communication of identified hazards to all workers.

To ensure a process is implemented to conduct routine and pre-start inspections of all felling and clearing

equipment.

8.1 Inspection and Auditing

The Department Manager EHS shall develop an inspection and audit program to assess compliance with this Standard (refer

PTVI EHS Inspection and Audit Procedure (SP14)).

Responsible Managers shall meet the requirements of the inspection and audit program e.g. Safety Observation – Inspection

and Job Cycle Check Program.

Responsible Managers shall manage contractors performing felling and clearing activities in accordance with the PTVI

Contractor Safety Management System.

8.2 Routine Inspection of Work Areas

Personnel supervising the work must perform a site hazard inspection at the start of every shift and communicate relevant

information to workers at a work activity briefing as detailed in section 3.1.

The hazards identified and their controls must be documented in approved work procedures (refer section 1.4).

8.3 Pre-Start Inspections

All felling and clearing equipment must be inspected prior to use, including use of checklists for power tools.

9 REPORTING, ASSESSMENT AND CORRECTIVE ACTIONS

Objectives

To require all personnel conducting felling and clearing to identify, report, correct and record hazards.

To ensure all incidents and near misses associated with felling and clearing are reported and corrective actions

applied.

9.1 Hazards and Defects

Processes shall be in place for the reporting, assessment and correction of hazards compromising felling and clearing safety

and must address:

Demarcation/barricading and communication of the hazard.

The recording of actions taken to control the hazard.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 17 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

Any equipment that is damaged, faulty, out-of-certification, has been modified from OEM specifications without authorisation or

has had unauthorised maintenance carried out on it, must be removed from service and an Out-of-Service tag attached in

accordance with PTVI Isolation and Lockout Procedure (SP04).

9.2 Incident Reporting and Corrective Actions

All felling and clearing incidents, including near misses shall be reported and investigated to ensure corrective action(s) are

implemented.

Incident reporting and management shall follow PTVI Incident Management Procedure (SP11).

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

NO: INS-004-VIEHS-MHS-16 Page: 18 of 18

PTVI – MAJOR HAZARD STANDARD

FELLING AND CLEARING Classification: Critical Rev.: 03

APPENDIX A: DECREE OF THE MINISTER OF MINES AND ENERGY

(Number: 555.K/26/M.PE/1995 on General Mine Occupational Health and Safety)

Article 255 – Bulldozers

(2) It is prohibited for any person to be in any area where bulldozers are clearing trees and where trees may be falling.

(3) Bulldozers used for work as required in paragraph (2) (clearing trees) shall be fitted with a sturdy canopy.

INTERNAL USE ONLY

UNCONTROLLED DOCUMENT WHEN PRINTED

HANYA UNTUK KALANGAN SENDIRI

DOCUMENT TIDAK DAPAT DIKONTROL PADA SAAT DIPRINT

You might also like

- L1 CHE PRO 031 Engineering Change ProcedureDocument24 pagesL1 CHE PRO 031 Engineering Change Procedure4493464No ratings yet

- L1-CHE-PRO-001 - Standard Waiver ProcedureDocument16 pagesL1-CHE-PRO-001 - Standard Waiver ProcedureCK TangNo ratings yet

- Benchmarking Best Practices for Maintenance, Reliability and Asset ManagementFrom EverandBenchmarking Best Practices for Maintenance, Reliability and Asset ManagementNo ratings yet

- Technical Authority FrameworkDocument22 pagesTechnical Authority Frameworkronelbarafaeldiego0% (1)

- L1-Che-Gdl-005 (8) Engineering Standards ListingDocument23 pagesL1-Che-Gdl-005 (8) Engineering Standards ListingCK TangNo ratings yet

- L0-SQE-MAN-002 v5 - Safety Management System ManualDocument10 pagesL0-SQE-MAN-002 v5 - Safety Management System ManualCK TangNo ratings yet

- 1.2 Points, Lines, PlanesDocument24 pages1.2 Points, Lines, PlanesDeo Di Lyn100% (1)

- Konecranes SMV37 52 GC Top Lift Container Handler BrochureDocument24 pagesKonecranes SMV37 52 GC Top Lift Container Handler BrochureCardoso MalacaoNo ratings yet

- Pa 020 0028 - PSSRDocument18 pagesPa 020 0028 - PSSRrizqi widodo100% (1)

- OPS - SP009 - Project ReportingDocument22 pagesOPS - SP009 - Project Reportingpuput utomoNo ratings yet

- Short Service Employees ProcedureDocument6 pagesShort Service Employees ProcedureriamegaNo ratings yet

- Petrofac Limited Hsseia StandardDocument19 pagesPetrofac Limited Hsseia Standardrodman823No ratings yet

- PGC.7.1-01-Risk Management ENG # 2021 05 12 # V8.1Document34 pagesPGC.7.1-01-Risk Management ENG # 2021 05 12 # V8.1MarcBenetPozo100% (1)

- Ita Hse Control of ContractorsDocument12 pagesIta Hse Control of ContractorsshivamNo ratings yet

- MQ SP I 7024 PDFDocument33 pagesMQ SP I 7024 PDFJaseelKanhirathinkalNo ratings yet

- SUDAIR-HSE-PR-012-01-PPE ManagementDocument19 pagesSUDAIR-HSE-PR-012-01-PPE ManagementGerardoNo ratings yet

- Petronas Technical Standards: Hazardous Area Classification (Supplements/Amendments To International Standards)Document13 pagesPetronas Technical Standards: Hazardous Area Classification (Supplements/Amendments To International Standards)Benjamin LeeNo ratings yet

- Report On ERTMS Longer Term PerspectiveDocument21 pagesReport On ERTMS Longer Term Perspectiveaurelian curcaNo ratings yet

- Contractor Monthly Report ProcedureDocument8 pagesContractor Monthly Report ProcedureAl Hamra Ayashofiya100% (1)

- MQ SP I 7025 PDFDocument16 pagesMQ SP I 7025 PDFJaseelKanhirathinkalNo ratings yet

- MQ SP I 7002 PDFDocument83 pagesMQ SP I 7002 PDFJaseelKanhirathinkalNo ratings yet

- Mhs08-Lifting and SupportingDocument41 pagesMhs08-Lifting and SupportingWidya BungaNo ratings yet

- PEC-HS-PRO-X-13858 Subcontractors' HSSE Prequalification and Management Procedure - REV 1Document21 pagesPEC-HS-PRO-X-13858 Subcontractors' HSSE Prequalification and Management Procedure - REV 1Joemon T JoyNo ratings yet

- E 09 GP 005 Contractor Health and Safety Plan AssessmentDocument9 pagesE 09 GP 005 Contractor Health and Safety Plan AssessmentJohn KalvinNo ratings yet

- Keppel Land Limited: Document No.: Qehsms01 Revision No.: 03 Revision Date: 8 April 2019Document32 pagesKeppel Land Limited: Document No.: Qehsms01 Revision No.: 03 Revision Date: 8 April 2019bpdvietNo ratings yet

- Mhs02-Operasi KendaraanDocument21 pagesMhs02-Operasi KendaraanWidya BungaNo ratings yet

- OSHEMSP 72 - Management of Change Rev.01Document6 pagesOSHEMSP 72 - Management of Change Rev.01Venkadesh Periathambi100% (1)

- Department Integrated Management System Manual: IS/ISO/9001: 2015 IS/ISO/14001: 2015Document58 pagesDepartment Integrated Management System Manual: IS/ISO/9001: 2015 IS/ISO/14001: 2015IskerNo ratings yet

- PROCEDURE-0109 Management ReviewDocument3 pagesPROCEDURE-0109 Management ReviewIsmail Hamzah Azmatkhan Al-husainiNo ratings yet

- MQ SP I 7001 PDFDocument18 pagesMQ SP I 7001 PDFJaseelKanhirathinkalNo ratings yet

- Health Safety Environment & SD Specification For Ionising RadiationDocument40 pagesHealth Safety Environment & SD Specification For Ionising RadiationcgnanaponNo ratings yet

- Best Practice Guide Management of Change Processes in Relation To Pressure Equipment Integrity ManagementDocument10 pagesBest Practice Guide Management of Change Processes in Relation To Pressure Equipment Integrity ManagementJavier BravoNo ratings yet

- SMP-088: Preventive Maintenance Program Supplement For All Standard PlantsDocument14 pagesSMP-088: Preventive Maintenance Program Supplement For All Standard PlantsAndrea TegriaNo ratings yet

- SP 1231Document28 pagesSP 1231SUJITH KUZHIKATTILNo ratings yet

- BCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageDocument15 pagesBCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageCarwell AbatayoNo ratings yet

- MoC Procedure PDFDocument14 pagesMoC Procedure PDFjanuary1969100% (4)

- Iso14971 ManualDocument43 pagesIso14971 ManualMachinfabrik- QCNo ratings yet

- Yps1 0 04 0001 3 - PQPDocument81 pagesYps1 0 04 0001 3 - PQPRubén Crespo MartínezNo ratings yet

- 024 - Competence Requirements For Drilling and WellDocument14 pages024 - Competence Requirements For Drilling and WellAminNo ratings yet

- Chapter 16Document12 pagesChapter 16Al UcupNo ratings yet

- PSSR Procedures and Check ListDocument16 pagesPSSR Procedures and Check ListJUAN JOSE ARAQUE AYCARDINo ratings yet

- DRP001-OUF-PRO-Q-000-503 B1 NCR ProcedureDocument13 pagesDRP001-OUF-PRO-Q-000-503 B1 NCR ProcedureDaniel Martinez50% (2)

- Specification - Specification Update ProcedureDocument6 pagesSpecification - Specification Update ProcedureAzhar AliNo ratings yet

- Iso13485 ManualDocument42 pagesIso13485 ManualMachinfabrik- QCNo ratings yet

- 08 - Tata Power Permit To Work ProcedureDocument24 pages08 - Tata Power Permit To Work Procedurehse bsjNo ratings yet

- Annex 1Document23 pagesAnnex 1Richu PaliNo ratings yet

- 7057.151.04 Er HS 003 WHSDocument10 pages7057.151.04 Er HS 003 WHSsandyyansikuNo ratings yet

- Section 43 - Process Hazard Analysis Protocol PDFDocument5 pagesSection 43 - Process Hazard Analysis Protocol PDFzironelNo ratings yet

- Mhs15-Rotating and Moving EquipmentDocument50 pagesMhs15-Rotating and Moving EquipmentWidya BungaNo ratings yet

- Certification Specifications For Standard Changes & Standard Repairs (CS-STAN) - Phase 1Document58 pagesCertification Specifications For Standard Changes & Standard Repairs (CS-STAN) - Phase 1BENoNo ratings yet

- GM-NOC-ENV-008 - Rev00 Environmental Monitoring and ReportingDocument25 pagesGM-NOC-ENV-008 - Rev00 Environmental Monitoring and Reportingtho03103261No ratings yet

- SOP InspeksiDocument20 pagesSOP InspeksioliaNo ratings yet

- Lead Stress Engineer Ref ManualDocument8 pagesLead Stress Engineer Ref Manualabhishek186186No ratings yet

- Itp - Inspection and Testing Plan (Creation and Management)Document11 pagesItp - Inspection and Testing Plan (Creation and Management)rohit12389No ratings yet

- 726 AbDocument142 pages726 AbGabrielNo ratings yet

- Guideline Incident Reporting Investigation and ReviewDocument15 pagesGuideline Incident Reporting Investigation and ReviewEndrico PratamaNo ratings yet

- Nabl 126Document31 pagesNabl 126Gazal GuptaNo ratings yet

- ITP Plan For Piping Pre-Commisioning - Rev2Document23 pagesITP Plan For Piping Pre-Commisioning - Rev2Dwikappa Asri Utama100% (1)

- Point MechanismsDocument30 pagesPoint MechanismsSivaji KotipalliNo ratings yet

- Operation & Maintenance Engineering Guideline For RCM ImplementationDocument57 pagesOperation & Maintenance Engineering Guideline For RCM ImplementationGlad Blaz100% (2)

- 08 Permit To Work ProcedureDocument24 pages08 Permit To Work Procedureniteshsh31100% (1)

- Appendix 1Document35 pagesAppendix 1kim_jamjungNo ratings yet

- Tapa AGR Reg App BDocument35 pagesTapa AGR Reg App Bfoxbat05No ratings yet

- P 75-92 QTR 2 TG Module 2 Plant and Animal CellsDocument18 pagesP 75-92 QTR 2 TG Module 2 Plant and Animal CellsJane Limsan PaglinawanNo ratings yet

- Webinar Scope Cal IntroDocument60 pagesWebinar Scope Cal IntroKen OhNo ratings yet

- EU Igus Dry-Tech BEA1 2023 Catalogue 02-05 Iglidur Food ContactDocument38 pagesEU Igus Dry-Tech BEA1 2023 Catalogue 02-05 Iglidur Food ContactDaniel Andrés ReigNo ratings yet

- Land Rover Discovery SportDocument2 pagesLand Rover Discovery SportnikdianaNo ratings yet

- Design of Voltage Source Inverter Using SPWMDocument63 pagesDesign of Voltage Source Inverter Using SPWMAshiti Tufa100% (1)

- Mass Lynx SoftwareDocument94 pagesMass Lynx SoftwareKansy HaikalNo ratings yet

- This Study Resource Was: Practice Set 6 Demand Management and ForecastingDocument8 pagesThis Study Resource Was: Practice Set 6 Demand Management and ForecastingAbinashMahapatraNo ratings yet

- EZ9 Series HMI ManualDocument34 pagesEZ9 Series HMI ManualDanielito AlvaracinNo ratings yet

- HINO US Chap02Document10 pagesHINO US Chap02Andres GomezNo ratings yet

- Hot Rolling Mill IndustryDocument12 pagesHot Rolling Mill IndustryJanuar Kurniawan KurniawanNo ratings yet

- Warning: No Smoking! No Open Flame! While Installing Your Jet KitDocument2 pagesWarning: No Smoking! No Open Flame! While Installing Your Jet KitBrad MonkNo ratings yet

- 3001 - 236603235 - 00 - B00 - Stake SecureDocument6 pages3001 - 236603235 - 00 - B00 - Stake SecureHANUNNo ratings yet

- Canon BJC-3000 Printer: Error CodesDocument1 pageCanon BJC-3000 Printer: Error Codeseu mibNo ratings yet

- Reading Passage 1: IELTS Practice Tests PlusDocument16 pagesReading Passage 1: IELTS Practice Tests PlusNguyen Lan AnhNo ratings yet

- Updated Term Paper (5310) PDFDocument21 pagesUpdated Term Paper (5310) PDFSourae MridhaNo ratings yet

- Sri VidyameditationDocument24 pagesSri VidyameditationClaudia ShanNo ratings yet

- 7000 Distiller ManualDocument12 pages7000 Distiller ManualvicdiaNo ratings yet

- MDRDocument3 pagesMDRjeffreymacasero100% (1)

- DIGITAL CONTROL SYSTEMS April 2018Document8 pagesDIGITAL CONTROL SYSTEMS April 2018KOTHYADA JOSHNANo ratings yet

- Analog Circuits II Lab ManualDocument47 pagesAnalog Circuits II Lab ManualParesh SawantNo ratings yet

- Muscular Tissues: Skeletal MusclesDocument3 pagesMuscular Tissues: Skeletal Musclesalimsaadun alimsaadunNo ratings yet

- Bokk, Fiber, Naam 1985, BasedDocument210 pagesBokk, Fiber, Naam 1985, BasedDoddy UskonoNo ratings yet

- State Map TSP Kayin MIMU696v03 09sep2016 ENG A3Document1 pageState Map TSP Kayin MIMU696v03 09sep2016 ENG A3Naing SoeNo ratings yet

- Expanded Immunization Program EpiDocument22 pagesExpanded Immunization Program EpiGirome BairaNo ratings yet

- Akg WMS40 PRODocument10 pagesAkg WMS40 PROParesh BhedaNo ratings yet

- Official Ncm0200 Baird Parker Agar Base Technical Specifications en UsDocument3 pagesOfficial Ncm0200 Baird Parker Agar Base Technical Specifications en UsBty SaGNo ratings yet

- Different Drill Bits Used in Drilling OperationsDocument31 pagesDifferent Drill Bits Used in Drilling OperationsPeterMarkNo ratings yet