Professional Documents

Culture Documents

DB104 0315(Ring Adjustment Cone) r.4

DB104 0315(Ring Adjustment Cone) r.4

Uploaded by

서정윤Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DB104 0315(Ring Adjustment Cone) r.4

DB104 0315(Ring Adjustment Cone) r.4

Uploaded by

서정윤Copyright:

Available Formats

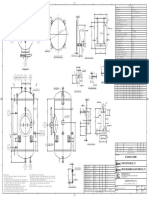

1 2 3 4 5 6 7 8

RIGHT HAND THREADS

2.0000 PITCH. FOR

FINISH SEE NOTE 4.

DETAIL N

P59.543

MINOR

REMOVE KNIFE EDGE FROM FACE OF SCALE 1/4"=1"

45° PARTIAL THREAD FORM WITH 1/4" TO 3/8" FLAT,

P

14

REMOVE REMAINING SECTION OF PARTIAL R1.50 B.12 TYP

P61.614

THREAD FORM THAT IS TOO THIN FOR FLAT.

MAJOR

R1.00 B.12 TYP

0.12 X 45`

A A

13

0.067

E .002

SECTION A-A

SCALE 1/8"=1"

30°

15 11.466 20 P81.500 R38.84 B.24

A

12X P0.33 Z 1.19

125

M10x1.5 - 6H Z 0.84 R3.27 B.12 TYP

EQUALLY SPACED 6.50 B.16

R0.094 R2.48 B.12

16 2.913

J 12 3X 44° 0.5296

17 2.323 R1.50 B.12

DETAIL E P

ALL DIMENSIONS ARE TYPICAL

SCALE 1/2"=1" R0.09 5X P2.480

21 SEE SECTION P-P FOR

24

R0.83 R0.98 B.08

7

43° COUNTERBORE

.82

6.0

48

14

R0.24

A

2 P78.740 B.C.

J

SECTION P-P

SCALE 1/4"=1"

22°

B B

5X P1.26 Z 4.06

M36x4 - 6H Z 2.63

11 45° EQUALLY SPACED AS SHOWN

SEE NOTE 5 (2.48)

START OF THREAD

SEE DIMENSION IN K-K

HOLE 4 3 39°

22 5.225

20°

G

55°

P76.61 B.31

18 P76.650

19 P65.512

C K +

23 P2.5591 - .0000

.0012

10 P0.39Z.81 L P.12 A BO C

C B THREAD

60° TIMING

B MARK

15°

K 9 2.5° NOTES:

1. CASTING MATERIAL TO BE HIGH STRENGTH CARBON STEEL. ASTM A148 GRADE

HOLE 1

C HOLE 3 90/60 (90,000 PSI MIN TENSILE STRENGTH, 60,000 PSI MIN YIELD STRENGTH, C

I C

20% MIN ELONGATION AND 40% MIN REDUCTION OF AREA).

6X P4.02 THRU

4 2. MATERIAL HARDNESS TO BE 180-228 BRINELL.

SPACED AS SHOWN

3. REFERENCE CHART FOR DEPTH OF HOLES (SEE TOP VIEW AND SECTION B-B):

HOLE # DEPTH "X"

A 8 P70.472 B.C.

E

1 5.815

2 2.413

HOLE 2 3 4.815

7 2X 120° 4 3.252

125

4. FINISH FOR ENTIRE PROFILE OF THREAD SHALL BE .

5 P85.827 B.C. 6 4x 60°

5. LOCATE START OF THREAD WHERE THE FLAT OF THE FULL THREAD

PROFILE IS FLUSH WITH THE TOP OF THE ADJUSTMENT RING.

D

6. VENDOR TO INCLUDE BOTH SUPERIOR INDUSTRIES PART NUMBER & REVISION NUMBER

2 TO BE ADDED IN A LEGIBLE, PERMANENT, AND NON-DESTRUCTIVE (NO WELDING) MANNER,

N LOCATED AS SHOWN.

5.57 B.16 0.50 B.08

15°

7. PRIME PAINT ENTIRE PART AND PROTECT MACHINED SURFACES FOR SHIPPING.

8. INSPECTION REQUIREMENTS PER TR000-0014, LATEST REVISION.

17° H

D INVENTOR DRAWING: DO NOT MODIFY WITH ANY OTHER PROGRAM. D

THIS DRAWING IS THE PROPERTY OF

SUPERIOR INDUSTRIES. IT IS NOT Equipment Division

SUPERIOR P.O. Box 684

TO BE REPRODUCED IN ANY

MANNER WITHOUT PERMISSION.

ALL DIMENSIONS IN INCHES (UNO) Highway 28 East ®

FINISH DIMENSION TOLERANCE (UNO) Morris, MN 56267

FRACTIONAL:

4 THREAD TIMING DIMENSION ADDED. DRAWING CLEAN UP 10/21/2021 SBE ± 1/16" RING,ADJUSTMENT,CONE,P400,PART

3 TOL. UPDATED 12/26/2018 SBE ANGULAR:

SEE TR000-0030

2 UPDATED NOTES 8/16/2018 B. BARRIOS DECIMAL:

1 CHANGED TAP DEPTH 3/6/2017 JLA .XX(>20.00) ±.12

0 INITIAL RELEASE 1/11/15 SBE

.XX(<20.00) ±.06

DRAWN BY DATE ASSEMBLY NO.

.XXX ±.020

REV

DESCRIPTION OF REVISION DATE AUTHOR .XXXX ±.005

AE LDR 11/9/2015

# SCALE (UNO) CHECKED BY SIZE DRAWING NUMBER

SHEET WEIGHT E-1 PART NO: THIRD ANGLE MACHINE FINISH 1/8"=1" SERICKSON

1 OF 2 5121.6 D-DB104-0315

PROJECTION 250 UNLESS OTHERWISE

INDICATED.

FILE

VAULT\DB104-0315

D DB104-0315

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

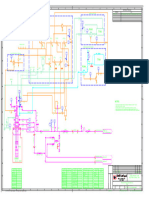

AREA FOR VIEW J-J

DETAIL H SECTION B-B

2 LABELING SEE NOTE 6

SCALE 1/4"=1" SEE NOTE 6 SCALE 1/4"=1"

4X P0.46 Z 6.22 SCALE 1/4"=1"

G 1/4-19 - Z 0.50 MIN 18.31 B.2

X P1.00 Z 0.19 3

2X P0.46 Z 8.87

LABEL TOP R0.98 B.08

R47.00 B.28 AS SHOWN ON A Ø63.58 B.C. G 1/4-19 - Z 0.50 MIN

A R38.84 B.24 A

5.00° TYP R3.00 B.12 TYP 3

SEE NOTE 3

LENGTH "X"

5.00° TYP

1.39

FOR

R40.31 B.28

5.75 B.16

4 X P0.374 DRILL Z 1.38

R1.00 B.12 TYP

R1.50 B.12 TYP

R1.49 B.12

R1.00 B.12 TYP 38.56 B.24

4

R3.27 B.12

15.00° TYP

R3.27 B.12

2.000

R2.52 B.12 INDICATES CORRECT

SECTION K-K

.16

R2.52 B.12 35 TIMING OF THREADS.

B

DETAIL I B

3B

SCALE 3/8"=1"

3.50 B.16 MEASURED IN PLANE

4.3

OF TIMING MARK

5 PLACES

START OF FULL

39

SCALE 1/2"=1"

R1.38 B.12 TYP

PROFILE THREAD

SEE NOTE 5

HAND GRIND RAMP

ON TOPSIDE OF

DETAIL G

SCALE 3/16"=1" 11

7.01 B.16 40.177 FLAT THREAD LEAD .14

B.

22

.28

FROM CENTER 2 B.

.16

2

.16

HAND GRIND ALL

0B

0B

3.00° LEADING EDGES R0.25

9.8

9.5

9.4

49

2.01

1.50

37

18

R1.00 B.12 .89

7.5 8

0 B.

CURCULAR SPOT FACES ALSO ACCEPTABLE 16 38

REMOVED PARTIAL 15

R0.51 TYP .00

THREAD FROM 1ST B.

2

AND LAST THREAD

SECTION C-C

SCALE 1/2"=1" 40 2X P0.512 Z 0.84

7/16 -20 UNF-2B TAP

30 SAE NO 4 PORT TOOL

Ø0.38 Z 2.84 ON Ø70.47 B.C. R2.13 B.12

C C

3/4 -16 UNF-2B TAP

31 SAE NO 8 PORT TOOL 1.41

Ø0.68 DRILL, Z 5.71

R1.38 B.12

R0.98 B.08

DETAIL D

6 PLACES

SCALE 1/4"=1"

25.00°

R0.13

34 4.213

R0.51 B.08

5

12

R0.94 B.08

D INVENTOR DRAWING: DO NOT MODIFY WITH ANY OTHER PROGRAM. D

THIS DRAWING IS THE PROPERTY OF

SUPERIOR INDUSTRIES. IT IS NOT Equipment Division

+.5° 63 SUPERIOR P.O. Box 684

TO BE REPRODUCED IN ANY

32 55.00° - 36 45°

MANNER WITHOUT PERMISSION.

Highway 28 East

0° ALL DIMENSIONS IN INCHES (UNO) ®

FINISH DIMENSION TOLERANCE (UNO) Morris, MN 56267

B 33 P73.780 4 THREAD TIMING DIMENSION ADDED. DRAWING CLEAN UP 10/21/2021 SBE FRACTIONAL:

± 1/16" RING,ADJUSTMENT,CONE,P400,PART

0.50 3 TOL. UPDATED 12/26/2018 SBE

ANGULAR:

2 UPDATED NOTES 8/16/2018 B. BARRIOS SEE TR000-0030

DECIMAL:

1 CHANGED TAP DEPTH 3/6/2017 JLA .XX(>20.00) ±.12

0 INITIAL RELEASE 1/11/15 SBE .XX(<20.00) ±.06

DRAWN BY DATE ASSEMBLY NO.

.XXX ±.020

REV

DESCRIPTION OF REVISION DATE AUTHOR .XXXX ±.005

AE LDR 11/9/2015

# SCALE (UNO) CHECKED BY SIZE DRAWING NUMBER

SHEET WEIGHT E-1 PART NO: THIRD ANGLE MACHINE FINISH 1/2"=1" SERICKSON

2 OF 2 5121.6 D-DB104-0315

PROJECTION 250 UNLESS OTHERWISE

INDICATED.

FILE

VAULT\DB104-0315

D DB104-0315

1 2 3 4 5 6 7 8

You might also like

- Greenbook Research Industry Trends Report 2020Document126 pagesGreenbook Research Industry Trends Report 2020Paul KendallNo ratings yet

- Demon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Document12 pagesDemon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Gokul M PNo ratings yet

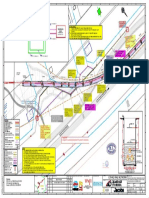

- CH 1718.878 CH 1731.078 CH 1743.278 CH 1755.478 CH 1855.478 CH 1780.478 CH 1805.478 CH 1830.478Document1 pageCH 1718.878 CH 1731.078 CH 1743.278 CH 1755.478 CH 1855.478 CH 1780.478 CH 1805.478 CH 1830.478Satyajit MondalNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofProfessor PuppiesNo ratings yet

- Single Rack-WindloadDocument13 pagesSingle Rack-WindloadAdnan TiroNo ratings yet

- Bronx Community-New Health Center-Mechanical Piping Shop Drawing 3-3-24Document3 pagesBronx Community-New Health Center-Mechanical Piping Shop Drawing 3-3-24Jose VizcarrondoNo ratings yet

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Document1 pageR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriNo ratings yet

- JCB Paw 01 DRG BHV 14 130141 - ADocument1 pageJCB Paw 01 DRG BHV 14 130141 - ADumindaNo ratings yet

- P94-1986 Inversor NGPDocument2 pagesP94-1986 Inversor NGPGonzalo GalvezNo ratings yet

- Utility Deck - Ahu SectionDocument1 pageUtility Deck - Ahu SectionLorenzo NakpilNo ratings yet

- JCB Paw 01 DRG BHV 14 110141 - ADocument1 pageJCB Paw 01 DRG BHV 14 110141 - ADumindaNo ratings yet

- Garage Complete Plans Final - 2Document15 pagesGarage Complete Plans Final - 2Nasir UllahNo ratings yet

- Pro Engineer: DescriptionDocument1 pagePro Engineer: DescriptionGonzalo GalvezNo ratings yet

- Cop 28 Map Blue Zone V5Document1 pageCop 28 Map Blue Zone V5Ezequiel CancliniNo ratings yet

- Cop 28 Map Blue Zone v5Document1 pageCop 28 Map Blue Zone v5vechannel2005No ratings yet

- Page 1Document1 pagePage 1JUN JUN ANCHETANo ratings yet

- Sb62-Ig225-Assembly Diagram. Circuit Breaker. v0Document2 pagesSb62-Ig225-Assembly Diagram. Circuit Breaker. v0hung.nguyenmanhNo ratings yet

- No. Description Oper Date: Production Routing ChartDocument2 pagesNo. Description Oper Date: Production Routing Chartpubg loversNo ratings yet

- Slab DetailsDocument1 pageSlab Detailshomitech LEBANONNo ratings yet

- Reference Drawings:: 4mm " 20mm "Document1 pageReference Drawings:: 4mm " 20mm "ArielNo ratings yet

- 3401-100-J-FM-EDO-00026REVX01-A1 A41Document1 page3401-100-J-FM-EDO-00026REVX01-A1 A41adelNo ratings yet

- DrawingsDocument3 pagesDrawingsAbdul HannanNo ratings yet

- QF02Document1 pageQF02pis.engineering007No ratings yet

- Fabrication Drawings-S0Document1 pageFabrication Drawings-S0Mark Roger Huberit IINo ratings yet

- Vms Approval: Section A-A Detail EDocument1 pageVms Approval: Section A-A Detail ELuong LeNo ratings yet

- Side View Top View Front View: Ihc Holland Beaver Dredgers B.VDocument1 pageSide View Top View Front View: Ihc Holland Beaver Dredgers B.VSélcio PaulinaNo ratings yet

- 11 152110 4800000644 Pet FPR DRG 021902 - ADocument1 page11 152110 4800000644 Pet FPR DRG 021902 - Aahmad.suliman.saeedNo ratings yet

- Foundation Drawing 01Document1 pageFoundation Drawing 01Pawan ShettyNo ratings yet

- 14 371200 4800000344 Bei Mec DRG 100010 - DDocument1 page14 371200 4800000344 Bei Mec DRG 100010 - Dbntaz37No ratings yet

- Grinding Mill Drawings PDFDocument1 pageGrinding Mill Drawings PDFBender Doblador Rodriguez100% (1)

- 6.14 Inch X 4Document1 page6.14 Inch X 4Andi Ramdan HamdaniNo ratings yet

- Genset Outline 1Document1 pageGenset Outline 1moosuhaibNo ratings yet

- Flue Gas Outlet DamperDocument1 pageFlue Gas Outlet Damperprth valveNo ratings yet

- 12Document1 page12mayankNo ratings yet

- As-Found Plan Partition Dimension Plan: Floor Plan and Door Tag ReferenceDocument1 pageAs-Found Plan Partition Dimension Plan: Floor Plan and Door Tag ReferenceDaniel Angelo DollisenNo ratings yet

- Table of Content For GenenstDocument1 pageTable of Content For Genenstahmad.suliman.saeedNo ratings yet

- 11 152110 4800000644 Pet FPR DRG 621901 - CDocument1 page11 152110 4800000644 Pet FPR DRG 621901 - Cahmad.suliman.saeedNo ratings yet

- Exhaust System Must Support Its Own Weight Turbochargers and Flex Expansion Joints Must Not Be Loaded Up Please Refer S-08242 For More Exhaust System Installation GuidelinesDocument1 pageExhaust System Must Support Its Own Weight Turbochargers and Flex Expansion Joints Must Not Be Loaded Up Please Refer S-08242 For More Exhaust System Installation GuidelinesDmitryNo ratings yet

- Arranjo Geral - Vitoria Recycle Grinder and BlowerDocument1 pageArranjo Geral - Vitoria Recycle Grinder and BlowerAndré Andrade RamosNo ratings yet

- Opteva 560 Cash Dispenser Through The Wall 4 HIGH WITH 40mm (1 9/16 ") SAFEDocument4 pagesOpteva 560 Cash Dispenser Through The Wall 4 HIGH WITH 40mm (1 9/16 ") SAFEDNSXNo ratings yet

- ABN-MTA90 - Rev ADocument2 pagesABN-MTA90 - Rev AkippcamNo ratings yet

- Earthgrid layout 1205-00-AEA-EL-0269.A.1.IFR (1)Document1 pageEarthgrid layout 1205-00-AEA-EL-0269.A.1.IFR (1)JNo ratings yet

- Bglr0412 Feeder 2Document1 pageBglr0412 Feeder 2Mani CadNo ratings yet

- Terrace Floor Architectural Frabrication SectionDocument1 pageTerrace Floor Architectural Frabrication SectionVishek BisenNo ratings yet

- Enterito Patron GratisDocument2 pagesEnterito Patron GratisHalison AriasNo ratings yet

- CFR Bgr-Pbd-Afc-023503-A-000Document1 pageCFR Bgr-Pbd-Afc-023503-A-000singaithamu_64462081No ratings yet

- GBPSAT-100-CE-1601-0001-A Grading Layout (Main Lot) - AFRY - 09032021Document2 pagesGBPSAT-100-CE-1601-0001-A Grading Layout (Main Lot) - AFRY - 09032021chrisNo ratings yet

- M56 TankDocument1 pageM56 Tankmanish318No ratings yet

- Mark Up DRG - ABDocument1 pageMark Up DRG - ABAnuNo ratings yet

- Schematic - 24 Hour Clock - 2023-12-16Document1 pageSchematic - 24 Hour Clock - 2023-12-16ianguiebNo ratings yet

- BSL-NE03-E&M-AB-CSRG-ELE-PLN-0004Document1 pageBSL-NE03-E&M-AB-CSRG-ELE-PLN-0004vikasnmrc1608No ratings yet

- PL14 Chin 89e 34069 G Srinivasaraju Site PlanDocument1 pagePL14 Chin 89e 34069 G Srinivasaraju Site PlanakiveeduplanningNo ratings yet

- L001-03100-CX-2397-28965C-1221_R2Document1 pageL001-03100-CX-2397-28965C-1221_R2Maroua HammamiNo ratings yet

- Parking Space Floor Elev 0Document1 pageParking Space Floor Elev 0Benjelou BreisNo ratings yet

- Parking Space Floor Elev 0Document1 pageParking Space Floor Elev 0Benjelou BreisNo ratings yet

- Part Drawing Sheet1Document1 pagePart Drawing Sheet1Shrikrushna MaliNo ratings yet

- Parkhills Complete Set 04062021Document20 pagesParkhills Complete Set 04062021Penales Chyle YhvanNo ratings yet

- Pro Engineer: DescriptionDocument1 pagePro Engineer: DescriptionGonzalo GalvezNo ratings yet

- 4041-188-S-010 - PipeRack Demolished Plan and Section (Signed) 2Document1 page4041-188-S-010 - PipeRack Demolished Plan and Section (Signed) 2thoriq ikhwanNo ratings yet

- Report On Substandard Floor Tiling Work in B6 Male BathroomDocument3 pagesReport On Substandard Floor Tiling Work in B6 Male BathroomYasith AbeywickramaNo ratings yet

- L001-03100-CX-2397-28965C-1216_R2Document1 pageL001-03100-CX-2397-28965C-1216_R2Maroua HammamiNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- The Titans Curse - Robert VendittiDocument134 pagesThe Titans Curse - Robert VendittimarianaqueirosluzNo ratings yet

- Barker CH Naish D - Where On Earth Dinosaurs and Other Prehistoric Life The Amazing History of Earth 39 S Most Incredible ADocument162 pagesBarker CH Naish D - Where On Earth Dinosaurs and Other Prehistoric Life The Amazing History of Earth 39 S Most Incredible ARumen Deshkov100% (3)

- Economic and Political WeeklyDocument8 pagesEconomic and Political WeeklynaveensarimallaNo ratings yet

- (G.R. No. 136448. November 3, 1999.) Lim Tong Lim, Petitioner, V. Philippine Fishing Gear Industries, Inc, Respondent. DecisionDocument23 pages(G.R. No. 136448. November 3, 1999.) Lim Tong Lim, Petitioner, V. Philippine Fishing Gear Industries, Inc, Respondent. Decisionalay orejudosNo ratings yet

- LEGAL REASONING SKILLS ProjectDocument19 pagesLEGAL REASONING SKILLS ProjectShreya Ghosh DastidarNo ratings yet

- Town Planning Assistant in A.P Towncountry PlanningDocument3 pagesTown Planning Assistant in A.P Towncountry Planningbhavesh gangurdeNo ratings yet

- Aromaterapia Emocional - doTERRADocument2 pagesAromaterapia Emocional - doTERRAAlvaro Andre Diaz100% (1)

- Invitation & RepliesDocument36 pagesInvitation & Repliesap831884No ratings yet

- Jimmy Van Heusen ScoreDocument16 pagesJimmy Van Heusen ScoreTrevorNo ratings yet

- Sworn Statement of Assets, Liabilities and Net WorthDocument2 pagesSworn Statement of Assets, Liabilities and Net WorthKal El DadiNo ratings yet

- Writing Project: A. Write A 800 - 1,000 Words Essay or Monograph in A Word Processor in FormatDocument4 pagesWriting Project: A. Write A 800 - 1,000 Words Essay or Monograph in A Word Processor in FormatEbri OjeNo ratings yet

- Of Mice and Men EssayDocument7 pagesOf Mice and Men Essayjon782No ratings yet

- Buy Xanax Online To Treat With Stress and Anxiety - Order Xanax OnlineDocument5 pagesBuy Xanax Online To Treat With Stress and Anxiety - Order Xanax OnlinelorendesuzaNo ratings yet

- Broadwater Farm Estate - The Active CommunityDocument5 pagesBroadwater Farm Estate - The Active CommunitycvaggasNo ratings yet

- Group2 Non Executive ResultsDocument3 pagesGroup2 Non Executive ResultsGottimukkala MuralikrishnaNo ratings yet

- Blackwood Aalisa Lesson Plan AssignmentDocument6 pagesBlackwood Aalisa Lesson Plan Assignmentapi-498288988No ratings yet

- Green AlgaeDocument3 pagesGreen AlgaeGladys CardonaNo ratings yet

- Manual Therapy in The Treatment of Facial WrinklesDocument4 pagesManual Therapy in The Treatment of Facial WrinklesKarolina MirosNo ratings yet

- ROWEB 03638 Mia UKDocument4 pagesROWEB 03638 Mia UKNounaNo ratings yet

- FIVE STAR BUS COMPANY INC. v. CADocument8 pagesFIVE STAR BUS COMPANY INC. v. CAAkiNo ratings yet

- Hispanic Tradition in Philippine ArtsDocument14 pagesHispanic Tradition in Philippine ArtsRoger Pascual Cuaresma100% (1)

- 85th BSC AgendaDocument61 pages85th BSC AgendaSiddharth MohantyNo ratings yet

- Marketing Approach To Promoting Banking ServicesDocument8 pagesMarketing Approach To Promoting Banking Servicessubbaiah aNo ratings yet

- The Wexford Carol (Arr Victor C Johnson)Document13 pagesThe Wexford Carol (Arr Victor C Johnson)Macdara de BurcaNo ratings yet

- Cooltech PPM (Final 3.8.17)Document54 pagesCooltech PPM (Final 3.8.17)Teri Buhl100% (1)

- Vocabulary A5Document149 pagesVocabulary A5Milton MollojaNo ratings yet

- Erp History PDFDocument2 pagesErp History PDFTiffanyNo ratings yet

- Final NHD Annotated BibliographyDocument7 pagesFinal NHD Annotated Bibliographyapi-616585007No ratings yet