Professional Documents

Culture Documents

50-00011(Bowl-Cone)-r.1

50-00011(Bowl-Cone)-r.1

Uploaded by

서정윤Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50-00011(Bowl-Cone)-r.1

50-00011(Bowl-Cone)-r.1

Uploaded by

서정윤Copyright:

Available Formats

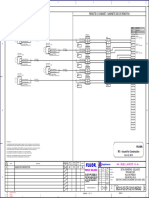

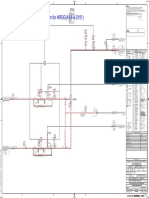

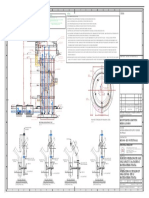

1 2 3 4 5 6 7 8

Notes:

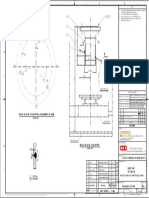

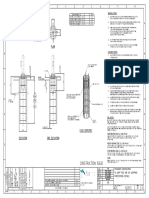

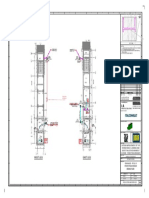

DETAIL C DETAIL D 1. CASTING MATERIAL TO BE HIGH STRENGTH CARBON STEEL ASTM A148 GRADE 90-60.

(90,000 MIN TENSILE STRENGTH, 60,000 MIN YIELD STRENGTH), 20% MIN. ELONGATION

2.17 AND 40% MIN. REDUCTION OF AREA. HARDNESS TO BE 180-228 BRINELL.

1.58 2. UNLESS OTHERWISE SPECIFIED, ALL DIMENSIONS ARE AS CAST.

3. NO DRAFT OR ANGLE ALLOWED IN AREA X. THIS ARE TO BE CAST SMOOTH AND FLAT.

0.591

4. FINISH FOR ENTIRE PROFILE OF THREAD SHALL BE 125 μIN.

1 5. VENDOR TO INCLUDE SUPERIOR PART NUMBER AND REVISION NUMBER IN A LEGABLE,

A A

Eliminate knife edge from face of PERMANENT, AND NON-DESTRUCTIVE (NO WELDING) MANNER, LOCATED AS SHOWN.

R0.063 R0.063 R1.22 B.12

partial thread from with 1/4" to 3/8" flat.

45.00° 6. PRIME PAINT ENTIRE PART AND PROTECT MACHINED SURFACES FOR SHIPPING.

Remove remaining section of

partial thread that is too thin for flat. R0.24 B.08 7. VENDOR TO ADHERE TO TR000-0014, INSPECTION AND QUALITY PROCEDURES.

R0.39

12X P0.69 THRU

SECTION A-A

M20x2.5 - 6H THRU 2X P0.75 Z 1.18

Equally spaced REAM Ø.787±.004 Z1.00

SPACED 180° APART 22.50 B.2

4.496

B A B E VIEW B-B

P56.693 B.C.

P52.756 B.C. C

D 125 Remove partial

4X P0.83 Z 1.85 threads

M24x3 - 6H Z 1.46

B B

Equally spaced Hand grind all

leading edges R0.25

19.03

7.5°

5.12

45° G

Area X

TYP-6 places 9.840

1.49

See note 3

6.66 B.16 10.830

P45.20 B.28

P42.520

P47.09 B.28

P54.331

P49.910

P58.50

P48.740

P41.57

3.00°

P38.11 B.24

Hand grind ramp

F on underside of

G thread lead

125

P40.551 B.C.

DETAIL F

C C

3X P0.69 Z 1.89

M20x2.5 - 6H Z 1.38

Equally spaced 2.52

125

A

E .004

125

DETAIL E 30.937

45° All thread dimensions typical

.12 x 45.00`

2.000 R0.20 TYP

all pocket edges

0.06

R0.12

0.5303

30° 0.12

VIEW G-G 15.00°

See note 5

Area for Label

centered on S bowl

P52.252 Major

+.25°

55.00° - 0°

P50.193 Minor

5

12

D INVENTOR DRAWING: DO NOT MODIFY WITH ANY OTHER PROGRAM. D

125

THIS DRAWING IS THE PROPERTY OF

SUPERIOR INDUSTRIES. IT IS NOT Equipment Division

500 SUPERIOR P.O. Box 684

TO BE REPRODUCED IN ANY

MANNER WITHOUT PERMISSION.

ALL DIMENSIONS IN INCHES (UNO) Highway 28 East ®

FINISH DIMENSION TOLERANCE (UNO) Morris, MN 56267

FRACTIONAL:

± 1/16" BOWL,CONE,P300,PART/WELD

23.00° ANGULAR:

SEE TR000-0030

DECIMAL:

Label Top R1.18 B.12 1 NOTE UPDATED 8/24/2018 SBE .XX(>20.00) ±.12

0 INITIAL RELEASE 12/2/2015 AE LDR

.XX(<20.00) ±.06

DRAWN BY DATE ASSEMBLY NO.

R0.31 REV

DESCRIPTION OF REVISION DATE AUTHOR

.XXX ±.020

.XXXX ±.005

AE LDR 9/23/2015

# SCALE (UNO) CHECKED BY SIZE DRAWING NUMBER

SHEET WEIGHT E-1 PART NO: THIRD ANGLE MACHINE FINISH 1"=8" SERICKSON

1 OF 1 4188.8 50-00011

PROJECTION 250 UNLESS OTHERWISE

INDICATED.

FILE

VAULT\50-00011

D 50-00011

1 2 3 4 5 6 7 8

You might also like

- Fact Sheets On Air Emission Abatement Techniques - Final 2009 02 20 PDFDocument152 pagesFact Sheets On Air Emission Abatement Techniques - Final 2009 02 20 PDFAini Zahra100% (1)

- MSRR 6522Document7 pagesMSRR 6522pradellesNo ratings yet

- 50-00039(Bowl-Cone)-r.2Document1 page50-00039(Bowl-Cone)-r.2서정윤No ratings yet

- WH2 GaDocument5 pagesWH2 GaRaveendra Babu CherukuriNo ratings yet

- TAGUIG-w-CLINIC_091923-Layout1 (1)Document1 pageTAGUIG-w-CLINIC_091923-Layout1 (1)Mary CariasoNo ratings yet

- At575 43Document1 pageAt575 43Juan BalderasNo ratings yet

- Huus 5.17.23Document9 pagesHuus 5.17.23Civil BuildersNo ratings yet

- ING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741Document1 pageING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741mhazarath murariNo ratings yet

- Copper TopologyDocument1 pageCopper TopologyinbNo ratings yet

- 1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevADocument2 pages1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevAmhazarath murariNo ratings yet

- 1jng10374d2x755 - Cooler Foundation and Roof Shed - Reva (1 of 2)Document1 page1jng10374d2x755 - Cooler Foundation and Roof Shed - Reva (1 of 2)mhazarath murariNo ratings yet

- Electrical Dwg.Document14 pagesElectrical Dwg.nurul momenNo ratings yet

- A059D245Document14 pagesA059D245Johann Fernandez De CastroNo ratings yet

- Biocharculture-Book - 20 - 8 - 2014 - finalSF KON TIKI HORNO DE PIROLISISDocument1 pageBiocharculture-Book - 20 - 8 - 2014 - finalSF KON TIKI HORNO DE PIROLISISpabloNo ratings yet

- D E F G H: Grating SpecificationsDocument1 pageD E F G H: Grating SpecificationssivagnanamNo ratings yet

- Legend Sheet P&ID For As-Built - Drafting On 20210722-1Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-1Ludi D. LunarNo ratings yet

- Notes:: Cross Over Platform - 2 Partial Plan at Pib Roof Cross Over Platform - 1 Partial Plan at Pib RoofDocument1 pageNotes:: Cross Over Platform - 2 Partial Plan at Pib Roof Cross Over Platform - 1 Partial Plan at Pib Roofokta.skfNo ratings yet

- Section ProjectDocument2 pagesSection Projectapi-592003671No ratings yet

- ING10374D2X742 STAIRCASE DETAIL - SHEET 1 OF 1-Rev - C-742Document1 pageING10374D2X742 STAIRCASE DETAIL - SHEET 1 OF 1-Rev - C-742mhazarath murariNo ratings yet

- Detail Detail: Issued For Public CommentDocument1 pageDetail Detail: Issued For Public CommentChilakamarri SrikamalNo ratings yet

- HD BoltDocument1 pageHD BoltrajamasaNo ratings yet

- Detail: Scale: NtsDocument1 pageDetail: Scale: NtsANIL PLAMOOTTILNo ratings yet

- 71.1000 Civil Construction and Works - Rev BDocument9 pages71.1000 Civil Construction and Works - Rev BHighline BuildersNo ratings yet

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0Document2 pagesField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0hugoNo ratings yet

- CB 1646 CombinedDocument3 pagesCB 1646 CombinedQuerubin RamirezNo ratings yet

- Tank 100KL 12M A3 - 5 Layout2Document1 pageTank 100KL 12M A3 - 5 Layout2Tarun SinghalNo ratings yet

- B224 Cdu TPL 101 CV DW 0097 1Document2 pagesB224 Cdu TPL 101 CV DW 0097 1Anonymous Clm40C1No ratings yet

- B224 Cdu TPL 101 CV DW 0097 1Document2 pagesB224 Cdu TPL 101 CV DW 0097 1Anonymous Clm40C1No ratings yet

- 1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevA (2 OF 2)Document1 page1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevA (2 OF 2)mhazarath murariNo ratings yet

- Construction Issue: General NotesDocument1 pageConstruction Issue: General NotesShokry AlkissyNo ratings yet

- Grating Specifications.: 40 THK Grating 40 THK GratingDocument1 pageGrating Specifications.: 40 THK Grating 40 THK GratingsivagnanamNo ratings yet

- Ta-249813-023 - C - P&id - Caustic Injection PacakgeDocument1 pageTa-249813-023 - C - P&id - Caustic Injection Pacakgerizwan.zamanNo ratings yet

- 0100-A - W-600-Equipment - Furniture-Basement FloorDocument1 page0100-A - W-600-Equipment - Furniture-Basement FloormiraclechigozirimfestusNo ratings yet

- Schematic, Electrical Wiring (Fixed Speed - Soft Starter) 23378540 FDocument2 pagesSchematic, Electrical Wiring (Fixed Speed - Soft Starter) 23378540 Fvalberto75No ratings yet

- B1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YardDocument1 pageB1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YarddeniNo ratings yet

- Ajv DPW 10 525 CL DWG 0695 03 R03Document1 pageAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNo ratings yet

- Lighting Pole DetailDocument1 pageLighting Pole DetailSohail YounisNo ratings yet

- Detail - 3 Section - L: Infineum JSGP Alliance (Ija) Projects Infineum Singapore LLPDocument1 pageDetail - 3 Section - L: Infineum JSGP Alliance (Ija) Projects Infineum Singapore LLPdharunesh182No ratings yet

- C2019 21 PQC Ajm DR DD 0010 PDFDocument1 pageC2019 21 PQC Ajm DR DD 0010 PDFRicky SolivenNo ratings yet

- Telecome MapDocument1 pageTelecome Maploc khaNo ratings yet

- A10 A Pid Va 718589 203Document1 pageA10 A Pid Va 718589 203zhangNo ratings yet

- Saudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Document1 pageSaudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Mohamed Wasim ShaikhNo ratings yet

- TP3086-L01 - LCP Drawing of 30MVAR 21kV SR - East SitraDocument5 pagesTP3086-L01 - LCP Drawing of 30MVAR 21kV SR - East Sitrawinston11No ratings yet

- Provision of Special Confining Reinforcement in FootingDocument1 pageProvision of Special Confining Reinforcement in FootingSS INFRAZONENo ratings yet

- Matchline N 8152.400 See DWG 3420-65H-003Document1 pageMatchline N 8152.400 See DWG 3420-65H-003JonathanSaucedoNo ratings yet

- Traverse Type C - 1015568Document1 pageTraverse Type C - 1015568Loki TroliNo ratings yet

- Auto Paper 03Document1 pageAuto Paper 03Ashiraf sserugoNo ratings yet

- Ahpl SHP DG Pen 1033 - R1Document3 pagesAhpl SHP DG Pen 1033 - R1ghalleyybroNo ratings yet

- Ground Floor: B RA-620717 001 B 961 G203Document1 pageGround Floor: B RA-620717 001 B 961 G203muthuvelaaNo ratings yet

- Shiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Document2 pagesShiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Kyaw Win TunNo ratings yet

- Batching Plant Architectural DrawingDocument1 pageBatching Plant Architectural DrawingTaposh Paul100% (1)

- R03 C07B01 IKP 01 GF SDW AR 10005 - Comments1Document1 pageR03 C07B01 IKP 01 GF SDW AR 10005 - Comments1Eleazar SacloloNo ratings yet

- q100-3-phase-data-e1Document1 pageq100-3-phase-data-e1kgthitmech07No ratings yet

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5022 0Document2 pagesField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5022 0hugoNo ratings yet

- 2BHKDocument2 pages2BHKajaz khanNo ratings yet

- Section D-D: NEST, LGA, 7X7,0.5X48, G3Document2 pagesSection D-D: NEST, LGA, 7X7,0.5X48, G3Ericson. TatlongmariaNo ratings yet

- A B C D: Reinforcement Detail of Roof LevelDocument1 pageA B C D: Reinforcement Detail of Roof LevelSampath S. WickramanayakaNo ratings yet

- Sb62-Ig233 - Location of Spans & Tensions. Profile View.v1Document2 pagesSb62-Ig233 - Location of Spans & Tensions. Profile View.v1hung.nguyenmanhNo ratings yet

- Wsd-Mkul-01-2022-Gad-001 & 002-1Document1 pageWsd-Mkul-01-2022-Gad-001 & 002-1Project ManagerStructuresNo ratings yet

- ADC Part 3Document1 pageADC Part 3Maung PDDNo ratings yet

- G.A, Foundation & Assembly Drawing - CPS R0-13.06.23Document6 pagesG.A, Foundation & Assembly Drawing - CPS R0-13.06.23newattelectricNo ratings yet

- Photo Report Bigroll BeringDocument19 pagesPhoto Report Bigroll BeringMỹ Phạm Hiếu (Mike PH)No ratings yet

- Xuper Nucleotec 2222Document2 pagesXuper Nucleotec 2222jose amad nolazcoNo ratings yet

- Biermann's Handbook of Pulp and Paper - Cap 01Document18 pagesBiermann's Handbook of Pulp and Paper - Cap 01chau_riberNo ratings yet

- Kill Sheet UcupDocument3 pagesKill Sheet UcupYusuf ArifinNo ratings yet

- Assignment 1 ENG 173 METAL FORMING First 2023 2024Document2 pagesAssignment 1 ENG 173 METAL FORMING First 2023 2024toursena44No ratings yet

- Apm Et13e Chapter 22 Welding and CuttingDocument30 pagesApm Et13e Chapter 22 Welding and CuttingBhakti SagarNo ratings yet

- Dr. Fixit Pidiseal Ps 41gDocument2 pagesDr. Fixit Pidiseal Ps 41gRb143No ratings yet

- Ductile-Iron Pressure Pipe: Standard Index of Specifications ForDocument2 pagesDuctile-Iron Pressure Pipe: Standard Index of Specifications ForTamil funNo ratings yet

- I/ Reading 1 1. What Is Plastic Injection Molding?Document5 pagesI/ Reading 1 1. What Is Plastic Injection Molding?Hieu Nguyen TrungNo ratings yet

- Keshab Machineries Brochure India - Crushing and Processing MachinesDocument4 pagesKeshab Machineries Brochure India - Crushing and Processing MachinesbosonranaNo ratings yet

- Kits LindeDocument11 pagesKits LindeFernando Gallardo UrrejolaNo ratings yet

- Facilities and Equipment For Cleaning of Manufacturing AreaaDocument2 pagesFacilities and Equipment For Cleaning of Manufacturing AreaaJai MurugeshNo ratings yet

- Welding Rod SpecDocument1 pageWelding Rod SpecMuhammad Hasbi AsidiqiNo ratings yet

- List of IndustryDocument14 pagesList of Industrybokul1No ratings yet

- Technical Data Sheet: Cleaner and Degreaser Aerosol SprayDocument1 pageTechnical Data Sheet: Cleaner and Degreaser Aerosol SprayDon HowardNo ratings yet

- Technology and Livelihood Education: Industrial Arts - Module 4Document19 pagesTechnology and Livelihood Education: Industrial Arts - Module 4Alvin Dotollo50% (2)

- The Welding Procedure and Its QualificationDocument51 pagesThe Welding Procedure and Its QualificationMohd Faya100% (8)

- #Conclave of Rolling Processes#: Malaviya National Institute of Technology JaipurDocument57 pages#Conclave of Rolling Processes#: Malaviya National Institute of Technology JaipurAnup MauryaNo ratings yet

- MSDS - ASMACO RTV GasketDocument2 pagesMSDS - ASMACO RTV GasketadminNo ratings yet

- 1 Anatomy of WeldDocument5 pages1 Anatomy of WeldGeorgeNo ratings yet

- Louvered Gable VentsDocument2 pagesLouvered Gable VentsJonathan Schauder100% (1)

- Learners Achievement Monitoring ReportDocument2 pagesLearners Achievement Monitoring ReportEm Boquiren Carreon100% (1)

- Spindle Speeds & Feed Rates: Page B1 Techsoft 2D Design Tools Guide WWW - Denford.co - UkDocument4 pagesSpindle Speeds & Feed Rates: Page B1 Techsoft 2D Design Tools Guide WWW - Denford.co - UkBerheNo ratings yet

- Hemadri Cements Production ReportDocument7 pagesHemadri Cements Production ReportJCSNo ratings yet

- Introduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415Document41 pagesIntroduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415VaikunthtendulkarNo ratings yet

- Ripstar 121: SpecificationDocument3 pagesRipstar 121: SpecificationAnkita Baban GavadeNo ratings yet

- Seven Cast 74 NL - Tds - EngDocument1 pageSeven Cast 74 NL - Tds - EngVukeNo ratings yet

- State Investment Promotion Board: List of Effective Mou'S For Chhattisgarh (Up To September, 2019)Document30 pagesState Investment Promotion Board: List of Effective Mou'S For Chhattisgarh (Up To September, 2019)suraj pandeyNo ratings yet