Professional Documents

Culture Documents

Page 14

Page 14

Uploaded by

gyoginderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Page 14

Page 14

Uploaded by

gyoginderCopyright:

Available Formats

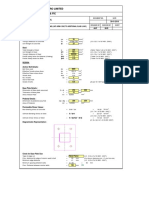

5.3.6.

Mesh generation

A mesh size of 0.2m is adopted for all panels.

5.4. Early Age Thermal Cracking (EATC)

The crack width induced by Early Age Thermal Cracking (EATC) is calculated as per guide published by CIRIA C766

[7]. According to table NA.1 of NA to BS 1992-3:2006, allowable crack width is interpolated between values of 0.2mm

(hD/h<5) & 0.05mm (hD/h>35). The calculated values are presented in the table below. For analysis purposes, the base

slab is considered to have end restraint, external walls and all internal walls to have edge restraint. Input parameters

are summarized in the below tables:

Table 4 – Concrete mix information

Concrete compressive strength class C45/55 BS 8500-1 2023 Table A.4

Maximum water-cement ratio 0.35 BS 8500-1 2023 Table A.4

Minimum cement content 380 kg/m3 BS 8500-1 2023 Table A.4

Maximum cement content 400 kg/m3 BS 8500-1 2023 Table A.4

Allowable cement/combination types IIA, IIB-M, IIC-M BS 8500-1 2023 Table A.4

(60% GGBS only)

Maximum aggregate size 20mm BS 8500-1 2023 Table A.4

Table 5 – EATC analysis Output

The crack width and reinforcement requirement is summarised below

wk

wk Bar Bar

wk1 (Long term

Type (ETC) Diameter Spacing

ETC)

mm mm mm mm mm

400thk Ext wall 0.16 0.05 0.14 25 125*

300thk Int wall 0.15 0.01 0.05 25 125

400thk Base Slab 0.16 0.10 0.16 25 125

All Parameters considered for EATC for each element has been mentioned in Appendix C

‘* The spacing requirement for the vertical rebar as per EATC calculations is 150mm c/c. however, 125mm c/c is

provided considering ease of lapping the bars with the bottom slab. Horizontal rebars are spaced at 150mm c/c.

You might also like

- Total Global Strategy Managing For Worldwide Competitive Advantage PDFDocument292 pagesTotal Global Strategy Managing For Worldwide Competitive Advantage PDFRamiro Fernando MosqueraNo ratings yet

- Parts Manual Serial No 23124Document200 pagesParts Manual Serial No 23124Cesar Augusto Aquino100% (1)

- Jurong West New TownDocument44 pagesJurong West New TownGrace TanNo ratings yet

- Ec2ei 12 10 09 PDFDocument64 pagesEc2ei 12 10 09 PDFPYAINo ratings yet

- Prestressed Concrete I Beam - Design ExampleDocument67 pagesPrestressed Concrete I Beam - Design ExampleNOEL RODRIGUEZ100% (1)

- Bba Certificate MBT Couplers Dec 2005Document8 pagesBba Certificate MBT Couplers Dec 2005belu diazNo ratings yet

- Design TemplateDocument19 pagesDesign TemplatePaul AlcantaraNo ratings yet

- Highway Steel Composite Bridge Design Using LimitDocument9 pagesHighway Steel Composite Bridge Design Using LimitDiya lizbeth joseNo ratings yet

- Britisch Code ManualDocument35 pagesBritisch Code ManualVengatesh Hari100% (1)

- Natural Frequencies and Mode Shapes of Optimized Stiffened PlatesDocument9 pagesNatural Frequencies and Mode Shapes of Optimized Stiffened PlatesGogyNo ratings yet

- Design of Reinforcement For RC Capping Beam: ProjectDocument1 pageDesign of Reinforcement For RC Capping Beam: ProjectNikit MaskeNo ratings yet

- PLDocument6 pagesPLAuYongTheanSengNo ratings yet

- (Eurocode 2) Design of Concrete Structures: Brian O'RourkeDocument20 pages(Eurocode 2) Design of Concrete Structures: Brian O'RourkeselinaNo ratings yet

- SQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsDocument9 pagesSQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsSUJAL SHAH - SKIPPER LIMITEDNo ratings yet

- Gym Area Boq For Nri Club HouseDocument5 pagesGym Area Boq For Nri Club HouseRamesh Arjun TNo ratings yet

- Kwik Hus Ez1 AnchorDocument8 pagesKwik Hus Ez1 Anchorsas999333No ratings yet

- Tensile Strength Conversion Sheet For Slab On Grade Fiber Dosage CalculationsDocument5 pagesTensile Strength Conversion Sheet For Slab On Grade Fiber Dosage Calculationsjana zongerNo ratings yet

- Weld Length - CheckDocument8 pagesWeld Length - CheckrishiNo ratings yet

- Rebar TableDocument4 pagesRebar TableyadavniranjanNo ratings yet

- Shear Tests On Hollowcore Slabs FinalDocument22 pagesShear Tests On Hollowcore Slabs FinaljcvalenciaNo ratings yet

- Sample WorkDocument135 pagesSample WorkmirceaNo ratings yet

- RE100 100% CapacityDocument1 pageRE100 100% CapacitySantosoNo ratings yet

- I. Partial Safety Factors: II. Section PropertiesDocument150 pagesI. Partial Safety Factors: II. Section Propertiespinakin nikash100% (1)

- MS Outside Scaffolding - Orkide RV00Document10 pagesMS Outside Scaffolding - Orkide RV00Thành CôngNo ratings yet

- B 910 - B 910M - 02 Qjkxmc9cotewts1sruqDocument5 pagesB 910 - B 910M - 02 Qjkxmc9cotewts1sruqJuan Sebastián Londoño MartínezNo ratings yet

- Design of Pile Cap (Pramod)Document159 pagesDesign of Pile Cap (Pramod)Lavender HoneyNo ratings yet

- Serviceability of Post-Tensioned Members Based On European CodeDocument14 pagesServiceability of Post-Tensioned Members Based On European CodeNgô Khánh TiểnNo ratings yet

- 33 KV Outdoor Type Current Transformer TSDocument6 pages33 KV Outdoor Type Current Transformer TSSandip AhireNo ratings yet

- BCI Series I-Joists PR-L323 Boise Cascade Wood Products, LLCDocument5 pagesBCI Series I-Joists PR-L323 Boise Cascade Wood Products, LLCImerNo ratings yet

- Plasma CUTDocument5 pagesPlasma CUTpmendonça_18No ratings yet

- Design of Base Plate LKP Arm 4-F-30.01.2018Document5 pagesDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Designing With An Inverted-F PCB Antenna: For The EM250 and EM260 PlatformsDocument15 pagesDesigning With An Inverted-F PCB Antenna: For The EM250 and EM260 PlatformsCS LumNo ratings yet

- 4 International Conference On Eartquake Engineering & Disaster MitigationDocument20 pages4 International Conference On Eartquake Engineering & Disaster MitigationAnis Aulia UlfaNo ratings yet

- Input Data - Design Summary: C E L L B E A M Ver. 10.3.1 (Build170)Document7 pagesInput Data - Design Summary: C E L L B E A M Ver. 10.3.1 (Build170)sloane01No ratings yet

- Introduction To Eurocodes (Part 2)Document33 pagesIntroduction To Eurocodes (Part 2)Aiman HakimNo ratings yet

- Previous Exams Combined DM G+4Document10 pagesPrevious Exams Combined DM G+4Mohamed ElsaneeNo ratings yet

- 1.0 Rectangular Column-BIAXIALDocument31 pages1.0 Rectangular Column-BIAXIALFranklyn P. Genove100% (1)

- Tensile Strength Conversion Sheet For Slab On Grade Fiber Dosage CalculationsDocument4 pagesTensile Strength Conversion Sheet For Slab On Grade Fiber Dosage CalculationsBurhan KanjetaNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1BHL6PNMMMVATF7Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1BHL6PNMMMVATF7Anonymous 6R10dB2RNNo ratings yet

- Detailing of Reinforcement in Concrete Structures Volume 1Document244 pagesDetailing of Reinforcement in Concrete Structures Volume 1Ahmed Refaey100% (4)

- Experimental Behaviour of Concrete Filled Thin Walled Steel Tubes With Tab StiffenersDocument16 pagesExperimental Behaviour of Concrete Filled Thin Walled Steel Tubes With Tab StiffenersJeno MscNo ratings yet

- Assignment No 1Document5 pagesAssignment No 1RitikNo ratings yet

- Tension Properties For Materials Used in ShipbuildingDocument10 pagesTension Properties For Materials Used in ShipbuildingKarla JuárezNo ratings yet

- Parametros de SoldaduraDocument17 pagesParametros de SoldaduraBenjamin Alvarez MedinaNo ratings yet

- General NotesDocument3 pagesGeneral NotesbillyNo ratings yet

- ETABS Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-14 Beam Section Designdimas cahyoNo ratings yet

- Concrete Frame Design ReportDocument1 pageConcrete Frame Design ReportMin KhantNo ratings yet

- Investigation of FRP Strengthening Design Rules For Insufficient RC ColumnsDocument20 pagesInvestigation of FRP Strengthening Design Rules For Insufficient RC ColumnsJhon EscobarNo ratings yet

- Roll Cage: Table 1: Material SpecificationsDocument2 pagesRoll Cage: Table 1: Material SpecificationsDevang KangadNo ratings yet

- TCVN 1651 2 2018Document33 pagesTCVN 1651 2 2018Francesco PaternosterNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-11 Beam Section DesignRey GonzalesNo ratings yet

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15No ratings yet

- Section Design For Crack WidthDocument8 pagesSection Design For Crack WidthYou TubeNo ratings yet

- One Way SlabDocument23 pagesOne Way SlabmeerahNo ratings yet

- Ribbed Slab ExampleDocument32 pagesRibbed Slab ExampleZekariyas AbushaNo ratings yet

- WG 950 2006 04Document4 pagesWG 950 2006 04'Lampa'No ratings yet

- A 126 - 95 r01 - Qteyni1sruqDocument5 pagesA 126 - 95 r01 - Qteyni1sruqQaisir MehmoodNo ratings yet

- ETABS 2015 15.1.0-Design DetailsDocument2 pagesETABS 2015 15.1.0-Design DetailsdenyfateNo ratings yet

- B 229 - 04 - QjiyoqDocument6 pagesB 229 - 04 - QjiyoqVIVEKNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Hart Communication ProtocolDocument12 pagesHart Communication ProtocolZujali ValopiNo ratings yet

- Print Challan Kapil VatsDocument1 pagePrint Challan Kapil VatsPankaj VatsaNo ratings yet

- Multiliteracies in The Educational ReformDocument9 pagesMultiliteracies in The Educational ReformMariel Mae PolancosNo ratings yet

- Rr210104 Surveying IDocument8 pagesRr210104 Surveying ISRINIVASA RAO GANTANo ratings yet

- Owner'S Manual: For Discovery OnlyDocument6 pagesOwner'S Manual: For Discovery OnlyBoNo ratings yet

- Gunslinger RevisedDocument5 pagesGunslinger RevisedStrejda Felix100% (1)

- Paquete de Información de Producto: Motor 25 HP 1760 RPM Nema 284TDocument11 pagesPaquete de Información de Producto: Motor 25 HP 1760 RPM Nema 284TCarolina AlexandraNo ratings yet

- Gauss Seidel MethodDocument32 pagesGauss Seidel MethodGerhan Pradana0% (1)

- Cat WireSENSOR enDocument56 pagesCat WireSENSOR enAlessandroAleottiNo ratings yet

- Min-Com Installation GuideDocument2 pagesMin-Com Installation GuideAmy ChanNo ratings yet

- SPE-200168-MS (Aramco - Gas Choking)Document11 pagesSPE-200168-MS (Aramco - Gas Choking)Alfonso RamosNo ratings yet

- Sono ChemistryDocument4 pagesSono ChemistryShyamol BoseNo ratings yet

- AmplifiersDocument2 pagesAmplifiersJon WestNo ratings yet

- RD 700gx RD 300gx BrochureDocument2 pagesRD 700gx RD 300gx BrochureYonathan Mikhael Susanto RambaNo ratings yet

- Capacitor ExerciseDocument19 pagesCapacitor ExerciseHARSHIT GARGNo ratings yet

- MIPSDocument119 pagesMIPSeldho k josephNo ratings yet

- Fit Up AccesoriesDocument4 pagesFit Up AccesoriesNofrizal HasanNo ratings yet

- FMEA TemplateDocument54 pagesFMEA TemplateKaty SanchezNo ratings yet

- Status Polar IV - ConstanzaDocument44 pagesStatus Polar IV - ConstanzaLuis PoccotayNo ratings yet

- Performance MetricsDocument6 pagesPerformance MetricsmohdtariqkhanNo ratings yet

- Fundamentals of Game Design, 2 Edition: by Ernest AdamsDocument61 pagesFundamentals of Game Design, 2 Edition: by Ernest AdamsNur AtikahNo ratings yet

- Boutique Hotels - Technology, Social Media and Green HighlightsDocument18 pagesBoutique Hotels - Technology, Social Media and Green Highlightsesther27No ratings yet

- AI Final ReportDocument15 pagesAI Final ReportDieu HaNo ratings yet

- IQSSLDocument4 pagesIQSSLkanilNo ratings yet

- Research Paper Small and Medium Scale BusinessDocument16 pagesResearch Paper Small and Medium Scale BusinessMusa0% (1)

- Dipl & Prassl - Drilling Engineering (093-115)Document23 pagesDipl & Prassl - Drilling Engineering (093-115)JordanNo ratings yet

- EnfuncDocument102 pagesEnfuncRafael OlaveNo ratings yet